Method for controlling dicharge temp of compressor

A technology of compressor exhaust and control method, which is applied in the field of compressors to achieve the effects of improving control logic, rationalizing system operation, and avoiding shutdowns.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

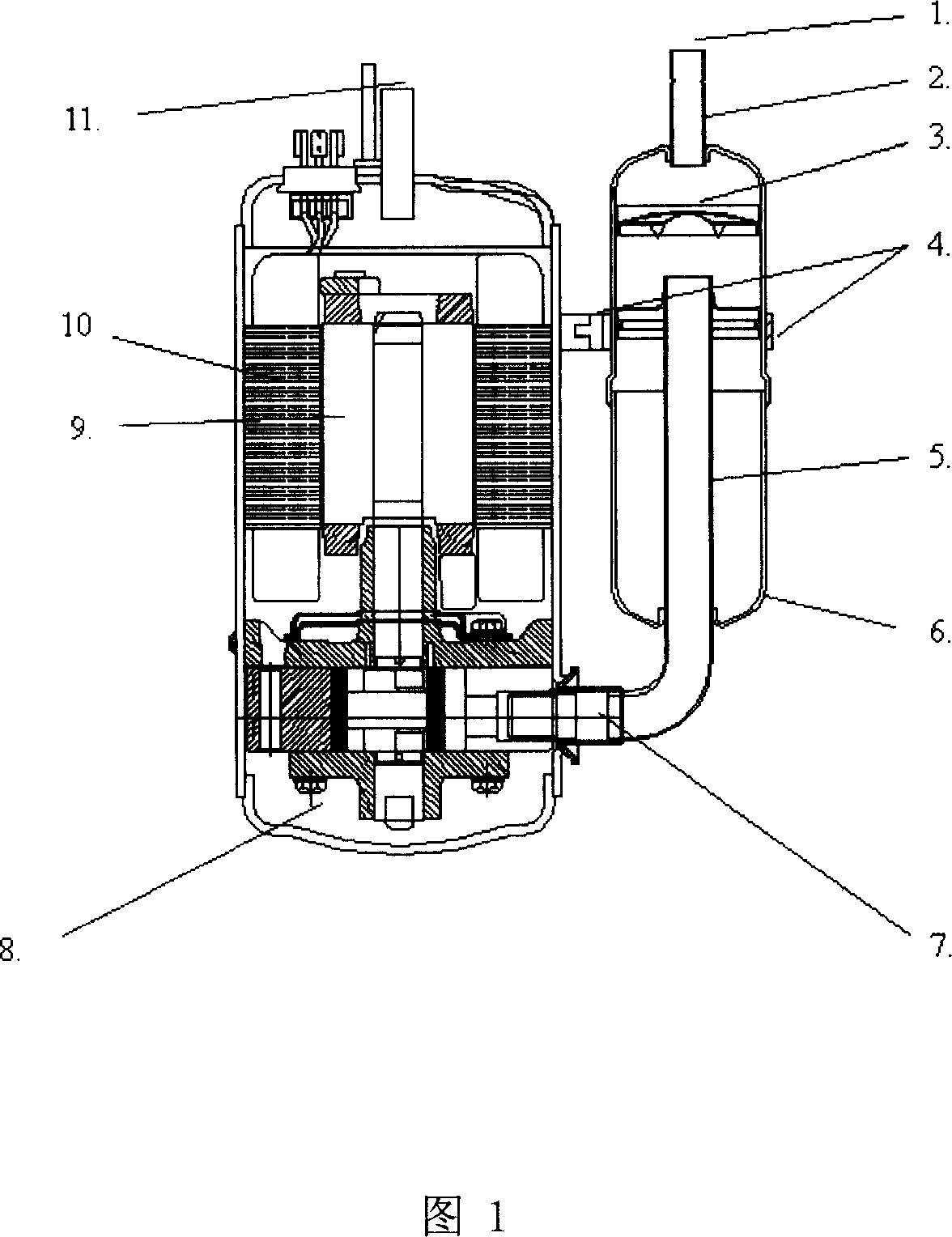

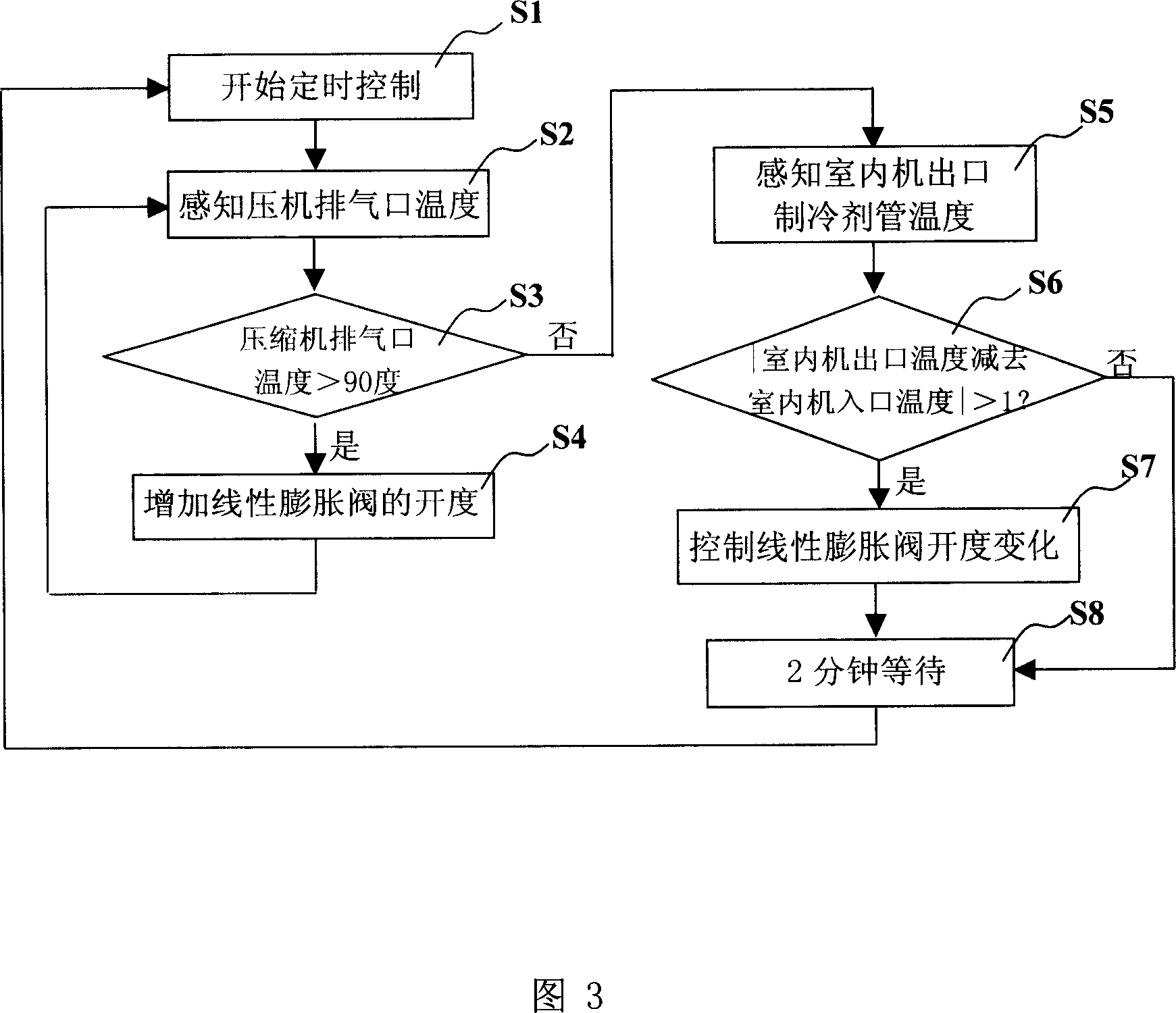

[0020] In the following, the method for controlling the discharge temperature of a compressor according to the present invention will be described in detail in conjunction with the drawings and specific embodiments.

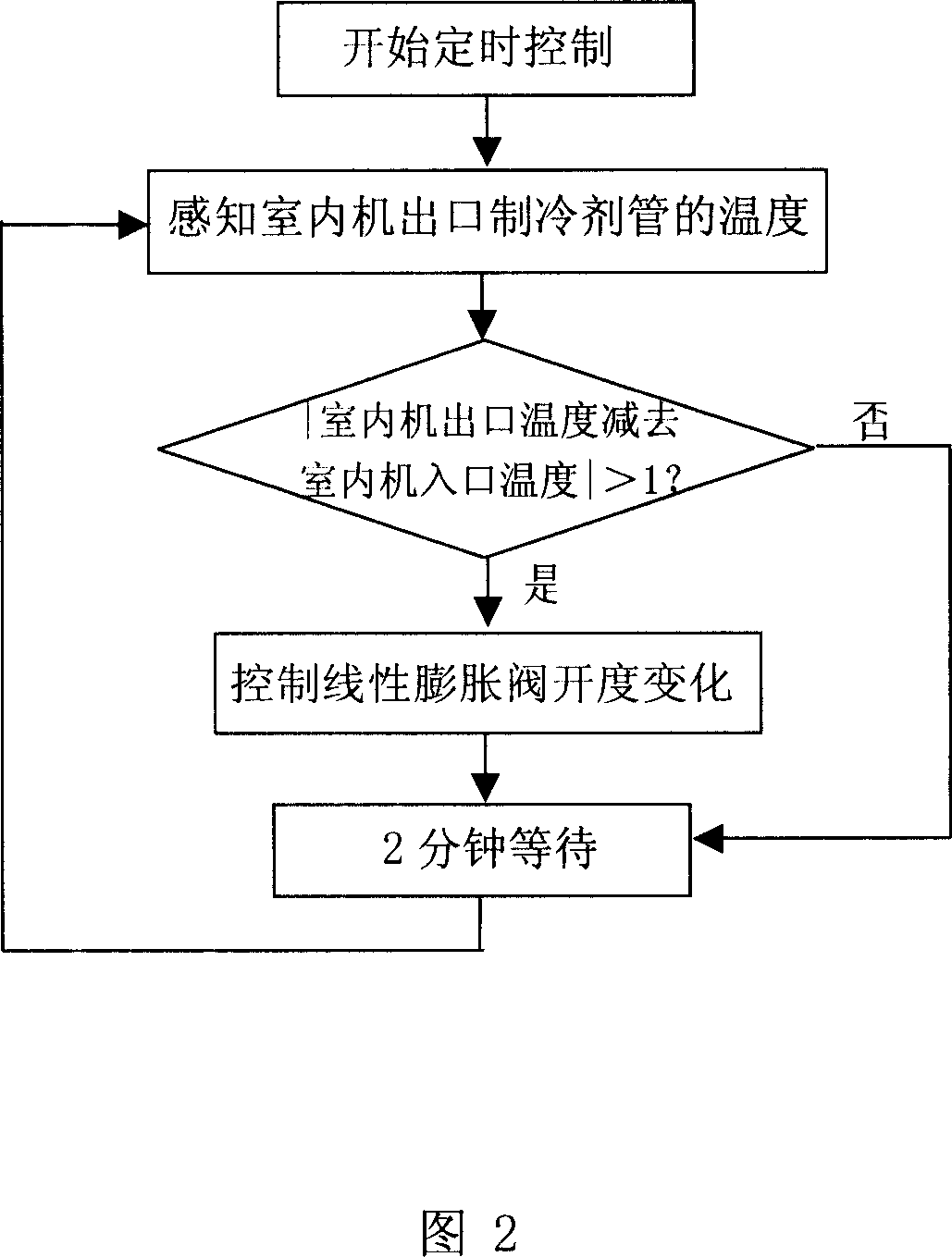

[0021] As shown in Figure 3, the control method of compressor discharge temperature of the present invention comprises the following steps: S1. start timing control; ; S3. judge whether the compressor exhaust port temperature is greater than the set temperature according to the perception result, the set temperature of the present embodiment is 90 degrees, when the judgment result is greater than the set temperature, enter S4, when the judgment result is less than When setting the temperature, enter S5; S4. Increase the opening of the linear expansion valve, the present invention executes 10 openings per minute, and then return to S2 to continue the above control process; S5. Perceive the temperature of the refrigerant pipe at the outlet of the indoor unit , that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com