Defrost control method of air conditioner

A control method and technology for air conditioners, applied in defrosting, heating and ventilation control systems, heating methods, etc., can solve the problems of air conditioners reducing heating operation rate and affecting users' use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

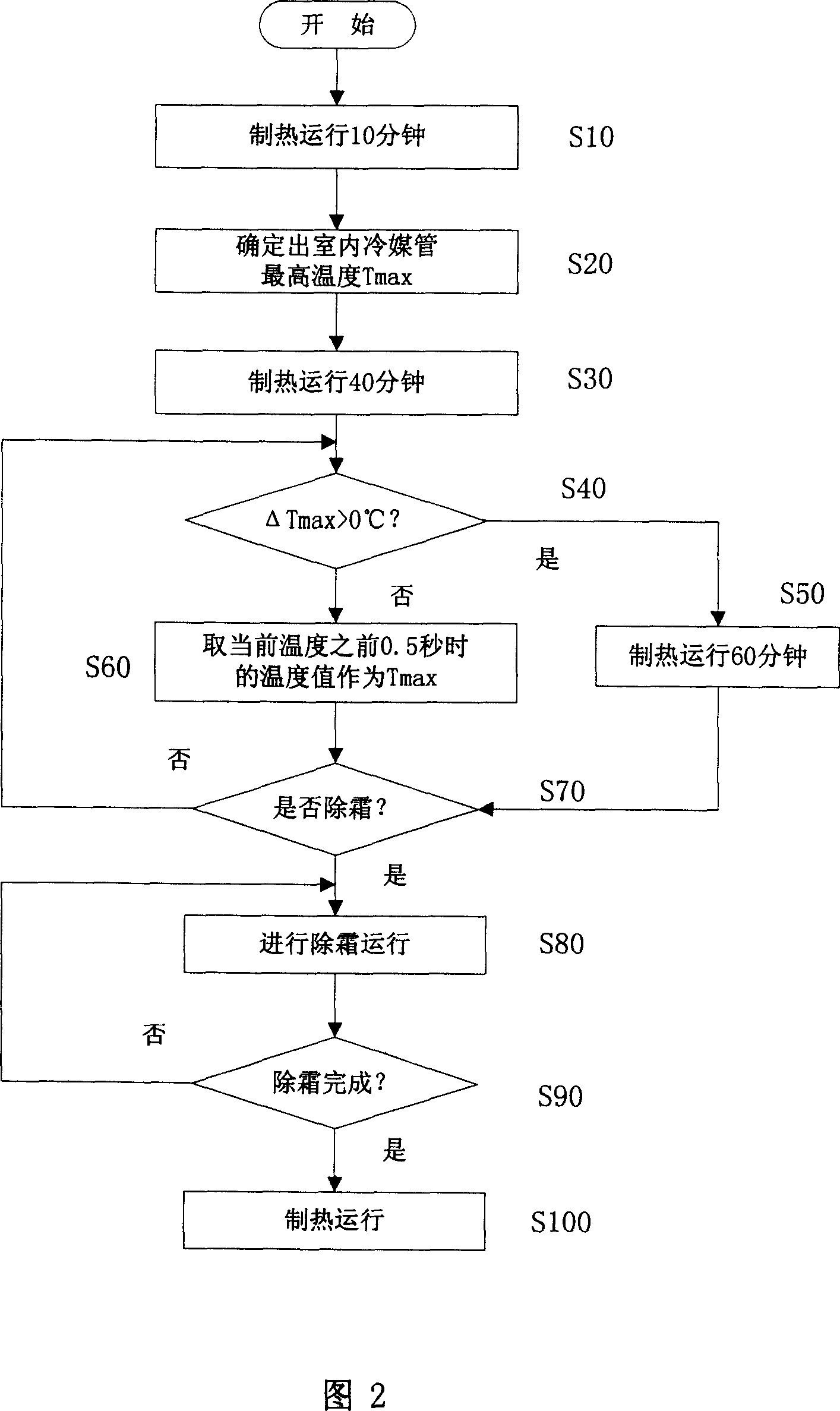

[0009] As shown in Figure 2, the defrosting control method of the air conditioner provided by the present invention includes starting to detect the temperature of the indoor refrigerant pipe after 10 minutes of heating operation and determining the maximum temperature T of the indoor refrigerant pipe. MAX S10, S20 stage; judge the maximum temperature T of the indoor refrigerant pipe every 4 minutes after heating operation for 40 minutes MAX The temperature difference ΔT between the current temperature of the indoor refrigerant pipe MAX Whether it is greater than the S30 and S40 stages of 0°C; if the judgment result of the S40 stage is the temperature difference ΔT MAX If the temperature is greater than 0°C, continue heating operation to the S50 stage for 60 minutes; if the judgment result of the S40 stage is the temperature difference ΔT MAX If it is less than 0°C, take the temperature value 0.5 seconds before the current temperature as T MAX S60 stage; S70 stage for judging...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com