Apparatus for cutting of an extruded strand of plastically deformable material, preferably of clay

A technology for cutting devices and deformed materials, applied in the direction of manufacturing tools, ceramic molding machines, etc., can solve the problems of reducing the service life, the difficulty of guiding the lateral movement of the clamping frame, increasing the load on the guiding surface, etc., and achieving the minimum cutting speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

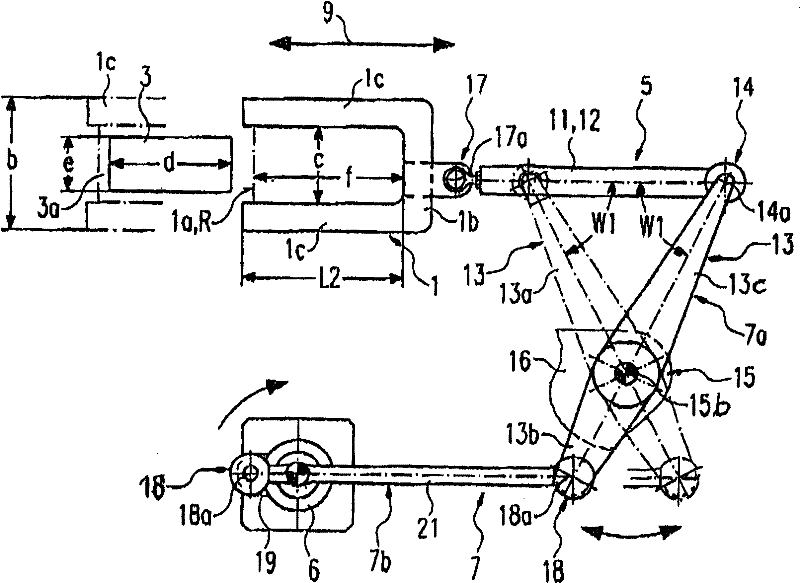

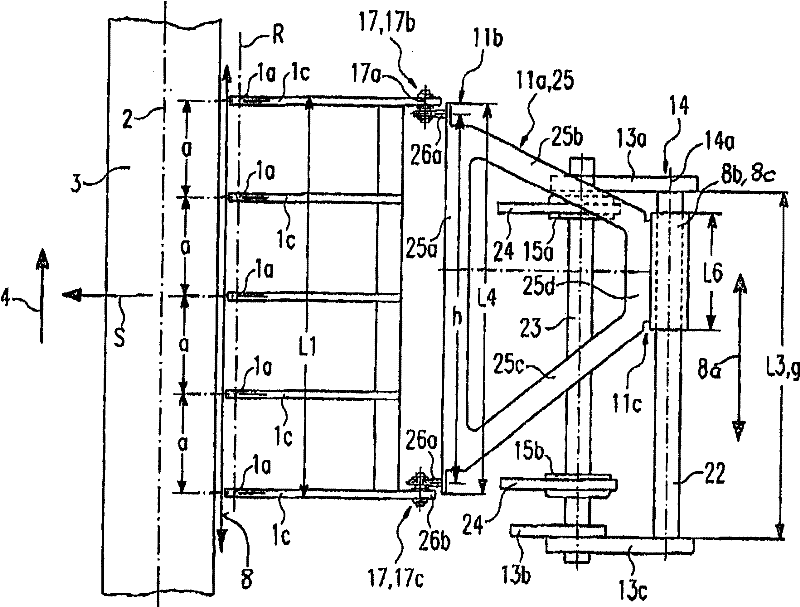

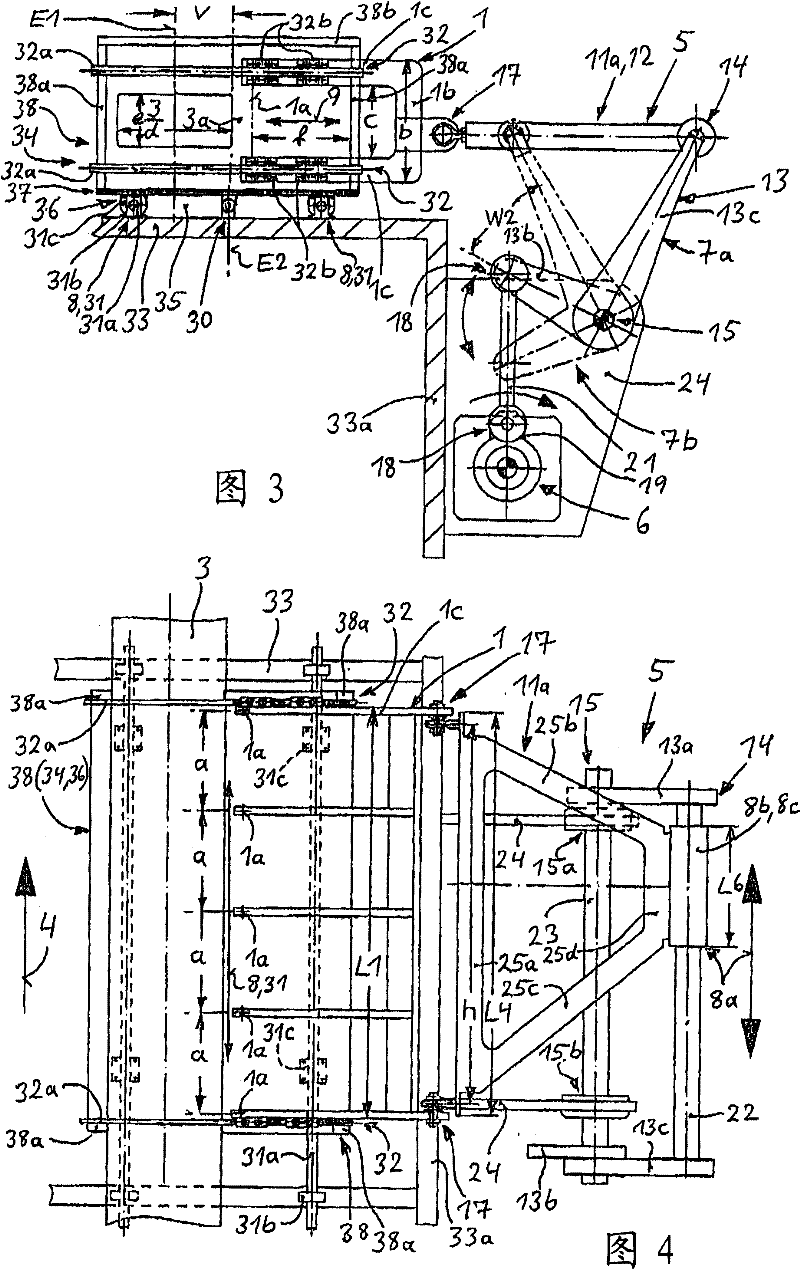

[0035] The essential part of the device shown in a simplified form is the holding frame 1 for at least one cutting line 1 a , which is shown in a simplified form of intersection, and which is fastened end-to-side in a manner not shown. The holding frame 1 and the cutting line 1a are arranged laterally offset in such a way that the holding frame 1 and the cutting line 1a is in a position laterally offset from the illustrated initial position of the channel 3a, at which position the channel 3a is formed. For this, the clamping frame 1 and the cutting line 1a are offset laterally below or above the channel 3a or relative to the channel 3a ( figure 1 )set up.

[0036] A plurality of cutting lines 1 a extending transversely to the longitudinal center axis 2 can be provided on the clamping frame 1 and form a distance a from one another extending along the longitudinal center axis 2 . For this, two or more cutting wires 1a, preferably three or four or more cutting wires 1a are fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com