New type lens, fabricating technique, and fabrication die

A new type of mold technology, applied in the field of lenses, can solve the problems of loose film mirror, film mirror falling off, impact and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0111] The above-mentioned and other technical features and advantages of the present invention will be described in more detail below in conjunction with the accompanying drawings.

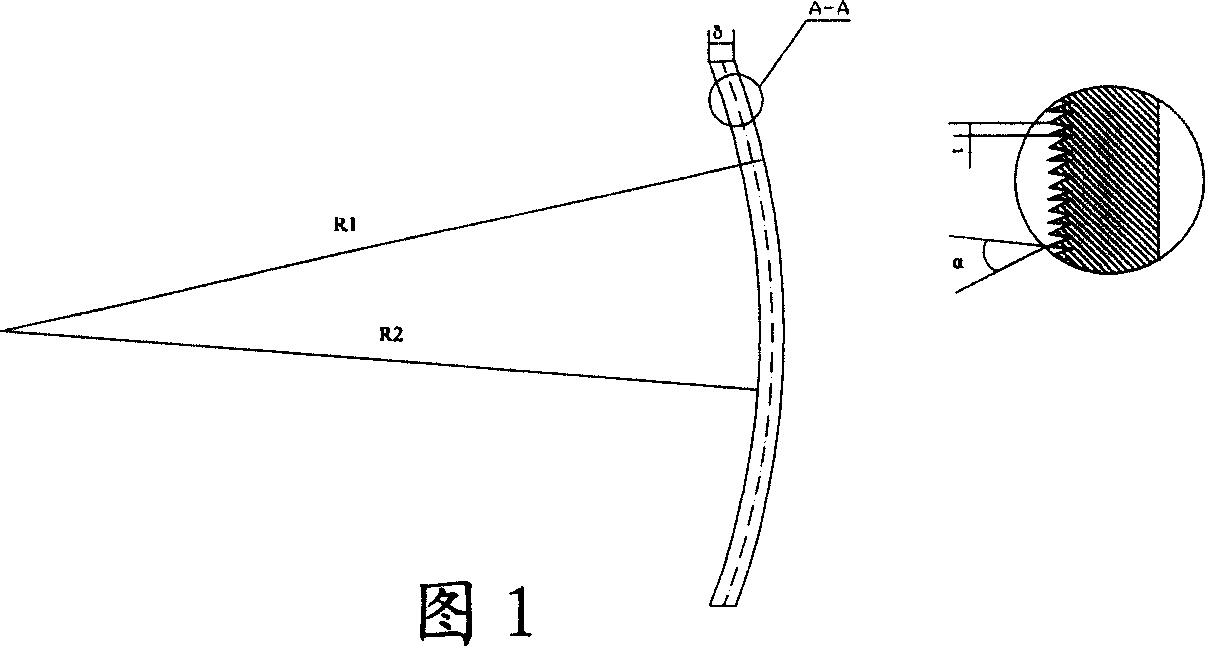

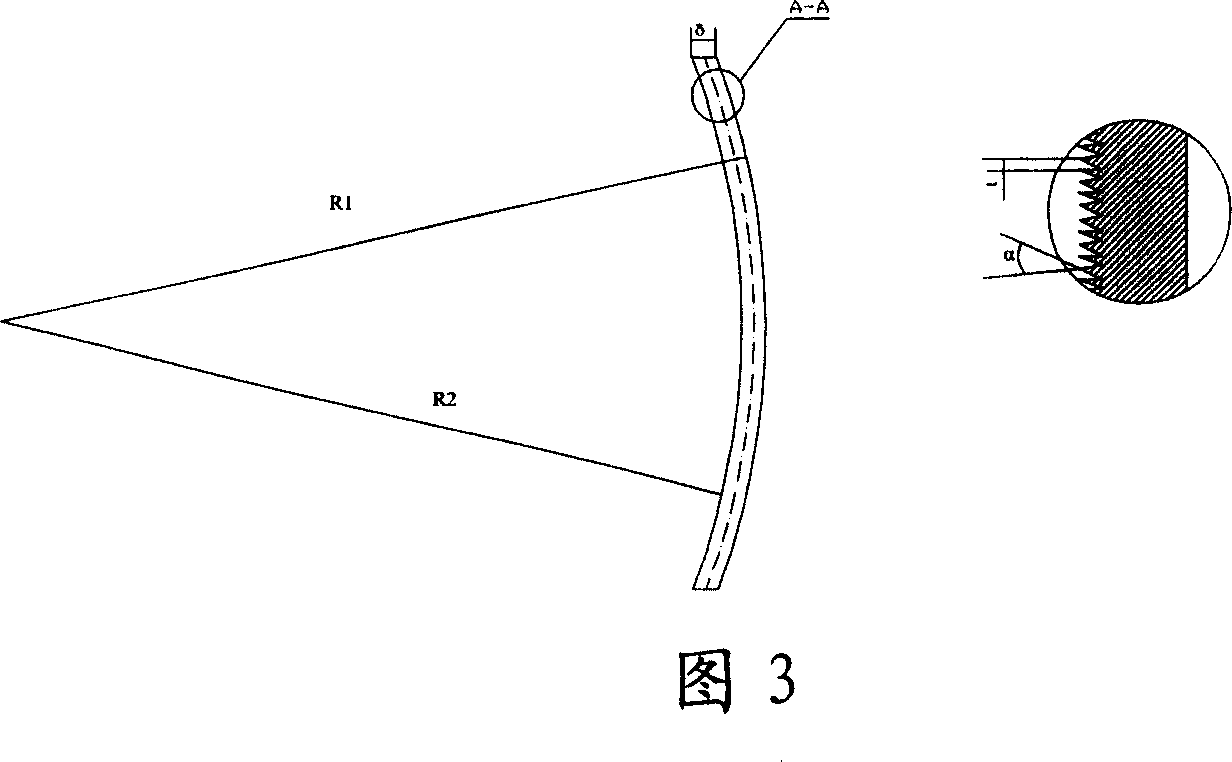

[0112] The present invention is a new type of thin lens, which is processed by integral molding technology, which includes a spherical lens part and a Fresnel prism part, the spherical lens part is arranged at the front part, and the Fresnel prism part set at the rear.

[0113] PMMA

PC

Density (1×10 3 kg / m 3 )

1.191

1.2

Refractive index (n)

1.491

1.5872

92-93%

85-90%

57.53

58

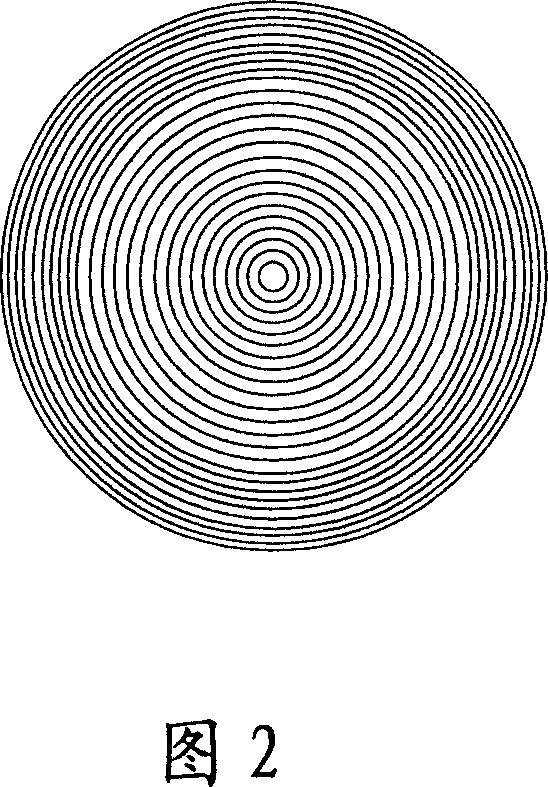

[0114] Please refer to Fig. 1, shown in Fig. 2, it is respectively the side view and the front view of the preferred embodiment one of novel lens of the present invention, and it is a kind of myopia mirror (concave lens), and it comprises spherical mirror part and Fresnel prism part , the thickne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com