Float push-pull type fiber filter

A fiber filter and filter technology, which is applied in the direction of gravity filter, loose filter material filter, filtration and separation, etc., can solve the problems of adding valves and increasing equipment operation steps, so as to reduce operation steps, ensure filtration effect and Cleaning effect, buoyancy reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

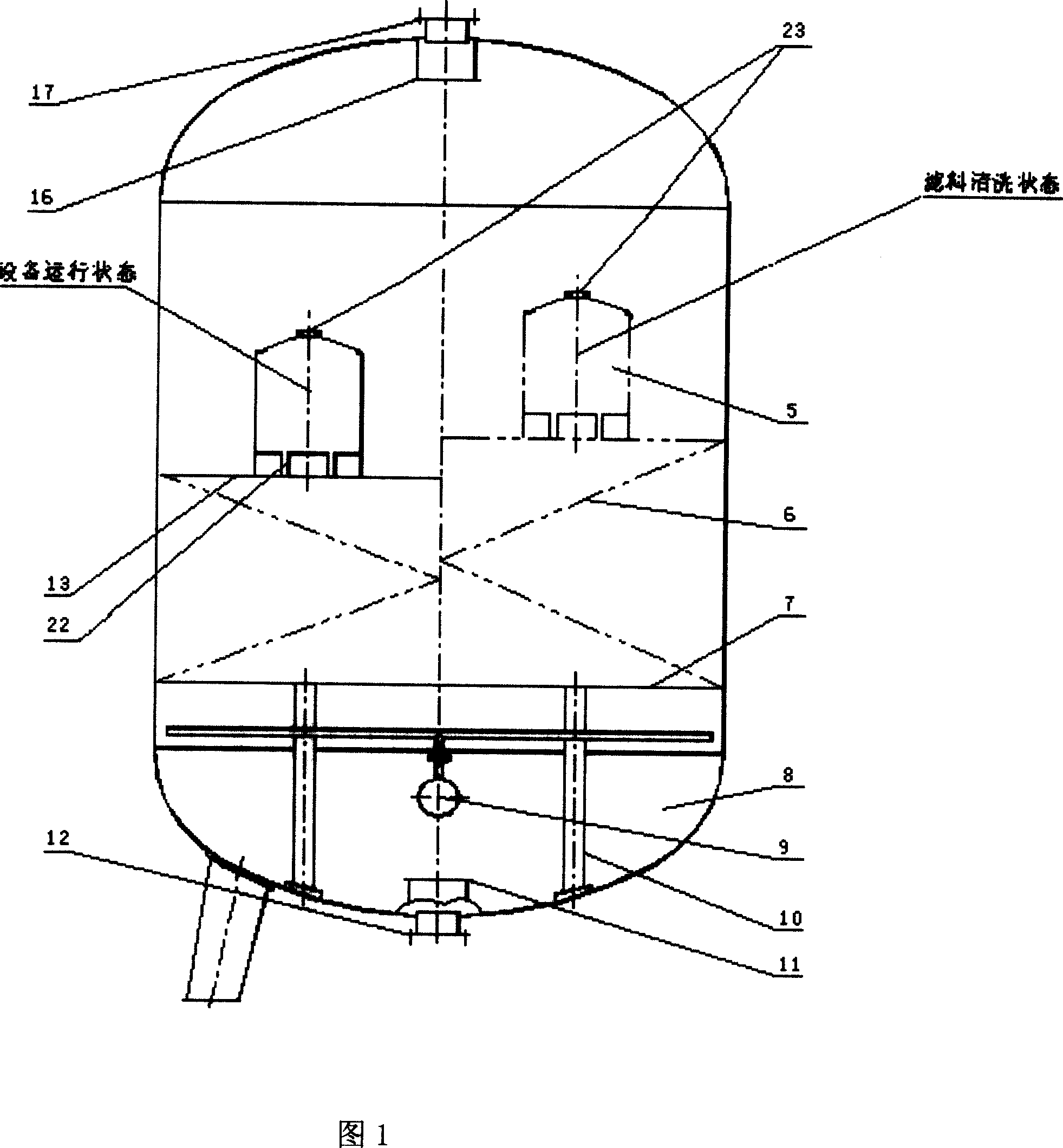

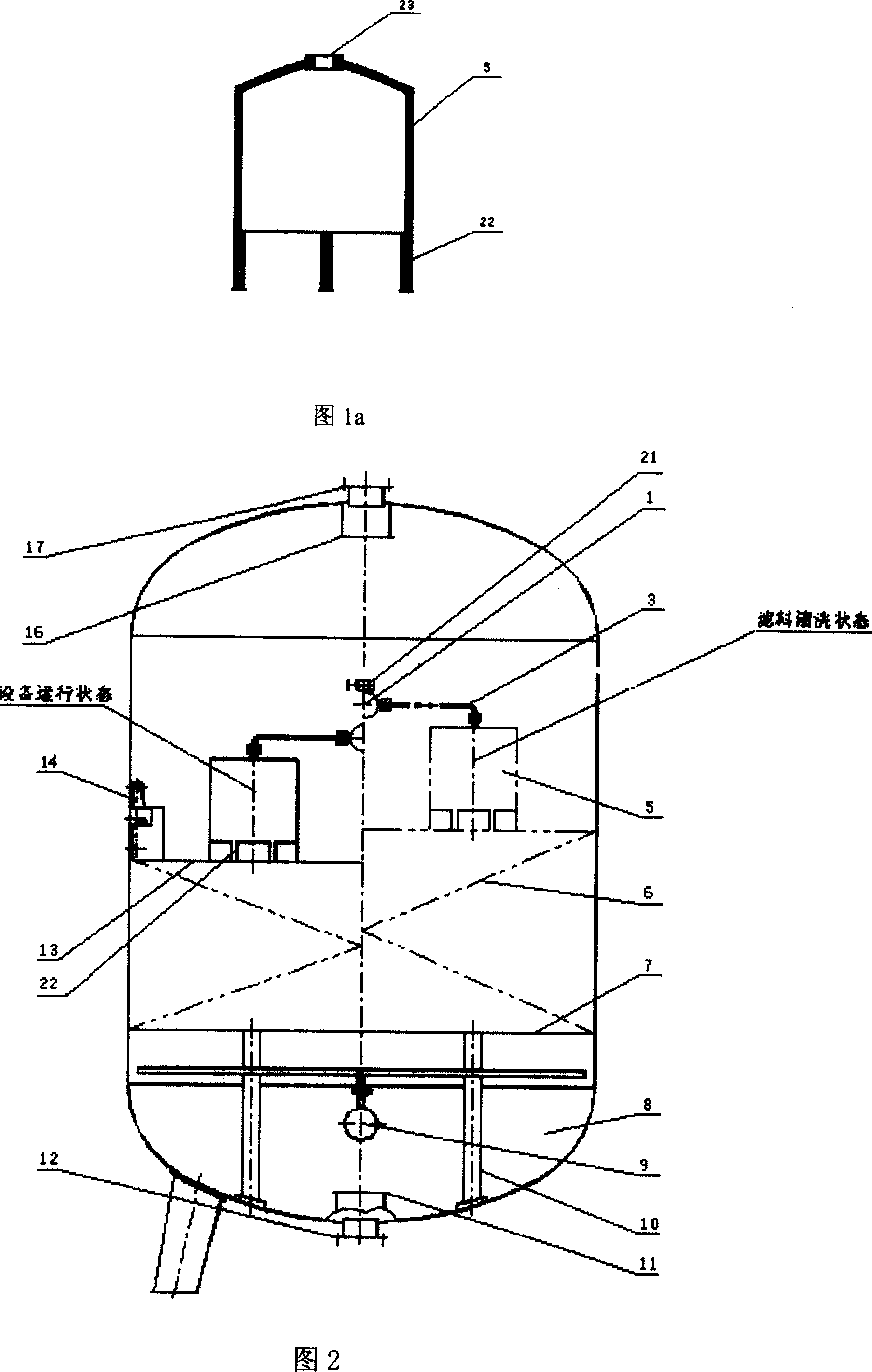

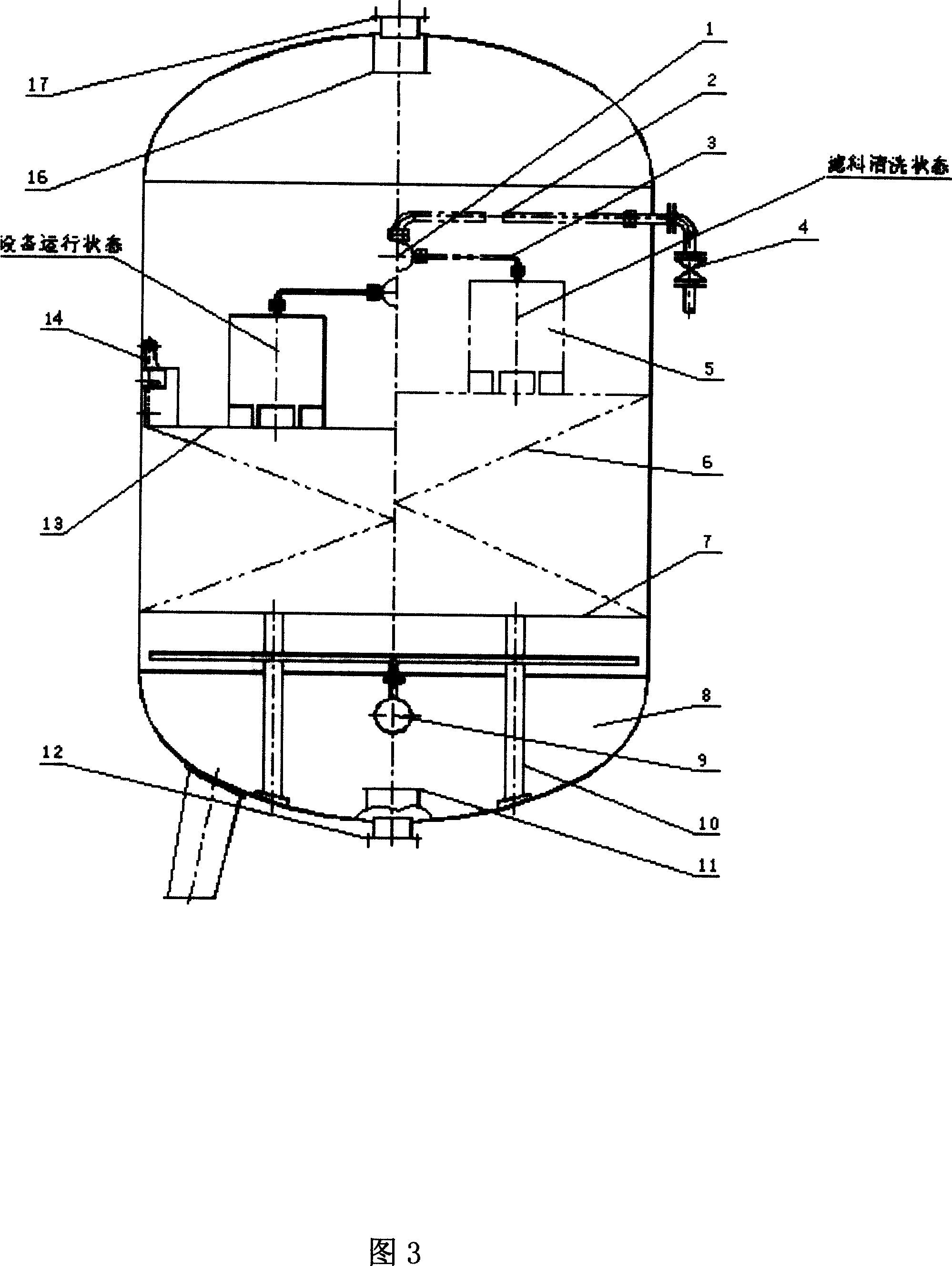

[0019] Referring to Fig. 1 and Fig. 1a, the fiber filter of the present invention mainly includes a housing 8, a fixed porous support device 7 installed in the housing 8, and a movable porous support device 13, which is fixed on the fixed porous support device 7 and the movable porous support device. The fiber bundle filter element 6 on 13, and the water inlet 17 and water outlet 12 installed on the housing 8, the upper water distribution device 16 and the lower water distribution device 11 installed on the housing 8, and the gas distribution device installed on the lower part of the housing 8 9; the fixed porous support device 7 is supported on the lower head through the support member 10; the movable porous support device 13 is arranged above the fixed support porous plate 7, the water inlet 17 is on the upper part of the housing 8, and the water outlet 12 is on the upper part of the housing 8 Bottom; the gas collecting hood 5 is set on the movable porous support device 13, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com