Clamp-proof device

An anti-clamping device and a technology of rotation angle, which is applied in the direction of transportation and packaging, elevators in buildings, etc., can solve the problems of being caught, etc., and achieve the effect of sensitive response, beautiful appearance and simple production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

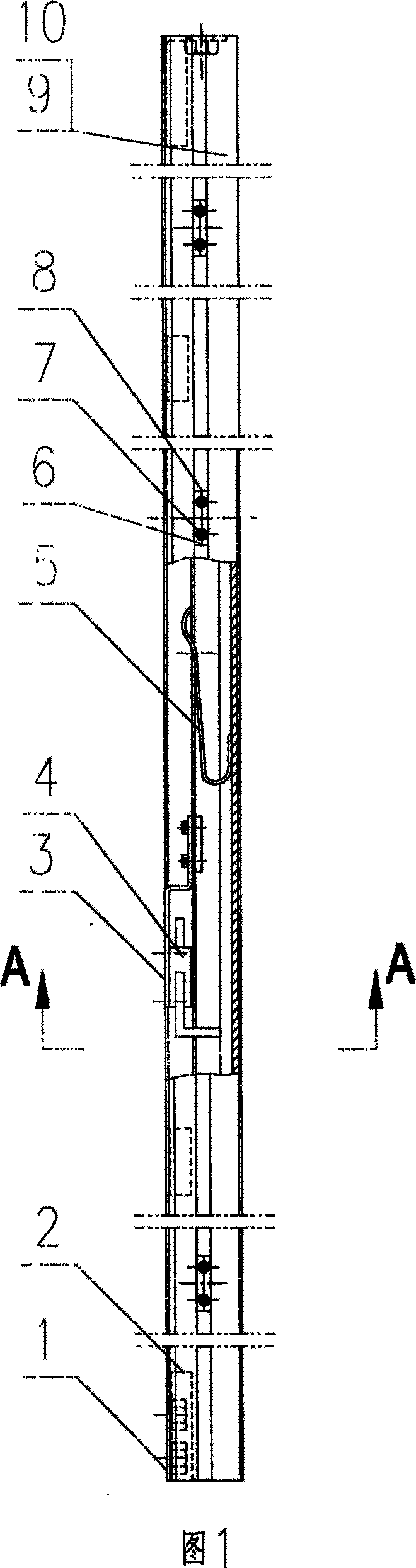

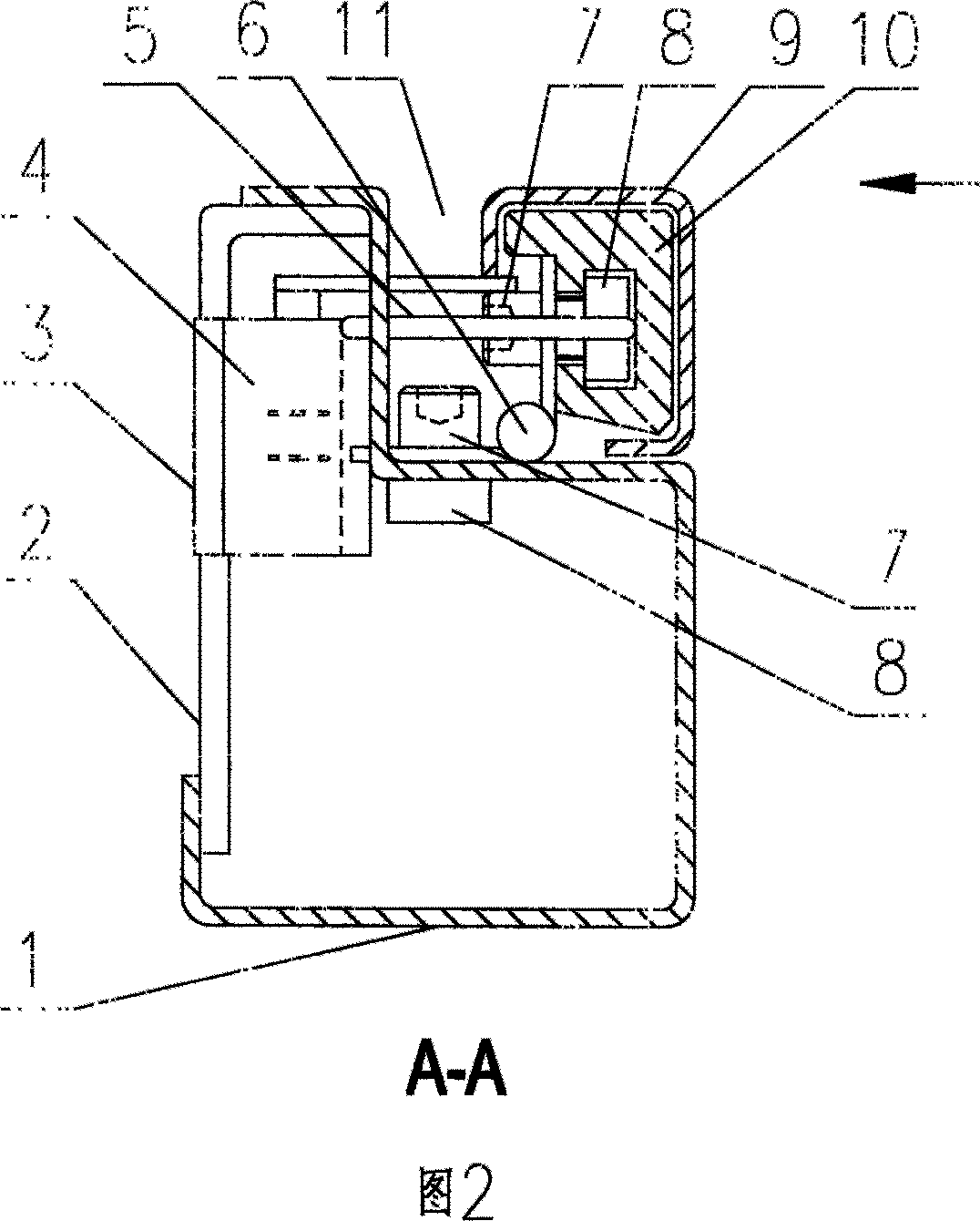

[0014] Referring to Fig. 1 and Fig. 2, this embodiment includes a main frame 1, a hinge 6, a rotating angle steel 9, a micro switch 4 and a return spring 5, wherein the main frame 1 is connected with the rotating angle steel 9 through a hinge 6 to form a Turn mechanism. There are installation holes on the main frame 1, and the screws 7 pass through the holes to connect with the double-hole nuts 8, and the main frame 1 and the hinge 6 are fixedly connected together, and the angle steel lining 10 is installed in the rotating angle steel 9, and the angle steel lining 10 There is a groove, and the double-hole nut 8 is placed in the groove, and then the rotating angle steel 9 and the hinge 6 are fixedly connected together by the screw 7 and the double-hole nut 8 . One end of the return spring 5 passes through the reserved hole on the main frame 1, and its other end is positioned in the groove on the angle steel lining 10, so that the rotating angle steel 9 is flexibly reset, and un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com