Jet fan for airflow movement

A technology for conveying airflow and jet flow, which is applied to the components of pumping devices for elastic fluids, engine working fluid, thin plate connections, etc., and can solve problems such as power consumption, running noise, deterioration, and harmful health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

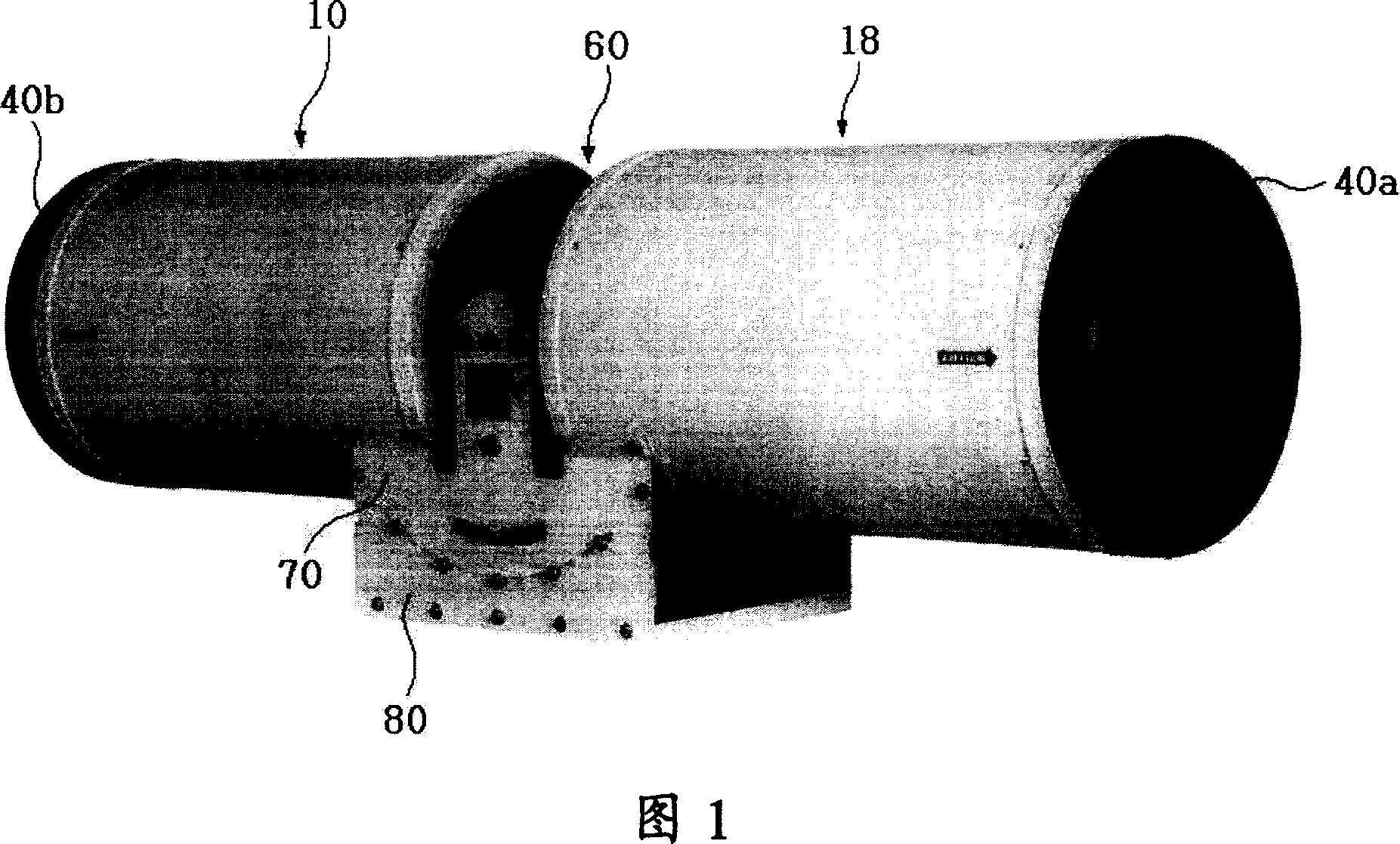

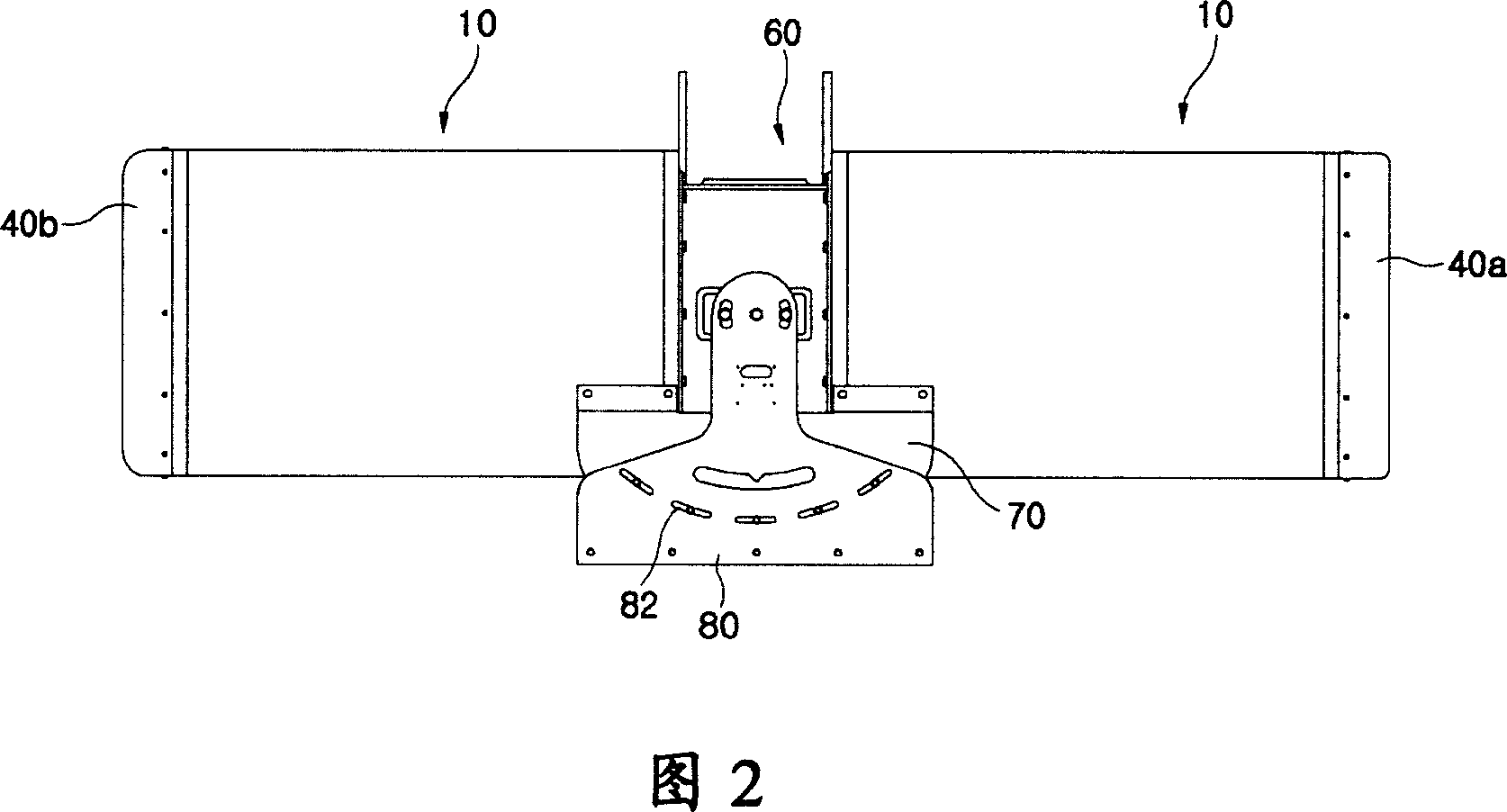

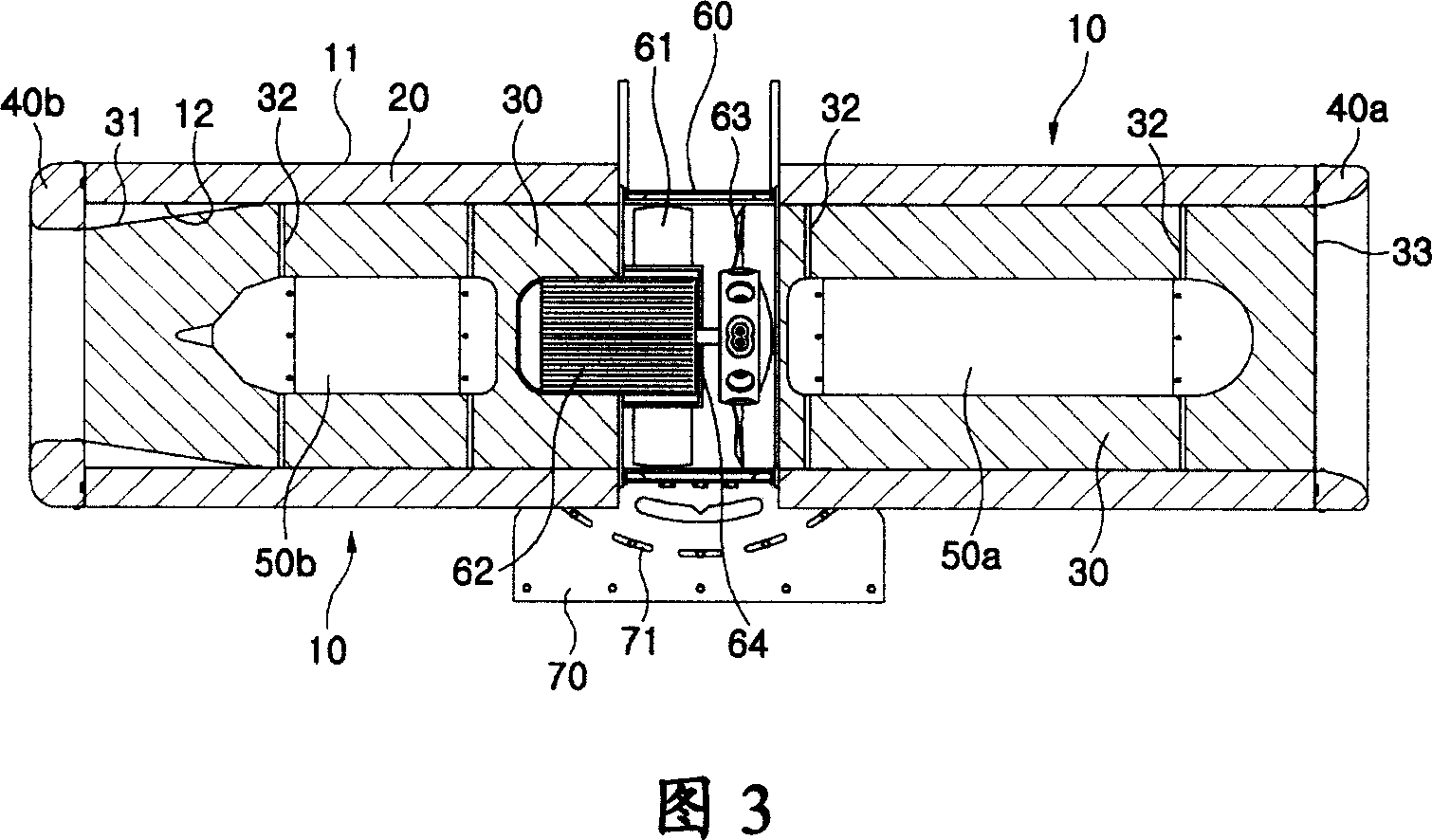

[0022] The present invention includes: two separate housings 10, arranged oppositely in the shape of cylinders, composed of an outer cylinder 11 and an inner cylinder 12 with a smaller diameter than the outer cylinder 11. The outer cylinder 11 and the inner cylinder 12 are A sound-absorbing element 20 for absorbing noise is provided in between; the containing pipe 30 is formed in the form of a perforated plate and is closely contained within the entire inside of the cylindrical body 12 of the housing 10, and is integrated on the inside of the front end of the discharge-side housing 10 A nozzle portion 31 with a gradually smaller diameter is formed; the introduction-side silencer 50a and the discharge-side silencer 50b are respectively located in the central part of the inner side of the housing pipe 30 of the above-mentioned separated housing 10, and both sides are passed through silencer bolts 32 is supported and fixed on the inner wall of the receiving pipe 30; the introduction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com