Ratio-variable feedback type digital fluid cylinder

A fluid cylinder, feedback technology, applied in the direction of fluid pressure actuation devices, etc., can solve the problems of complex control system, reduced working speed of digital cylinder, and reduced positioning accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

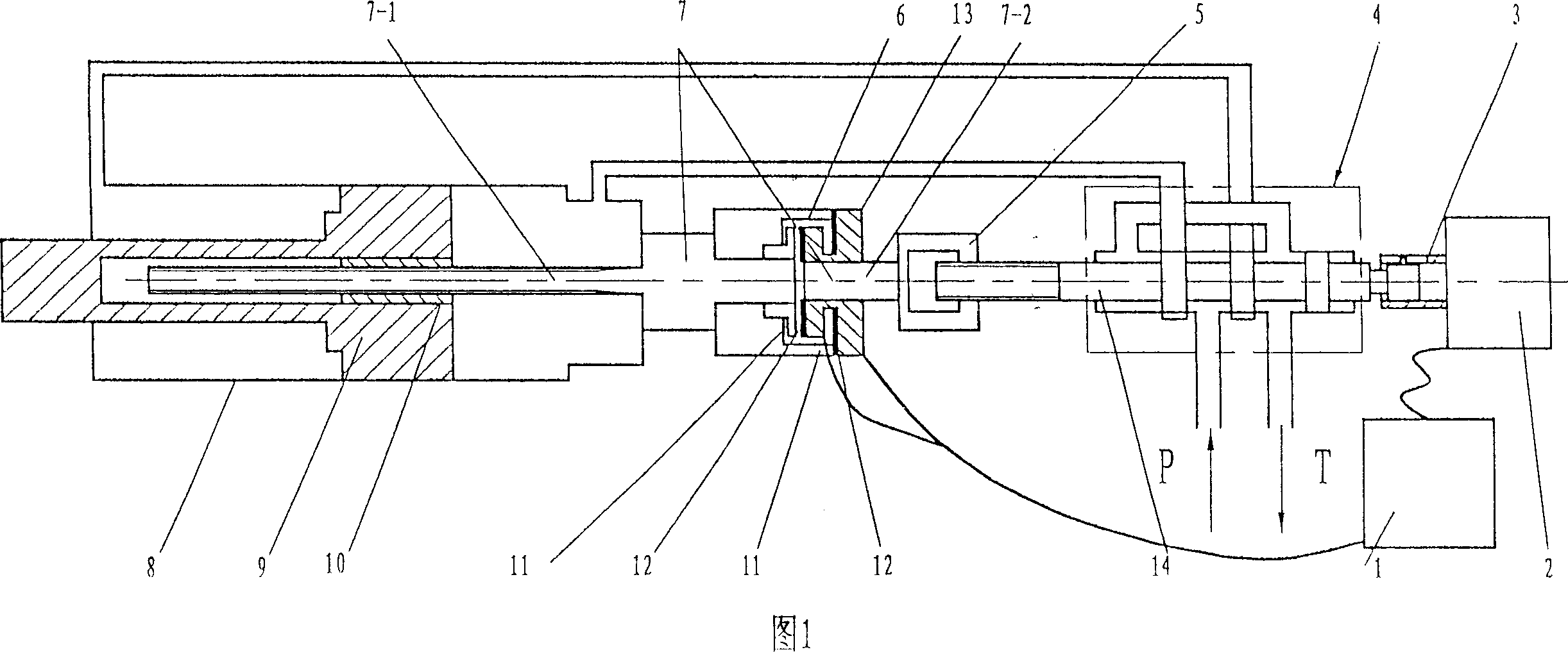

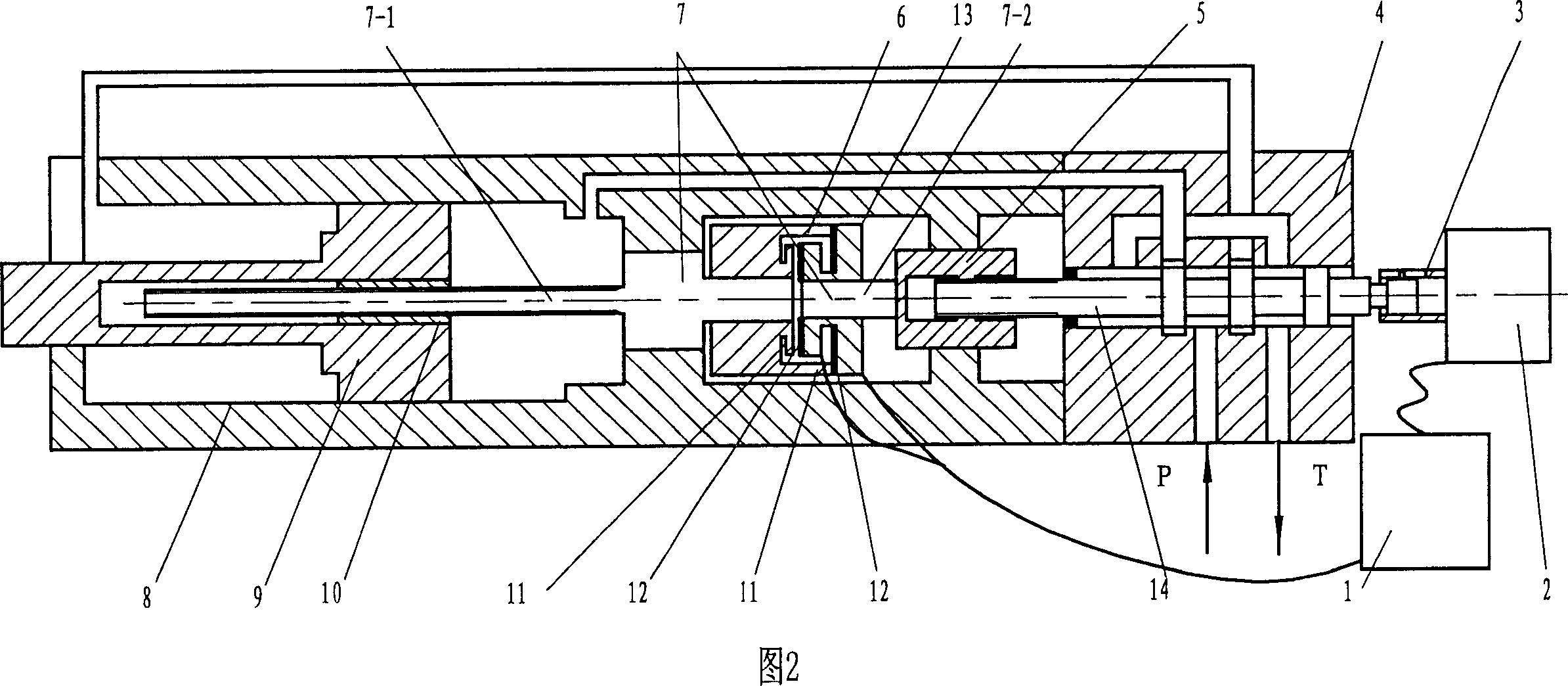

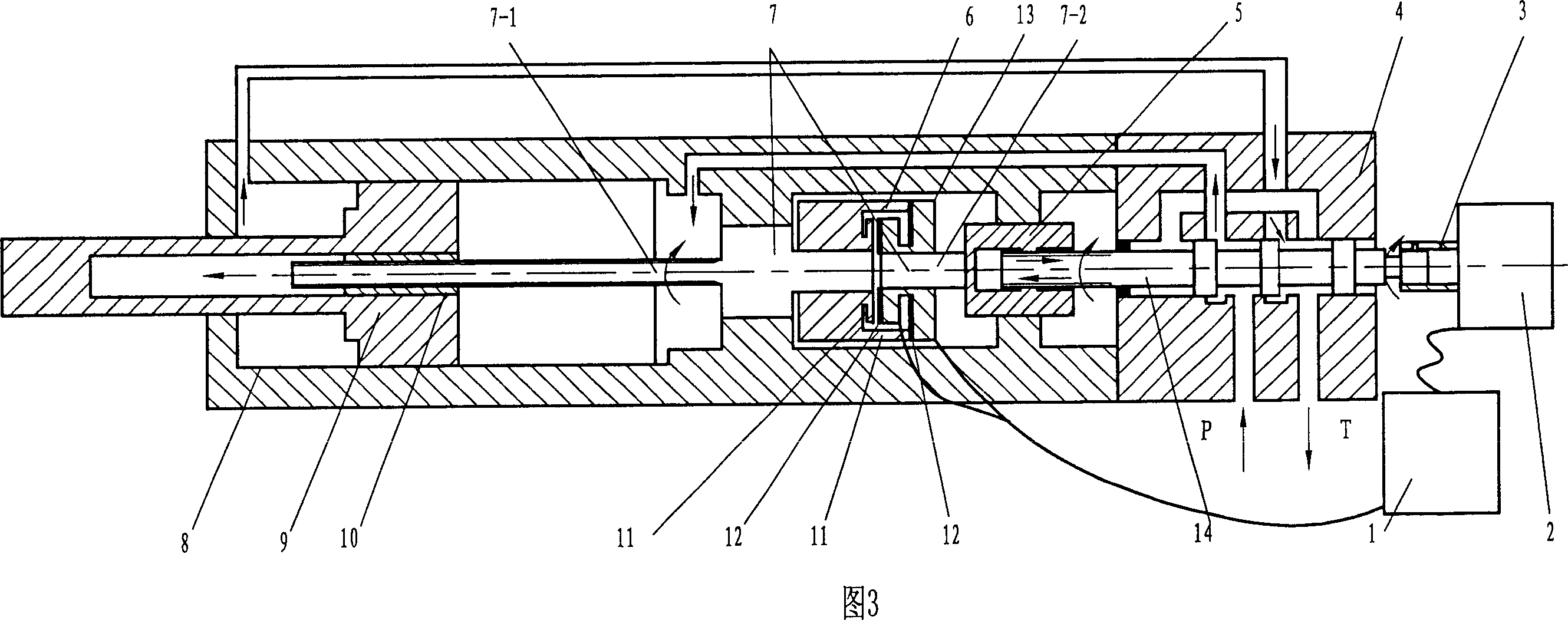

[0038] The variable ratio feedback type digital fluid cylinder of the present invention includes the parts and structures that the existing numerical control fluid cylinder also has: a numerical control device 1, a control drive motor 2, a cylinder body 8, and a piston 9 in the cylinder body 8, and a control valve 4 And the feedback lever 7, the control valve spool 14 is connected with the control drive motor 2 in the way of rotating the sliding sleeve 3, and the control valve 4 is a spool valve. The function of the control valve 4 is to realize the control of the start and stop of the piston movement and the change of the movement direction. The present embodiment controls the stepper motor for driving the motor 2 . The feedback mechanism in the present embodiment digital fluid cylinder is:

[0039] The feedback rod of the present invention is made up of two sections, wherein on a section adjacent to the piston 9 is a piston-end feedback rod 7-1, and one end of the piston-en...

Embodiment 2

[0045] Like Embodiment 1, the only difference is that the speed output end 11 of the transmission device and the clutch terminals 12 of the clutch 13 are different in number and relative proportion. The three speed output terminals 11 ball bearing transmissions are replaced by five speed output terminals 11 gear transmissions, that is, the five speed output terminals 11 of A, B, C, D, E, wherein, the A terminal and the piston end feedback rod 7-1 is directly connected, and the speed ratio of the rotational speed of the A terminal to the rotational speed of the feedback rod at the piston end is 1:1. Electromagnetic clutch 13 also has U, W, X, Y, Z five clutch terminals 12 that can be engaged with these five speed output terminals 11 respectively.

[0046] The feedback rod 7-2 at the control valve end is connected with the control valve 4 through the connection sleeve 5 in a spiral pair.

[0047] The output speeds of the five speed output terminals 11 of gear transmission devic...

Embodiment 3

[0056] As in embodiment 1, but the ball bearing speed changer with three speed output ends 11 is replaced by a friction wheel speed changer with two speed output ends 11 A and B, wherein the A terminal is directly connected to the feedback rod 7-1 at the piston end , the speed ratio is 1:1. Any one of the reciprocating speeds of the piston 9 can have two different rotational speed outputs at the speed output end 11 of the friction wheel speed changer. Sure. For example, when the reciprocating positioning accuracy of the piston 9 is 0.01 mm, the speed ratio of the two rotational speeds of the friction wheel speed changer can be 1:4. If the output speed of terminal A is 100 rpm, the speed of terminal B is 400 rpm.

[0057] The electromagnetic clutch 13 also has two clutch terminals 12, X and Y, engaged with the speed output end 11, and the clutch terminals 12 are respectively controlled by corresponding electromagnets to engage or disengage. Each electromagnet is connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com