Testing method of thermal resistance of heat-conducting material and testing clamp

A technology of heat-conducting materials and testing methods, which is applied in the field of testing, can solve problems such as poor test result accuracy, elevated temperature of the workbench, and the inability to put heat-conducting materials into the environmental test chamber, so as to achieve the effect of improving test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

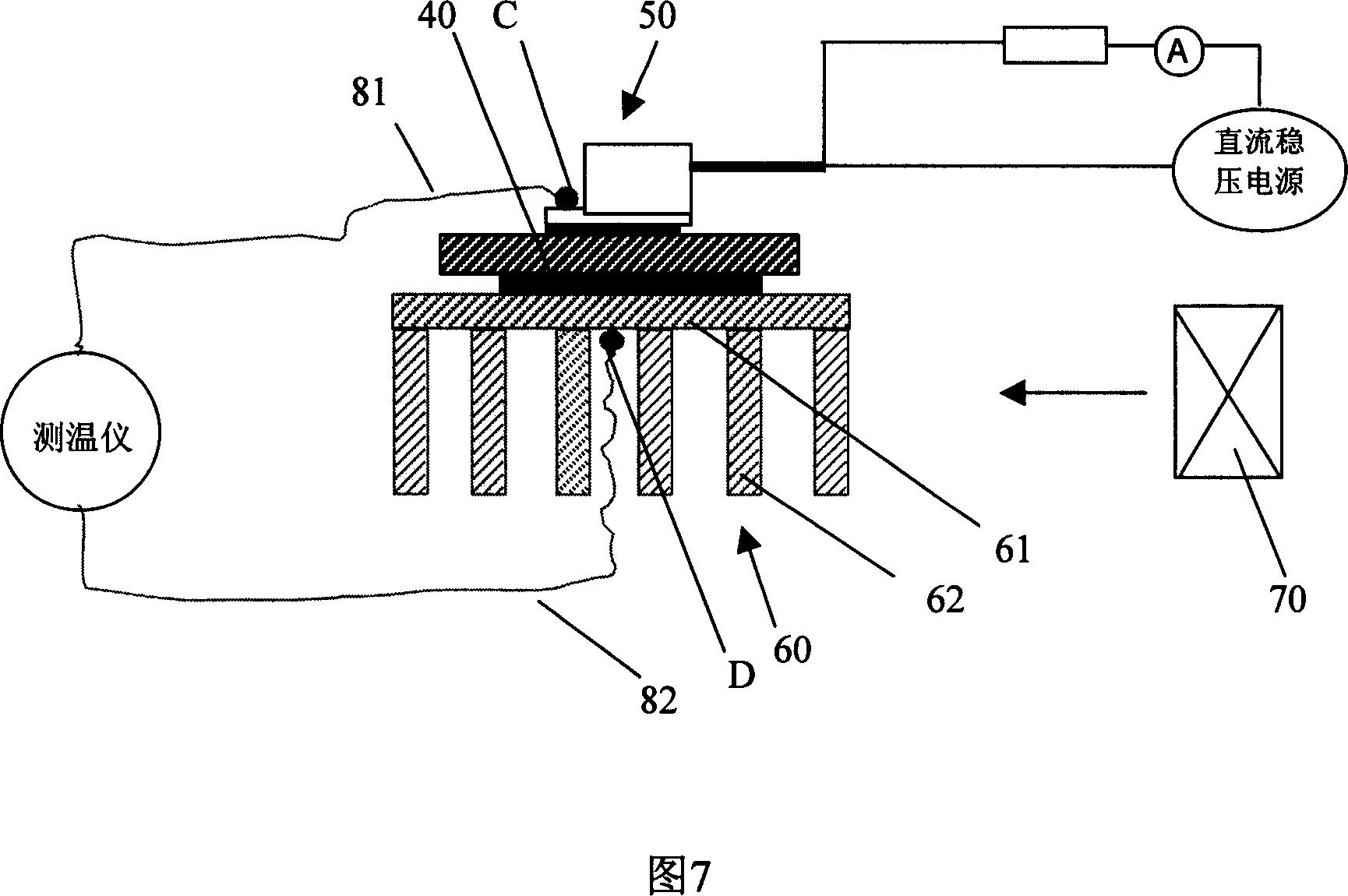

[0031] Below according to accompanying drawing and embodiment the present invention will be described in further detail:

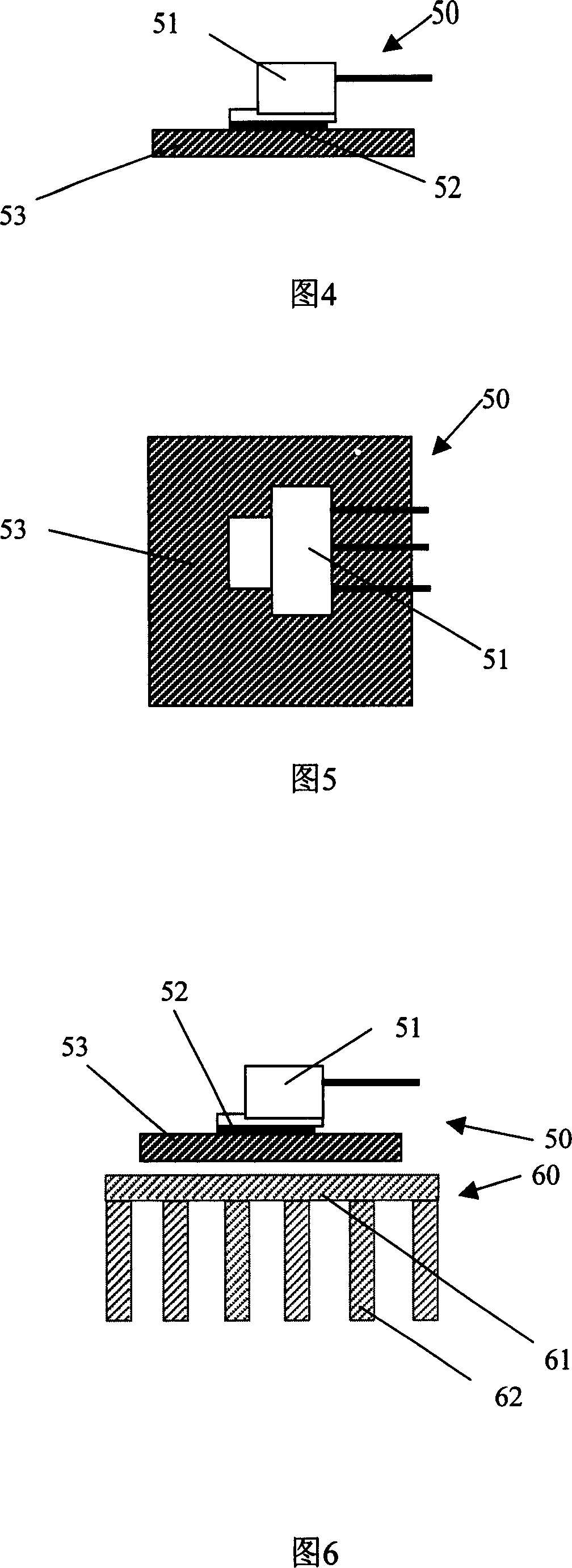

[0032] As shown in Figure 2 and Figure 7, the present invention provides a method for testing the reliability of thermal resistance of thermally conductive materials, comprising the following steps:

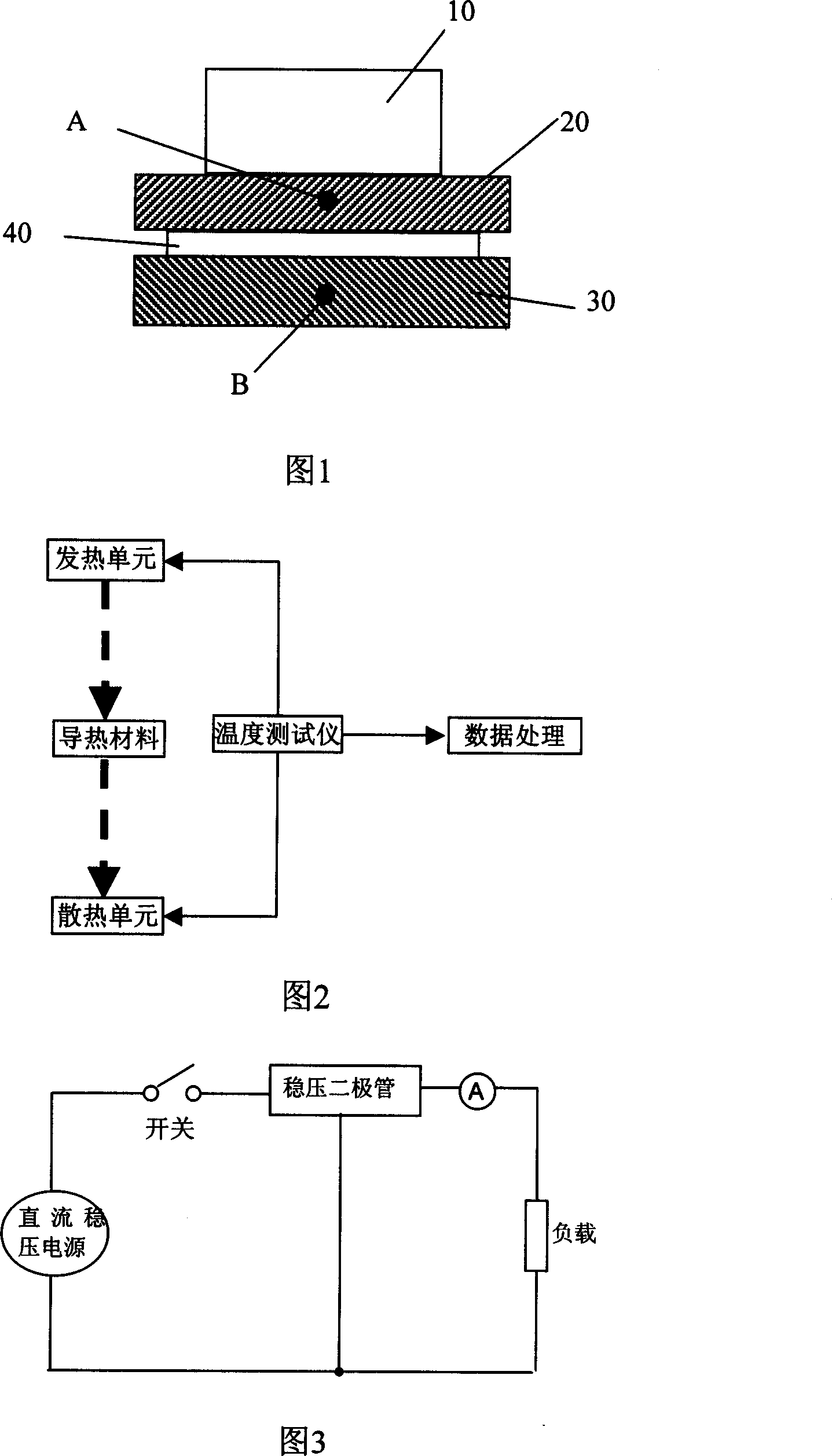

[0033] A test fixture that can be placed in an environmental test chamber consisting of a heating unit 50 and a heat dissipation unit 60 is provided, and the heat conducting material 40 is clamped between the heating unit 50 and the heat dissipation unit 60;

[0034] Put the test fixture holding the heat-conducting material 40 into the environmental test chamber, and set the parameters of the environmental test chamber to carry out the environmental test;

[0035] Take out the test fixture from the environmental test chamber, start the test after cooling to normal temperature, heat the heating unit 50 and conduct the heat to the heat dissipation unit 60 throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com