Shiftable hydrostatic compact drive unit

A driving device and vehicle driving device technology, which is applied in the directions of transmission, gear transmission, transmission control, etc., can solve the problem that the working capacity of the multi-disc clutch cannot be fully utilized, and is conducive to maintenance, saving installation space, and facilitating The effect of assembly or disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

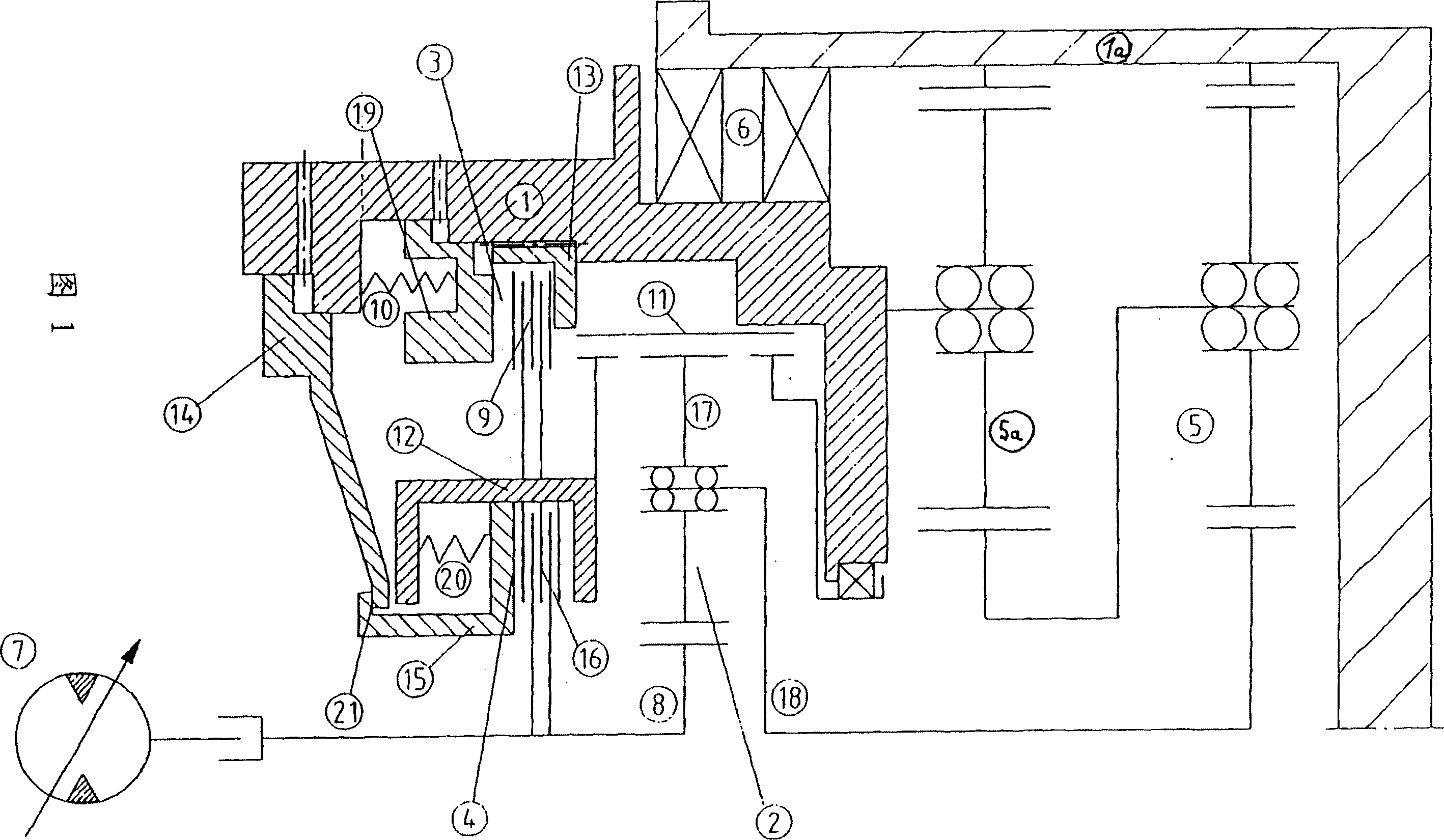

[0018] The shiftable hydraulic compact drive is surrounded by a housing 1 . The housing 1 accommodates a planetary gear stage 2 , a first multi-plate clutch 3 which can be engaged or disengaged, and a second multi-plate clutch 4 which can be engaged or disengaged. A hub shell 1 a is mounted on the shell 1 via a tapered roller bearing 6 . The hub shell 1a serves as the power output side for carrying automobile wheels. The first multiplate clutch 3 which can be engaged and disengaged connects the ring gear 11 of the planetary gear stage 2 to the housing 1 in a rotationally fixed manner. The sun gear 8 of the planetary stage 2 is non-rotatably connected to the ring gear 11 of the second planetary stage 2 via the second multidisk clutch 4 which can be engaged and disengaged. The sun gear 8 of the planetary stage 2 is driven by a hydraulic motor 7 . Instead, a planet carrier 18 of planetary stage 2 serves as an output and for this purpose it is connected to a downstream sun gear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com