Magnetron sputter electrode and sputtering apparutus using the magnetron sputter electrode

A magnetron sputtering and electrode technology, which is applied in the field of sputtering devices, can solve the problems of complex and tedious adjustment operations, readjustment of magnetic components, and inability to operate, and achieves the effect of simple and easy adjustment operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

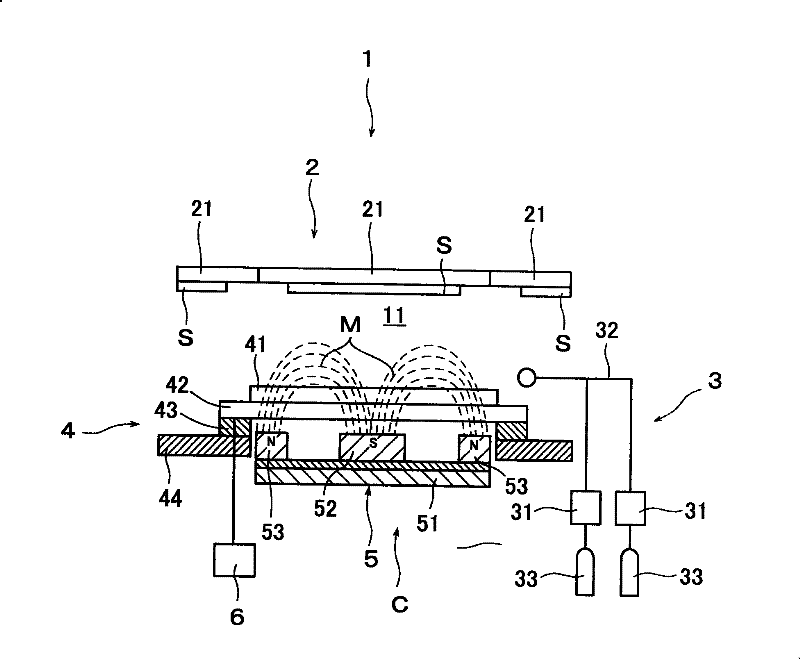

[0064] This embodiment is as Figure 6 The illustrated ITO film is formed on a processing substrate S by using a sputtering apparatus 10 . The processing substrate S is a glass substrate (1200mm×1000mm), and the targets 41α-41f are used in In 2 o 3 Add 10 wt% SnO on 2 , be made into 230mm * 1460mm external dimension and be installed on the backing plate 42 with known method. Then, an ITO film was formed on the glass substrate S by reactive sputtering.

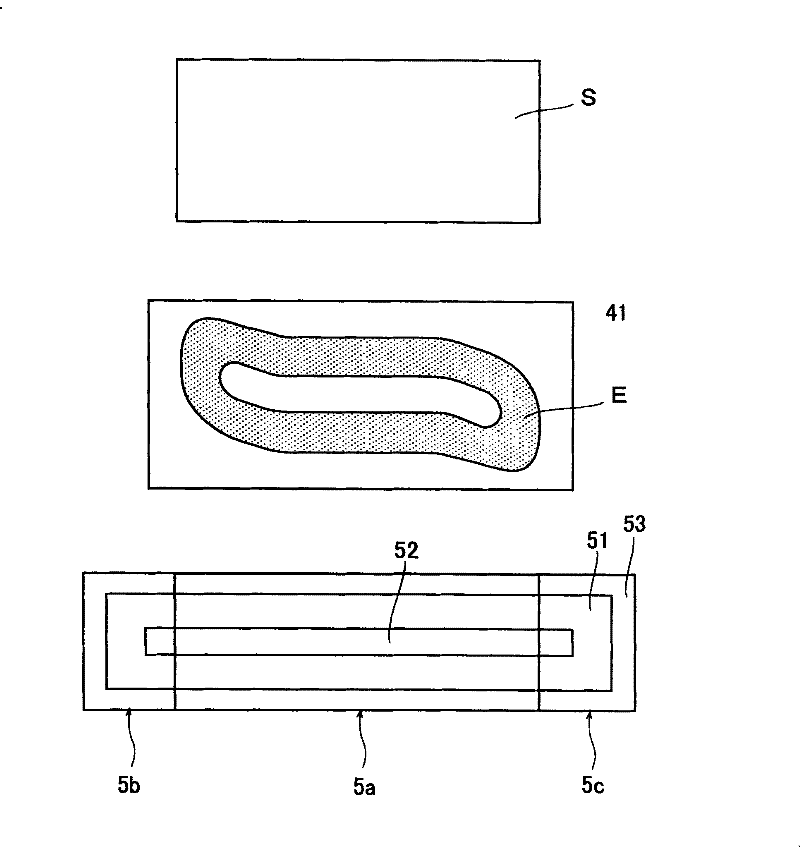

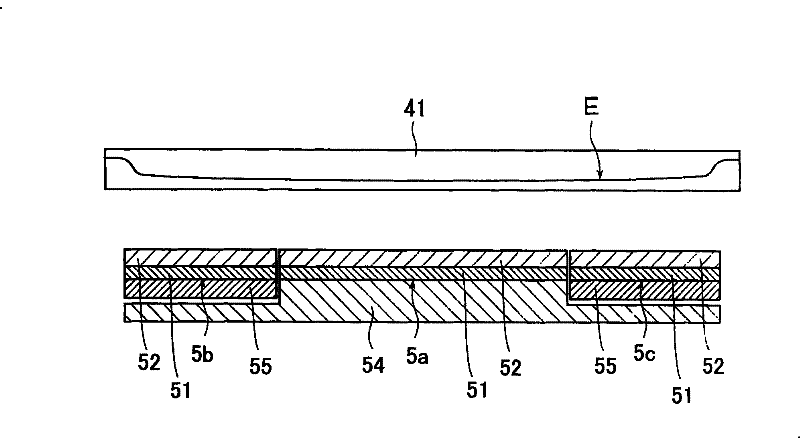

[0065] In addition, as the supporting plate 51 supported by each magnet assembly 50a-50f, the outer dimension is 130mm×1460mm, and the rod-shaped central magnet 52 along the length direction of the targets 41a-41f and the outer peripheral direction of the supporting plate 51 are arranged on each supporting plate 51. After the surrounding magnets 53 of the target 41a to 41f are separated, they are divided at positions about 40 mm from the edges in the longitudinal direction of the targets 41a to 41f. Then, by using the posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com