Rotor shaft greasing device for producing plastic-packaged motor in motor production line

A technology of plastic-encapsulated motor and oiling device, which is applied to devices and coatings that apply liquid to the surface, can solve many problems, such as unsatisfactory application effect and low work efficiency, even on the body, and achieve good results. , strong practicability and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

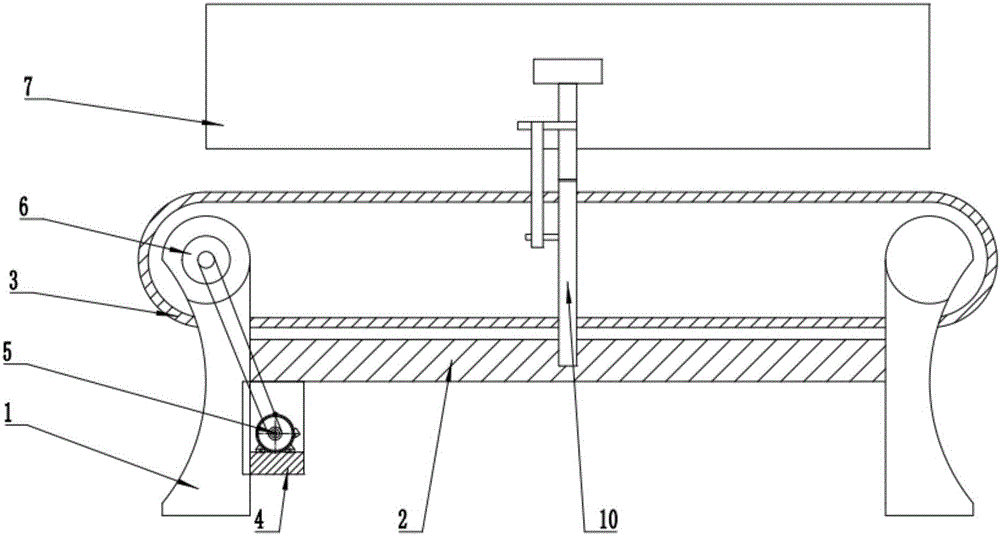

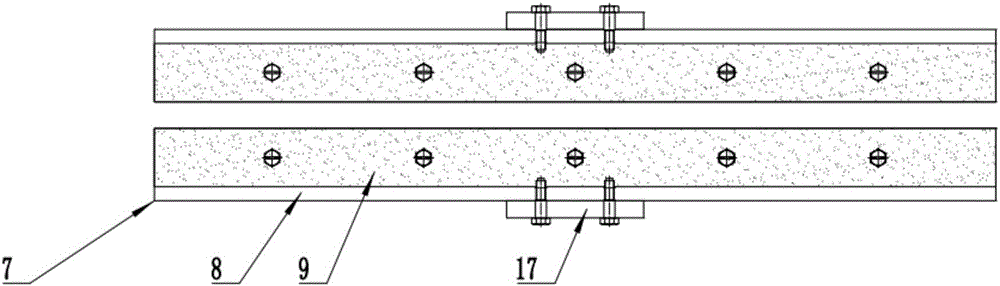

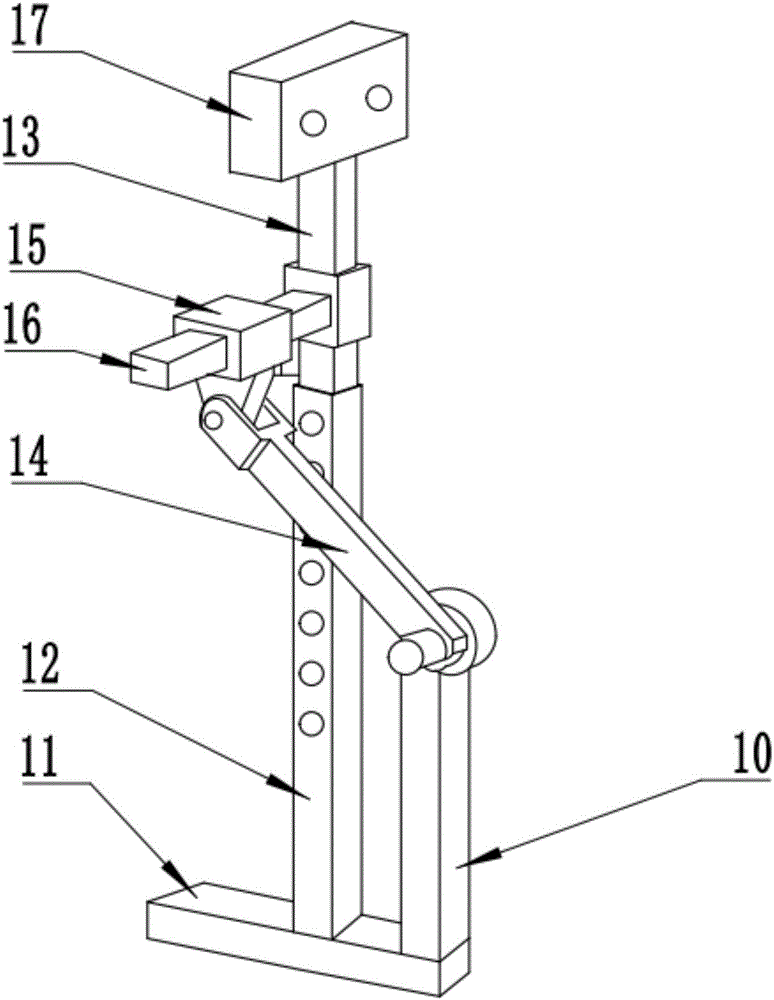

[0019] see Figure 1-3 , a motor production line production of plastic-sealed motor shaft oiling device, including a device body, the device body is mainly composed of a pillar 1, a beam 2, a transmission belt 3, an accommodation box 4, a transmission motor 5, a rotating shaft 6, and an oil immersion device 7 1. The adjustment frame 10 is composed of; the bottom of the device body is provided with pillars 1, and the pillars 1 are arranged at both ends of the device body, and the inner middle part of the pillar 1 is provided with a crossbeam 2, and the crossbeam 2 and the pillar 1 are fixedly connected , the overall structure of the device body is made more stable through the effect of the beam 2, a transmission belt 3 is arranged above the pillar 1, and a rotating shaft 6 is arranged at both ends of the transmission belt 3, and the rotating shaft 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com