Cable-supported grid stadium steel roof structure

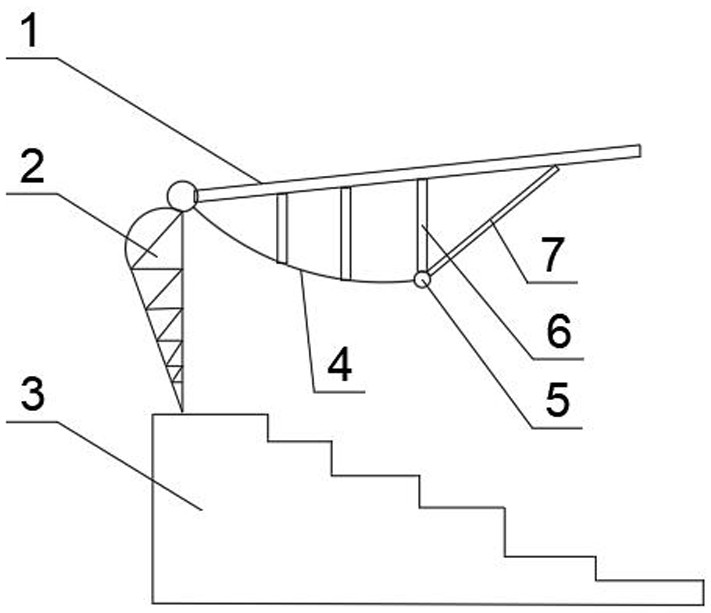

A technology for grid stadiums and steel roofs, which is applied to gymnasiums, roofs, building components, etc., and can solve the problems of difficult adjustment of steel roof cornice deformation, difficult construction operations, and lack of adjustability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

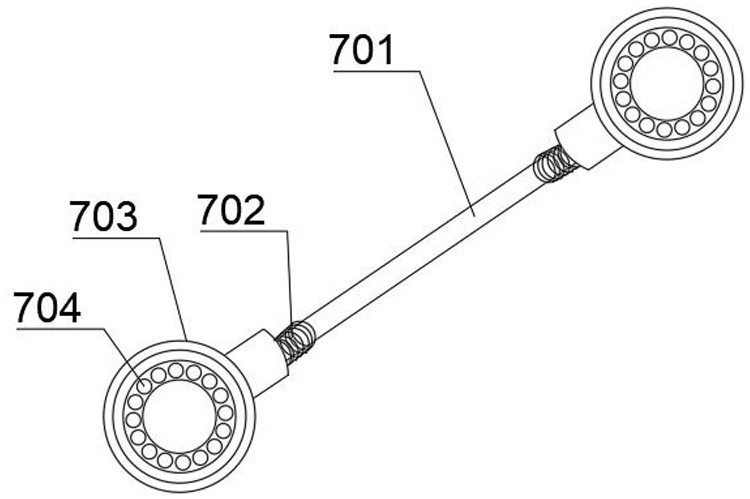

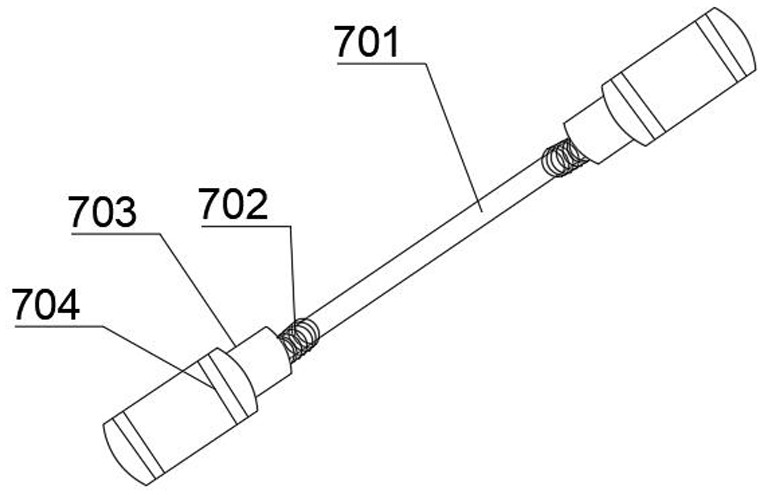

[0034] Others are consistent with the scheme of Embodiment 1, the rod 701 is a steel pipe column, the diameter of the steel pipe column is 180-200mm, and the wall thickness of the steel pipe column is 8-10mm.

Embodiment 3

[0036] The rest are consistent with the solution of Embodiment 1 or 2, and the adjustment range of the stroke of the adjustment screw assembly 702 is 0-60 mm.

Embodiment 4

[0038] The rest are consistent with any one of the embodiments 1-3, and the angle adjustment range of the ball hinge ear piece 703 is 0-15 degrees.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com