Guiding rail type composite wall structure capable of adapting to vertical tolerance

A rail-type, composite wall technology, applied in the direction of walls, building components, building structures, etc., can solve the problems of industrial production and highly assembled installation of indoor walls, difficulty in realizing removable functional walls, and labor-intensive problems. , to achieve the effect of convenient installation, reduced material cutting and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The preferred embodiments provided by the present invention will be specifically described according to the accompanying drawings.

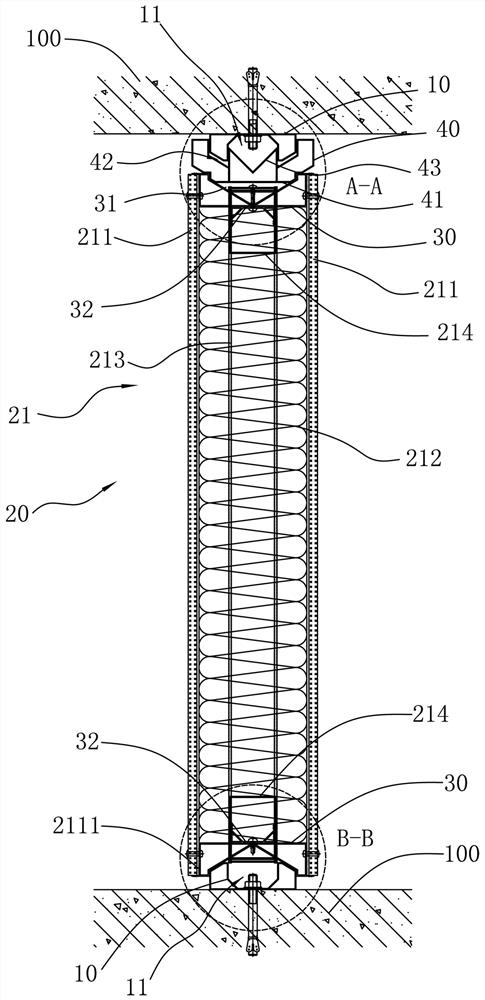

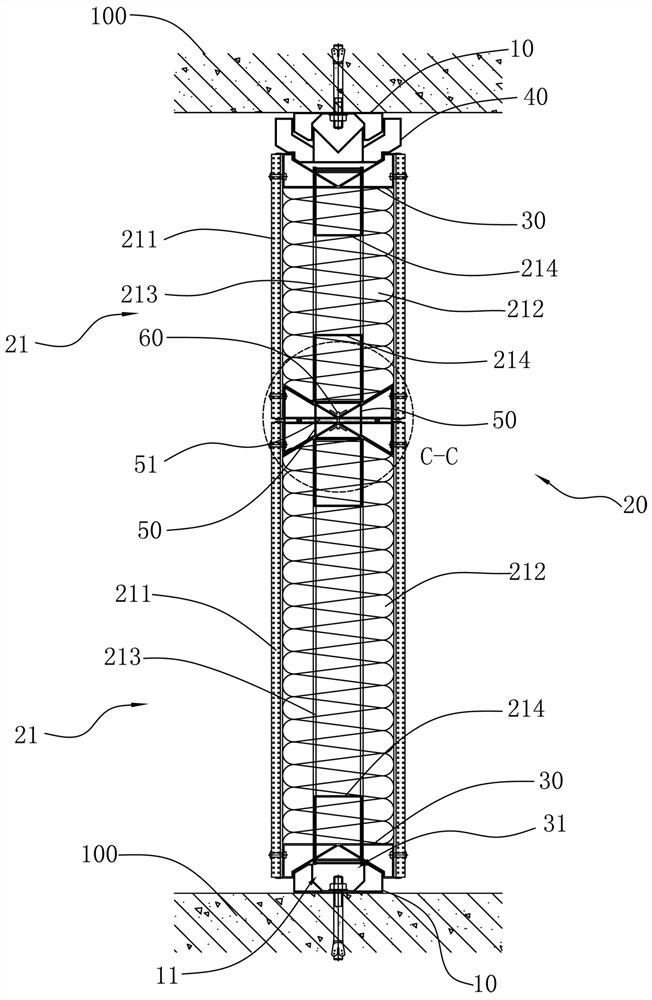

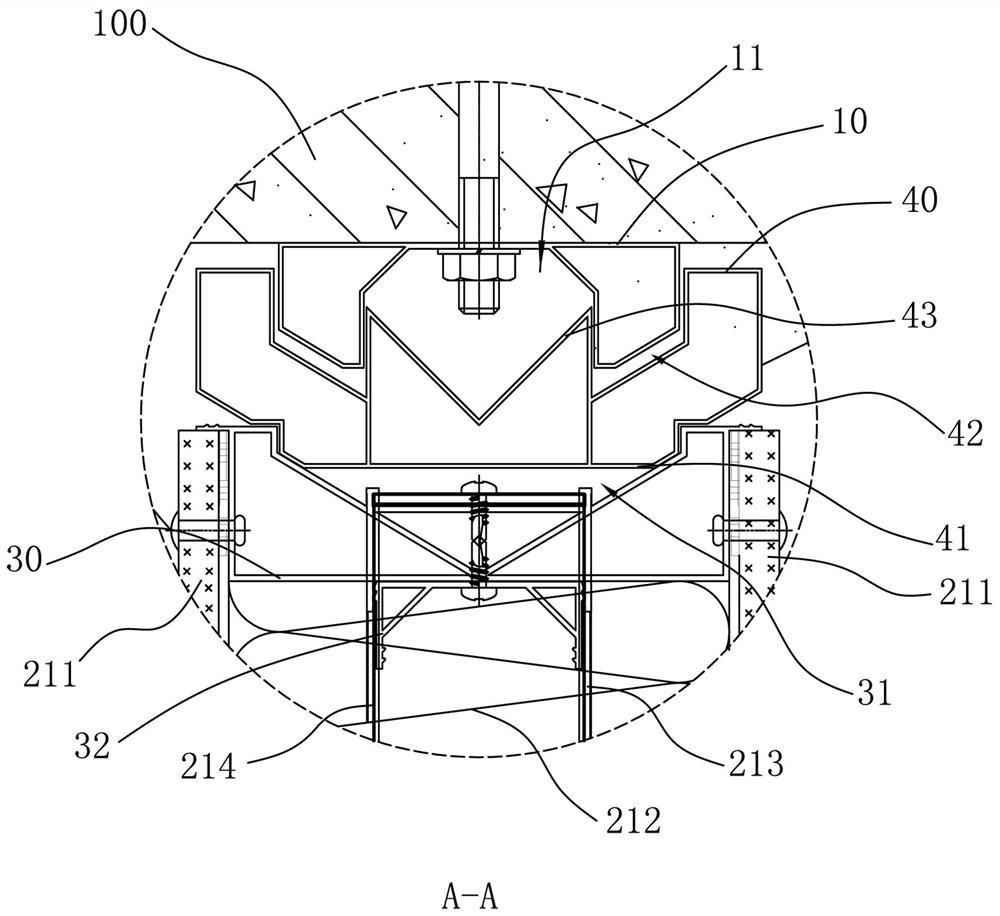

[0024] Figure 1 to Figure 5 , which is a preferred embodiment of a rail-type combined wall structure that can adapt to vertical tolerances provided by the present invention. like Figure 1 to Figure 5 As shown, the guide rail type combined wall structure that can adapt to the vertical tolerance includes the bottom channel beam 10 installed on the top wall 100 and the bottom wall 100 respectively, and the wall 20 between the top wall and the bottom wall. The wall 20 Including at least one wall unit 21, adjacent wall units 21 are overlapped, the top and bottom of the wall body 21 are respectively provided with side beams 30, the side beams 30 are provided with side beam grooves 31 facing the bottom groove beam 10, and the bottom groove The beam 10 is provided with a bottom groove 11 facing the side beam 30, the side beam groove 31 at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com