Calibrating plate for an extrusion tool for manufacturing plastic profiles

A technology for plastic profiles and shaping plates, which is applied in the field of shaping plates applied to extrusion dies for manufacturing plastic profiles, can solve problems such as damage to guide elements, reduction in quality of profiles, and loose positions of inserting elements, and achieves easy adjustment, Simple to manufacture, good for tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

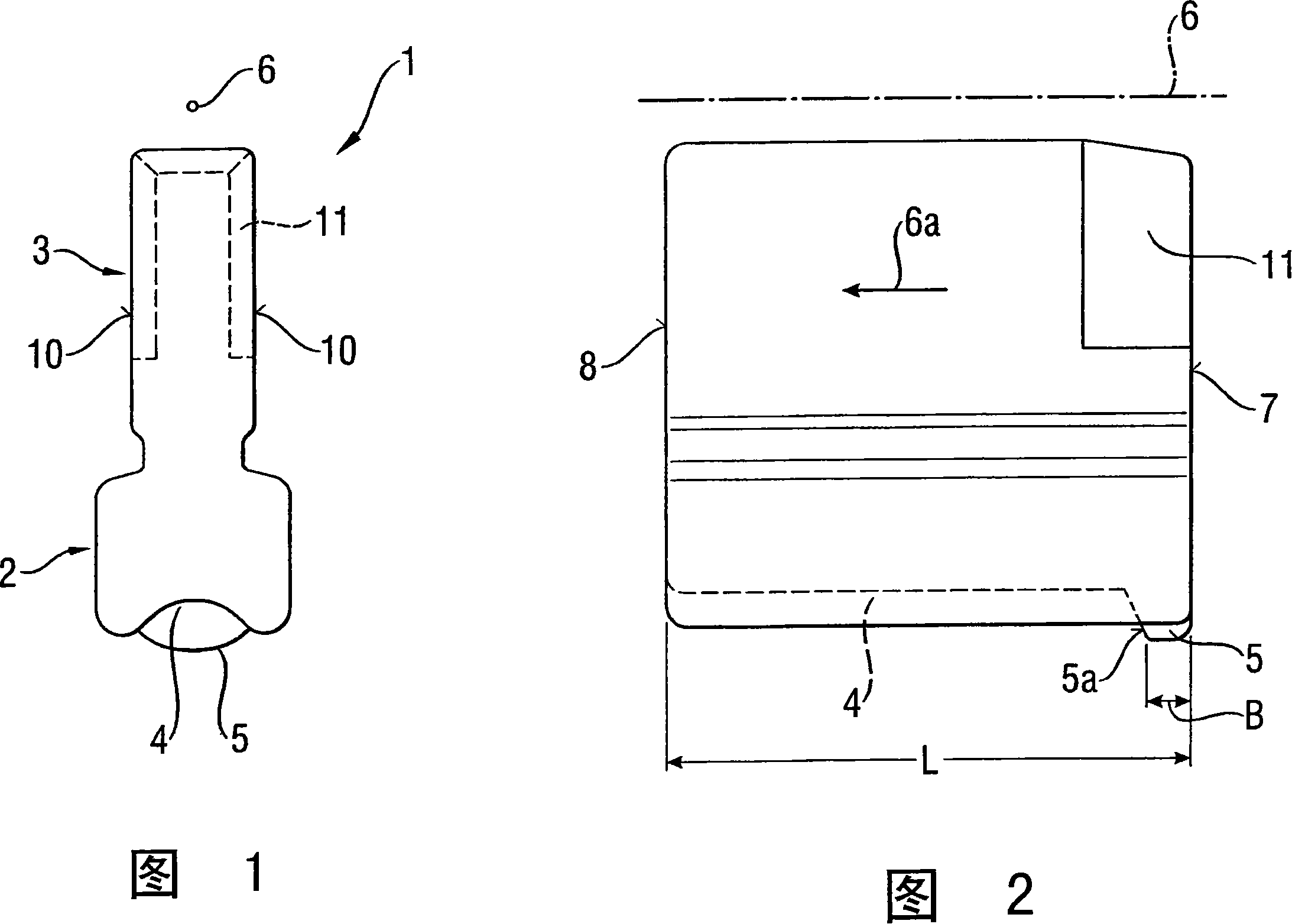

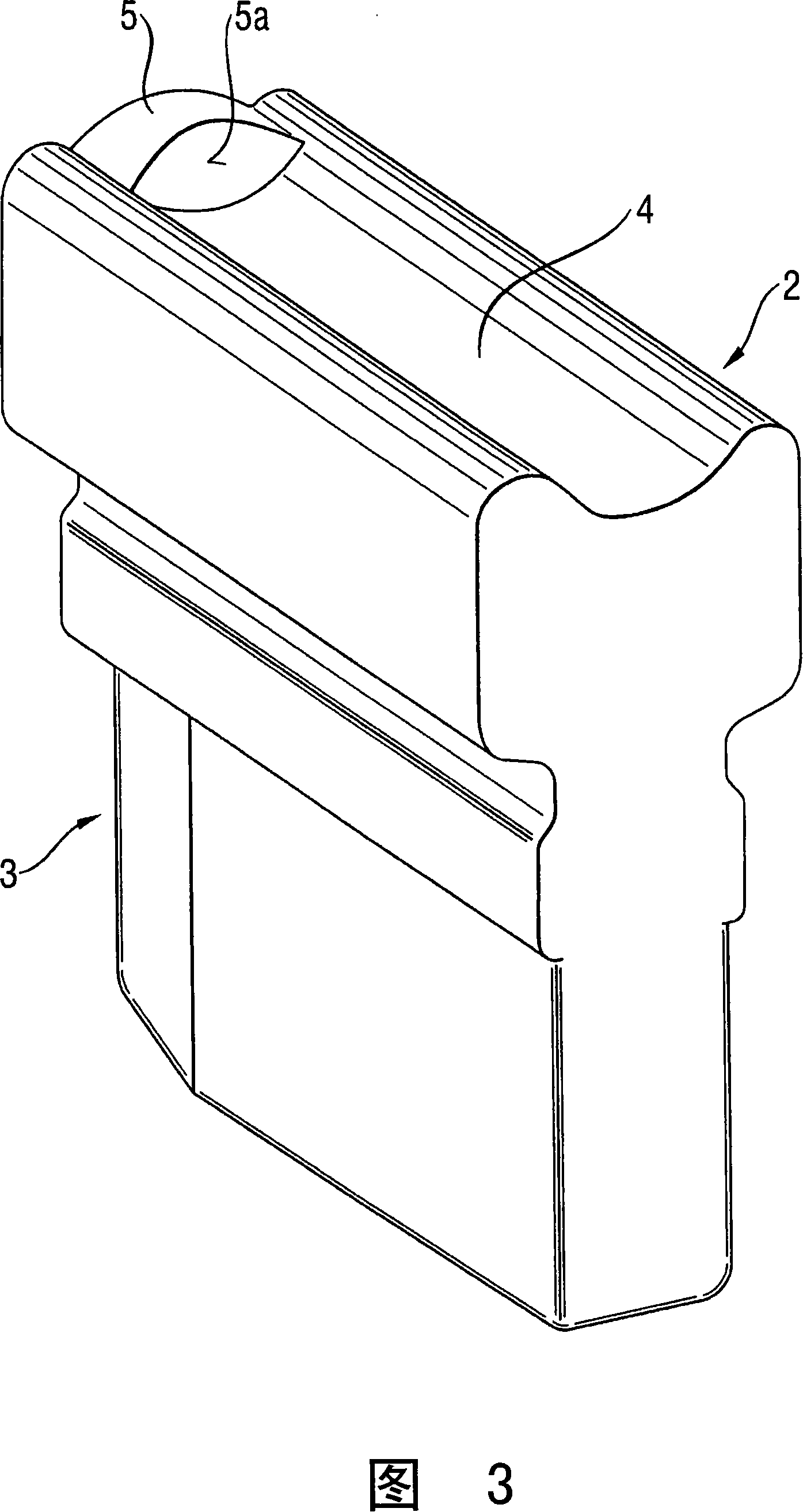

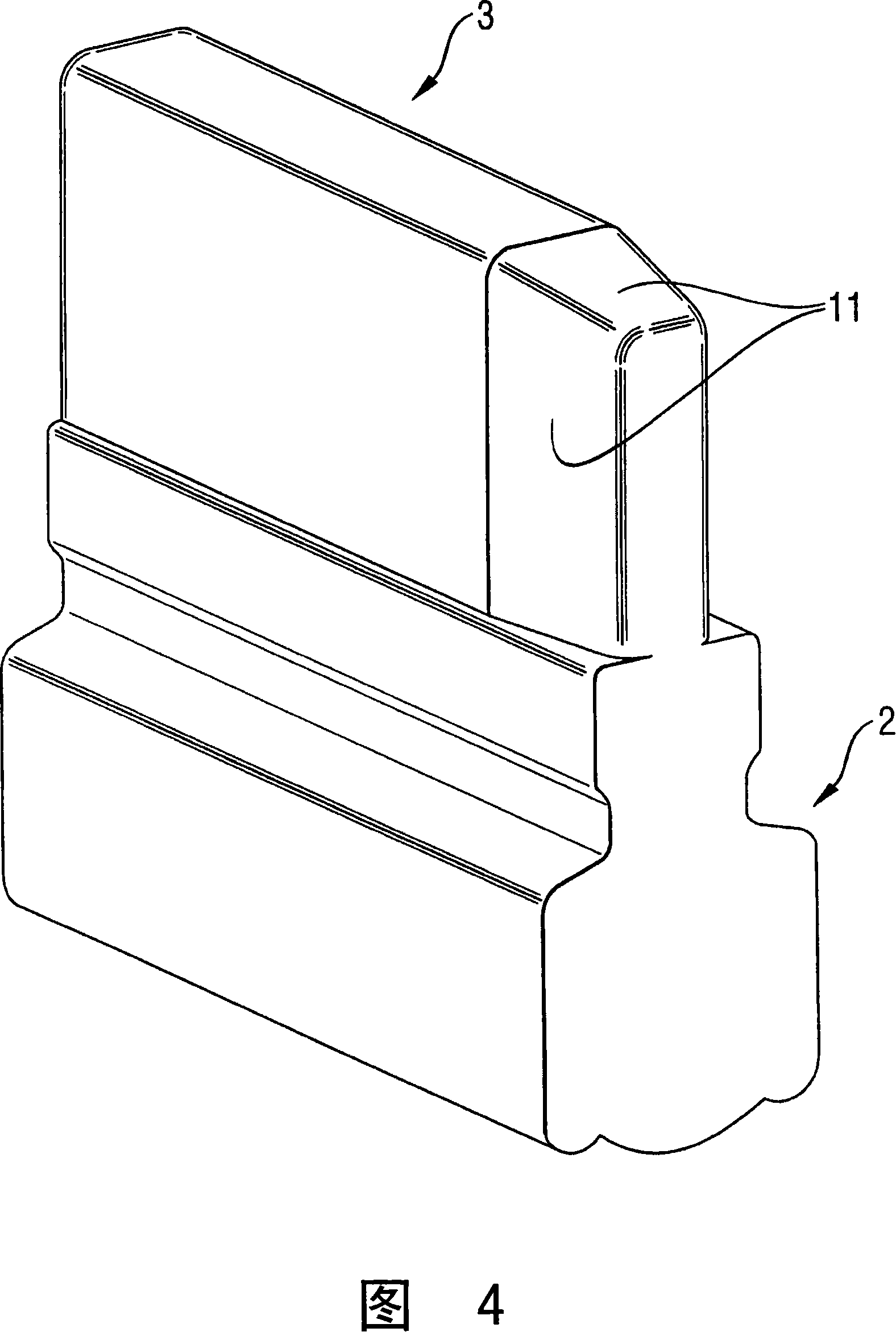

[0028] The insert part 1 in FIGS. 1 and 2 essentially consists of a holding part 2 and a shaping part 3 . At the bottom of the shaped part 3 there is a recess 4 of part circular cross section. At the end of the groove 4, protruding from the bottom of the groove, a defined stop 5 is used to hold the insert element 1 in the axial direction. The extrusion axis or an axis parallel to it is marked with reference numeral 6 . FIG. 2 additionally shows the direction of extrusion with 6 a , which shows that the limiting stop 5 is placed directly on the upstream surface 7 of the insert element 1 . Apart from defining the stop 5 , the holding part 2 comprises only a cylindrical surface 9 . These surfaces consist of generatrices parallel to the extrusion axis 6 .

[0029] FIG. 2 shows that the limiting stop block 5 has an extension B in the axial direction, which roughly corresponds to 1 / 10 of the total length L of the insertion element. The stop surface 5 a defining the stop block 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com