Marking plate sticking structure of drawer panel for washing machine

A marking board, washing machine technology, applied in other washing machine, marking, application and other directions, can solve the problem of sliding, the marking board 57 can not be close to the drawer panel and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

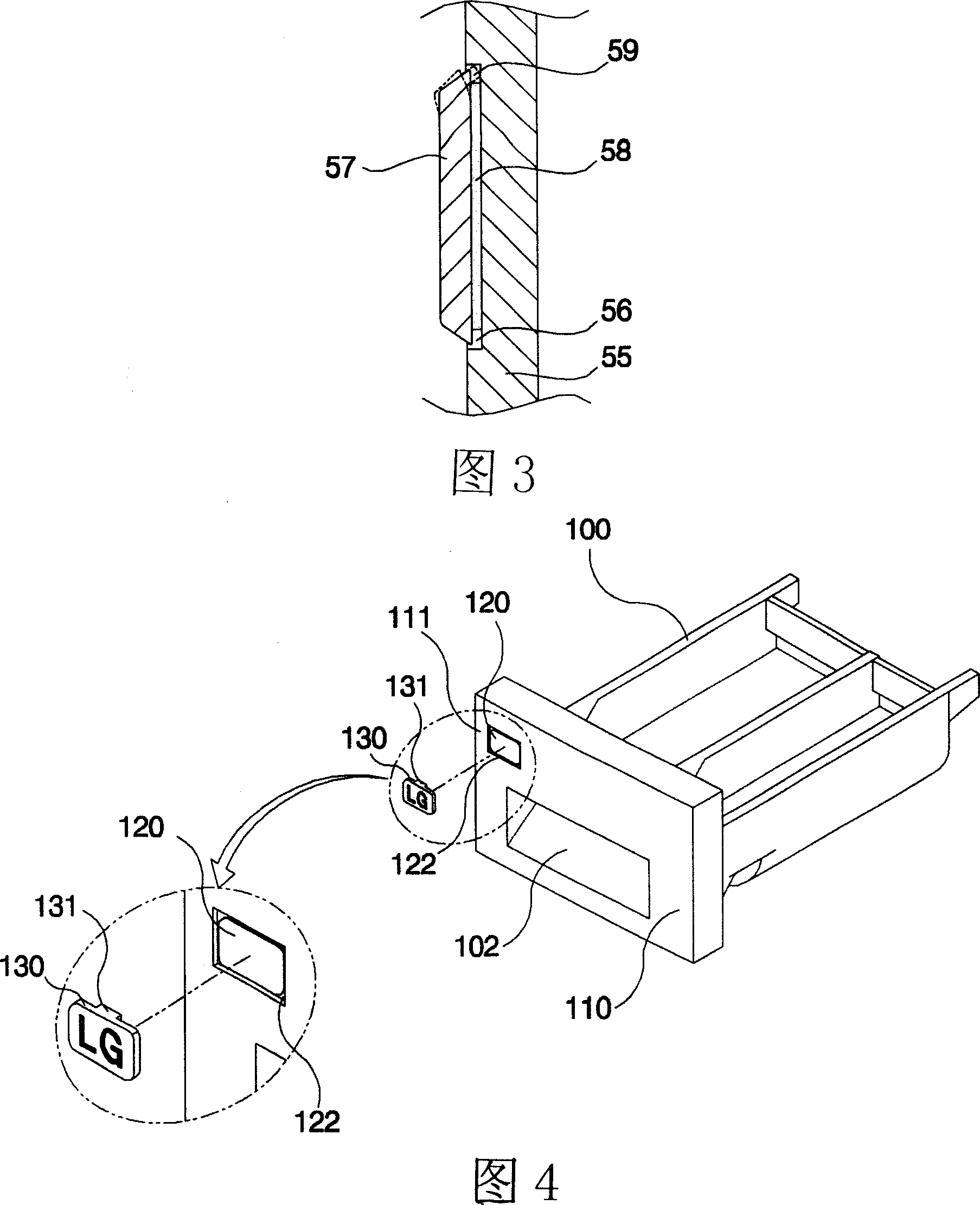

[0033] As shown in Figures 4 and 5, in the marking plate pasting structure of the drawer panel for washing machine of this embodiment, the drawer panel 110 is combined with the front of the detergent box 100, and a handle 102 is formed. The front of the drawer panel 110 is one A sticking part 120 is formed on the side, and a marking plate 130 is sticked to the sticking part 120.

[0034] The handle 102 is a hole formed on the lower side of the drawer panel 110 and elongated in the left-right direction.

[0035] The drawer panel 110 is made of plastic synthetic resin, and the drawer panel 110 is connected to the front surface of the detergent box 100 through a suspension device such as a hook, a coupling device such as a bolt, or a bonding device such as an adhesive.

[0036] The attachment portion 120 is formed at a position other than the handle 102.

[0037] The attachment portion 120 is formed recessed from the front surface 111 of the drawer panel 110.

[0038] In the present ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com