Multilayer inductor

A technology of stacking inductors and suppression layers, applied in the direction of inductors, fixed inductors, fixed signal inductors, etc., can solve the problem of inductance reduction, achieve the effect of preventing the reduction of inductance value and improving the DC superposition characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach 〕

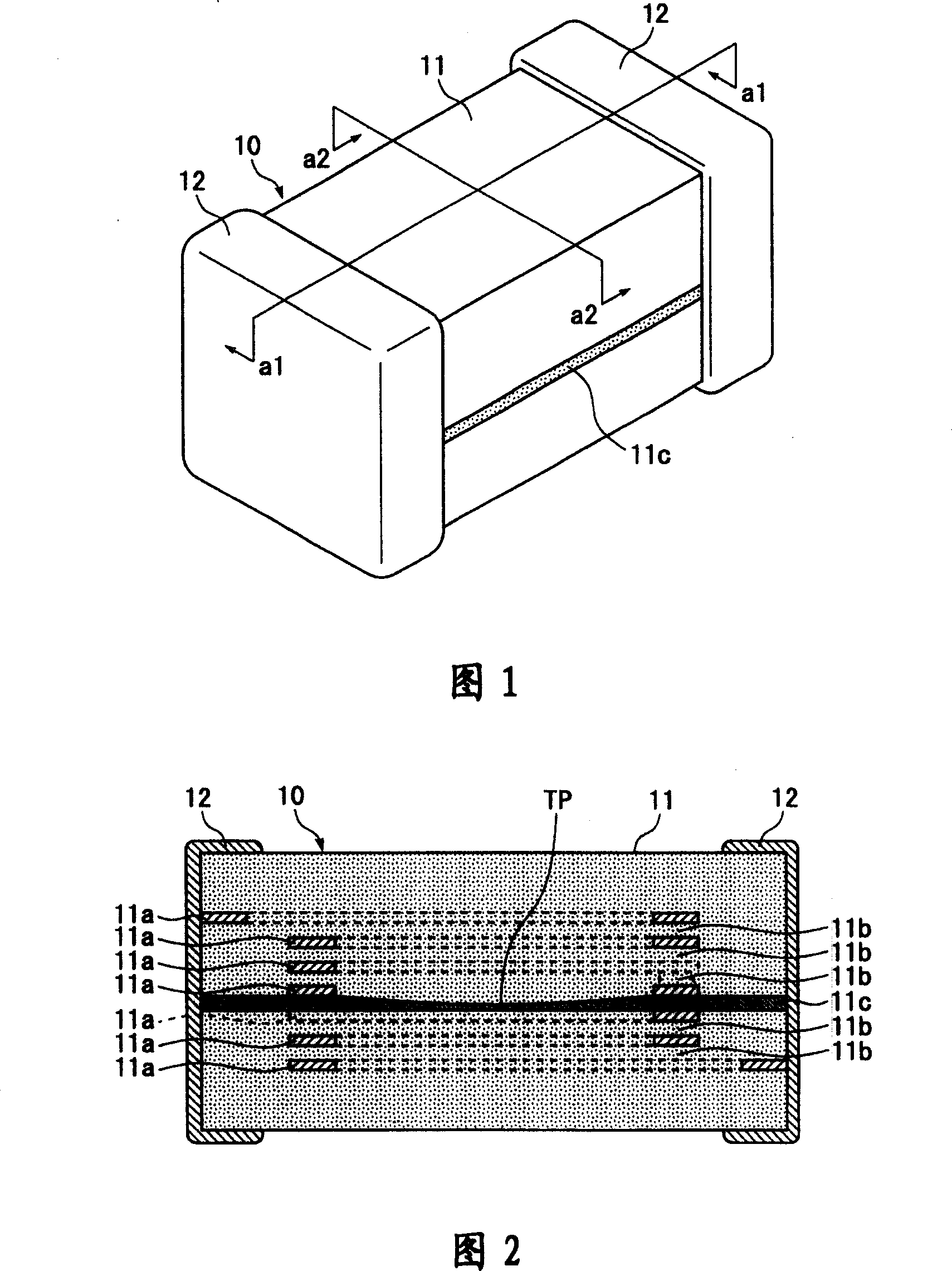

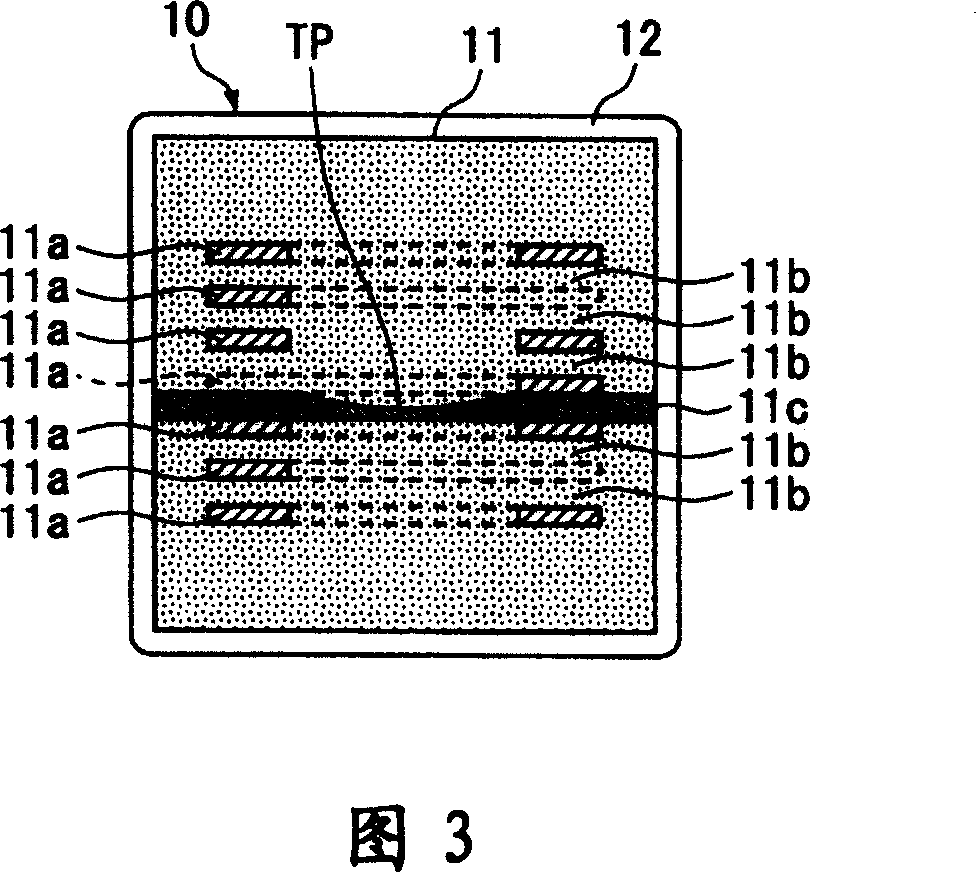

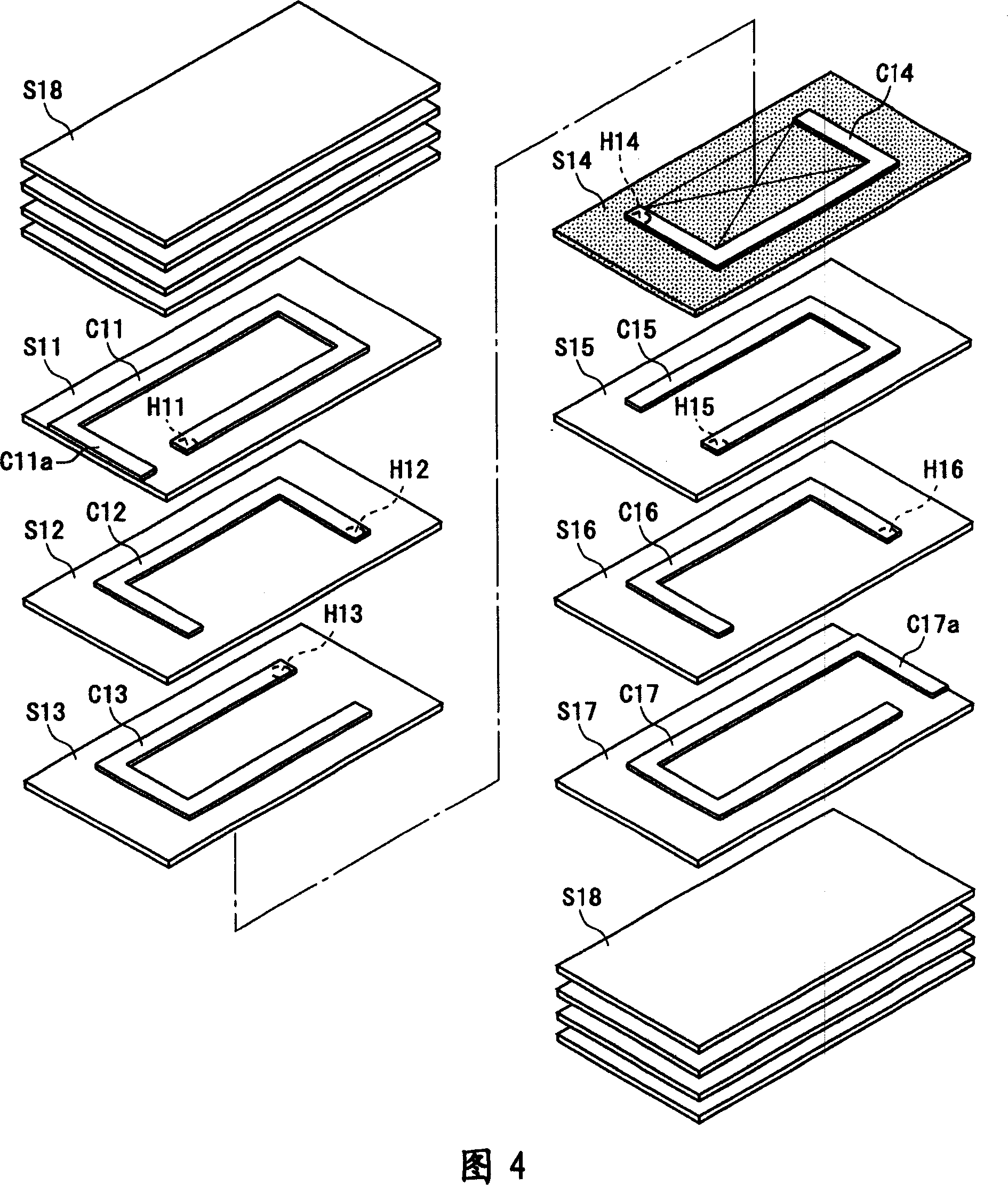

[0031] 1 to 11 show a first embodiment of the present invention. Fig. 1 is a perspective view of a laminated inductor, Fig. 2 is a sectional view taken along line a1-a1 in Fig. 1 , Fig. 3 is a sectional view taken along line a2-a2 in Fig. 1 , and Fig. 4 is an exploded perspective view of the laminated body shown in Fig. 1 , and Fig. 5 and 6 are partial perspective views and a 3-a3 line sectional view showing a part of the manufacturing steps of the multilayer inductor shown in FIG. 8 is a graph showing the inductance change rate of the multilayer inductor shown in FIG. 1, FIG. 9 and FIG. 10 are partial perspective views and a4-a4 line sectional views showing modified examples of the manufacturing steps, and FIG. 11 is another modification showing the manufacturing steps. Cutaway view of the example.

[0032] First, the structure of the multilayer inductor 10 will be described with reference to FIGS. 1 to 3 .

[0033] The multilayer inductor 10 includes a rectangular parallel...

no. 2 Embodiment approach 〕

[0061] 12 to 17 show a second embodiment of the present invention. Fig. 12 is a perspective view of a laminated inductor, Fig. 13 is a cross-sectional view taken along line b1-b1 in Fig. 12, Fig. 14 is a cross-sectional view taken along line b2-b2 in Fig. 12, and Fig. 15 is an exploded perspective view of the laminated body shown in Fig. 12, Fig. 16 and 17 are a partial perspective view and a b3-b3 sectional view showing a part of the manufacturing steps of the multilayer inductor shown in FIG. 12 . 18 and 19 are partial perspective views and b4-b4 line sectional views showing modified examples of manufacturing steps.

[0062] First, the configuration of the multilayer inductor 20 will be described with reference to FIGS. 12 to 14 .

[0063] The multilayer inductor 20 includes a rectangular parallelepiped multilayer body 21 , and external electrodes 22 , 22 provided on both ends of the multilayer body 21 in the longitudinal direction and made of a metal material such as Ag. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com