Nicuzn based ferrite and electronic component using the same

A technology of electronic components and ferrites, which is applied in electrical components, inductors with magnetic cores, circuits, etc., can solve the problems of not disclosed invention composition, not improving DC superposition characteristics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

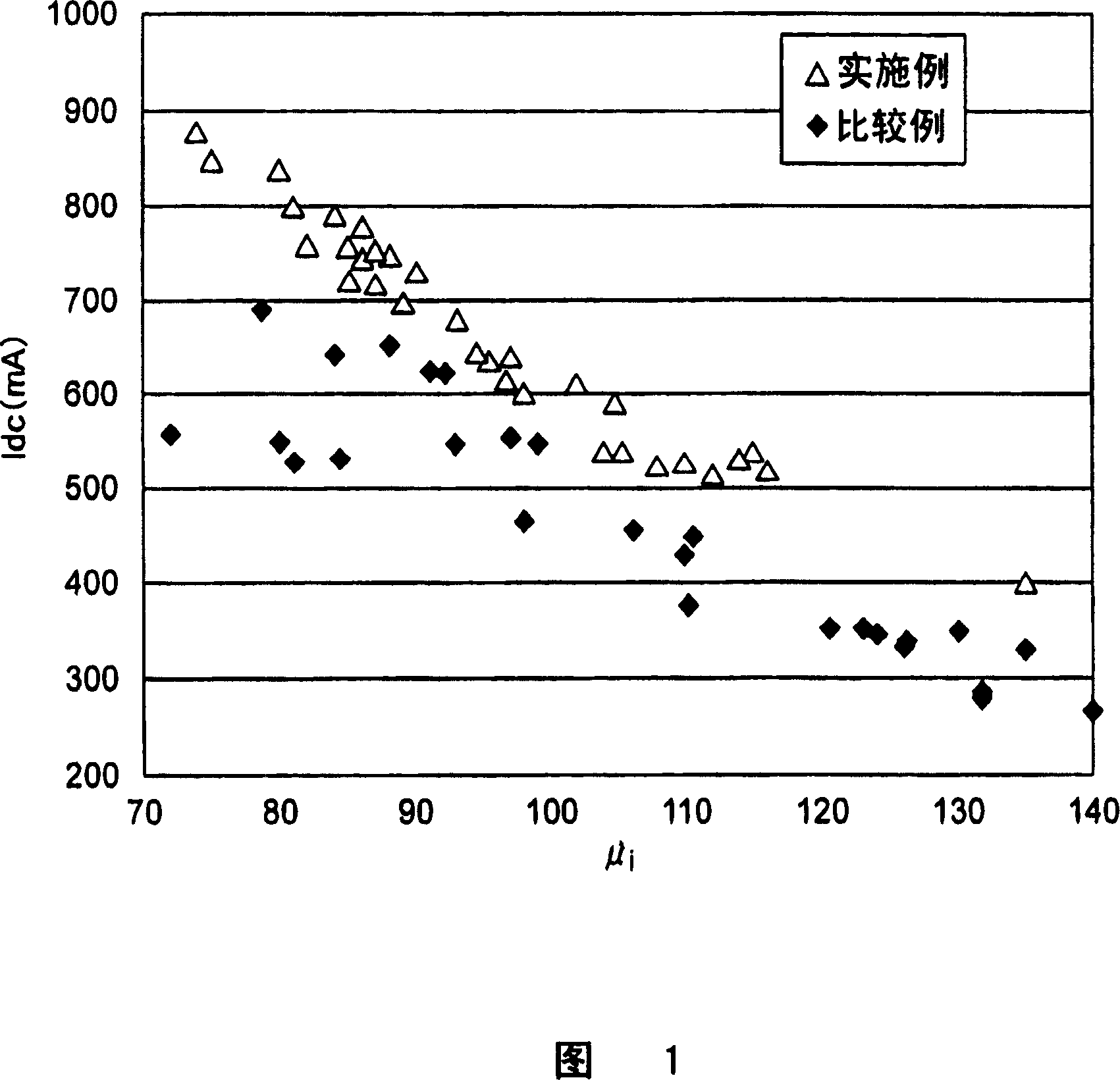

Examples

Embodiment Construction

[0014] Hereinafter, the NiCuZn-based ferrite (oxide magnetic material) of the present invention will be described in detail.

[0015] For the substantial main component in the NiCuZn system ferrite of the present invention contains: Fe 2 o 3 Contains 45.0-49.0 mol% of iron oxide (especially preferably 47.0-48.8 mol%); 5.0-14.0 mol% of copper oxide as CuO (especially 7.0-12 mol%); 1.0-32.0 mol of zinc oxide as ZnO % (particularly preferably 14.0 to 28.0 mol%); NiO contains nickel oxide as the balance mol%.

[0016] Furthermore, in the NiCuZn-based ferrite of the present invention, with respect to the main component, as a subcomponent, Bi 2 o 3 Calculated, bismuth oxide is greater than 0.25% by weight, 0.40% by weight or less (especially preferably 0.26~0.33% by weight); 2 In total, tin oxide is 1.00 to 2.50% by weight (especially preferably 1.00 to 2.20% by weight).

[0017] For the composition range of the above-mentioned main components, if iron oxide (Fe 2 o 3 ) conte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com