Oblique conic gate valve

A gate valve and inclined cone technology, applied in the field of inclined cone gate valves, can solve the problems of blocking the sealing surface of the valve, reducing the sealing performance of the butterfly valve, and poor sealing performance of the butterfly valve, so as to achieve enhanced sealing performance, long service life and good sealing performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

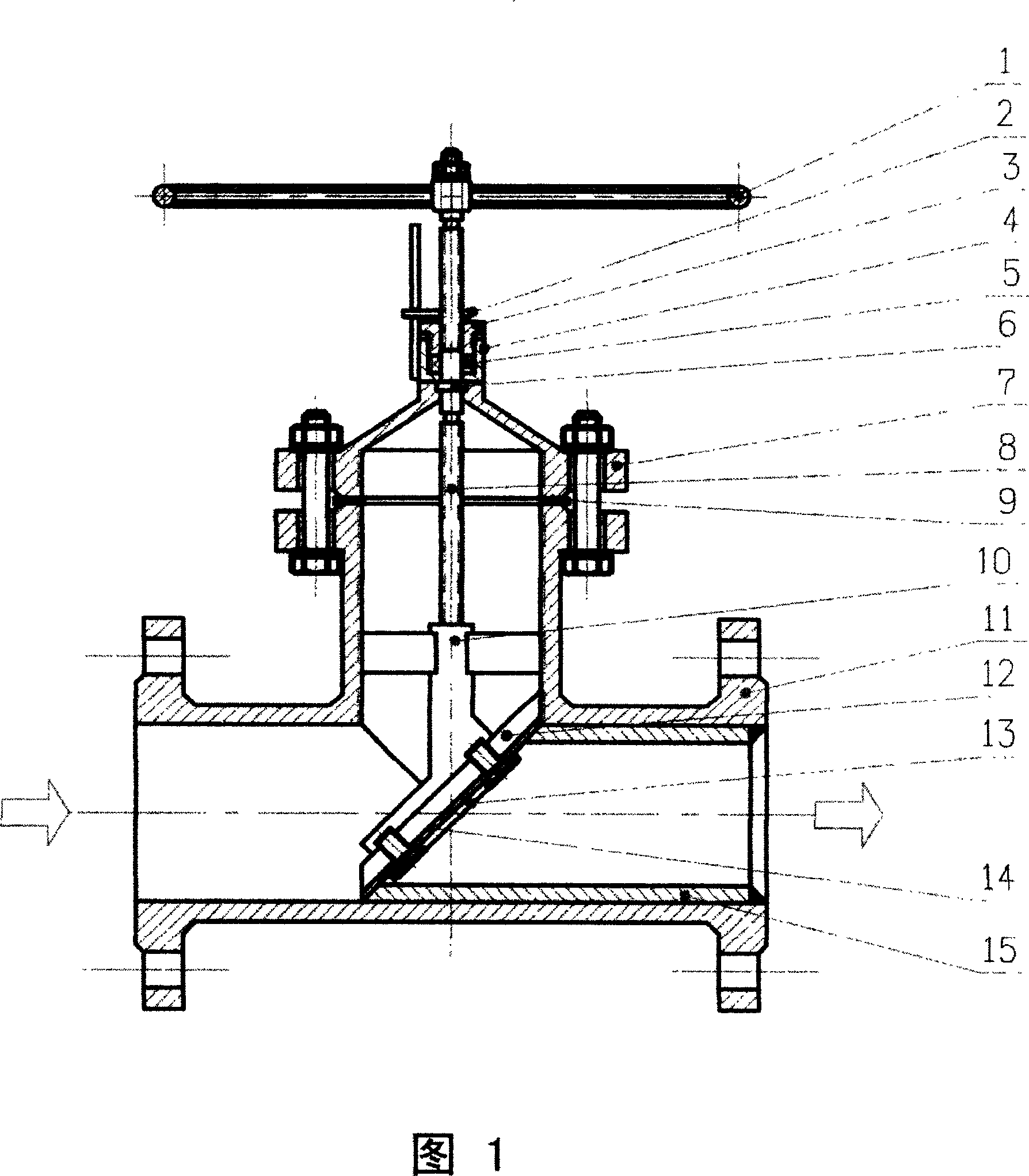

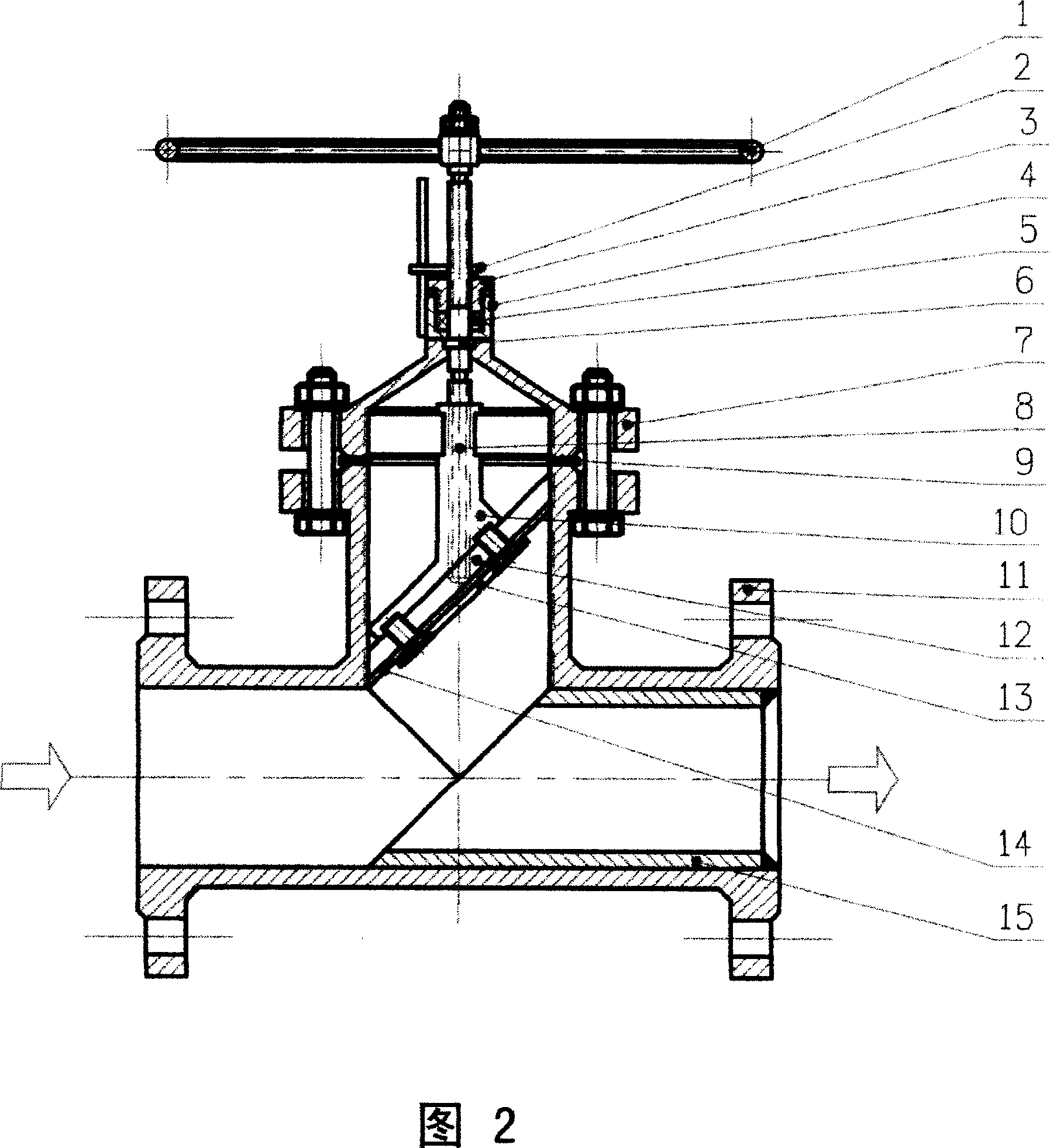

[0032] As shown in Figures 1-2, the valve seat 15 is placed in the hole at the outlet end of the valve body 11, so that the center of the standard oval ring of the valve seat 15 coincides with the center of the valve body 11, and the other end of the valve seat 15 is aligned with the valve body 11. The flange welding (metal) or welding (non-metallic), the valve core 10 and the gate plate 12, the elastic pad 14 and the supporting plate 13 are connected together with multiple bolts, and the slide plate on the upper part of the valve core 10 is inserted into the concave hole of the valve body 11. The groove is pushed to the bottom of the valve body 11, and the elastic pad 14 is attached to the valve seat 15, and one end of the valve core 10 is threadedly connected to the valve stem 8. Place the gasket 9 and the valve cover 7 on the flange sealing surface of the branch pipe of the valve body 11 in sequence, and fasten the valve body 11 and the valve cover 7 with fasteners. Insert ...

Embodiment 2

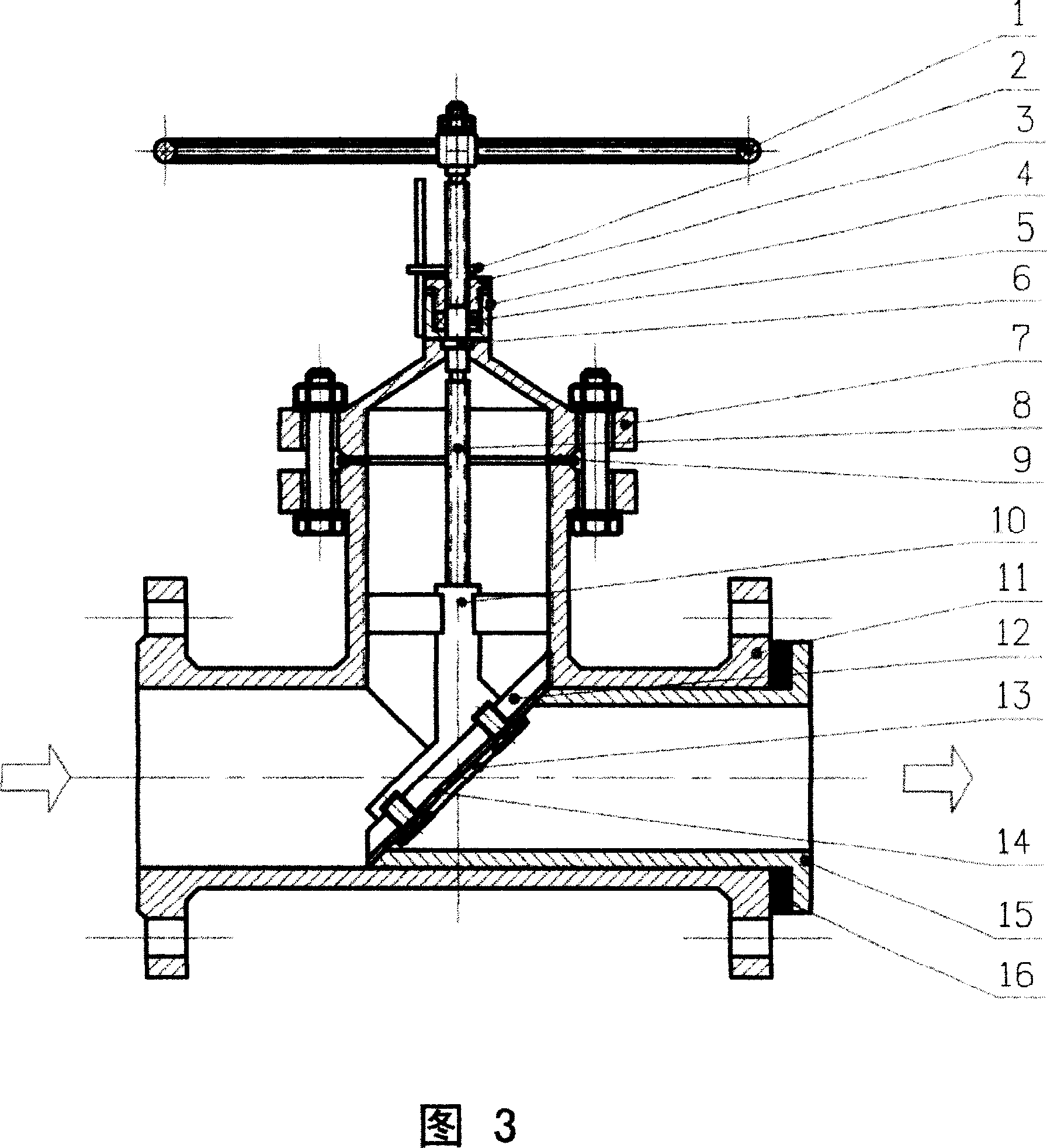

[0034] As shown in Figure 3, the valve seat 15 is placed in the water outlet hole of the valve body 11, and a plurality of backing rings 16 are placed between the other end of the valve seat 15 and the valve body. After the joint surface is worn, remove a thin cushion surface, and then install the valve seat to compensate, and the contact will be good.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com