Direct downward back light module

A backlight module, direct type technology, applied in optics, nonlinear optics, instruments, etc., can solve the problem of low brightness of backlight module

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

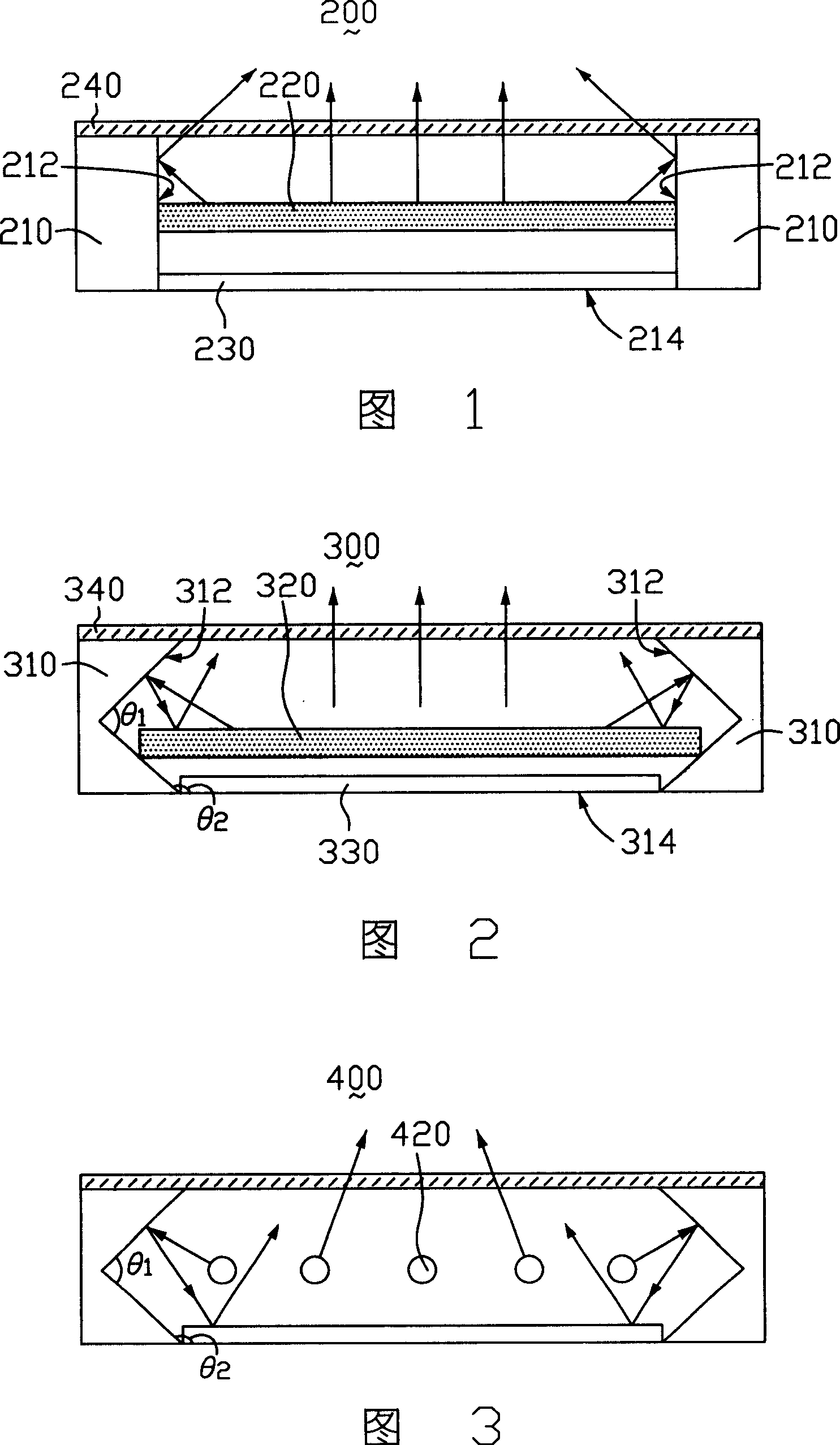

[0014] Please refer to FIG. 2 , which is a schematic structural diagram of the first embodiment of the direct type backlight module of the present invention. The direct type backlight module 300 includes a frame 310 , a light source 320 , a reflector 330 and a diffuser 340 . The frame 310 is generally a rectangular box structure with an opening, which is generally made of plastic, and includes four inner sides 312 and a bottom 314 , the four inner sides 312 are arranged opposite to each other and connected to the bottom 314 . The diffusion plate 340 is disposed on the opening of the frame 310 to form a closed space with the frame 310 for accommodating the light source 320 and the reflection plate 330 . The light source 320 is a linear light source, such as a cold cathode ray tube (cold cathode fluorescent lamp, CCFL), which abuts against two opposite inner sides 312 of the frame 310 and is parallel to the diffuser plate 240 . The reflection plate 330 is located on the bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com