Cheese and methods for making firm cheese

A cheese and slurry technology, applied in the field of cheese and its preparation, can solve problems such as loss of cheese components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

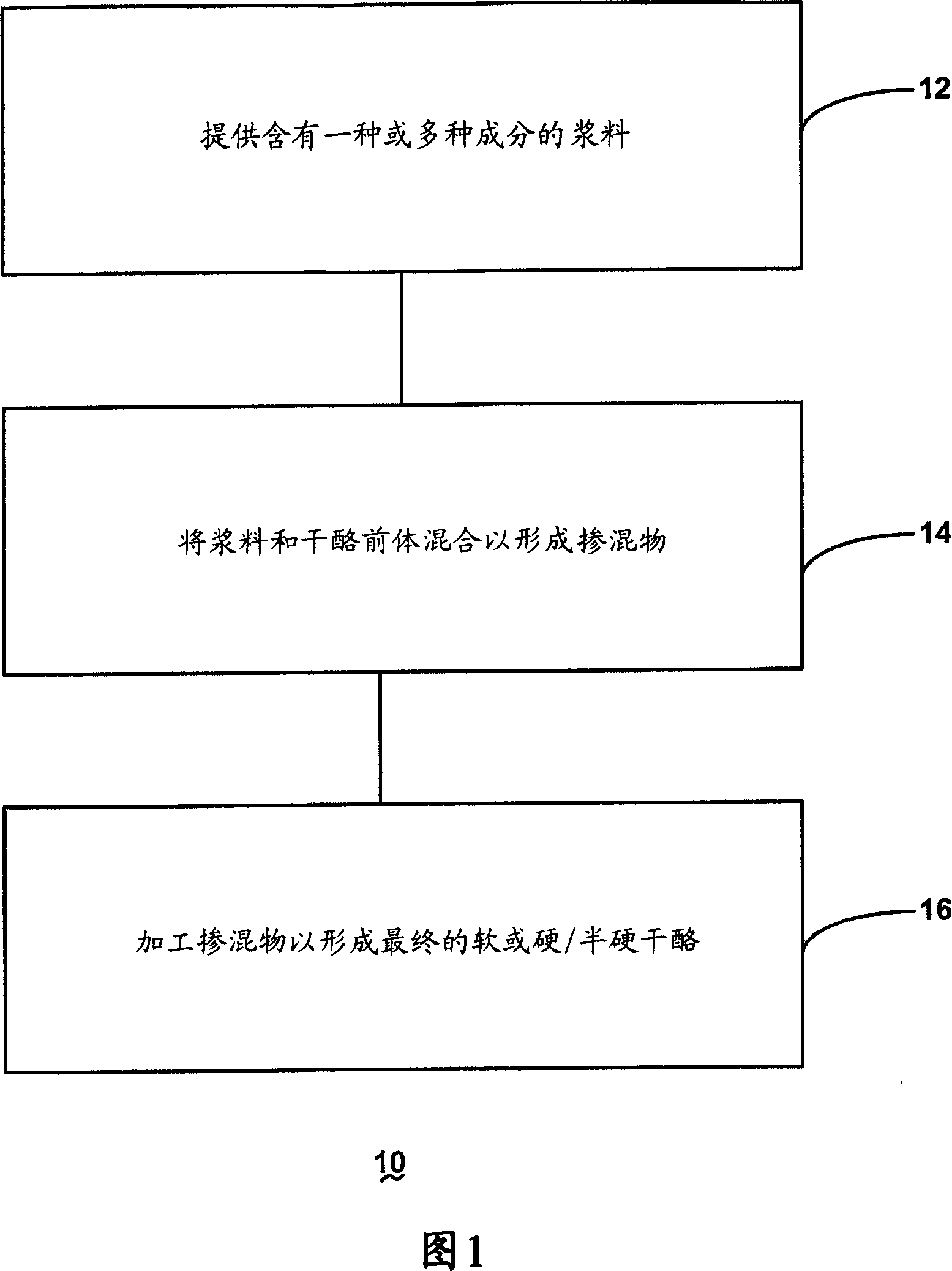

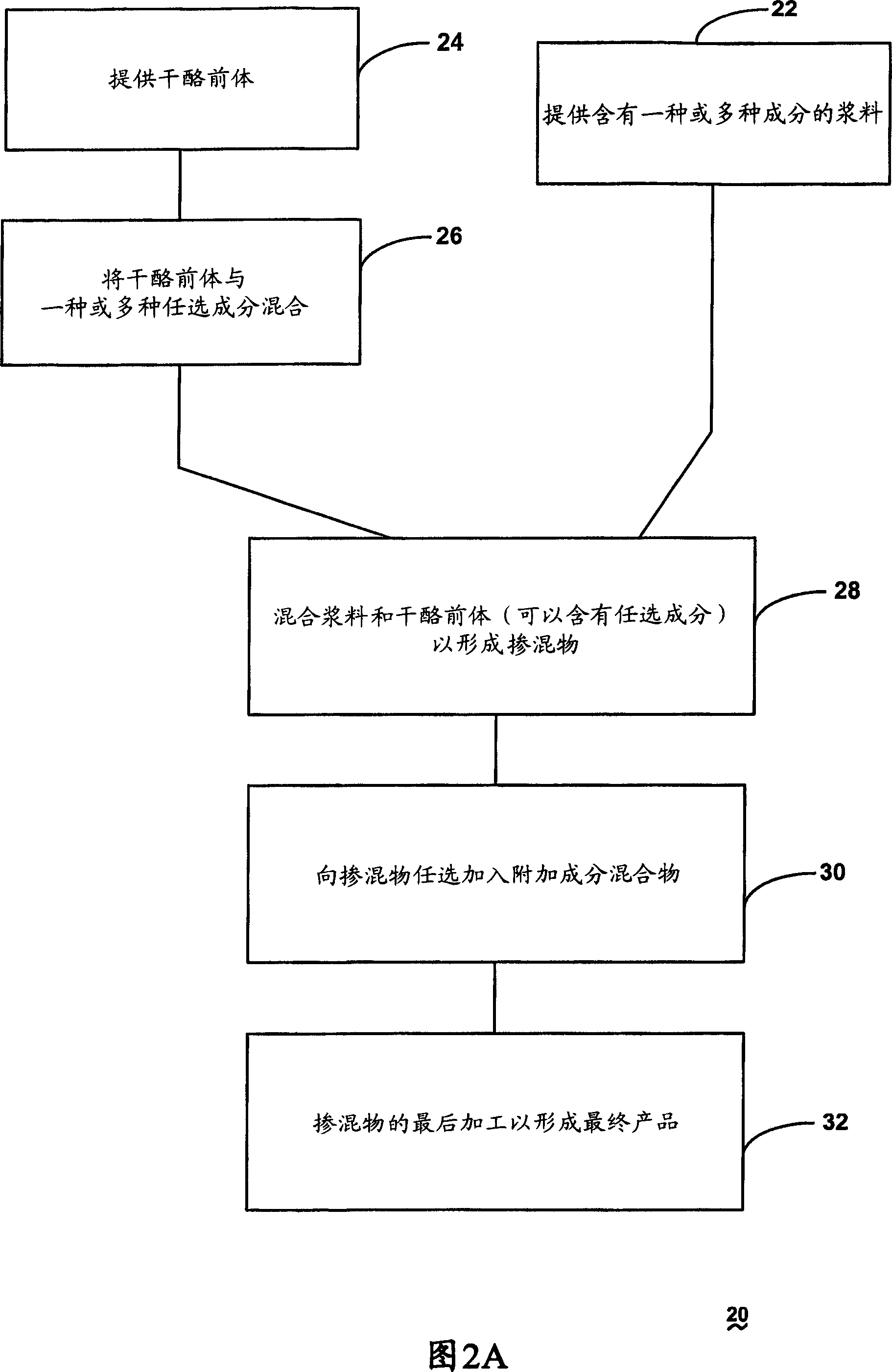

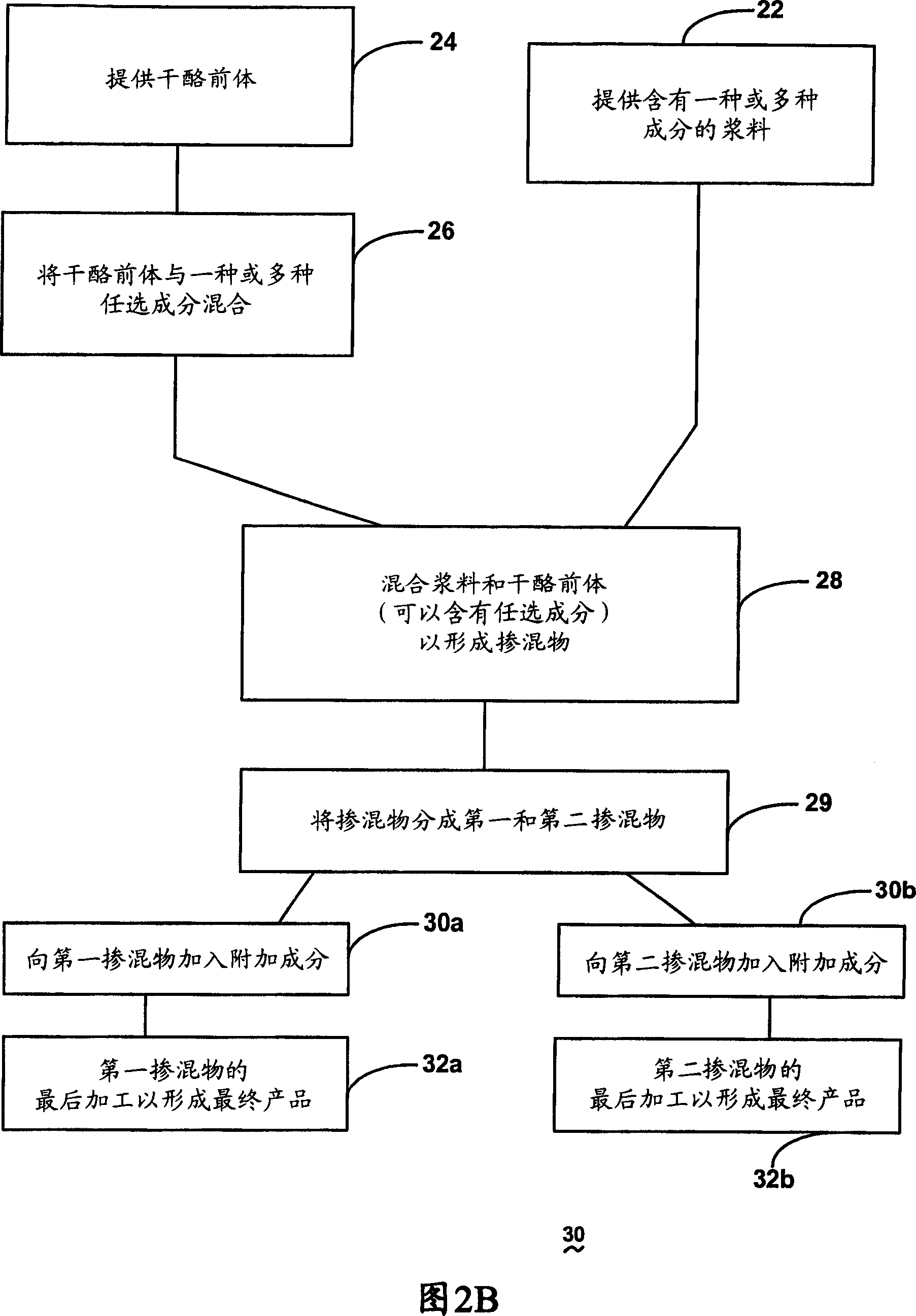

Method used

Image

Examples

Embodiment

[0182] Three different levels of nonfat dry milk (NDM) (2.5 wt%, 6.0 wt% and 12.0 wt%) were introduced into mozzarella cheese either directly in powder form (see Examples a, c, and e) or as A portion of the slurry added to the cheese curds (see examples b, d and f). The slurry composition includes NDM, and salt, cream, water, and gluconic acid, wherein the gluconic acid is added to the slurry as a processing aid to reduce the viscosity of the slurry prior to cooking. The viscosity makes the slurry easier to pump through the digester and other system equipment. The relative amounts of the slurry ingredients used in the slurry examples (i.e., Examples b, d and f) are summarized in Table 1:

[0183] Table 1: Slurry Composition thing

[0184] processing

%NFDM

%Salt

%cream

%water

(50%TS)

Example b. As a slurry

Add 2.5% NBM

54.19

5.8

29.63

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com