Combing machine

A combing machine and combing technology, applied in the field of combing machines, can solve problems such as complex movement, intermittent acceleration of fiber strips, and material reversal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

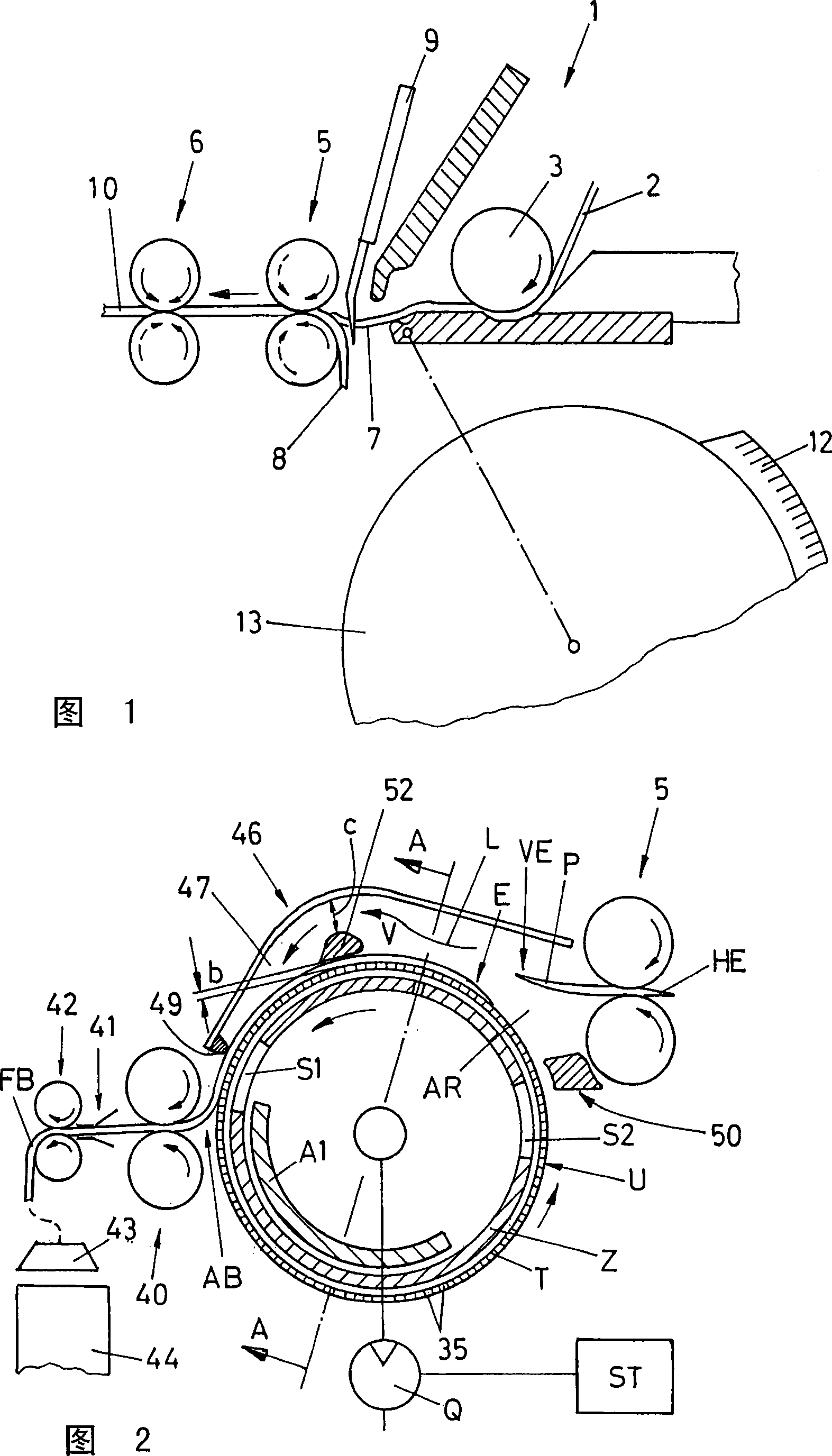

[0057] Figure 1 shows an embodiment according to the prior art, in which a lap sheet 2 supplied by a clamping assembly 1 is supplied via a supply cylinder 3 to a pair of take-off rollers 5 (also called detachment rollers). The fiber fringe 7 protruding from the open gripper 1 enters in this case on the carded fiber strip 10, so that the fiber fringe 7 enters the take-off roller 5 due to the forward movement of said take-off roller in the jaws of the In this case, fibers not held by the lap sheet or the retaining force of the gripper are torn out of the composite structure of the lap sheet. During this separating operation, the fiber ear is additionally drawn by the needles of the fixed comb 9 . The stationary comb 9 in this case causes to comb the rear part of the removed fiber ear and also retains neps, impurities etc. Because of the speed difference between the take-off speed of the lap sheet 2 and the detaching roller, the taken-off fiber ear is drafted to a certain lengt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com