Stack desulfurization device

A desulfurization device and body technology, applied in the use of liquid separation agent, lighting and heating equipment, and separation of dispersed particles, can solve the problems of increasing the overall desulfurization cost of the exhaust gas desulfurization device, limited reaction time, and poor desulfurization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

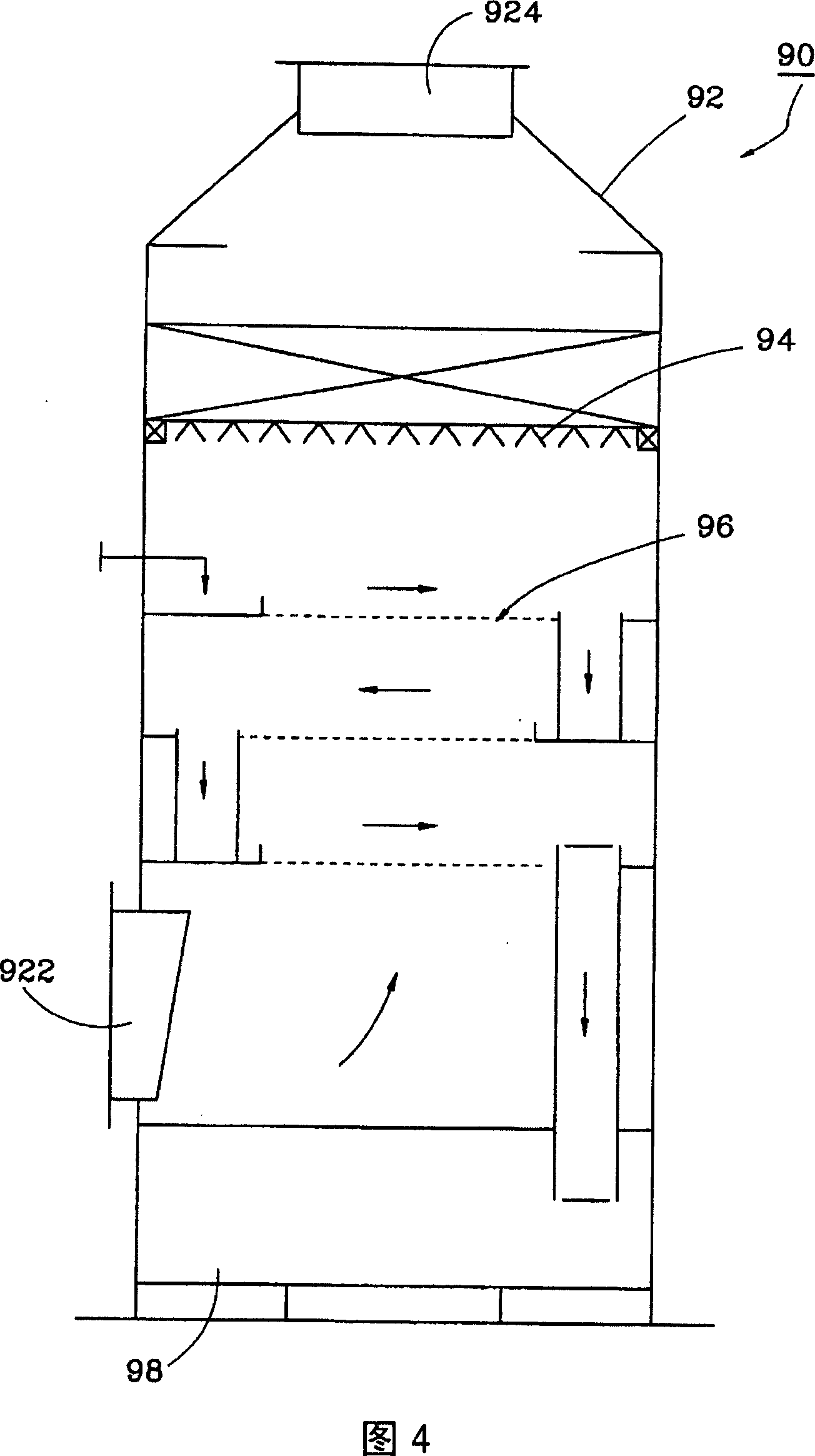

[0026] Hereinafter, two preferred embodiments are listed in conjunction with the accompanying drawings to describe the structure and effect of the present invention in detail.

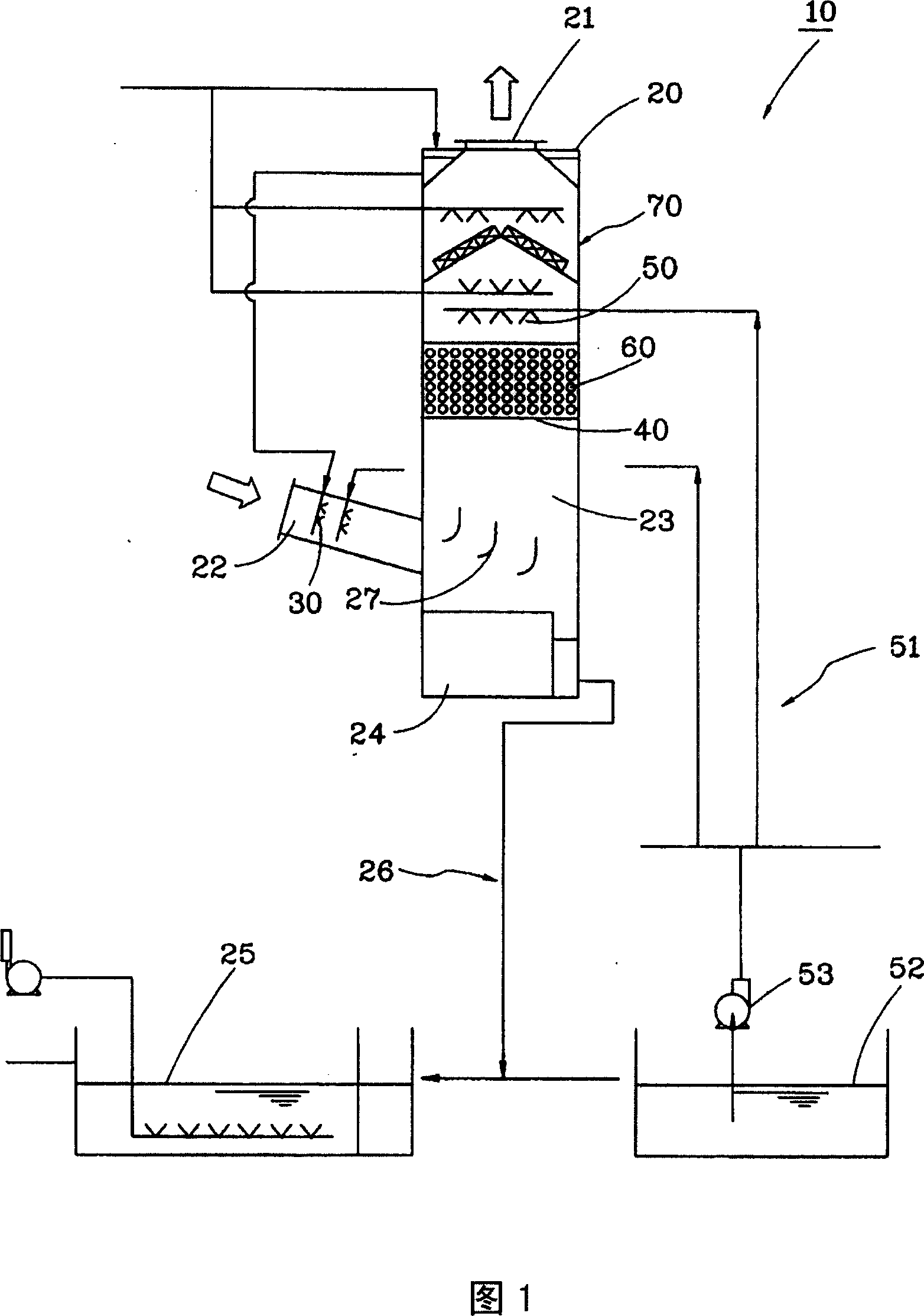

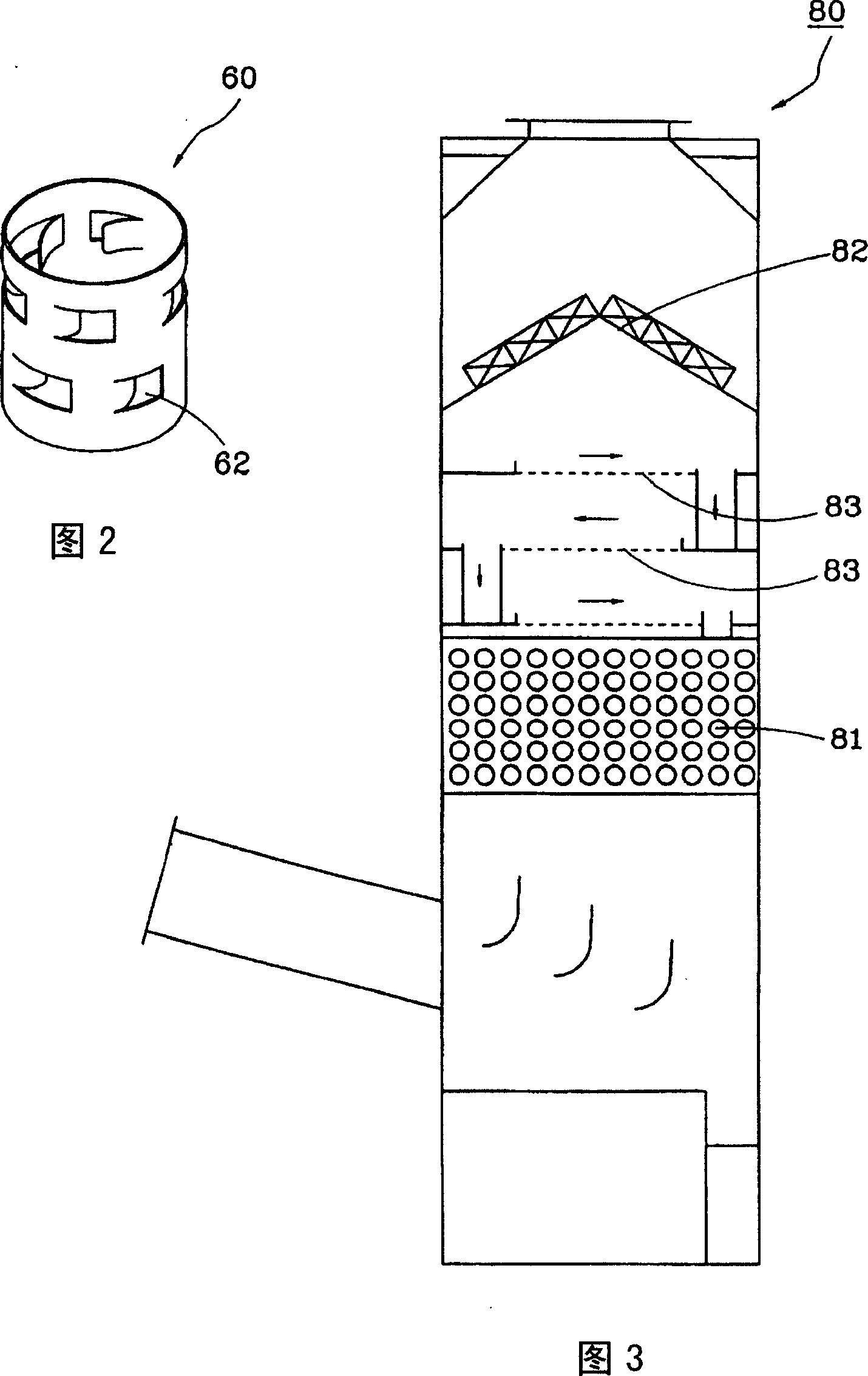

[0027] Referring to FIG. 1, the flue gas desulfurization device (10) provided by the first preferred embodiment of the present invention includes a main body (20), a quencher (30), a sprayer (50), and a support frame (40) ), a number of packings (60), and a water vapor separator (70).

[0028] The main body (20) has a channel (23) through which the exhaust gas can pass through, the top of the main body (20) has an outlet (21) that runs through the channel (23), and the main body (20) has a channel (21) that runs through the channel near the bottom. (23) entrance (22). The channel (23) of the main body (20) has three baffles (27) (the number of the baffles is not limited to three, and can be adjusted according to actual needs), and the three baffles (27) are located close to each other in an interval s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com