Flue gas treatment device for asphalt workshop

A flue gas treatment and workshop technology, which is applied in gas treatment, combined device, air quality improvement and other directions, can solve the problems of insufficient purification of flue gas, deposition of pollutants in pipelines, affecting normal emission of flue gas, etc., and achieves increased contact Time and area, avoid impurity accumulation and blockage, and improve the effect of flue gas purification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

[0019] Example.

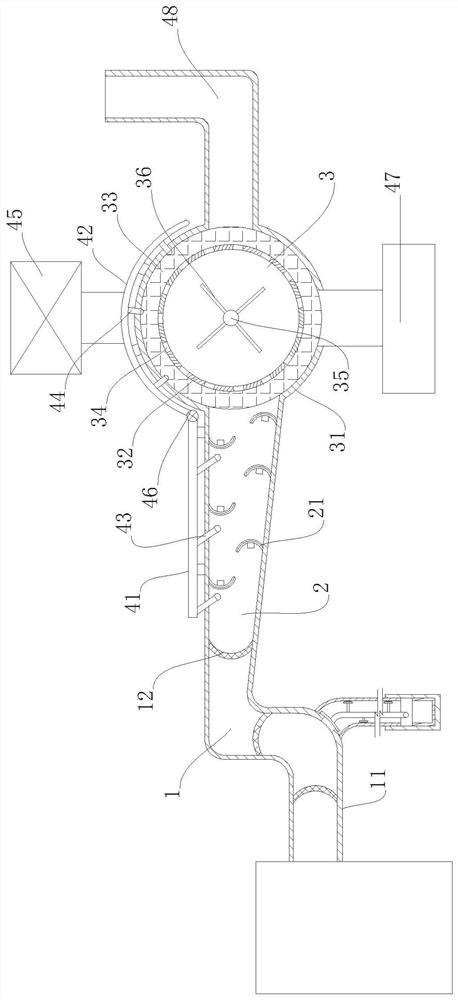

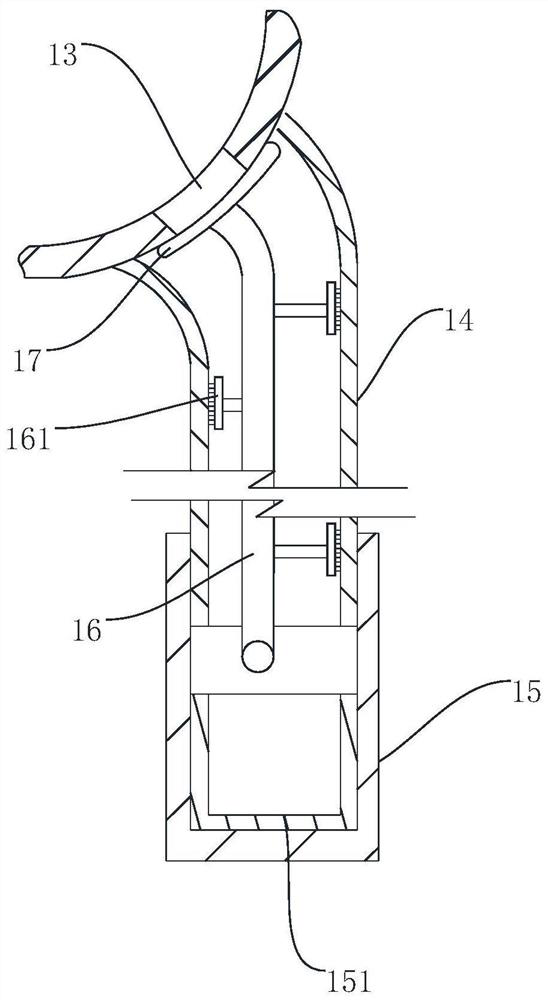

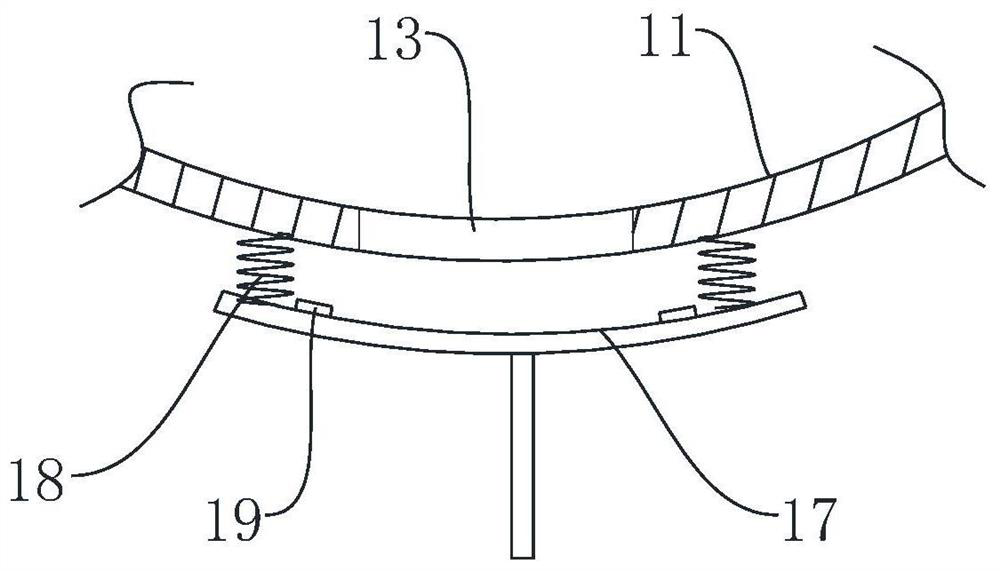

[0020] Such as Figure 1-4 As shown, a flue gas treatment device in an asphalt plant includes a filter area 1, a discharge area 2 and a purification area 3 arranged in sequence. The filter area 1 is composed of a curved pipe 11, and several filter screens are arranged in the pipe 11 12. The bottom bend of the pipeline 11 is provided with a dust outlet 13, and the outside of the bottom bend of the pipeline 11 is provided with a downwardly extending dust discharge pipe 14, and the outside of the dust discharge pipe 14 is provided with a dust discharge pipe 14 The sliding sleeve 15 that moves up and down, the inside of the dust discharge pipe 14 is provided with a connecting rod 16, the lower end of the connecting rod 16 is connected with the sliding sleeve 15, and the upper end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com