Torque limiter having over-speed protection

a technology of torque limiter and protection, which is applied in the direction of couplings, slip couplings, couplings, etc., can solve the problems of dangerously high number of revolutions per minute of input and output elements rotating at dangerous speeds, and not providing any protection when an over-speed condition is experienced, etc., to achieve the effect of increasing torqu

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

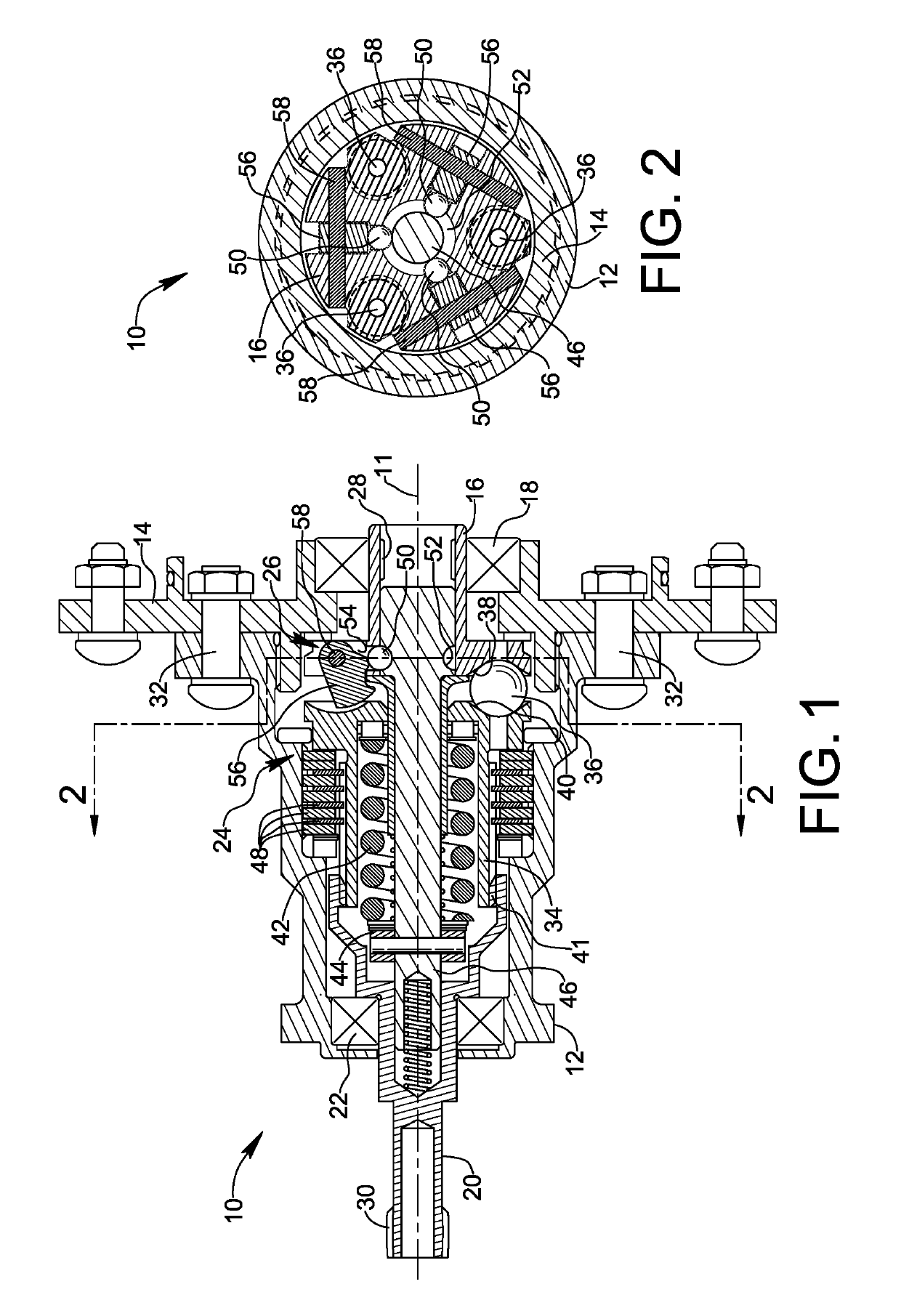

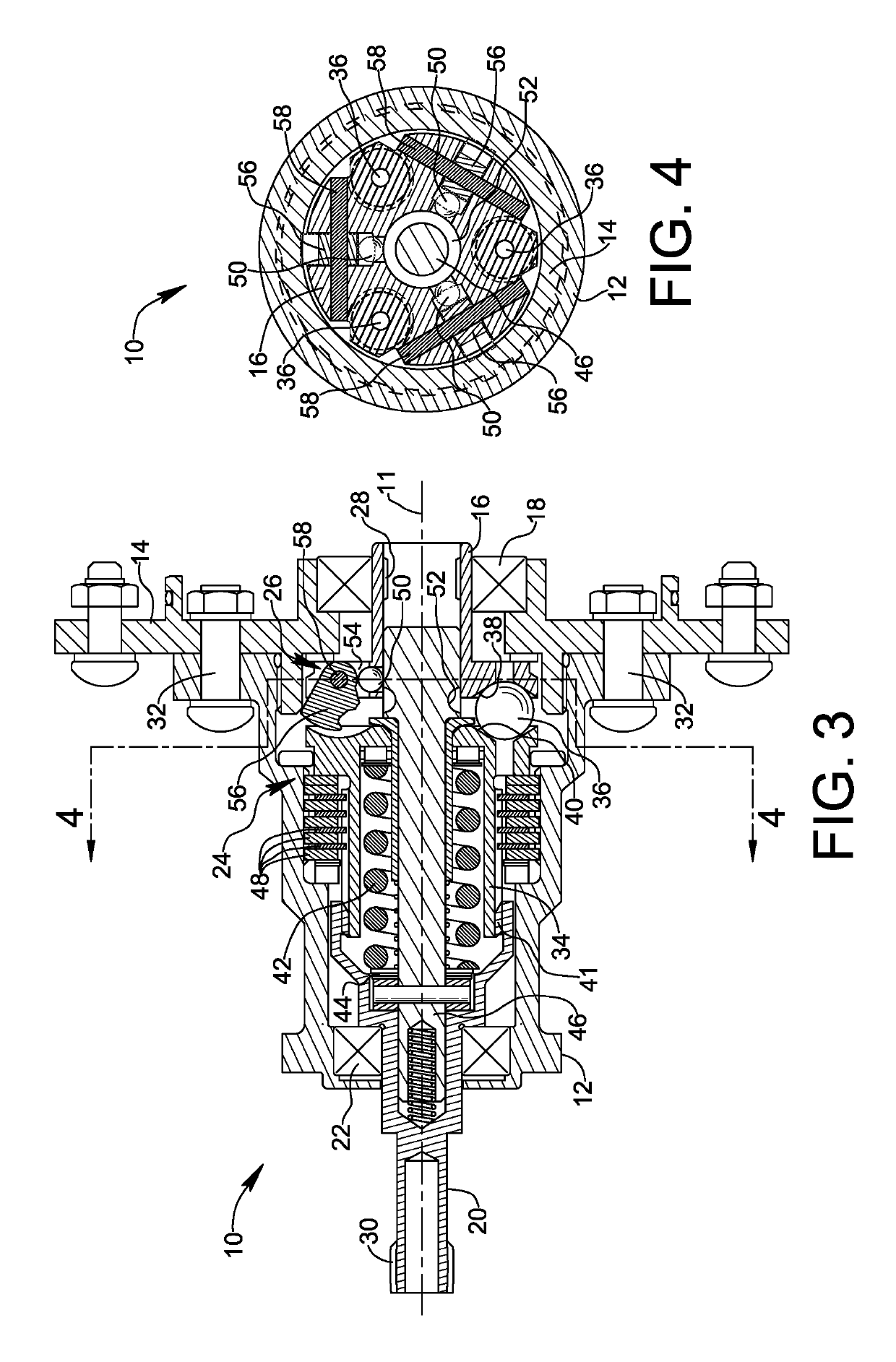

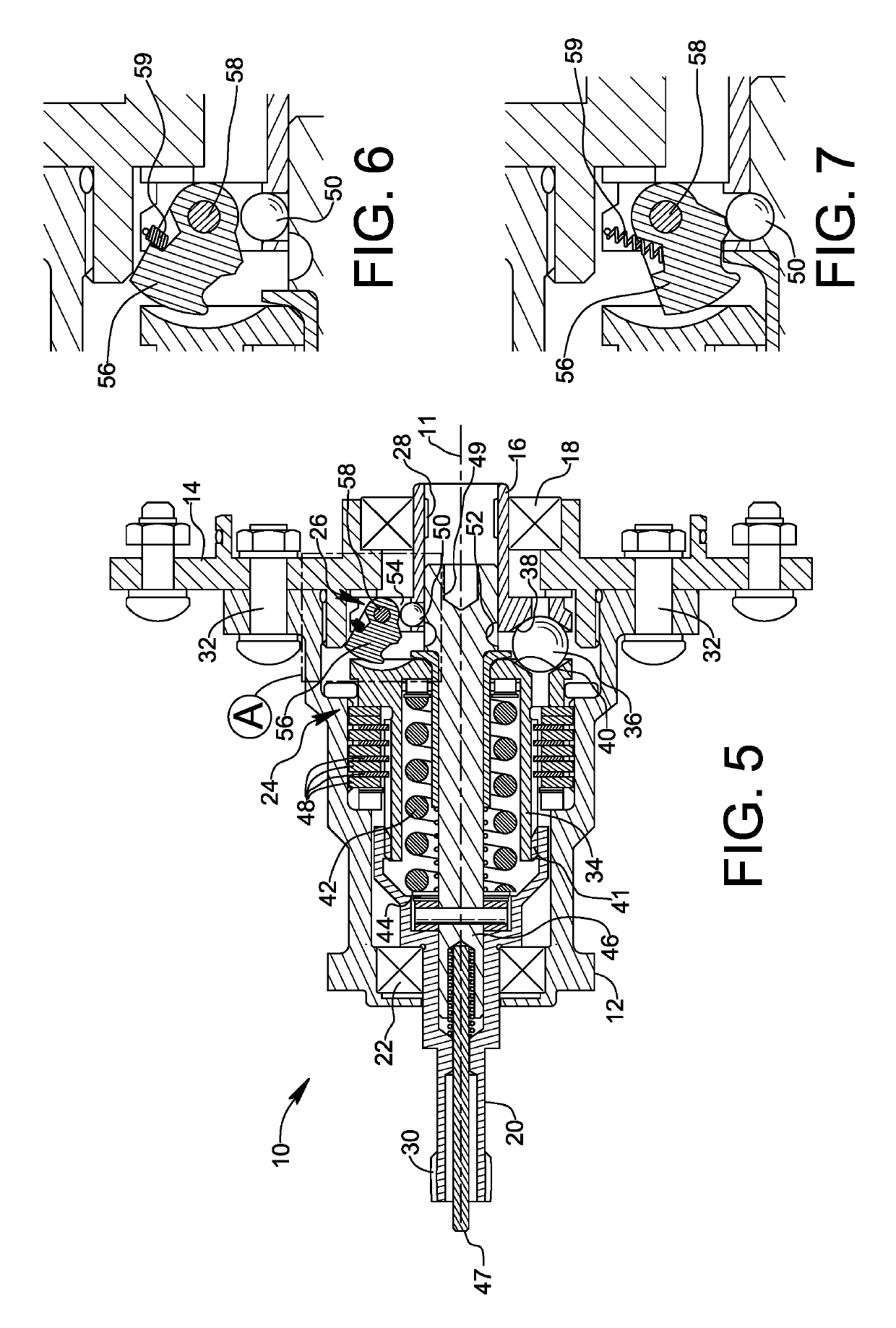

[0023]Reference is made initially to FIGS. 1-4, wherein a torque limiter apparatus formed in accordance with a first embodiment of the invention is shown and identified generally by reference numeral 10. Apparatus 10 comprises a structural ground in the form of housing members 12 and 14, an input element 16 rotatable about a rotational axis 11 relative to the structural ground by virtue of a rotary bearing 18, and an output element 20 rotatable relative to the structural ground by virtue of another rotary bearing 22. Apparatus 10 further comprises a torque limiter 24 and an over-speed governor 26 described in greater detail below. As will be understood, apparatus 10 is useful for connecting a rotational drive member (not shown) to a rotational driven member (not shown) by coupling the drive member to input element 16 and by coupling the driven member to output element 20. Coupling of the drive member to input element 16 may be achieved by a splined connection to a spline 28 of input...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com