Abnormal wearing detection device for seal members and rotor device

a detection device and sealing technology, applied in the direction of fluid tightness measurement, instruments, machines/engines, etc., can solve the problems of unnecessari replacement, unusable measurement of temperature, and abnormal wear of oil seals which do not need to be replaced,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

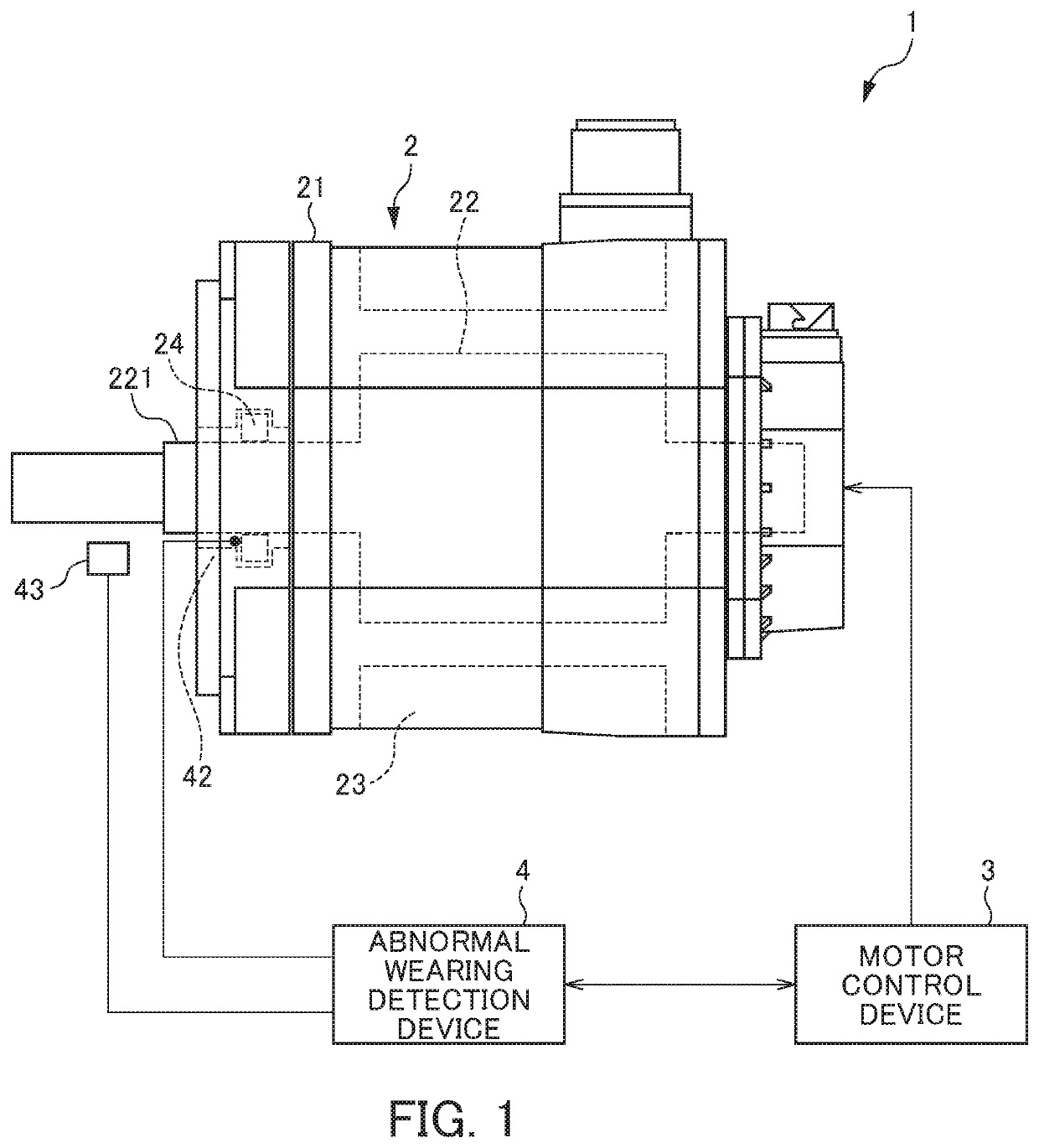

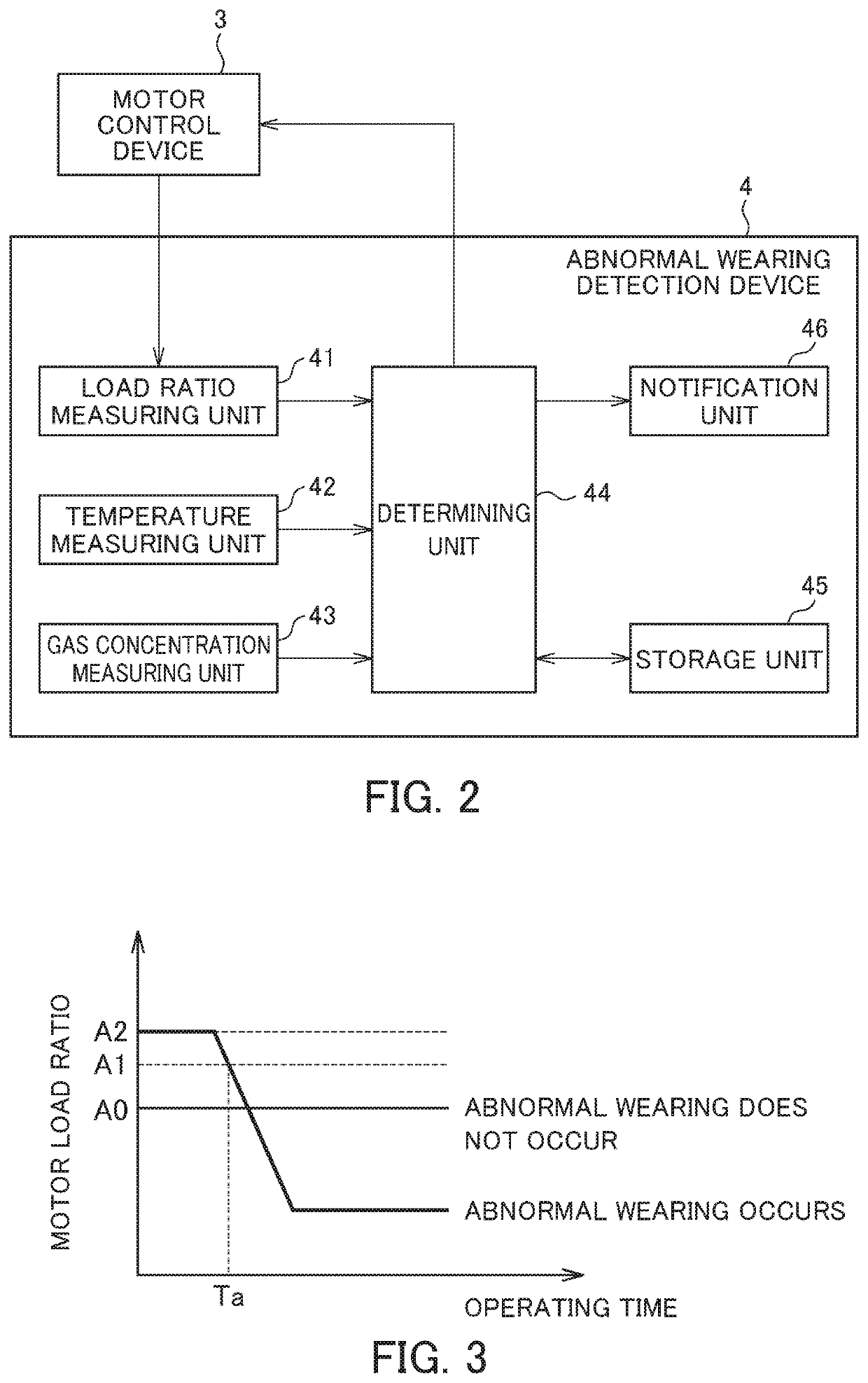

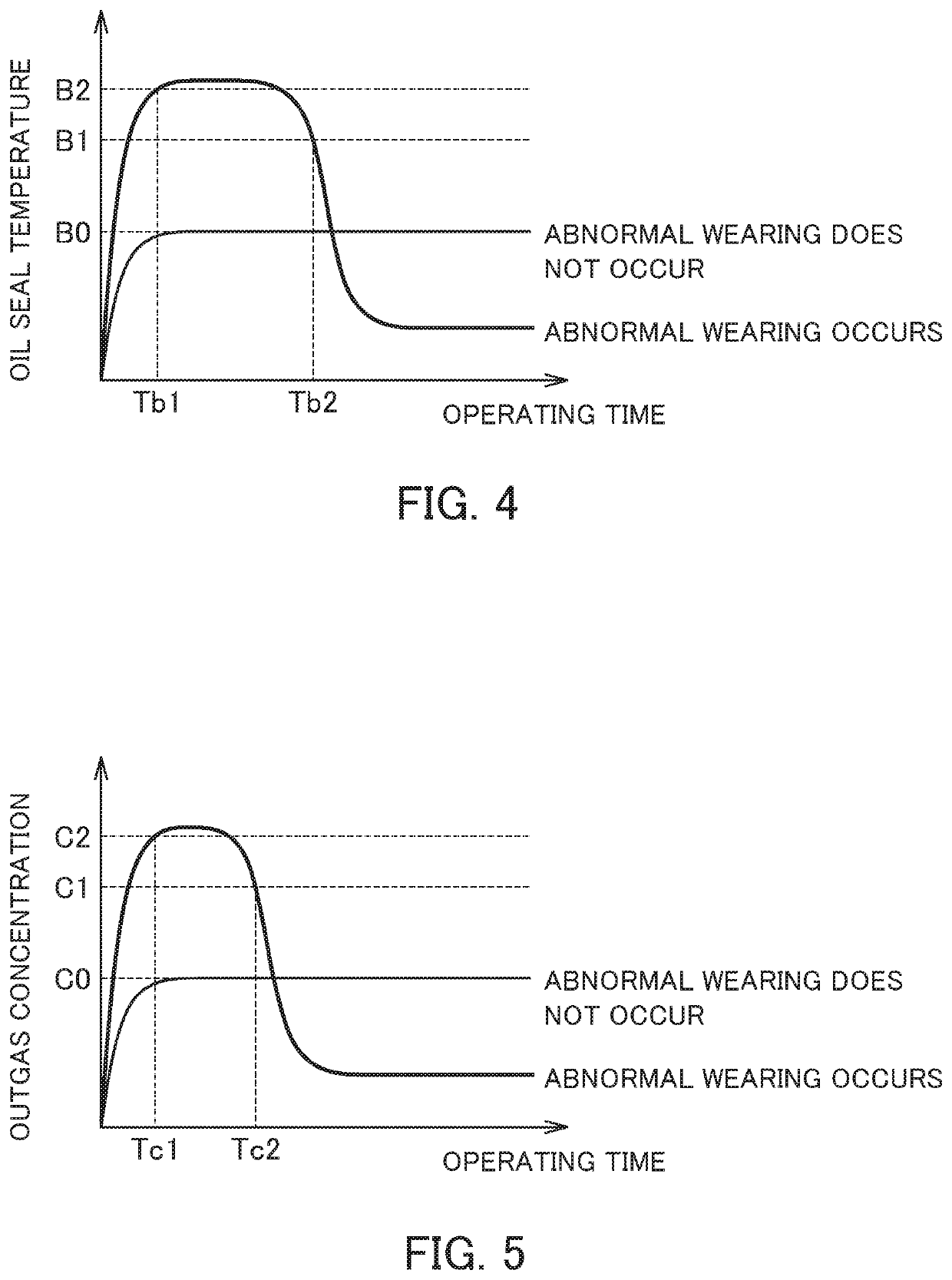

[0018]Hereinafter, an embodiment of the present invention will be described with reference to the drawings. FIG. 1 is a diagram for describing an embodiment of a rotor device having an abnormal wearing detection device for seal members according to the present invention. FIG. 2 is a block diagram for describing a configuration of an abnormal wearing detection device for seal members. In the present embodiment, a motor device 1 having a motor (an electric motor) 2 will be described as an example of a rotor device.

[0019]The motor device 1 according to the present embodiment includes a motor 2, a motor control device 3, and an abnormal wearing detection device 4. The motor 2 has a rotor 22 rotatably accommodated in a housing 21 and a stator 23 surrounding an outer circumference of the rotor. The stator 23 is fixed to an inner surface of the housing 21. When a predetermined driving current output from the motor control device 3 is applied to a coil of the stator 23, a rotating force is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| load ratio | aaaaa | aaaaa |

| temperature measuring | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com