Liquid crystal display device and method for manufacturing the same

a technology of liquid crystal display and liquid crystal, which is applied in the direction of optics, instruments, optical light guides, etc., can solve the problems of backlight loss, increased process difficulty, and reduced utilization rate, so as to facilitate improvement in processing speed and reduce operational difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

A liquid crystal display device and a method for manufacturing the same according to an embodiment of the present disclosure will be described in detail with reference to the drawings. It shall be pointed out that the drawings may not necessarily be drawn in scale. In contrast, emphasis shall generally be placed on the explanation of the principle of the present disclosure. Hence, the size, position, etc. of various elements, films, layers, etc. shown in the drawings do not represent the authentic size, position, etc., and are aimed only to facilitate understanding of the implementation and principle of the present disclosure.

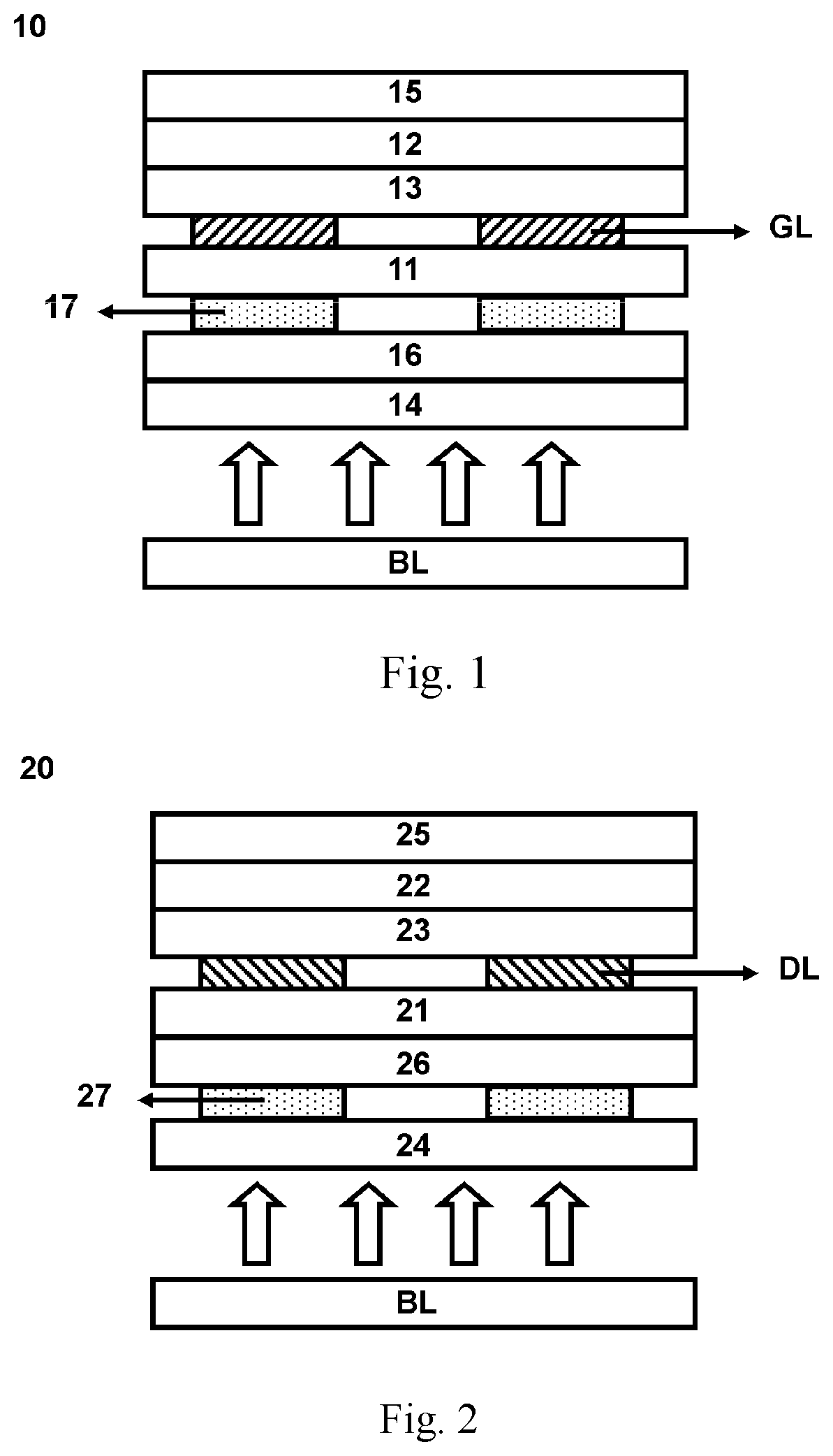

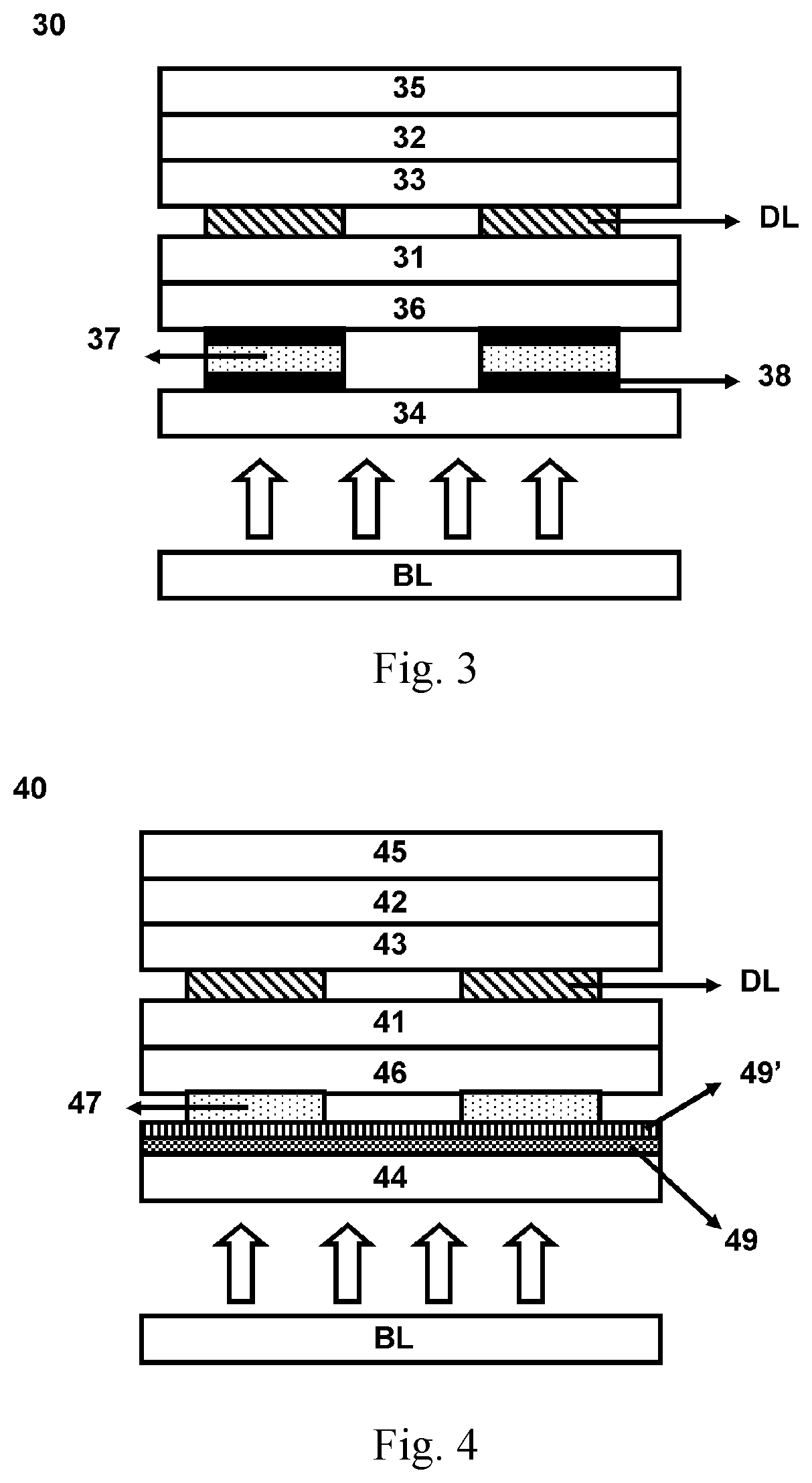

With reference to FIG. 1, it schematically illustrates a cross-sectional view of a liquid crystal display device according to an embodiment of the present disclosure. The liquid crystal display device 10 may comprise an array substrate 11 and an aligning substrate 12 that are oppositely arranged, a liquid crystal layer 13 disposed between the array substrate 11...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| shape | aaaaa | aaaaa |

| transparent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com