Access door for cooling device with product space

a technology of access doors and cooling devices, which is applied in the field of cooling devices, can solve the problems of forming a substantial burden on the environment, requiring relatively large amounts of energy for cooling means, and increasing energy costs, and achieves the effect of fast and efficient attachment to the cooling device on-si

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

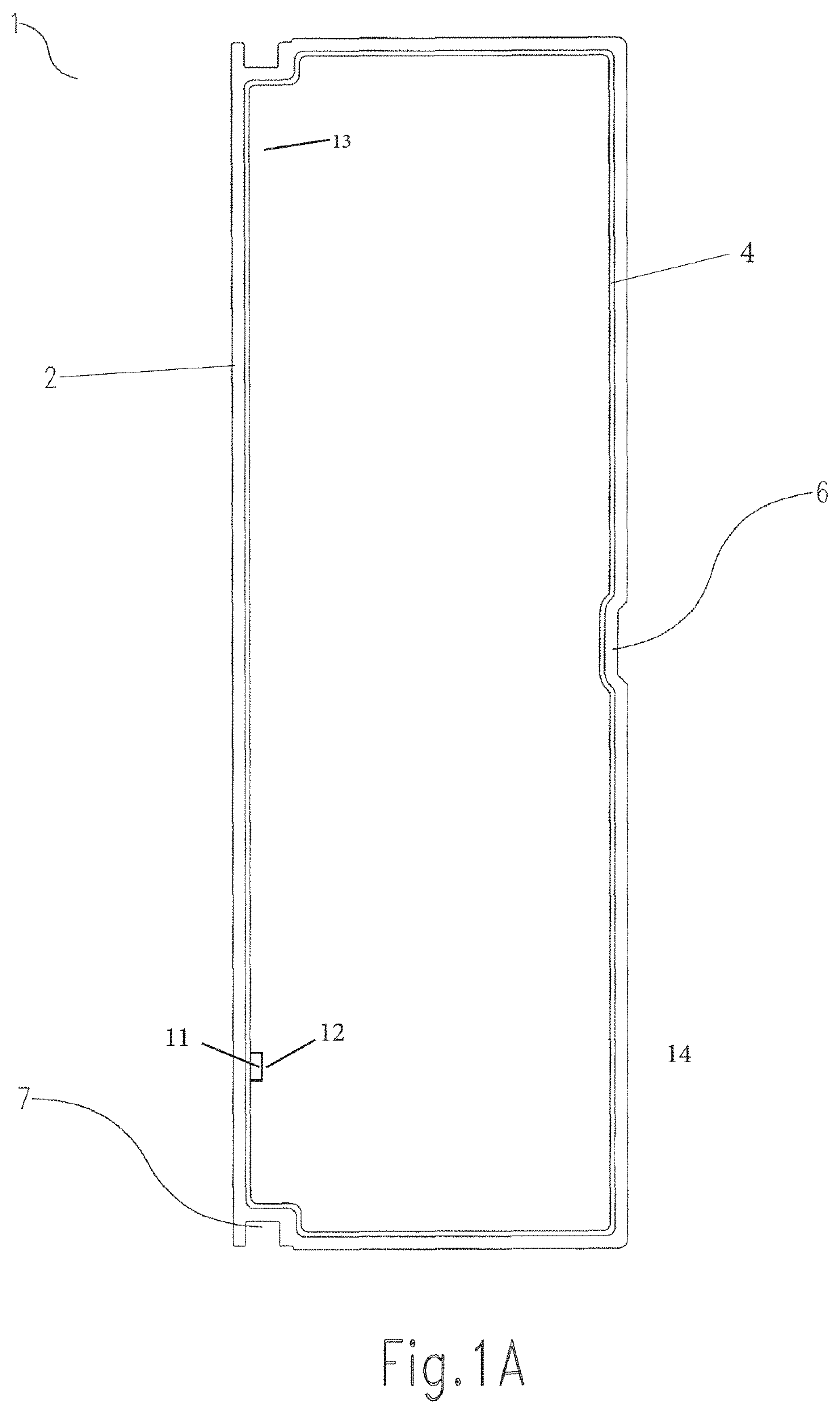

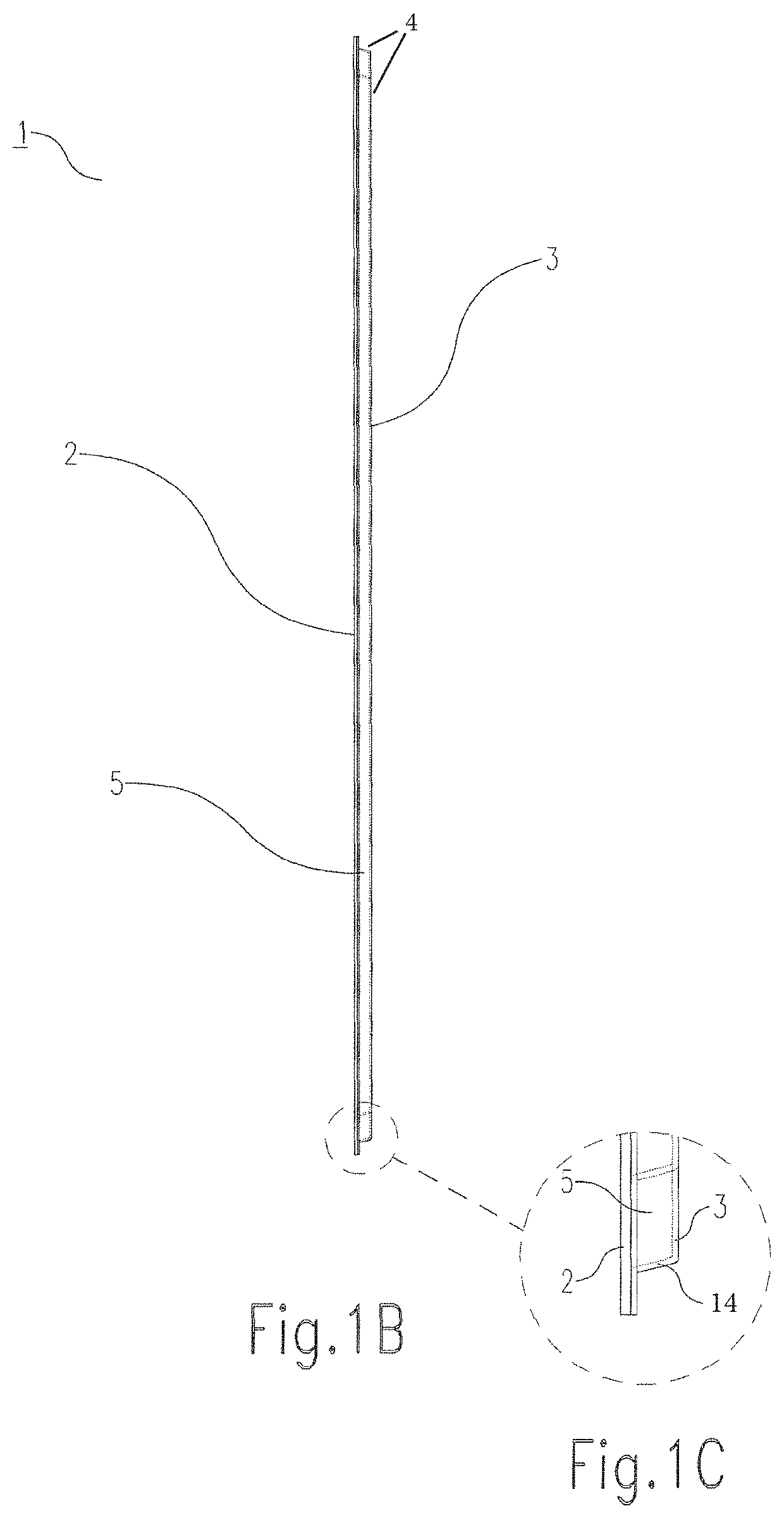

[0020]As shown in FIG. 1A up to and including FIG. 1C an access door (1) for use in a cooling device (8) according to the present invention comprises a completely uninterrupted first plate-shaped wall (2) of plastic at an exterior visible side. The first wall (2) is moreover made of cast polymethylmethacrylate (cast PMMA), which is a particularly suitable plastic for use in the access door of a cooling device due to its good transparency. With its own flat edge part the first wall (2) is attached to an edge part of a plane-parallel second wall (4) which is also fully made of cast polymethylmethacrylate. FIG. 1B shows the access door (1) suspended at that the opening of the cooling device (8), The second wall (4) comprises a substantially flat central part (3) which is offset from the edge part to leave room for a cavity (5) bounded by the walls. Consequently, the second walls forms as it were a box-shaped body with a flat edge part against which the first wall is easily attachable, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com