Tire

a technology of tires and wheels, applied in the field of tires, can solve the problems of deterioration of dry steering stability, block rigidity reduction, etc., and achieve the effect of dry steering stability and on-ice performan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

working example (example)

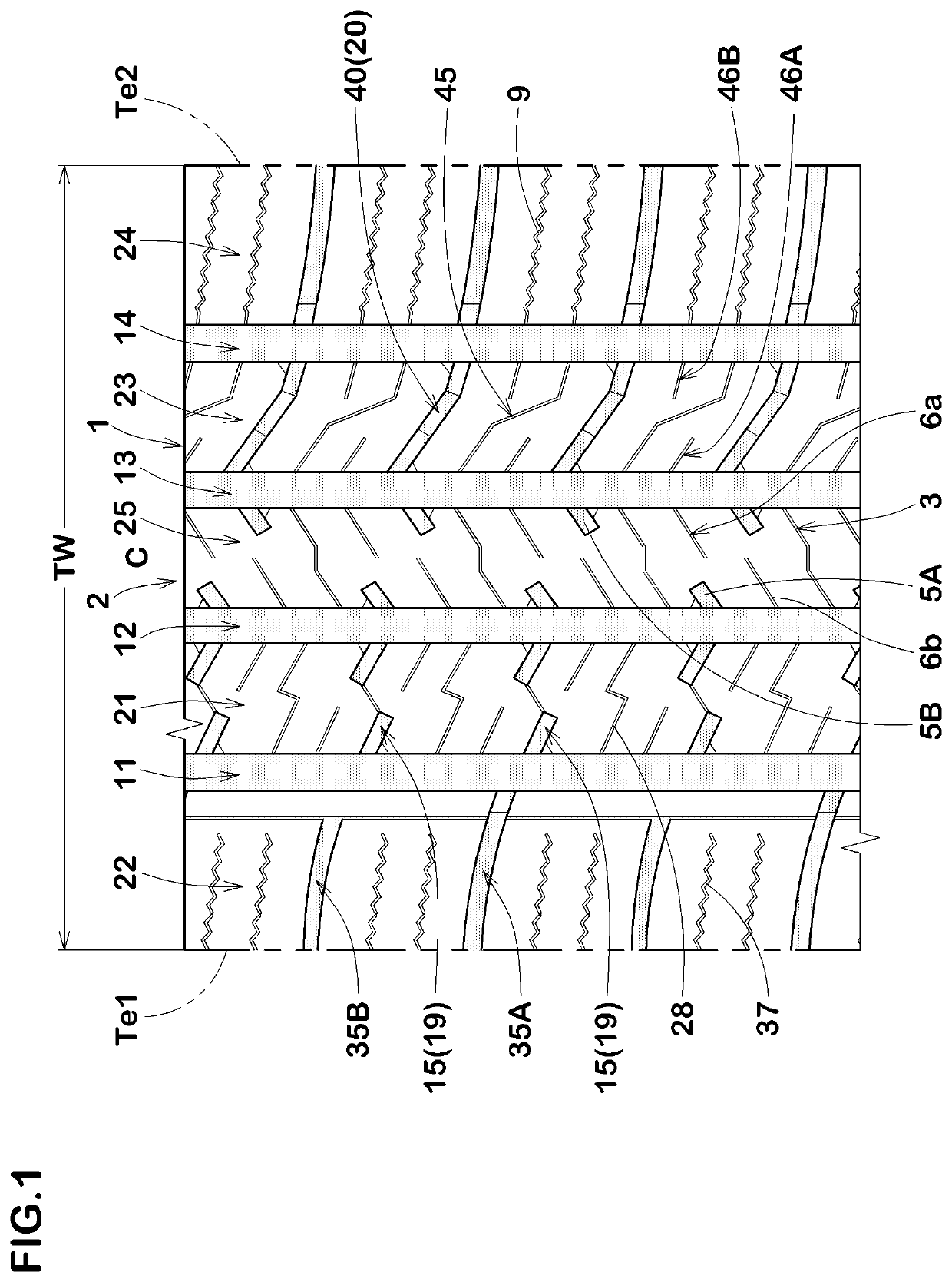

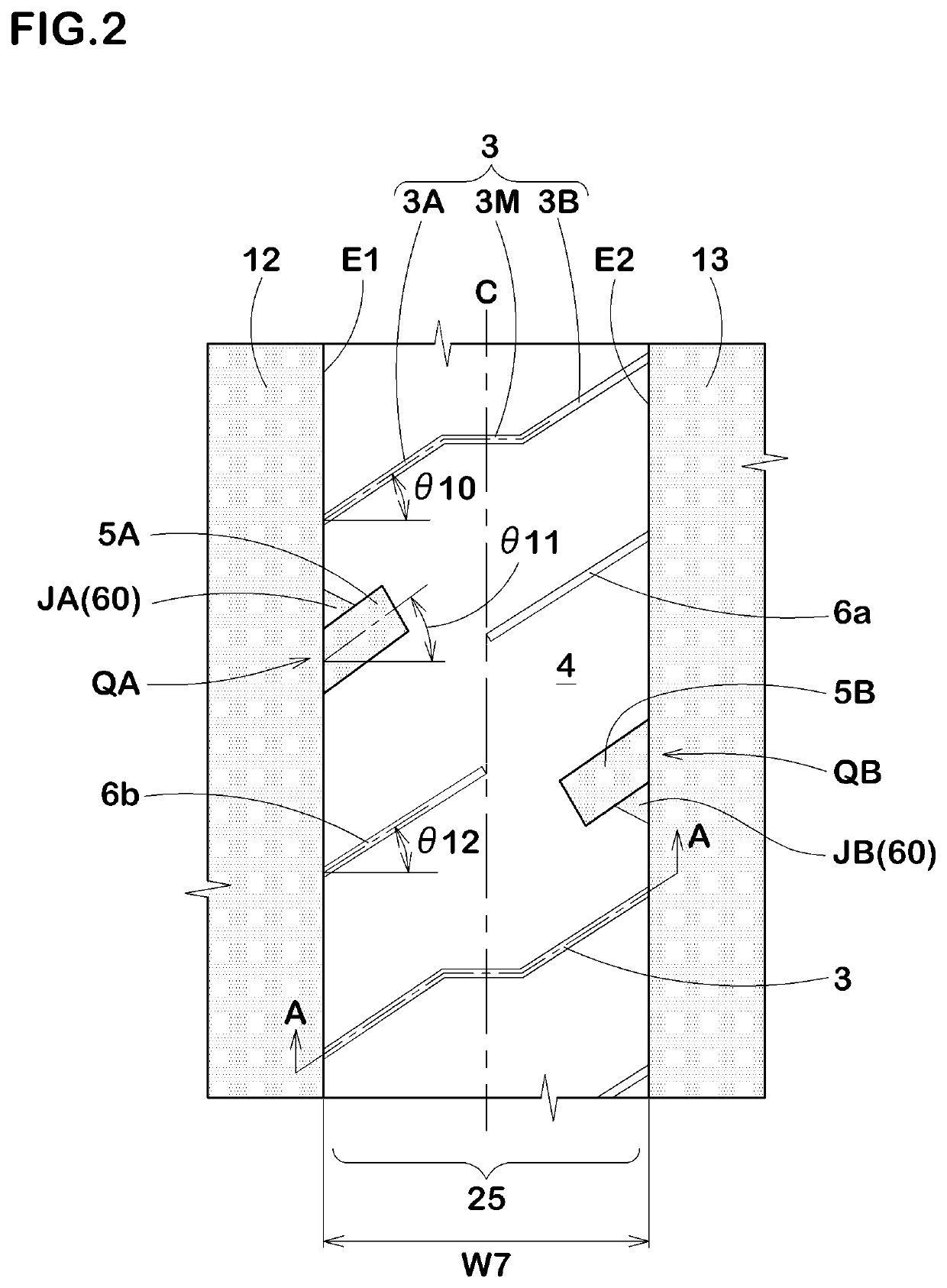

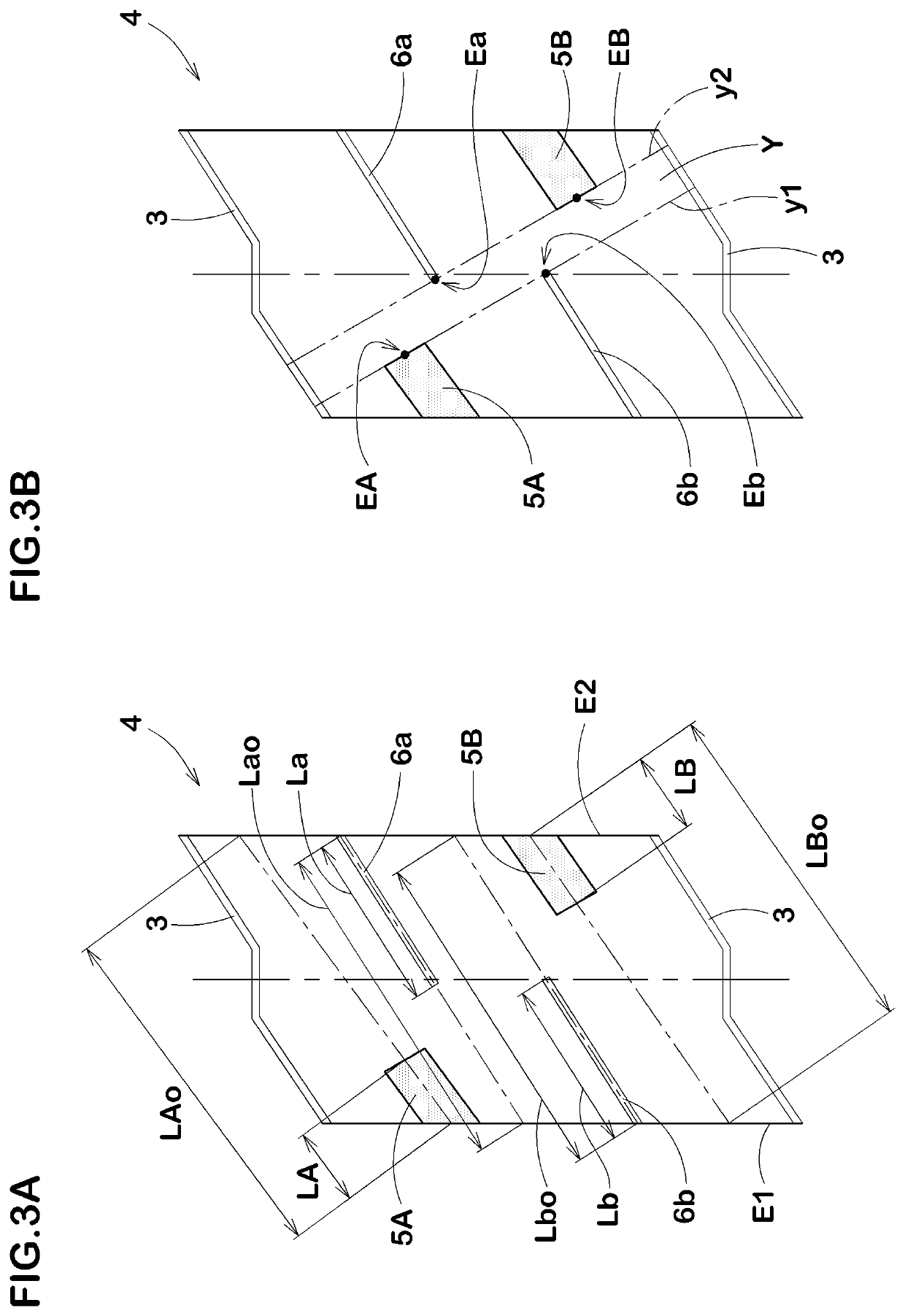

[0131]Tires of size 215 / 60R16 having a basic tread pattern shown in FIG. 1 were made by way of test according to the specification listed in Table 1. In Reference 1, as shown in FIG. 4A, the first center lateral groove 5A and the second center closed sipe 6a are not opposed to each other and the first center closed sipe 6b and the second center lateral groove 5B are not opposed to each other, whereby the high rigidity region Y is not formed. In Reference 2, the length Lb is smaller than one third of the extended length Lb0 and the length La is smaller than one third of the extended length La0, therefore, edge lengths are insufficient although the high rigidity region Y is formed. In Reference 3, the length Lb is larger than two thirds of the extended length Lb0 and the length La is larger than two thirds of the extended length La0, therefore, the high rigidity region Y is not formed. In Reference 4, the length LA is larger than a half of the extended length LA0 and the length LB is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com