Patents

Literature

62results about How to "Drying stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tire

Owner:SUMITOMO RUBBER IND LTD

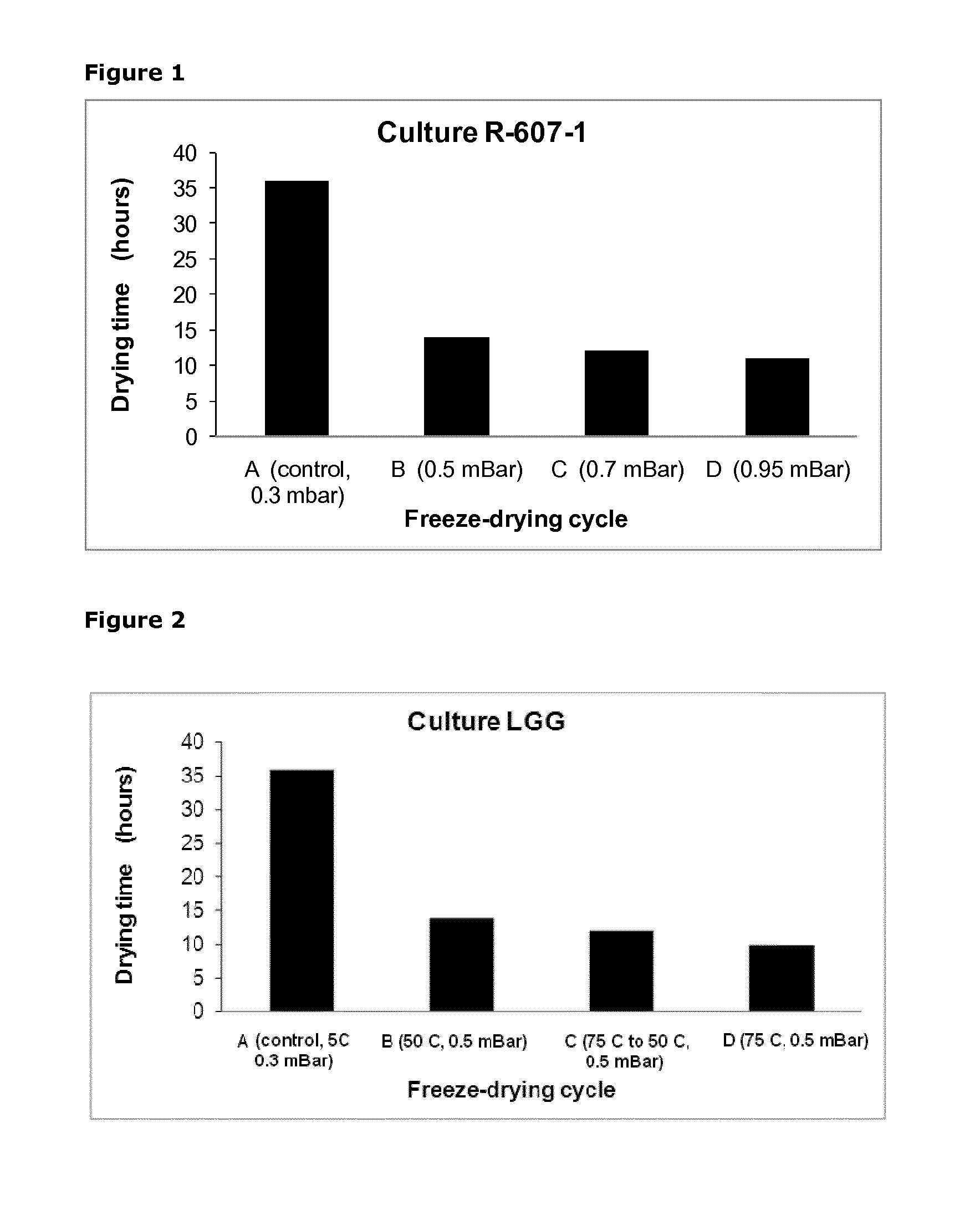

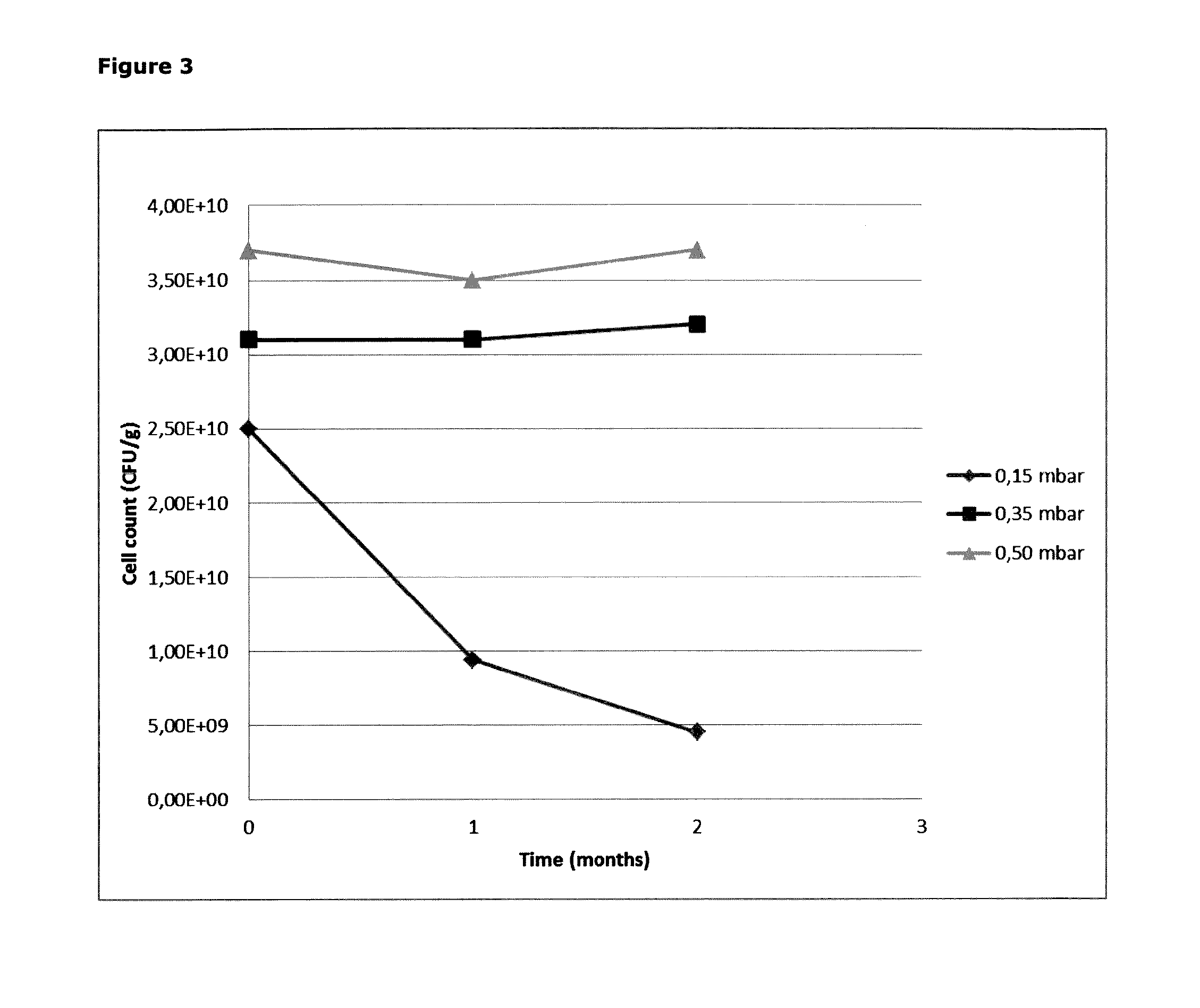

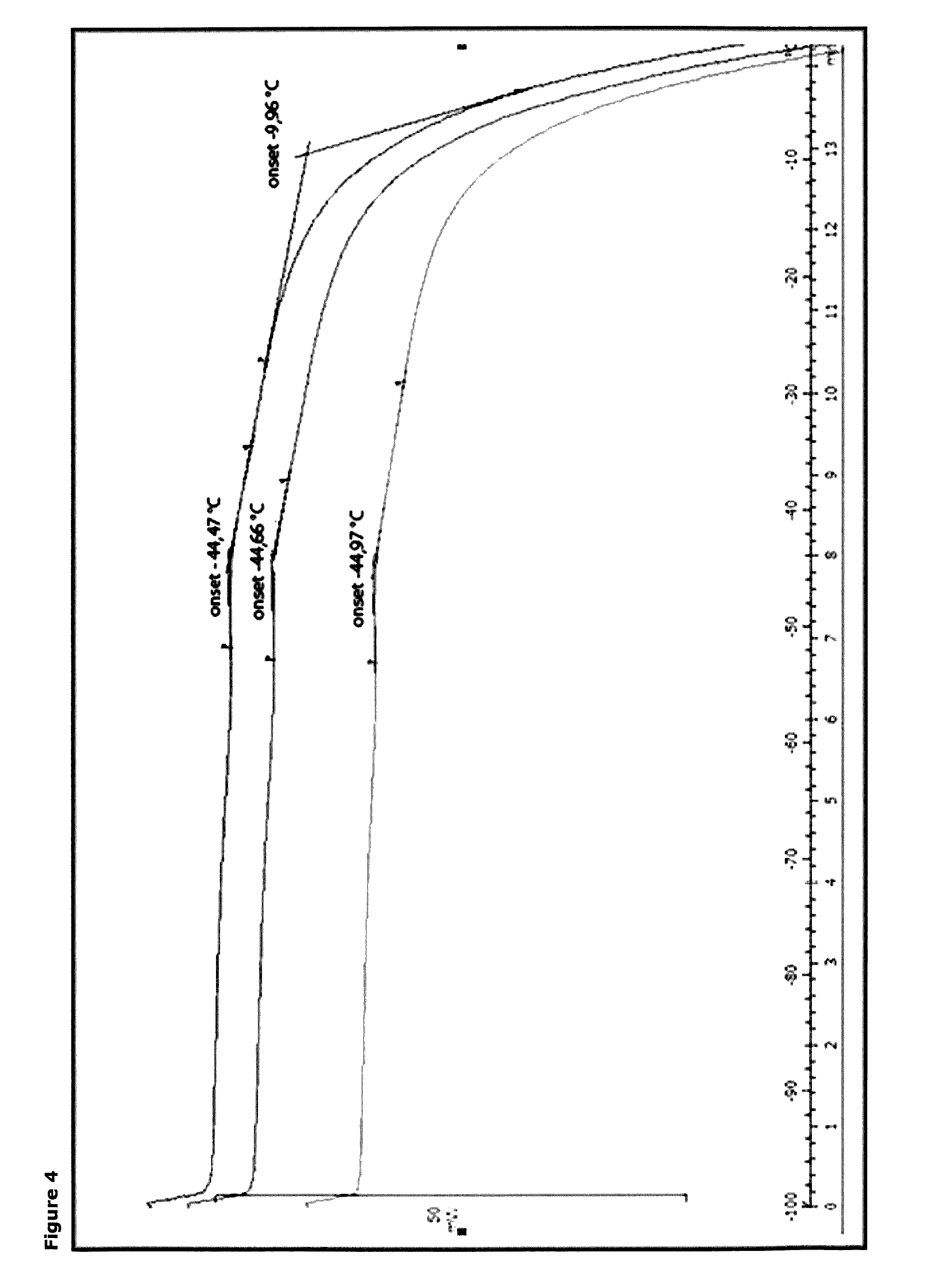

Method for optimizing a process for freeze drying a bacteria-containing concentrate

ActiveUS20150232801A1Good storage stabilityDrying stabilityMilk preparationBacteriaFreeze-dryingFreeze dry

The present invention relates to a process for optimizing the storage stability of a freeze dried bacteria-containing product obtained from a bacteria-containing concentrate, wherein the process is carried out at a pressure which will provide a sublimation temperature which is at least 10° C. above the melting point of the frozen bacteria-containing concentrate. Further, the present invention relates to the freeze dried concentrates per se.

Owner:CHR HANSEN AS

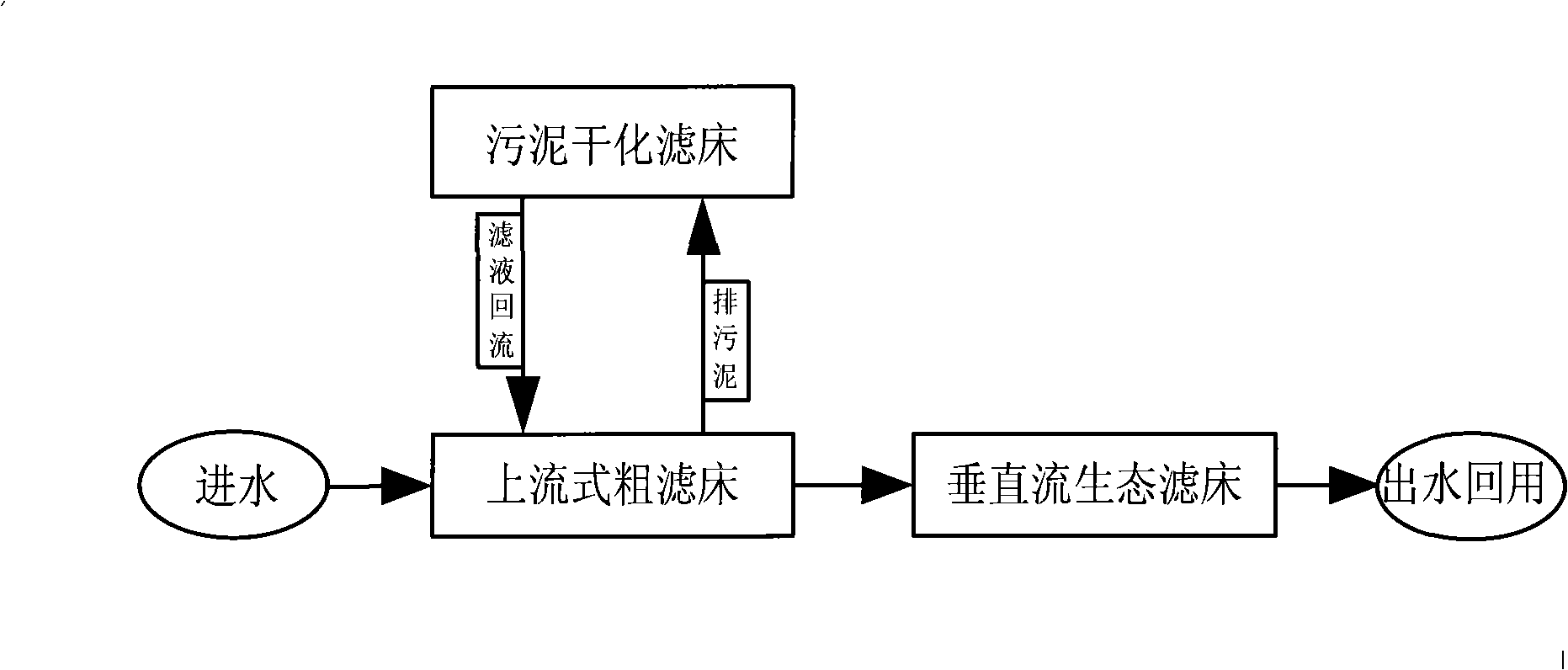

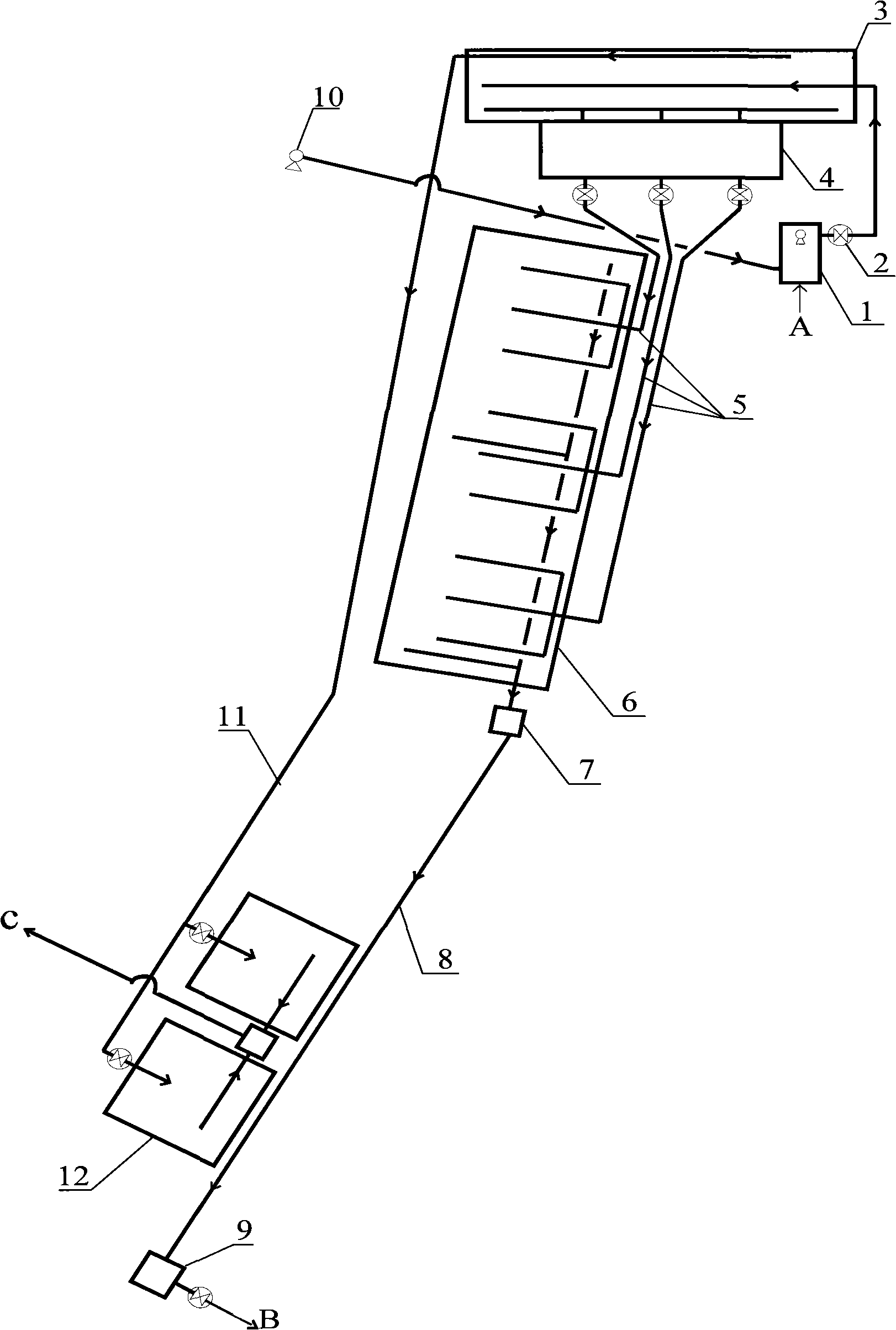

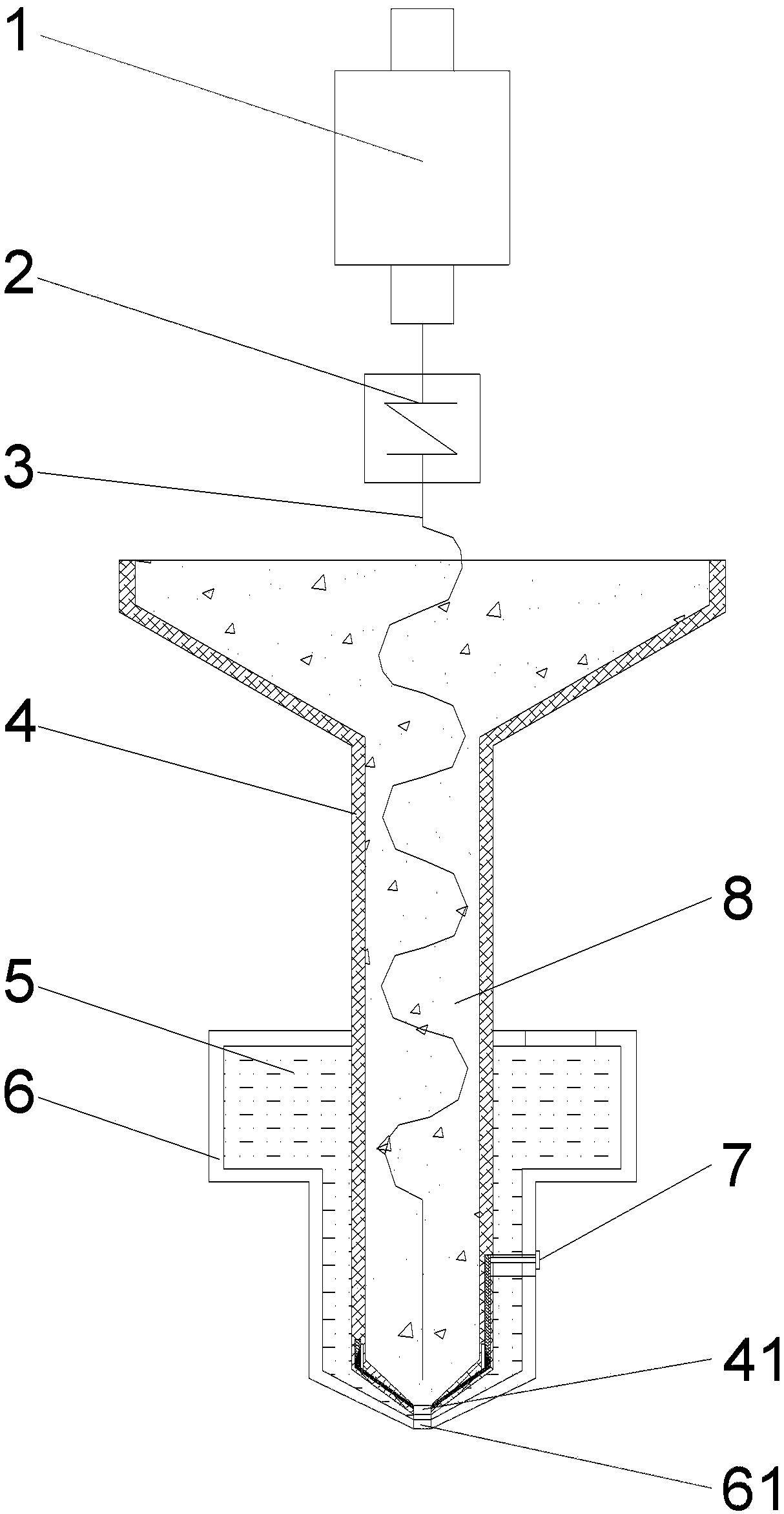

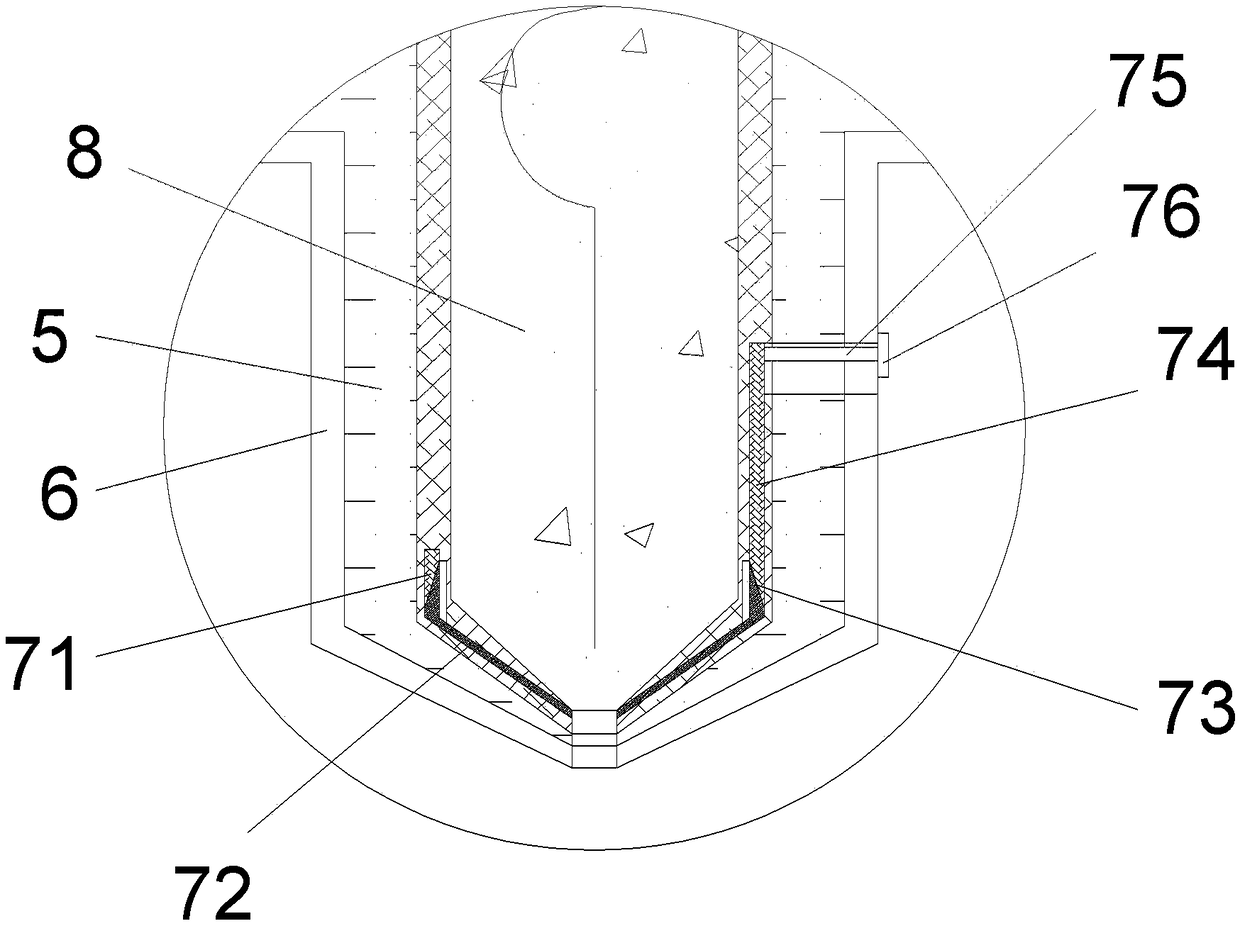

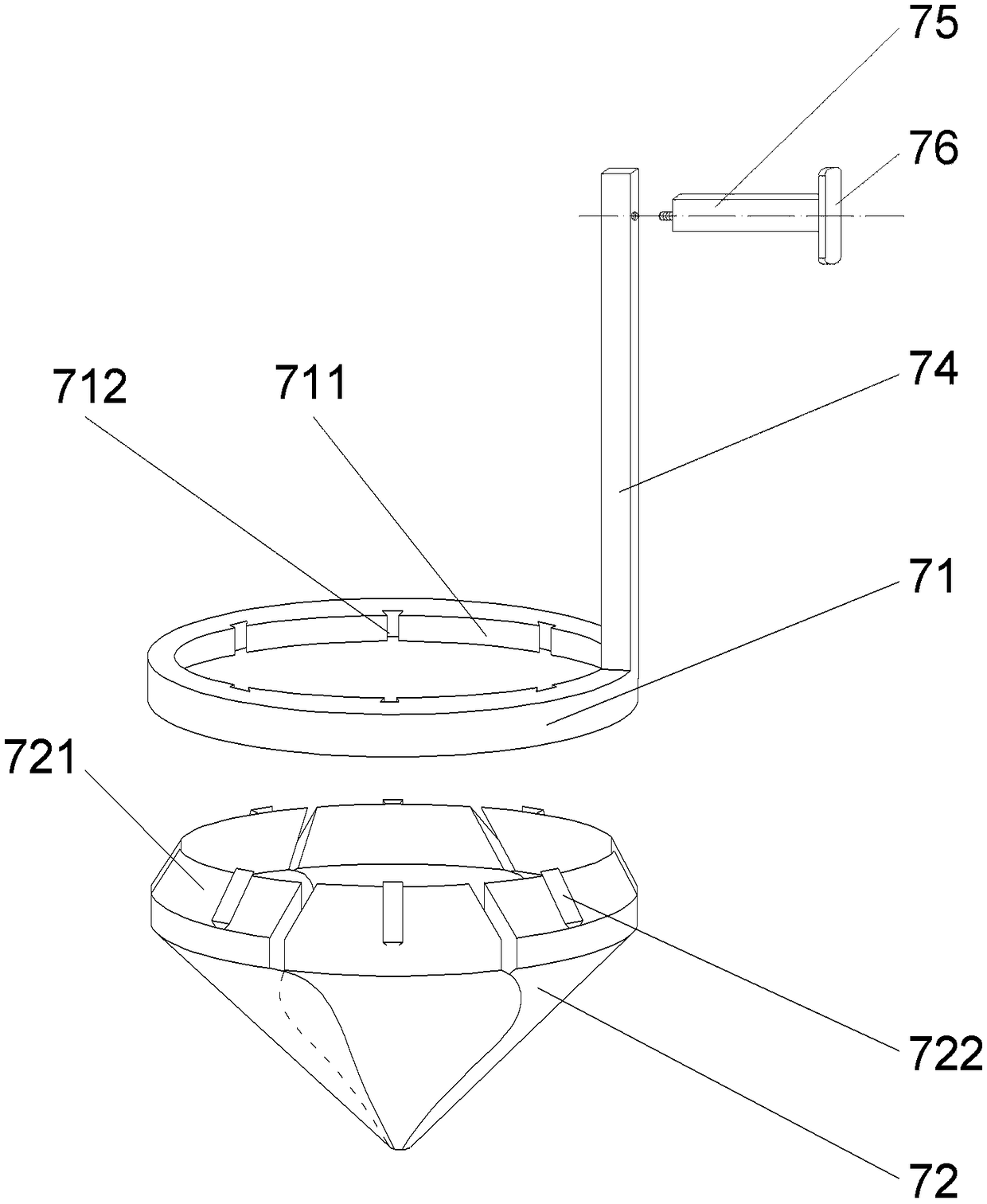

Method for treating eutrophication water with artificial wet land and facilities thereof

ActiveCN101314512AResolve disposal issuesReduce odorSludge treatment by de-watering/drying/thickeningMultistage water/sewage treatmentConstructed wetlandEutrophication

The invention provides a method for treating an eutrophication water body by utilizing an artificial marsh and a facility thereof. The method comprises the following steps that: an eutrophication water body to be treated is sent to an upflow type coarse filtering bed by a pumping and collecting pipeline; the upflow type coarse filtering bed carries out removing treatment to suspended substances and algae substances in the eutrophication water body; the water body treated by the upflow type coarse filtering bed is evenly distributed to a vertical flow ecological filtering bed by a water feeding and distributing system and subject to secondary biochemical treatment by the vertical flow ecological filtering bed; effluent water is recycled and reused; deposited sludge in the upflow type coarse filtering bed is discharged to a sludge drying filtering bed for stabilization treatment; and a wet sludge filtrate reflows to the upflow type coarse filtering bed for aftertreatment. The proposal of the invention adopts a method of combining the upflow type coarse filtering bed, the vertical flow ecological filtering bed and the sludge drying filtering bed to treat the eutrophication water body, can not only effectively remove the suspended substances and the algae substances but also solve the problem of treating blue algae sludge with low cost, has the characteristics of good algae removing effect and large water treatment amount and is widely suitable for the long-term water purification of the eutrophication water body.

Owner:苏州德华生态环境科技股份有限公司

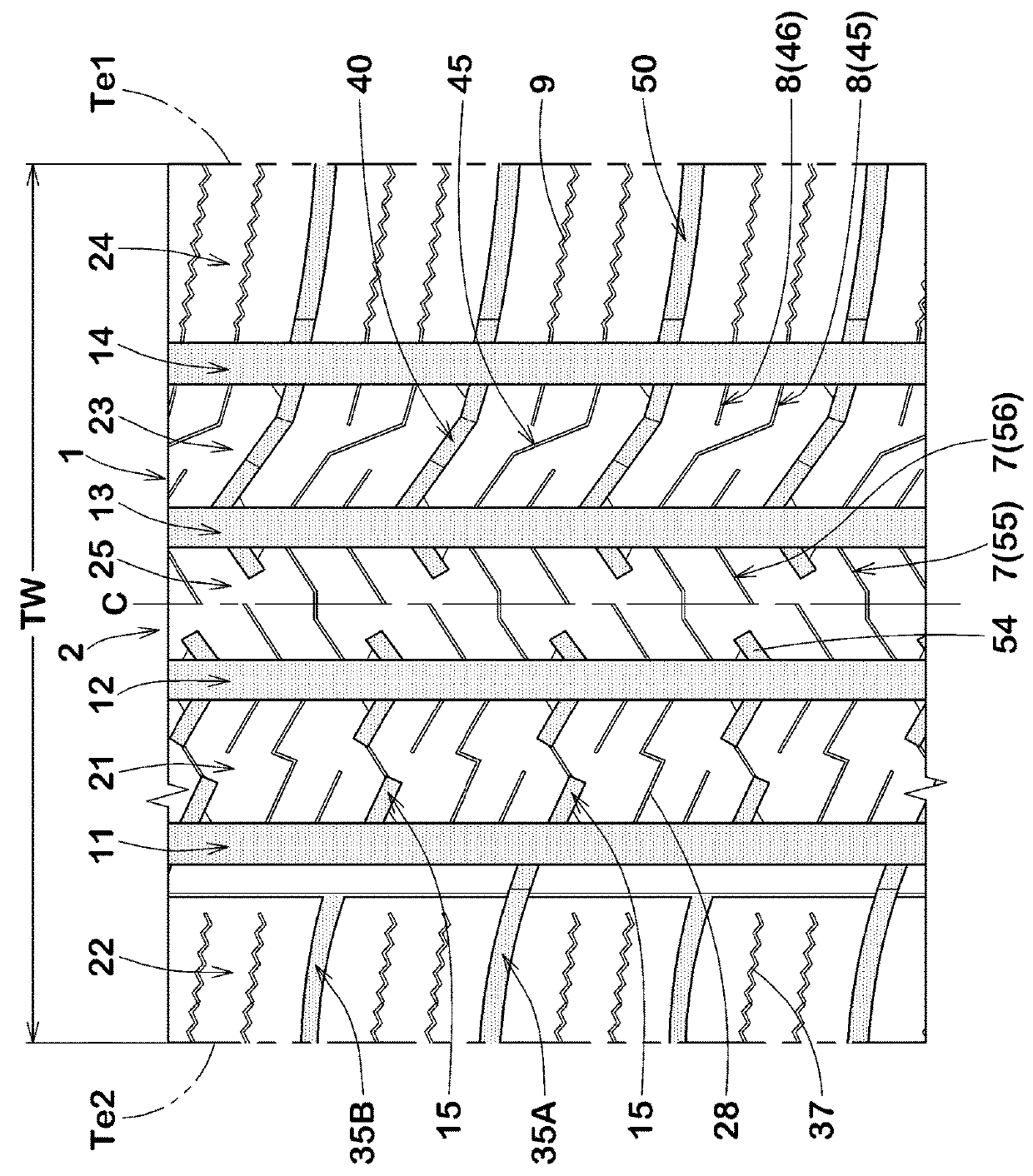

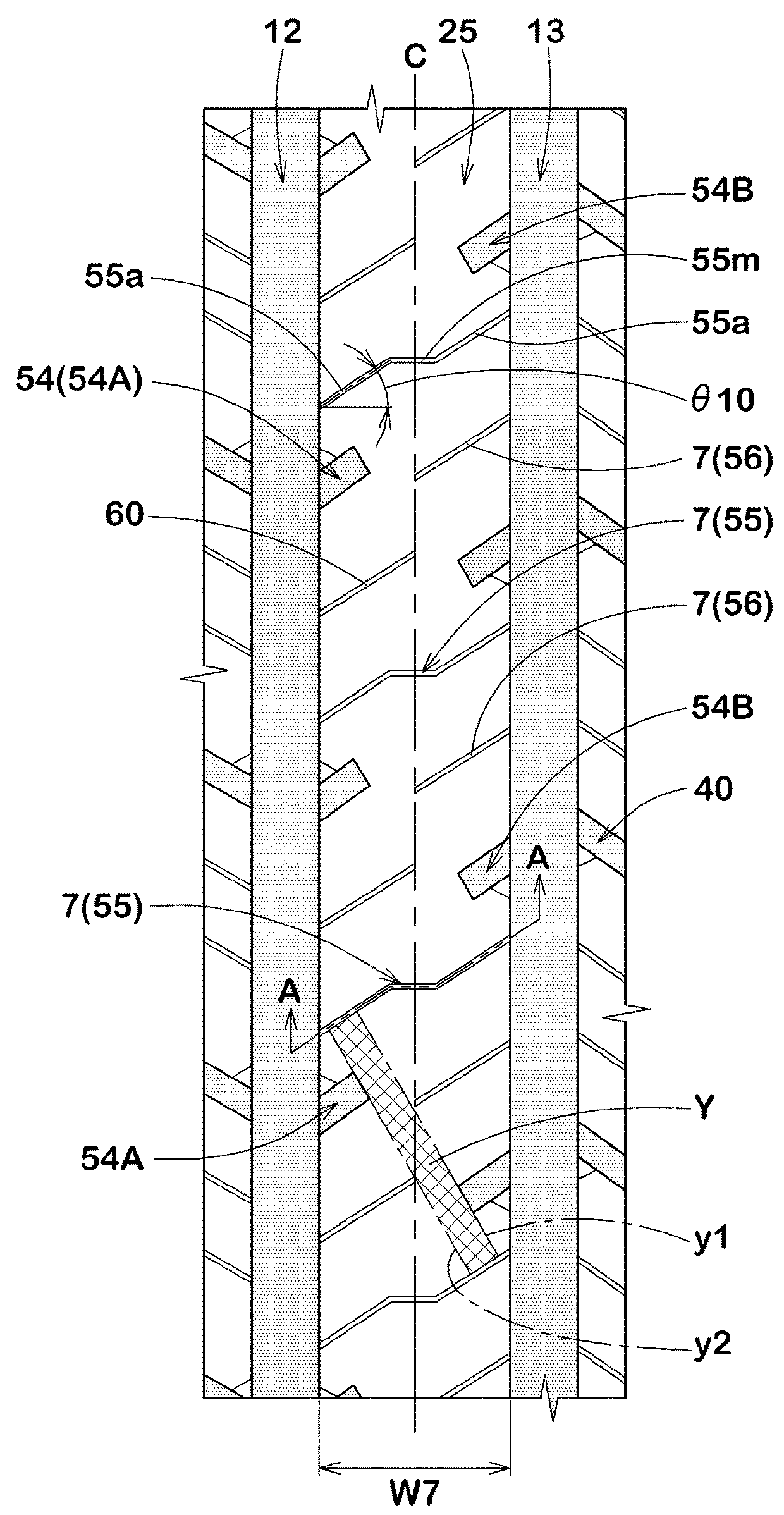

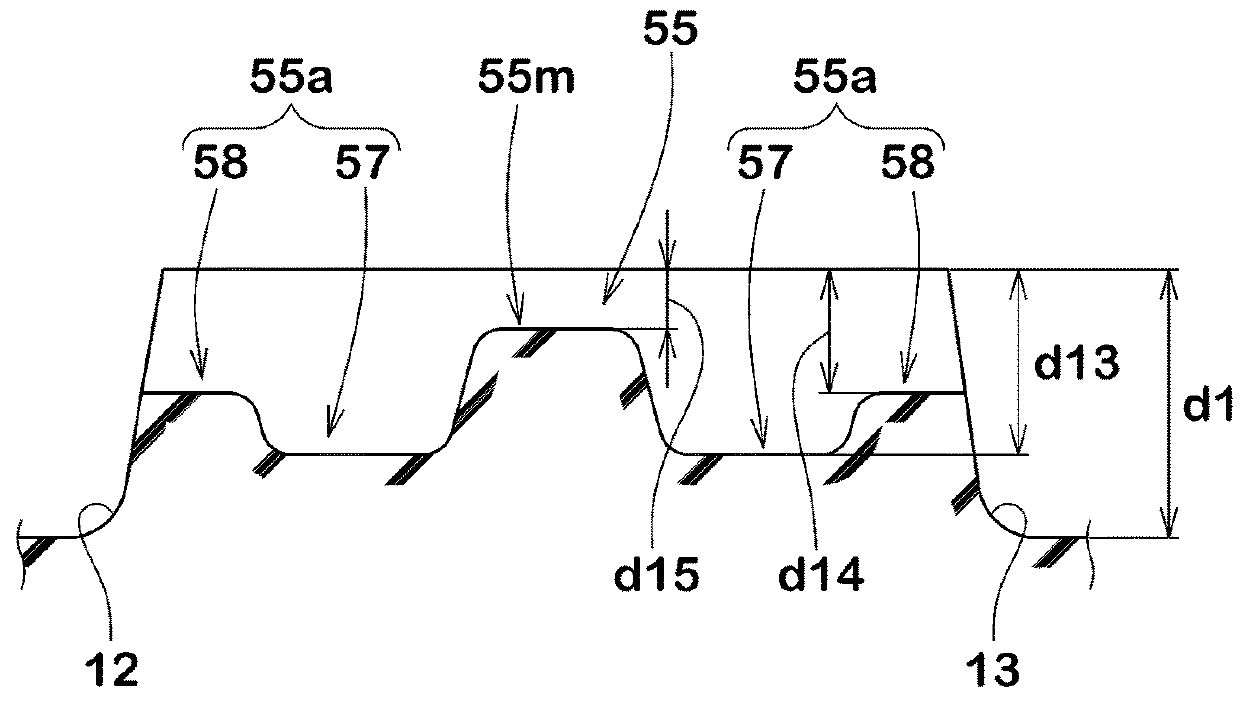

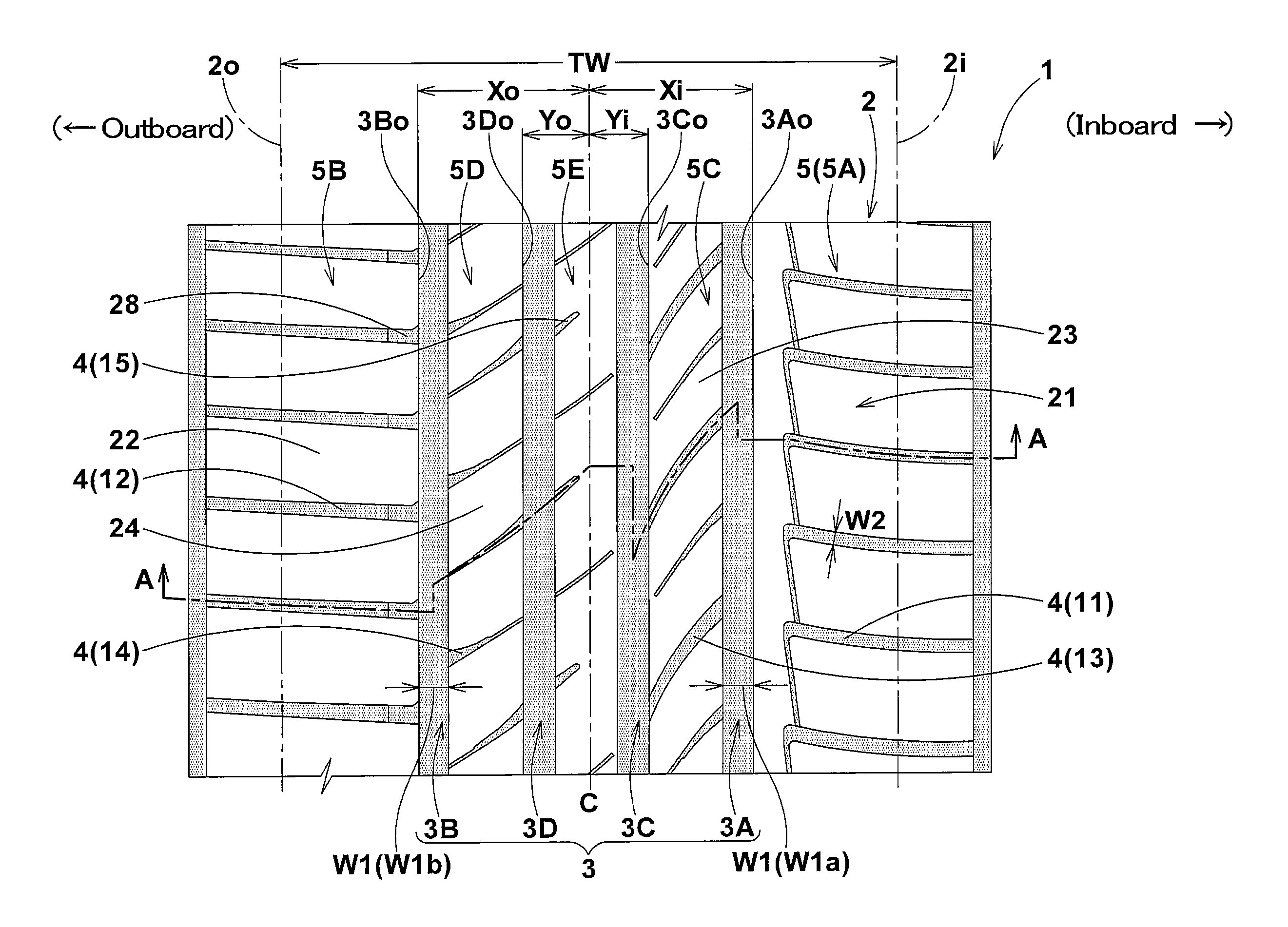

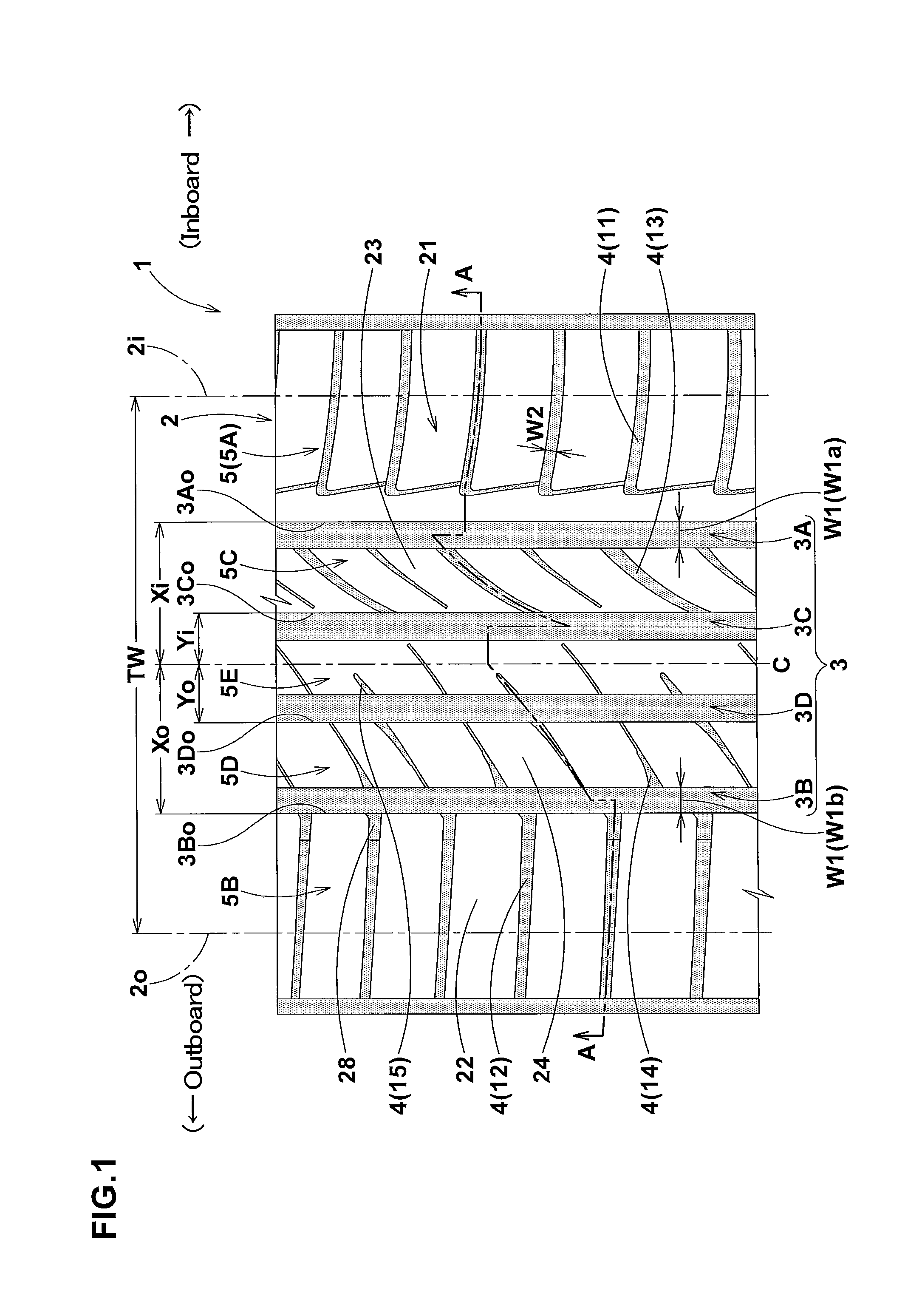

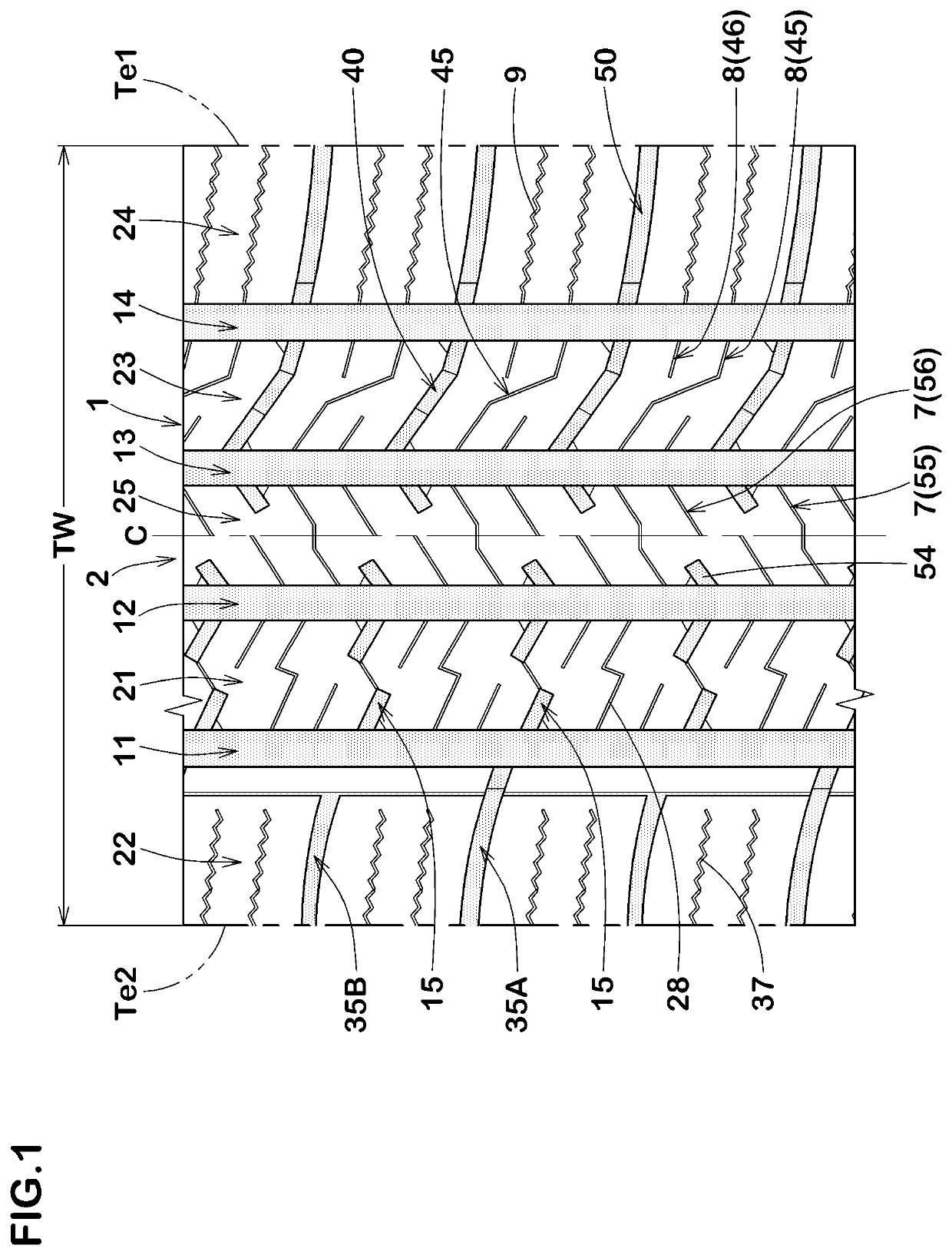

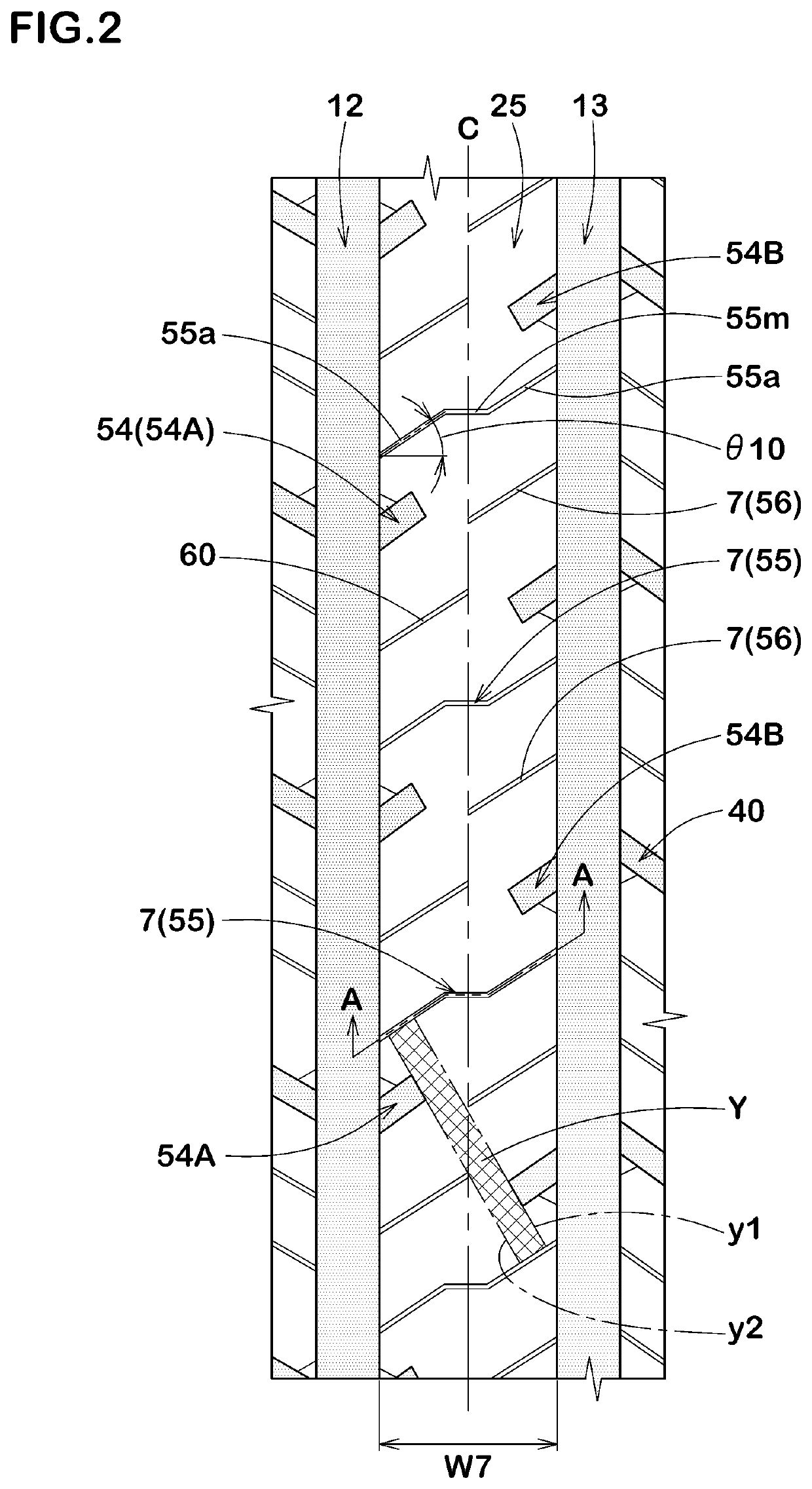

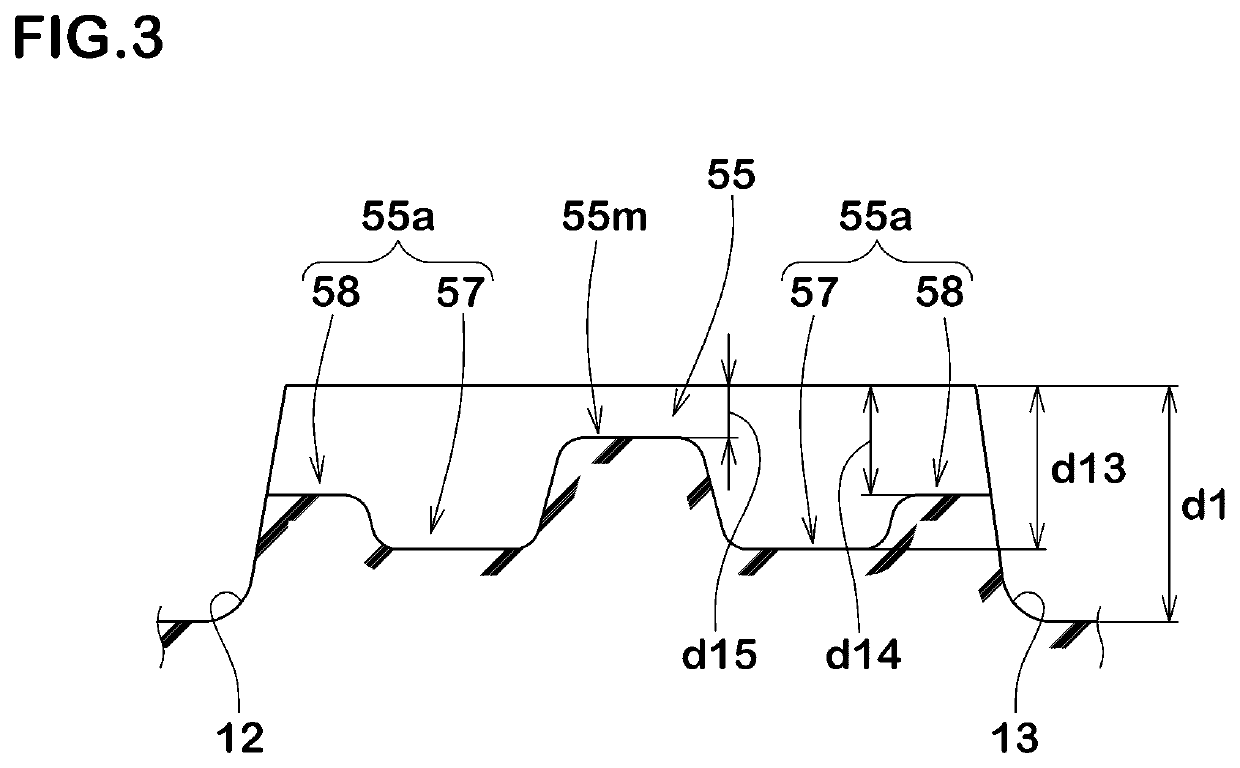

Pneumatic tire

ActiveUS20120132334A1Sacrificing steering stabilityImprove drainage capacityInflatable tyresTyre tread bands/patternsEngineeringAxial distance

Owner:SUMITOMO RUBBER IND LTD

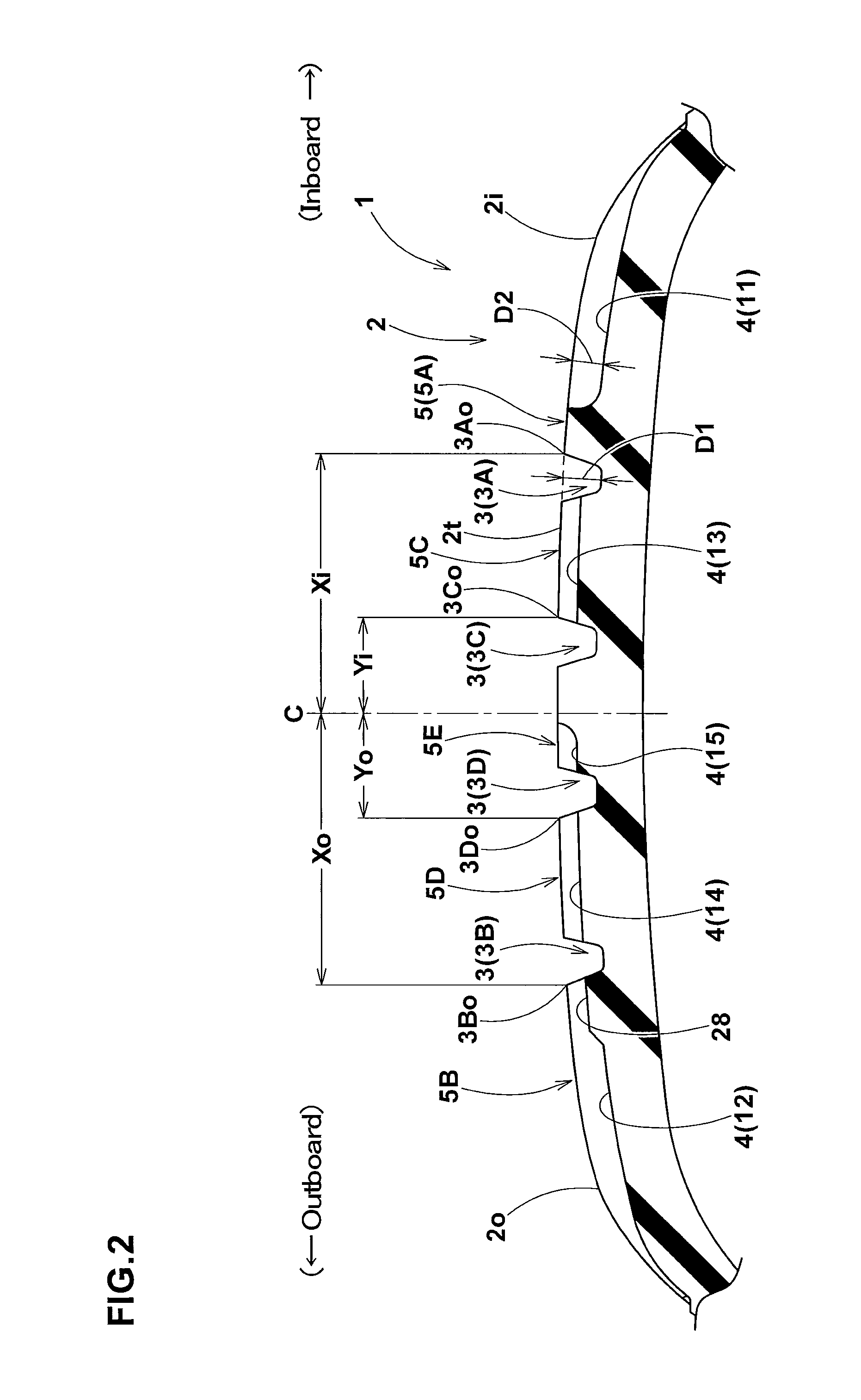

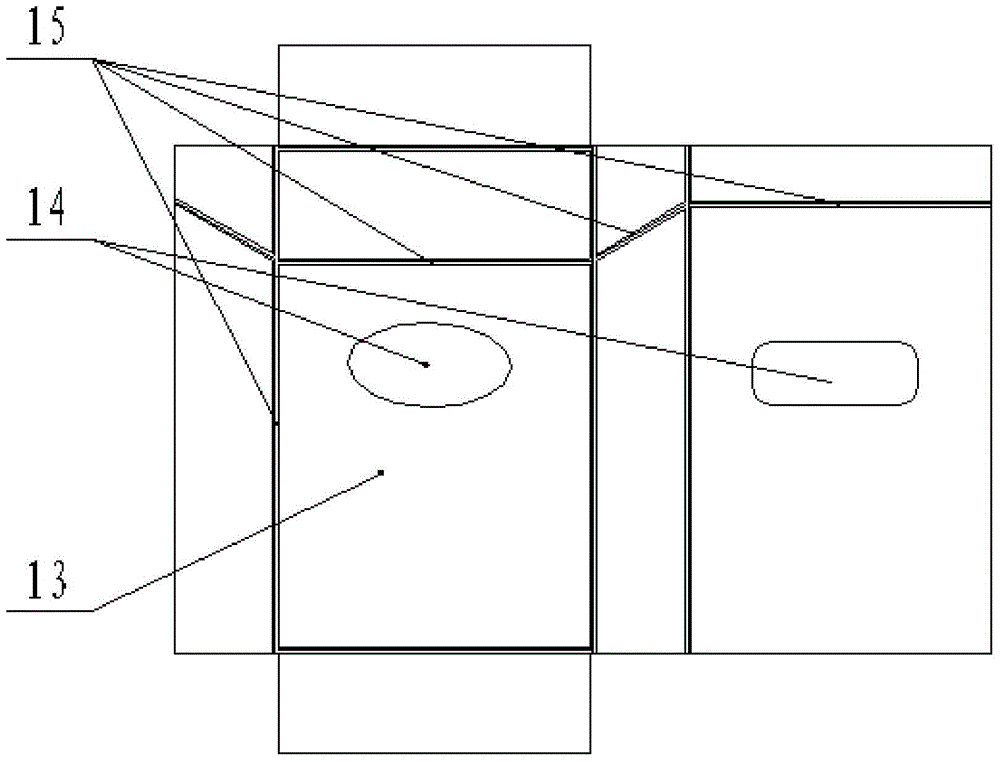

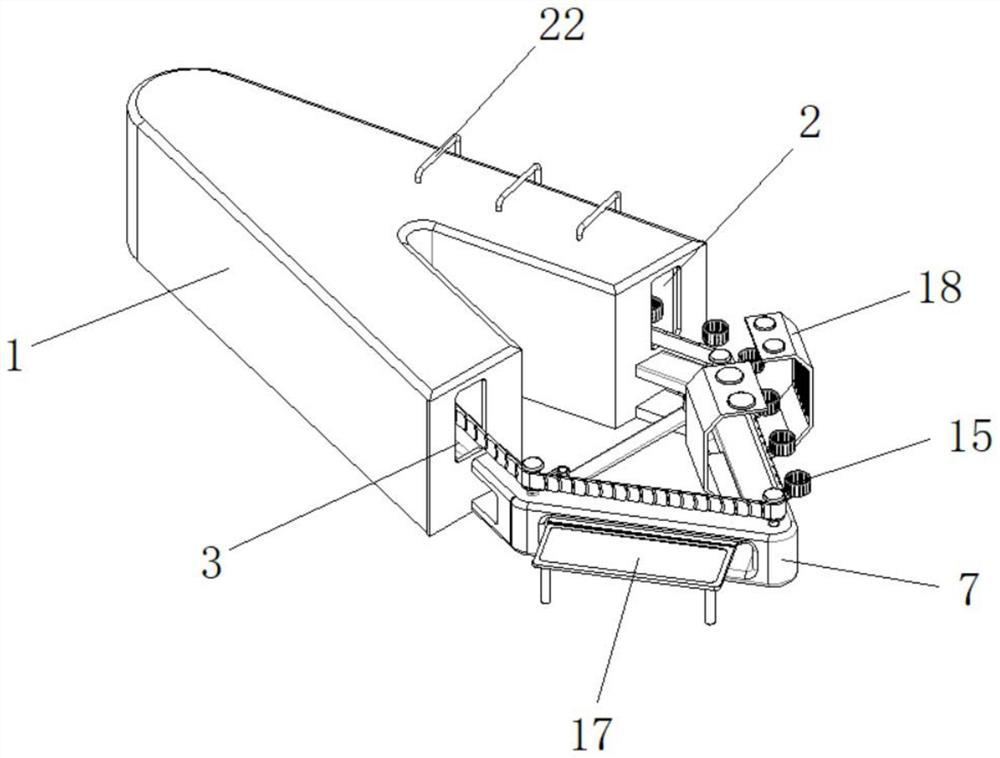

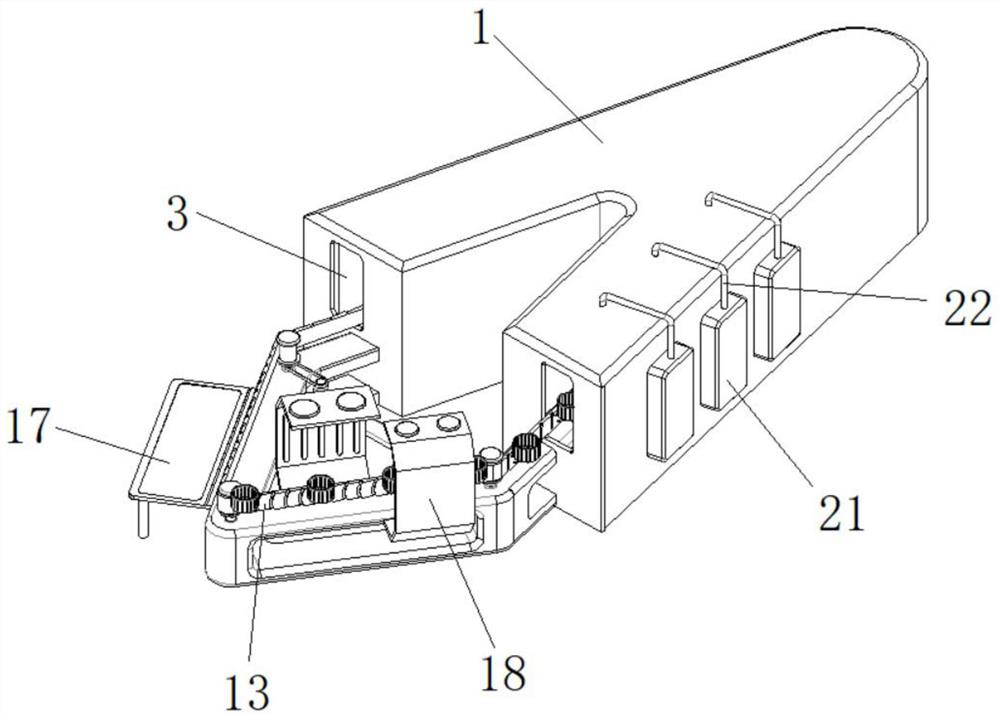

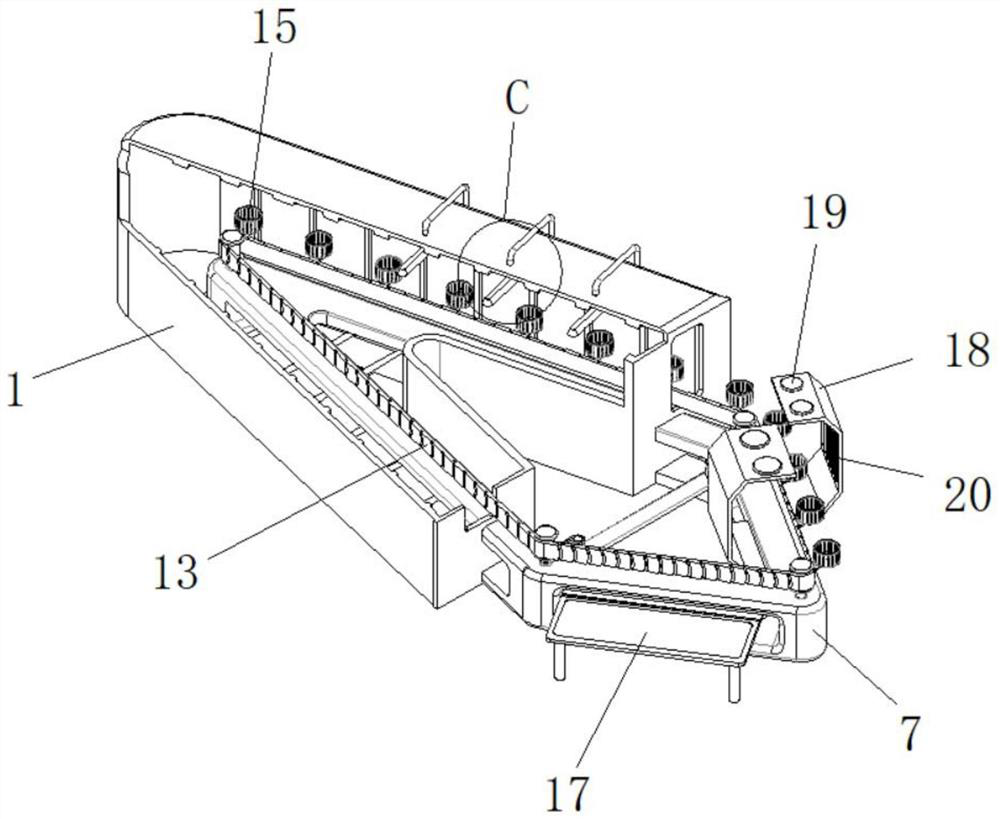

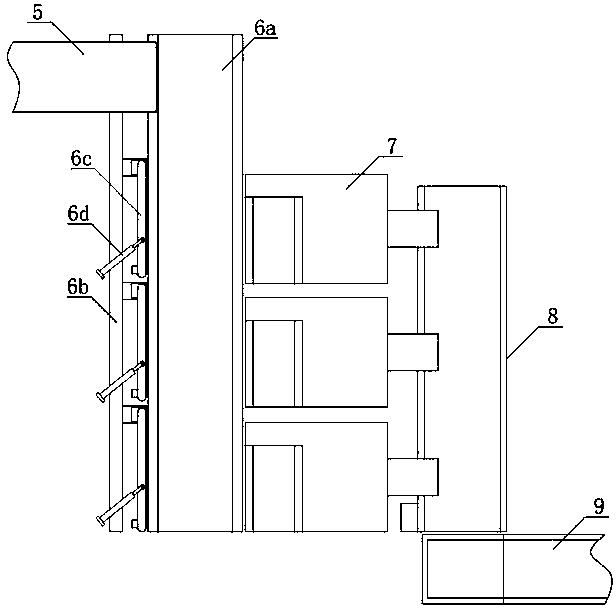

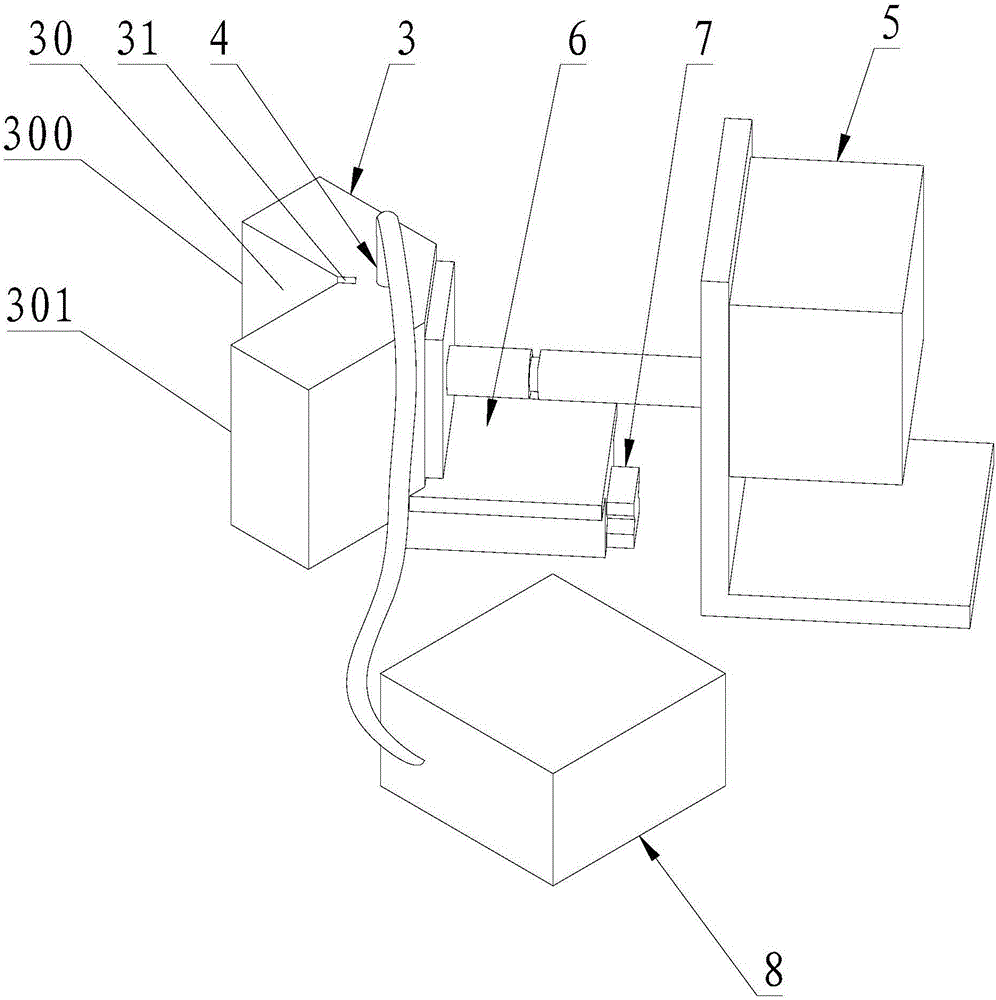

Processing method and integrated processing device for hard shell cigarette packaging box

InactiveCN104626738AIncrease productivityAvoid rubbingRotary pressesBronze printingCardboardEngineering

The invention belongs to the technical field of printing and packaging devices, and particularly relates to a processing method and integrated processing device for a hard shell cigarette packaging box. The processing method comprises the following steps that white cardboard rolls are uncoiled, gilded and printed to form semi-finished paperboards; the paperboard are dried; the pressing mark technology is carried out on the semi-finished paperboards to form a plurality of folding marks; die cutting is carried out on the semi-finished paperboards to form packaging paper; the packaging paper is folded and stuck to form the square and strips-shaped hard shell cigarette packaging box. The integrated processing device comprises a rack, an uncoiling mechanism, a gilding film paying-off device, a gilding mechanism, a printing mechanism, a waste film taking-up mechanism, a drying device, a pressing mark mechanism and a die cutting mechanism which are sequentially arranged on the rack. The gilding mechanism comprises an upper gilding and printing film and a gilding bearing base. A heating disc and a temperature sensor are arranged on the upper gilding and printing film. According to the processing method and device, the cigarette packaging and printing quality is better ensured, the production efficiency is high, and the production cost is saved.

Owner:CHUXIONG JIXING COLOR PRINTING

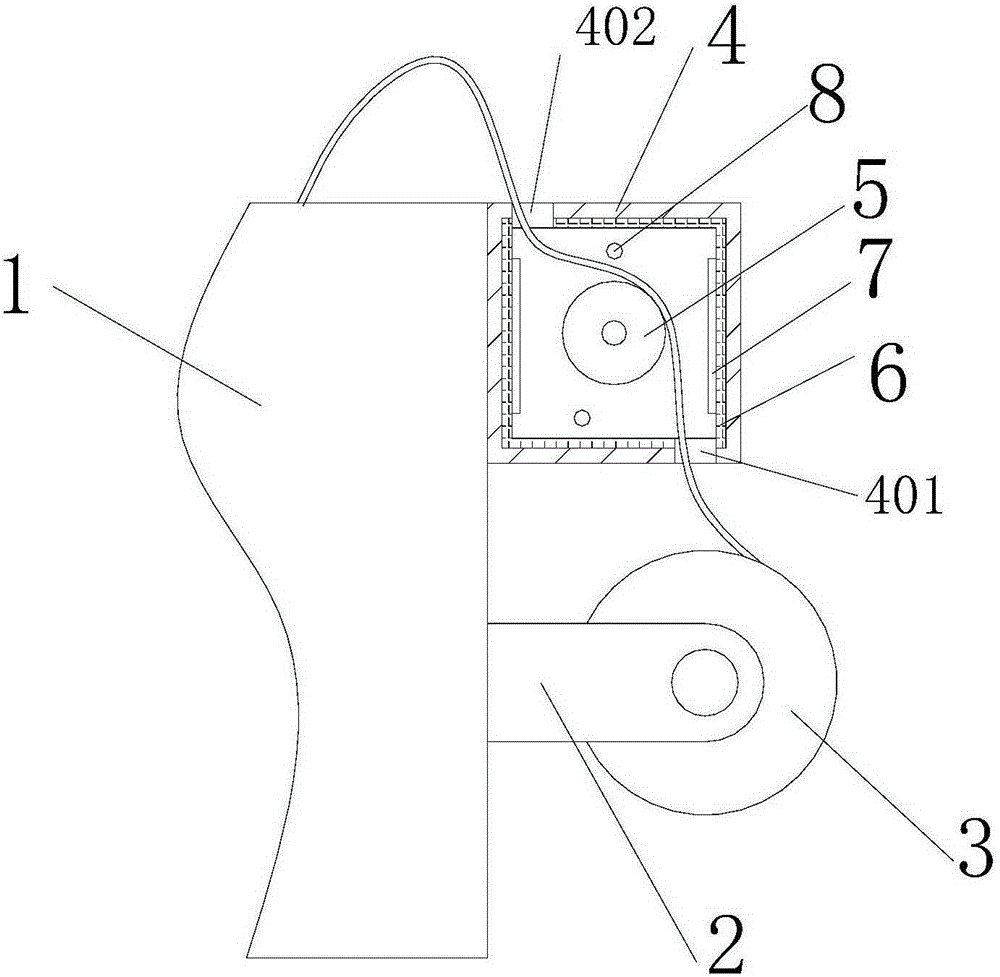

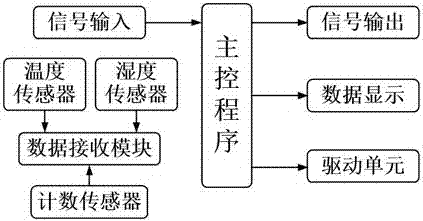

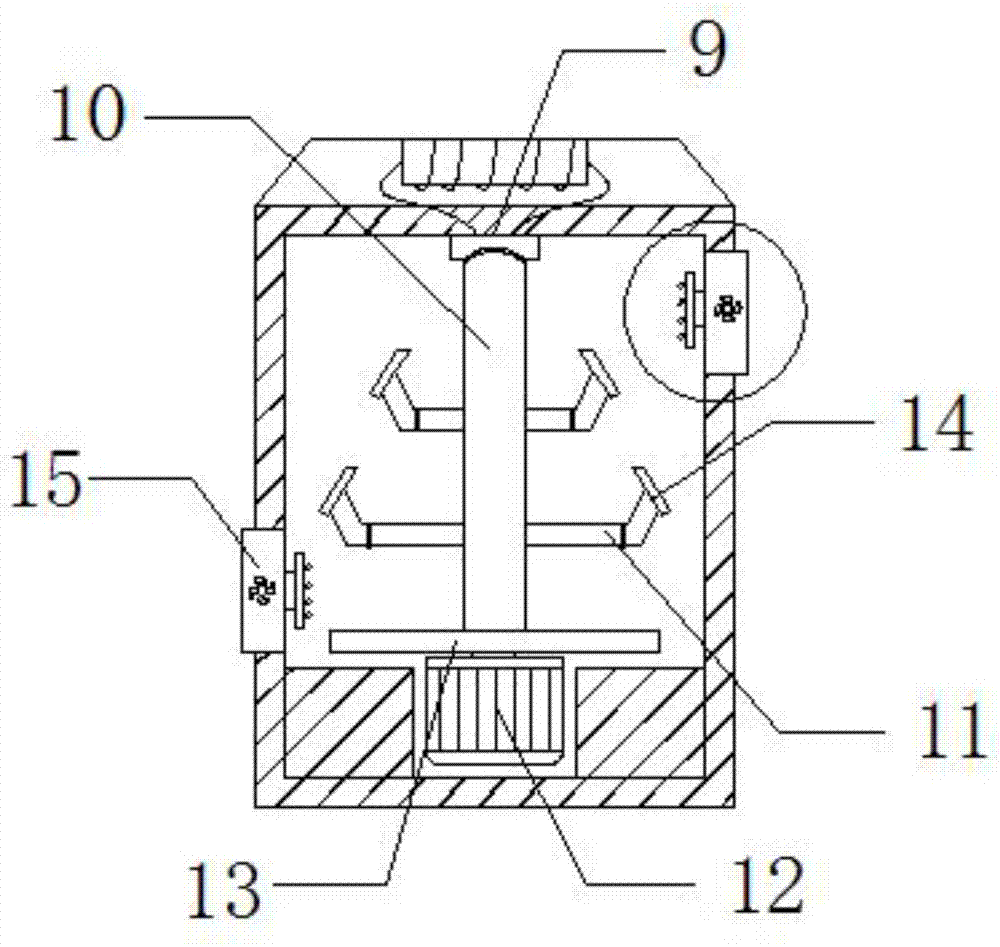

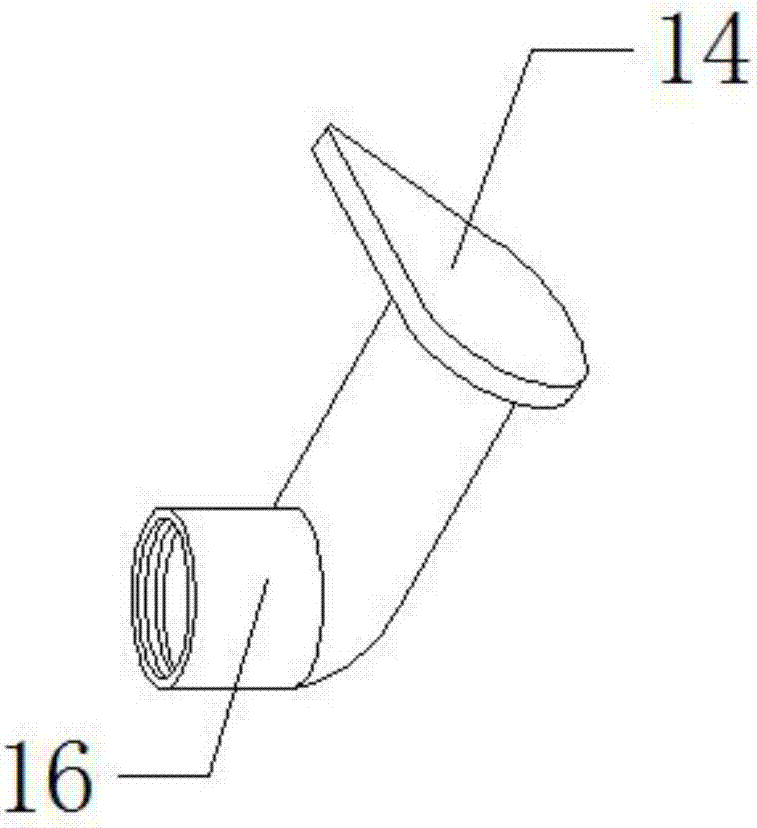

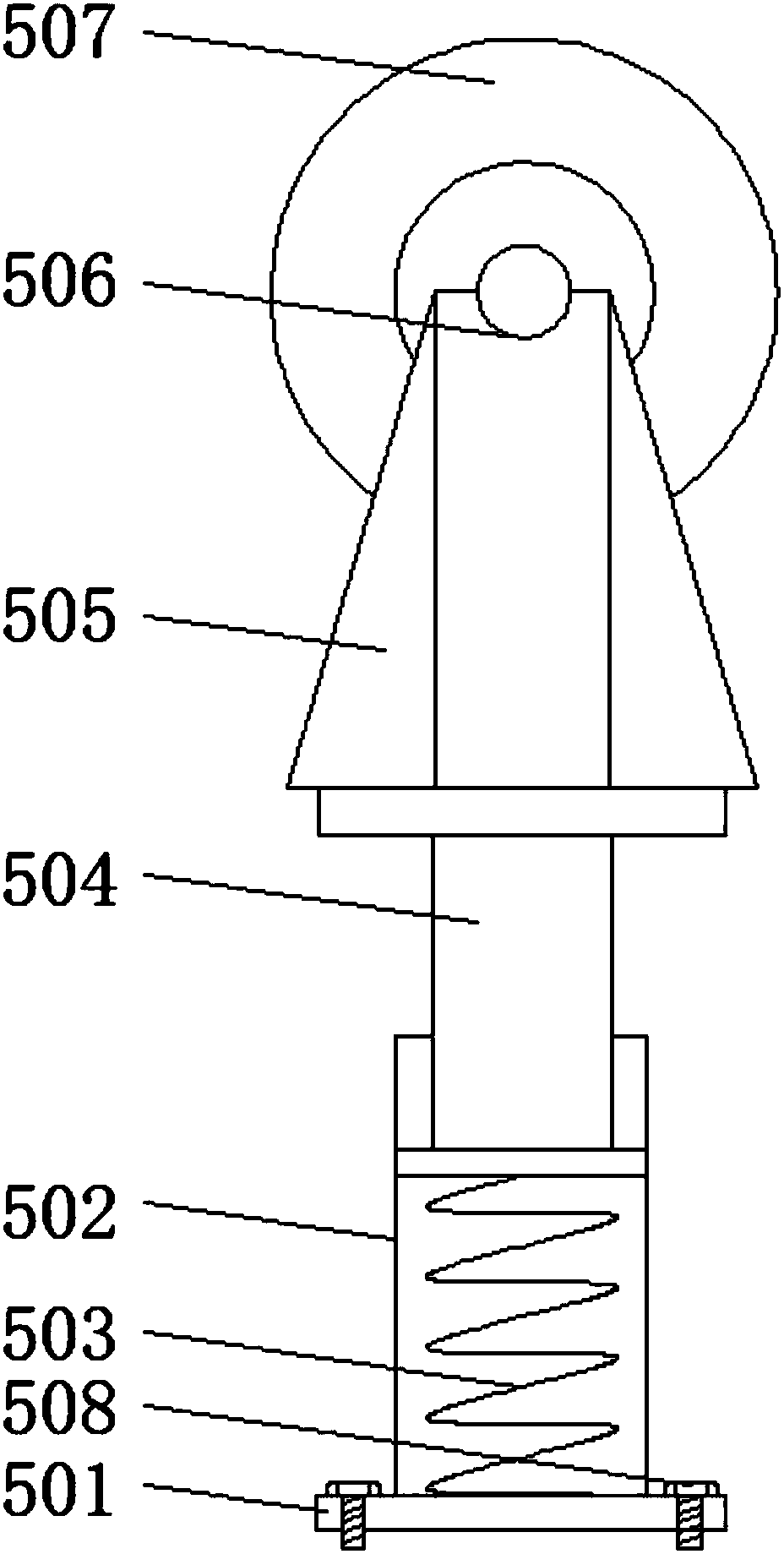

Consumable material drying device of 3D printer

InactiveCN105216313AHeating fastReduce performanceAdditive manufacturing apparatusEngineering3d printer

The invention relates to a consumable material drying device of a 3D printer. The consumable material drying device comprises a printer body. A fixing piece is arranged on one side of the printer body. A consumable material coiling block is arranged on the fixing piece. A drying box is arranged on one side of the printer body. A feeding hole is formed in one side of the lower end of the drying box, and a discharging hole is formed in the other side of the upper end of the drying box. A guiding wheel is arranged in the drying box. A thermal insulating layer is arranged on the inner wall of the drying box. Heating plates are arranged on the side walls of the thermal insulating layer. A plurality of temperature sensors are arranged in the drying box. When the consumable material drying device is used, a consumable material enters from the feeding hole and winds around the guiding wheel to stretch out of the discharging hole. The consumable material is heated through the heating plates, and the consumable material is rapidly heated. By means of the temperature sensors, the stability of the temperature in the drying box can be ensured, drying of the consumable material is accelerated. The 3D printing consumable material only needs to be dried at a time or does not need to be dried, and the influence of the high temperature on the performance of the consumable material during drying is reduced.

Owner:周末

Tire

ActiveUS20180264892A1Dry on-ice performanceDry stability performanceTyre tread bands/patternsEngineering

Owner:SUMITOMO RUBBER IND LTD

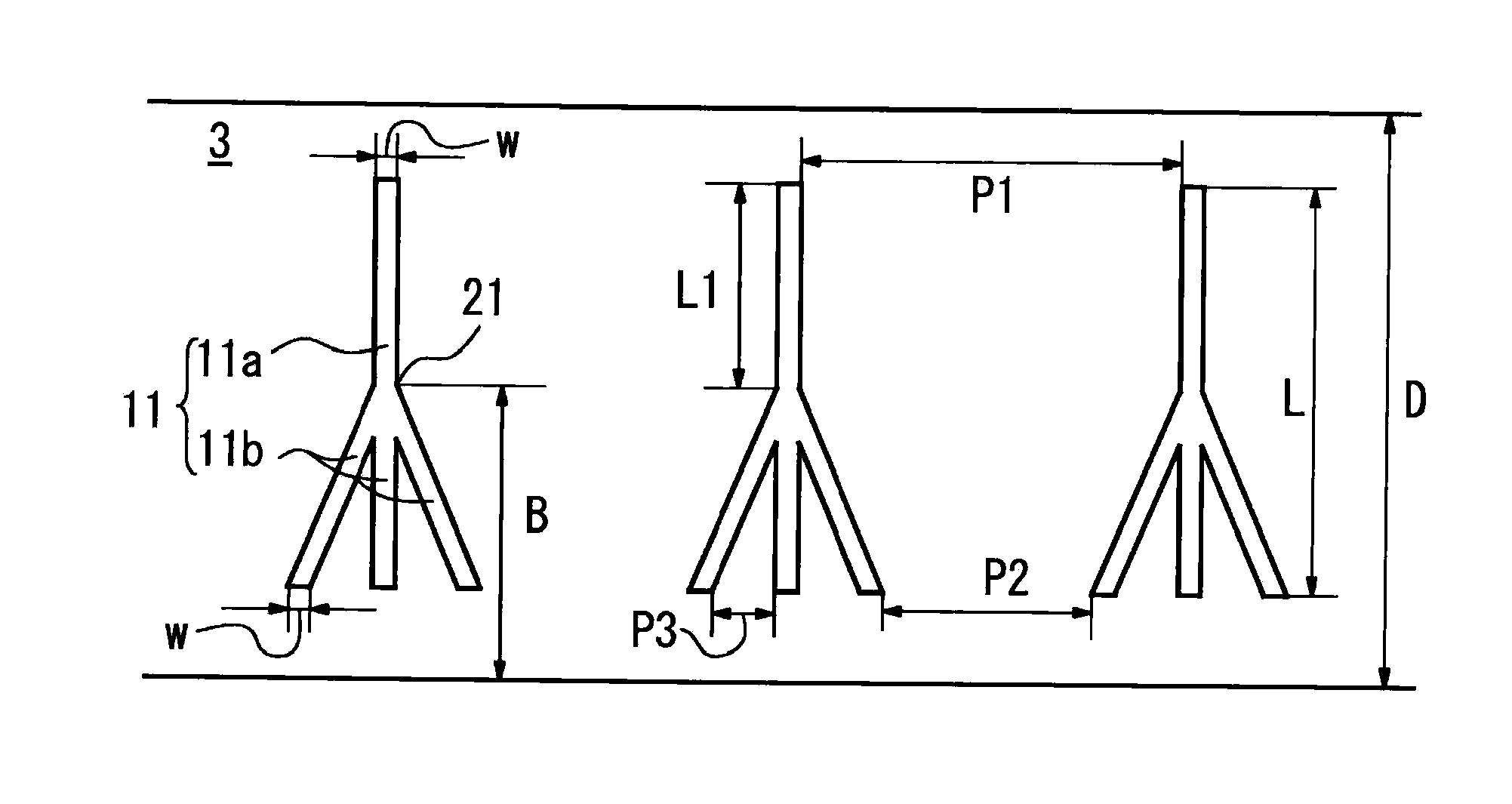

Pneumatic Tire

InactiveUS20100288408A1Reduce stiffnessIncrease airflowTyre tread bands/patternsNon-skid devicesResonanceNoise level

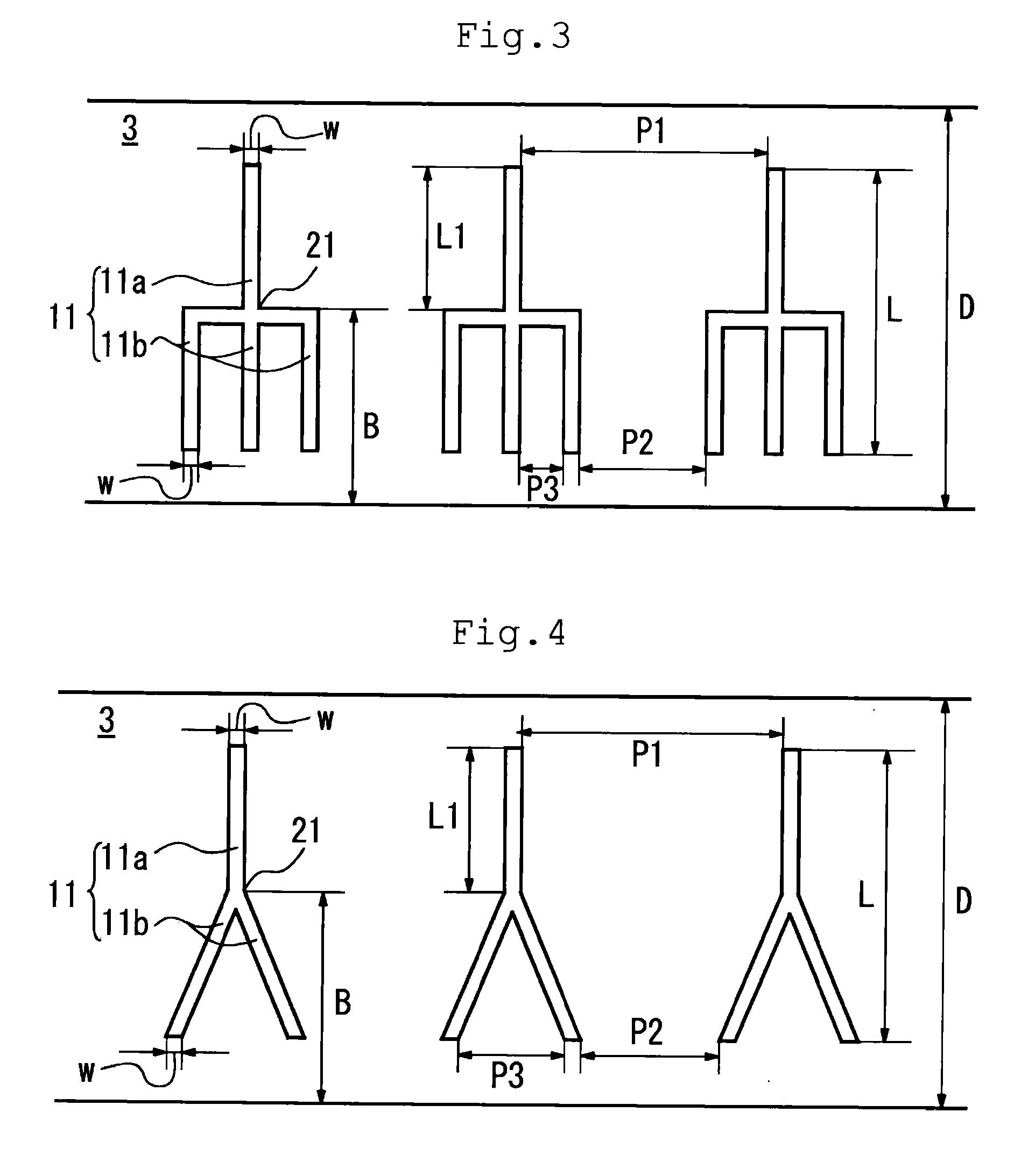

A pneumatic tire with improved steering stability without raising air columnar resonance noise level is provided. The pneumatic tire comprises upper thin grooves 11a extending from a branch point 21 in the depth direction of a main groove on the tread surface side and a plurality of lower thin grooves 11b extending from the branch point 21 in the depth direction of the main groove on the groove bottom side, which are formed at intervals along the tire circumferential direction R in a sidewall of the main groove and a distance B from the groove bottom of the main groove 1 to the branch point 21 is 30 to 60% of the depth D of the main groove 1.

Owner:TOYO TIRE & RUBBER CO LTD

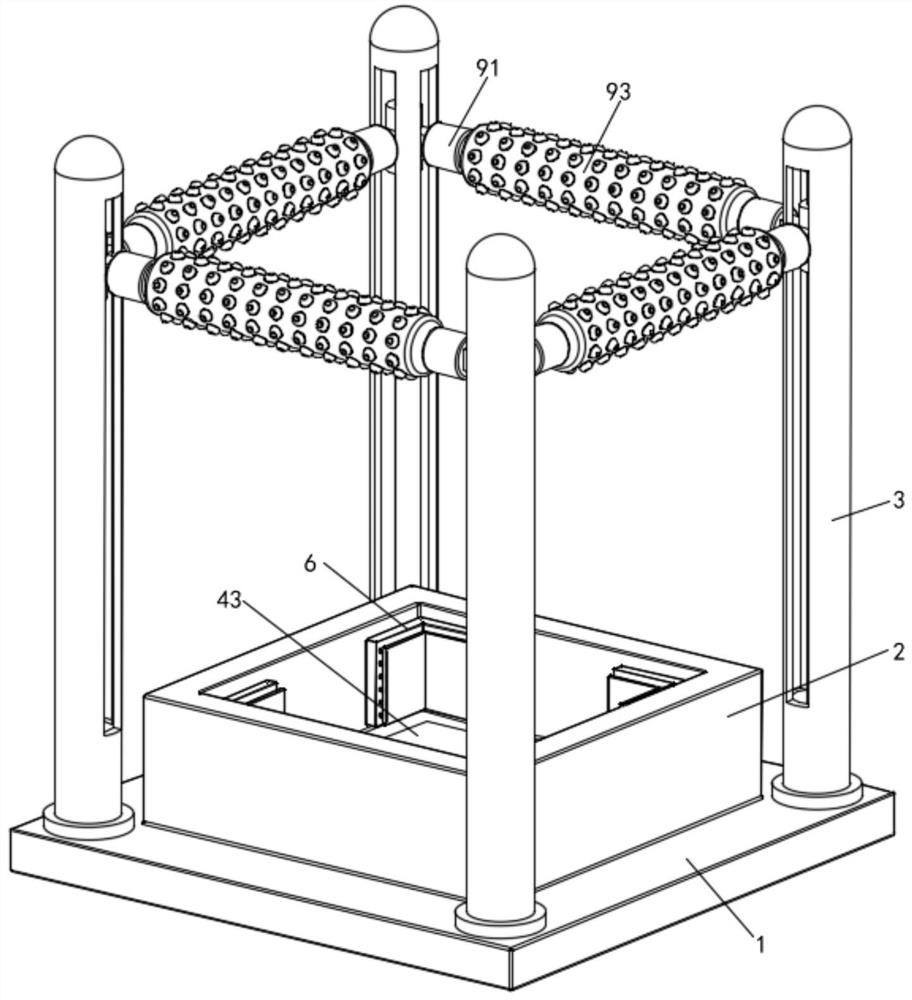

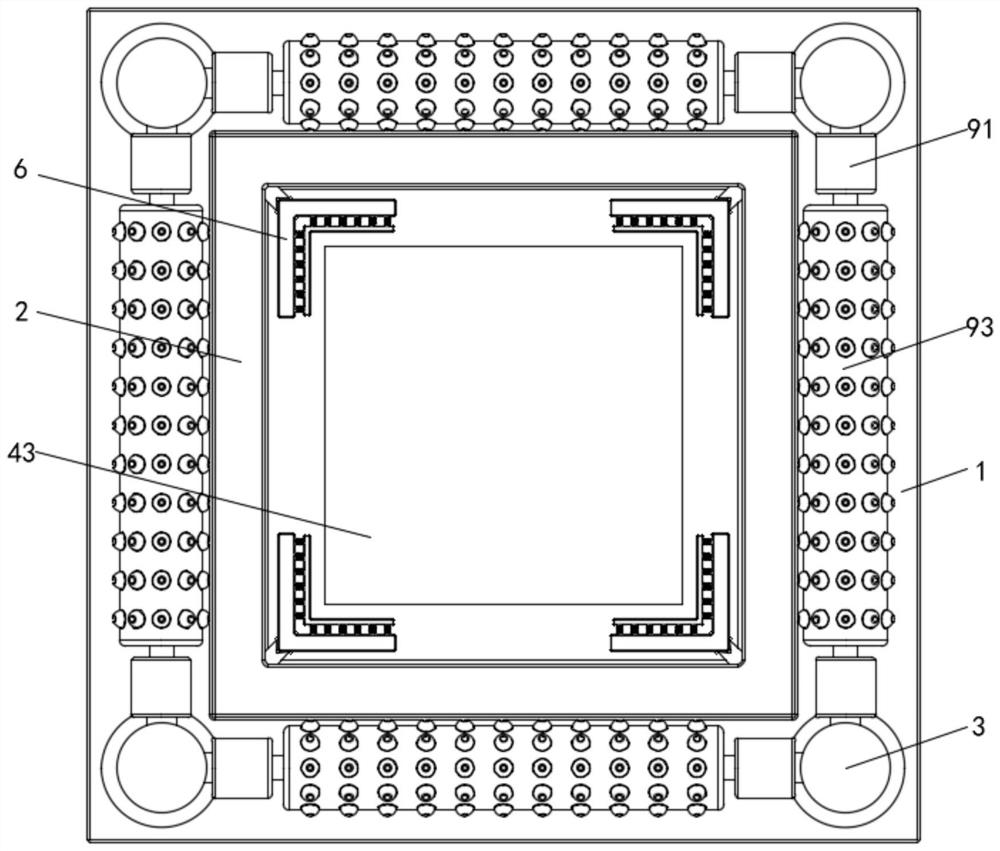

Lifting type cleaning mechanism for optical part obtained after coating

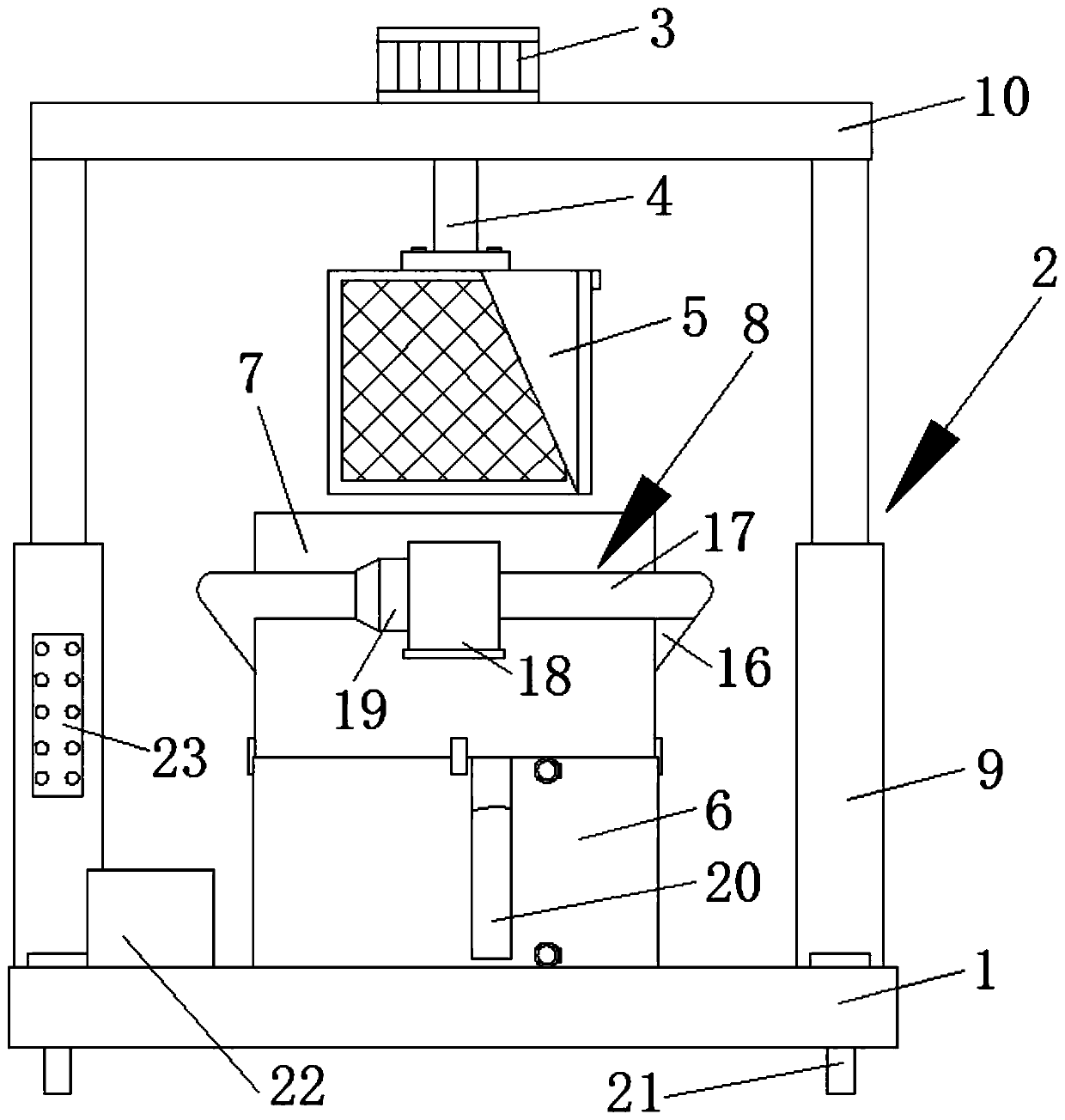

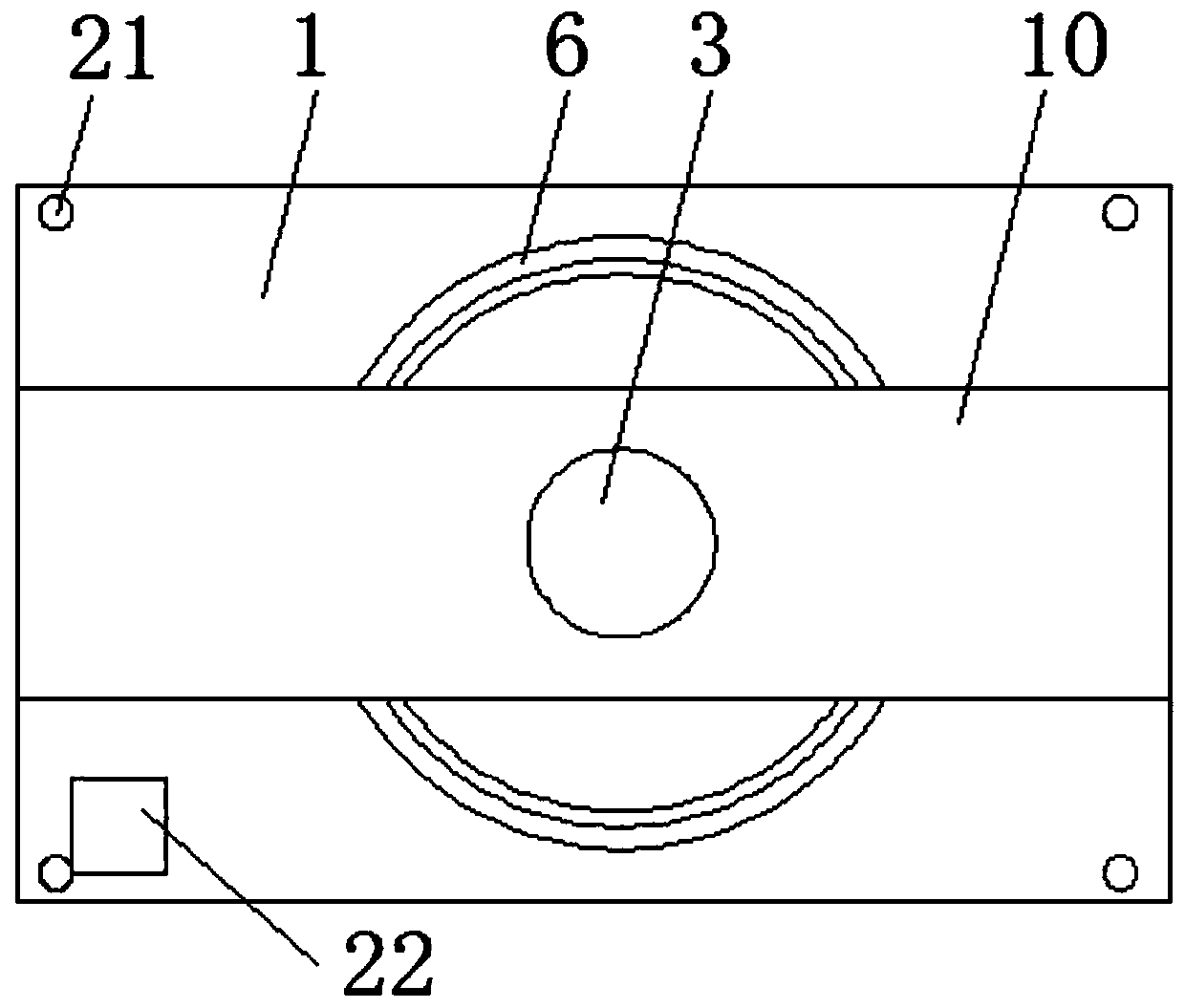

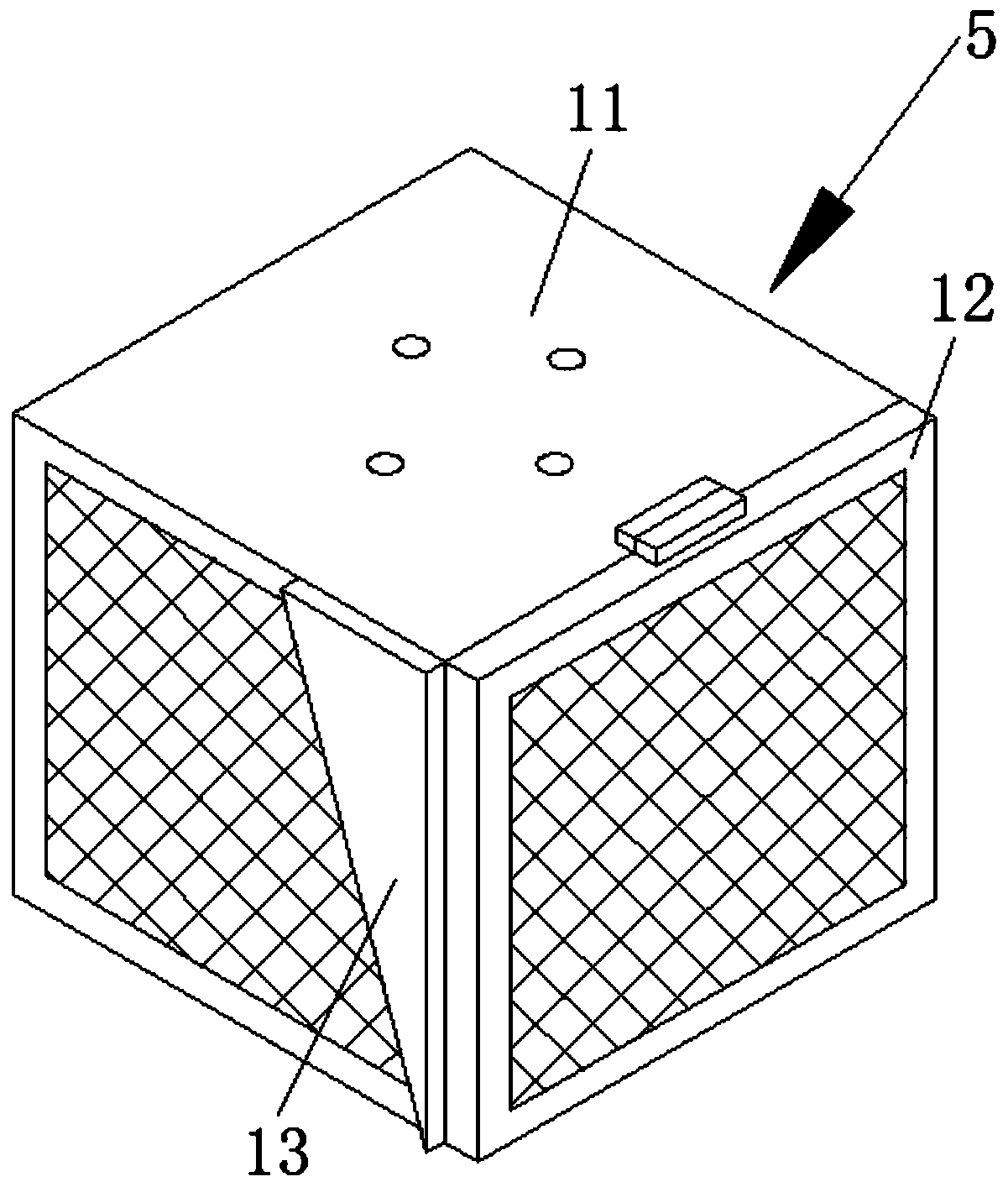

InactiveCN110586563AEasy to cleanDrying stabilityDrying solid materials with heatDrying solid materials without heatCouplingEngineering

The invention discloses a lifting type cleaning mechanism for an optical part obtained after coating. The lifting type cleaning mechanism comprises a workbench, a height adjusting device, a storage device and a drying device. The height adjusting device is welded to the top end of the workbench. A rotary motor is connected to the top end of a transverse plate of the height adjusting device througha screw. A rotary shaft is connected to an output shaft of the rotary motor through a coupling, and the lower half of the rotary shaft penetrates through a vertical through hole dug in the transverseplate. A round plate is welded to the bottom end of the rotary shaft. The storage device is connected to the round plate through a vertical bolt. A liquid storage bucket is arranged in a holding groove dug in the workbench. A protection device is arranged above the liquid storage bucket, and the drying device communicates with the periphery of the protection device. The height adjusting device comprises a vertical hydraulic rod and the transverse plate. Through the lifting type cleaning mechanism for the optical part obtained after coating, stable cleaning and drying can be conducted fast, and work efficiency is promoted.

Owner:扬州辰亚光学科技有限公司

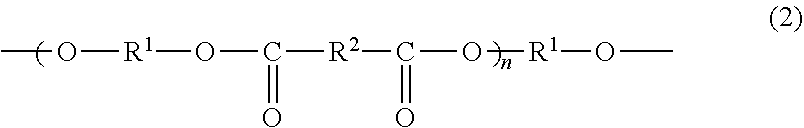

3D printing head, application method thereof and glue applied to 3D printing head

ActiveCN108327040AImprove smoothnessWide forming rangeAdditive manufacturing apparatusCeramic shaping apparatusFiberAsphalt

The invention provides a 3D printing head. The 3D printing head comprises a charging barrel, an aperture expansion device and a glue outlet device. The lower end of the charging barrel is provided with a discharge hole. The aperture expansion device is provided with a movable baffle. The glue outlet device is arranged on the periphery of the charging barrel in a surrounding mode. The lower end ofthe glue outlet device is provided with a glue outlet. The invention further provides an application method of the 3D printing head. The application method comprises the steps of applying force to theaperture expansion device to reform a new discharge hole; extruding out a printing material in the charging barrel from the new discharge hole to enable the peripheral surface of the printing material to be stained with the glue. The invention further provides the glue for the printing head. Concrete serves as the printing material. The glue comprises softening oil, asphalt, rubber, reinforced fiber, kieselguhr and a stabilizing agent. The 3D printing head has the advantages that the aperture expansion device is mounted on the 3D printing head; the discharge cross section of the discharge hole becomes smaller, and the material with the small cross section can be extruded; meanwhile, the glue outlet device is additionally arranged, the glue outlet is arranged outside the discharge hole, the surface of the printing material can be stained with the glue after the printing material is extruded out from the discharge hole, and the next step of bonding is facilitated.

Owner:NANTONG INST OF TECH

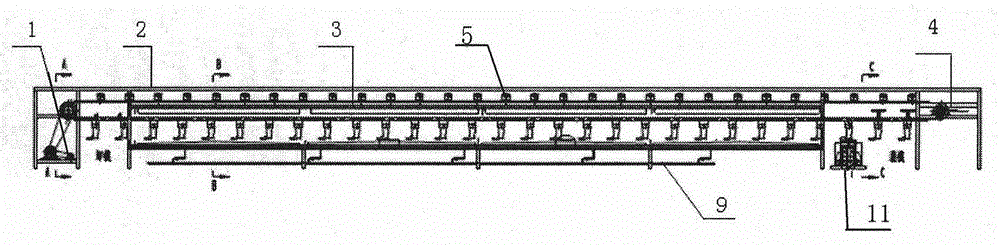

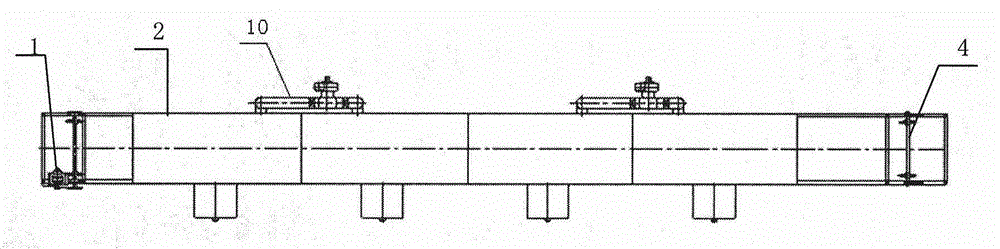

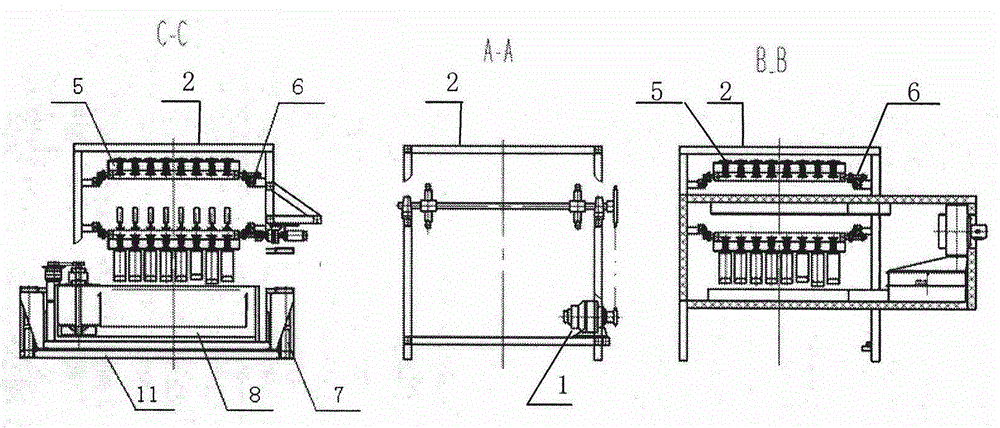

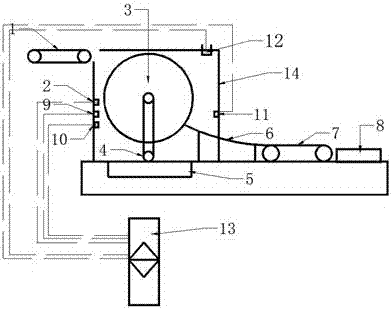

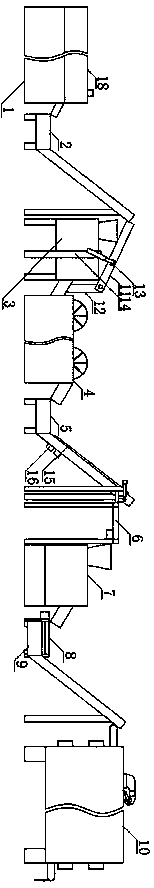

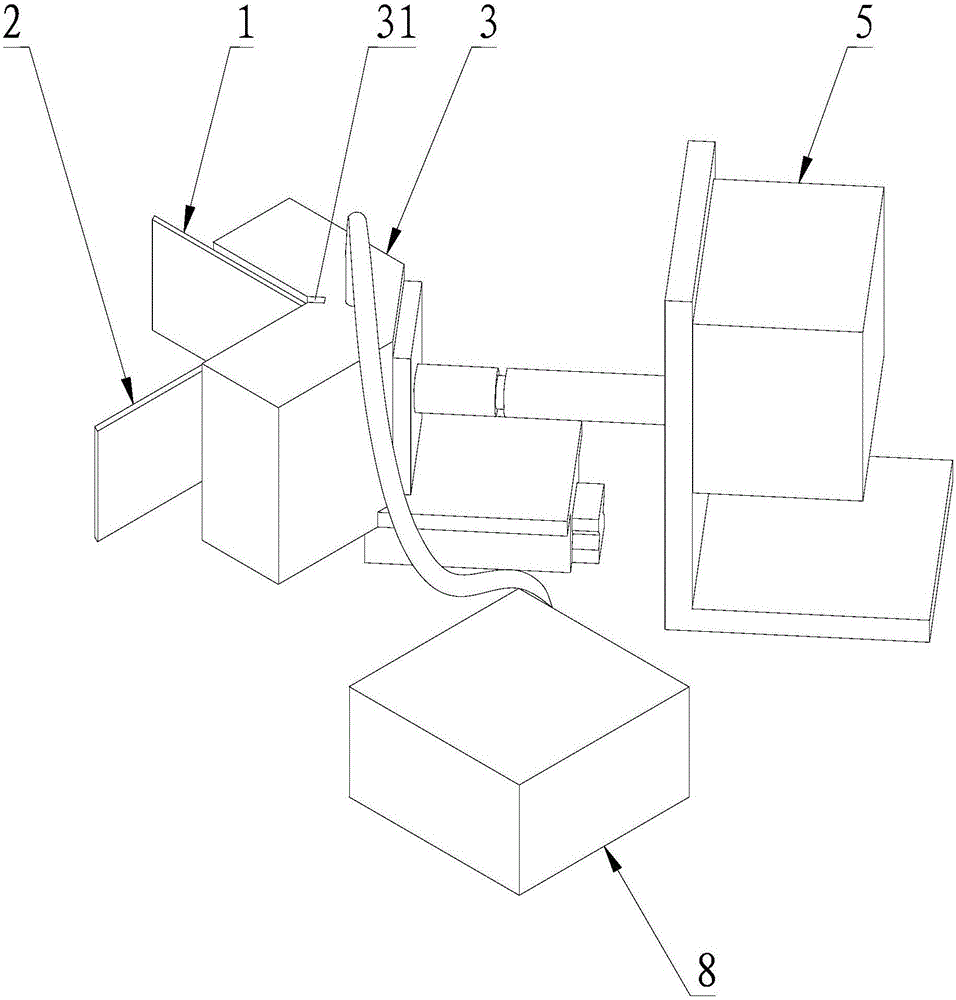

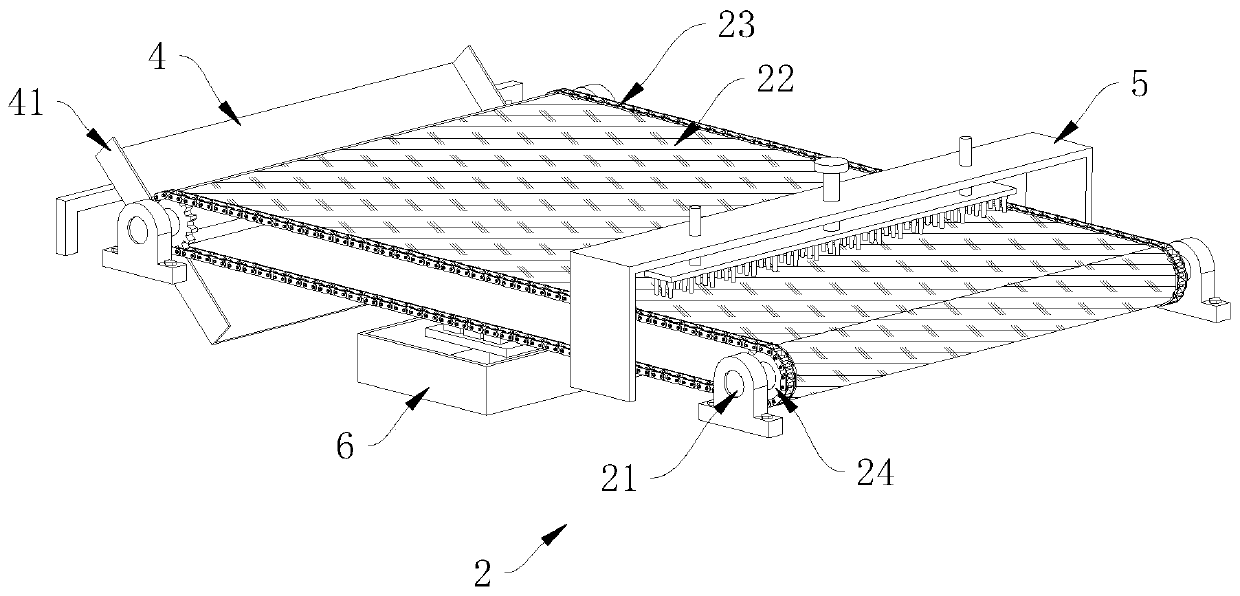

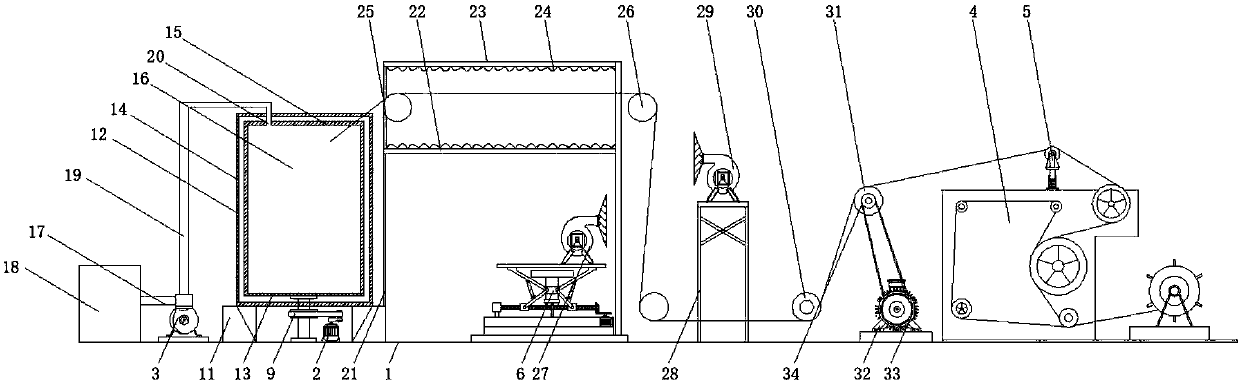

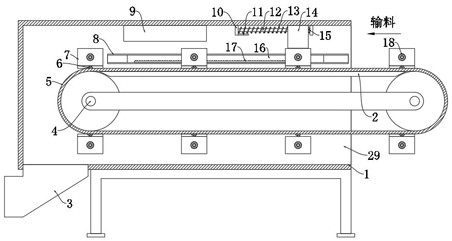

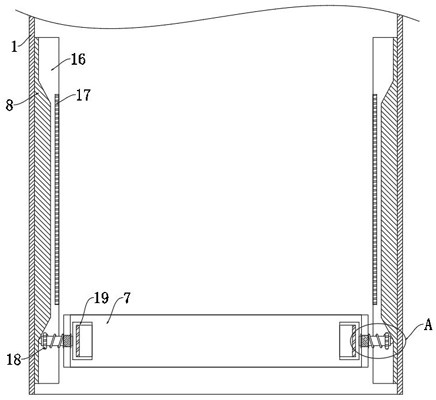

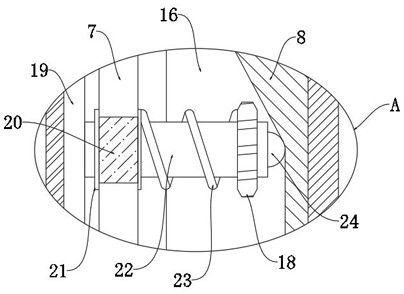

Rubber shoe lining impregnation device and method for automatically impregnating rubber shoe linings by rubber shoe lining impregnation device

The invention belongs to a rubber shoe lining impregnation device and a method for automatically impregnating rubber shoe linings by the rubber shoe lining impregnation device. The impregnation device comprises a driving part, a frame, an oven, a driven wheel part, mold cars, a chain part, an impregnation groove, a steam pipeline and moisture exhaust parts, wherein the driving part, the oven, the driven wheel part, the mold cars, the chain part, the impregnation groove, the steam pipeline and the moisture exhaust parts are fixed on the frame. The rubber shoe lining impregnation device is characterized in that the driving part and the driven wheel part are distributed at two ends of the frame, the oven and the impregnation groove are sequentially arranged in the frame from left to right, the chain part is sleeved with the driving part and the driven wheel part respectively, the driving part drives the driven wheel part to rotate by the chain part, the mold cars are arranged on the chain part, shoe trees are arranged on the mold cars and provided with shoe linings, and the shoe trees on the mold cars sequentially pass the impregnation groove and the oven as the chain part rotates. The rubber shoe lining impregnation device and the method for automatically impregnating the rubber shoe linings can substitute for a manual rubber coating mode, production efficiency is greatly improved, stability in production is ensured, and serious harms to health of workers due to pollution are avoided.

Owner:北京华腾橡塑乳胶制品有限公司

Panel processing equipment for furniture manufacturing

InactiveCN109489394AEffective compactionAvoid deformationDrying solid materials with heatDrying machines with progressive movementsEngineeringMoisture sensor

The invention discloses panel processing equipment for furniture manufacturing. The panel processing equipment comprises a driving machine case, a rack, a conveying belt, a driving press roll, an infrared heating tube and a drying room body. The driving machine case is arranged on the rack and provided with the conveying belt. The drying room body is arranged above the conveying belt and mounted on the driving machine case. A temperature sensor and a humidity sensor are mounted on the top wall inside the drying room body. The infrared heating tube is mounted on the inner wall of the drying room body. The driving press roll and a driven press roll are mounted inside the drying room body. The top of the drying room body is provided with a temperature and humidity adjustment opening. The panel processing equipment for furniture manufacturing is simple in structure and convenient to use; by means of the drying room body, different panels can be better in adaptability, the drying process ismore stable, and the drying effect is better; the panels can be compacted effectively; the problem that the panels deform due to drying is prevented; the drying temperature and humidity are controlled precisely; and the panel processing equipment is stable in performance and good in processing effect.

Owner:泰兴市万福隆红木家具有限公司

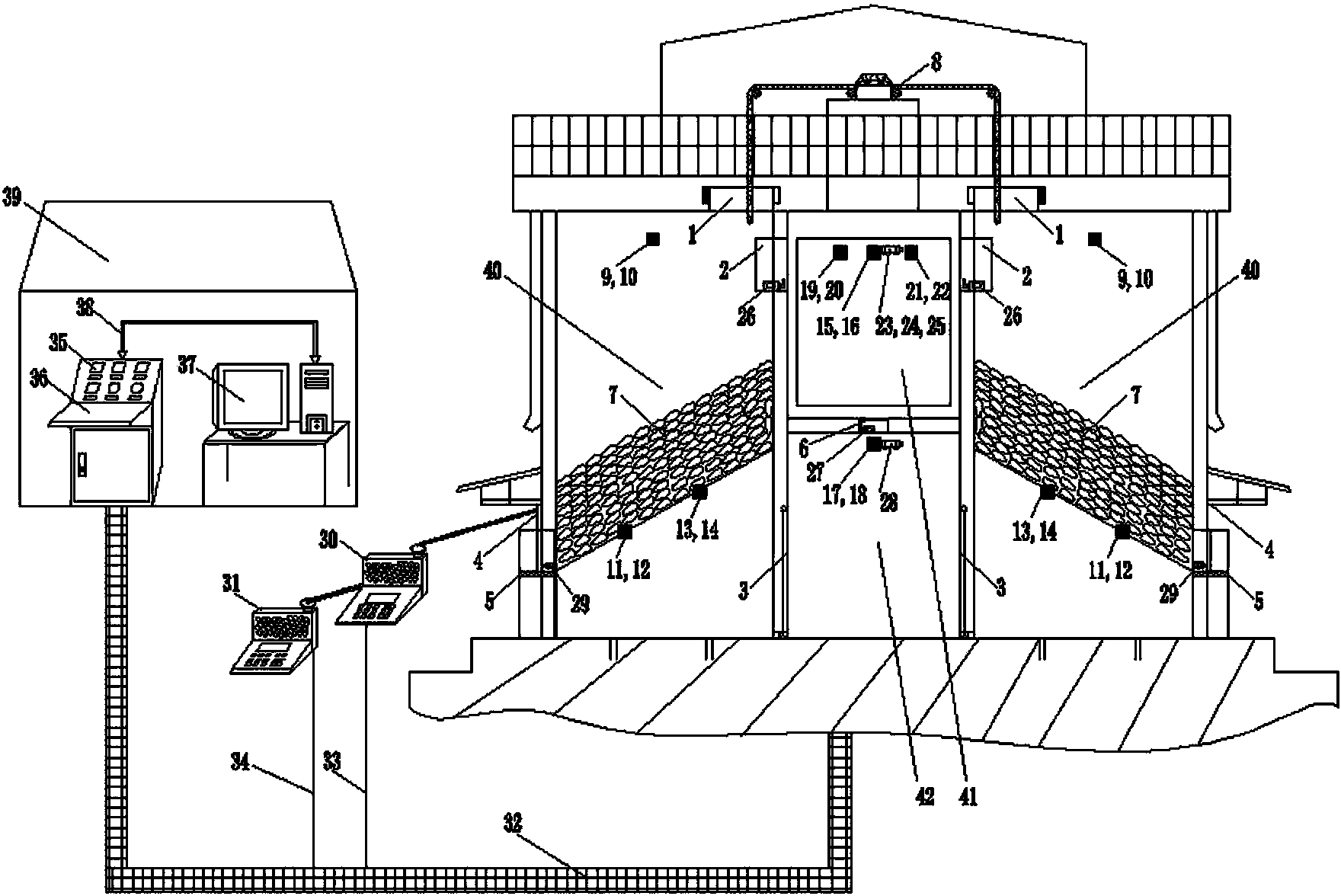

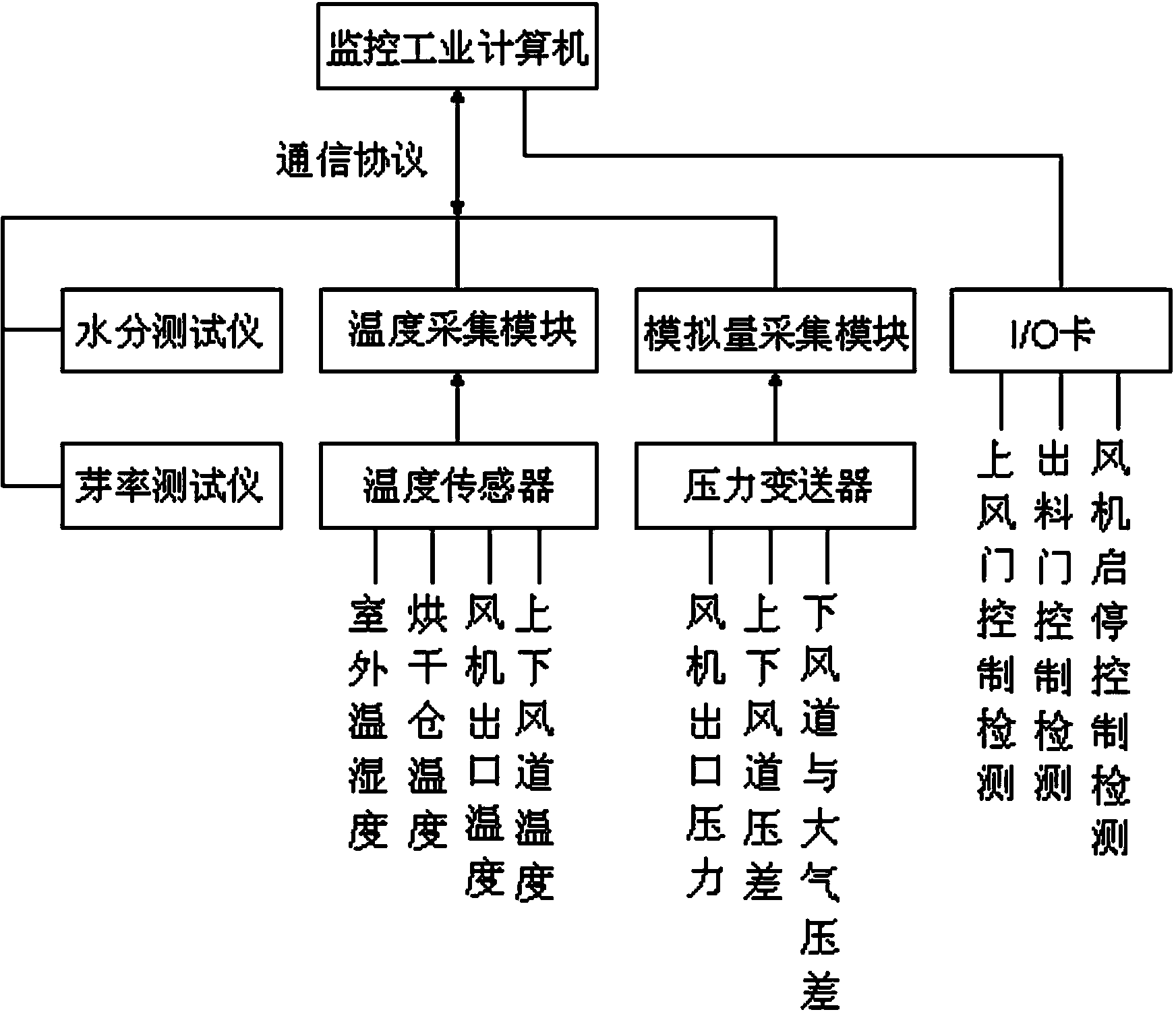

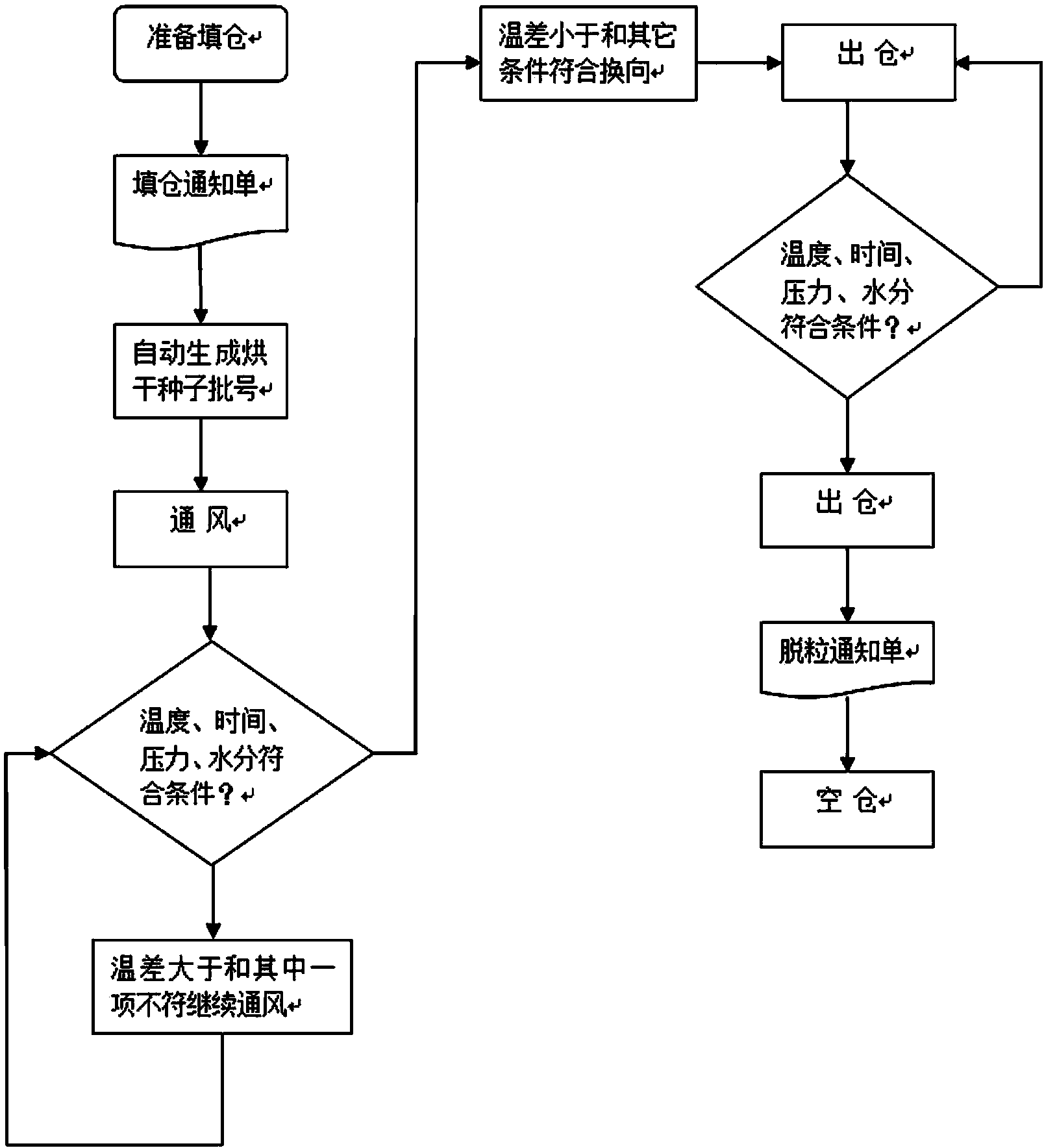

Online corn seed drying, measurement and control system

InactiveCN103744410ASpeed up dryingImprove germination rateTotal factory controlProgramme total factory controlDynamic displayProcess engineering

An online corn seed drying, measurement and control system is mainly formed by a multipoint connection temperature sensor, a temperature collecting unit, an analog collecting module, a monitoring industrial computer and software, a voltage stabilizing power supply and a UPS (uninterrupted power supply) for power-off delay; the temperature detection of the field temperature sensor adopts a thermalcouple compensation lead, and the compensation lead forms a closed loop by a high-temperature spot-welding processing and cold-end prolonging technology; a mode of obtaining an average value by multipoint connection is adopted, and measurement and control points are conveniently, reasonably and uniformly distributed in upper and lower bins. Corns in the bins adopt an oblique heaping mode in different bins. The computer software has the functions of dynamic display realizing, real-time and historical curve displaying, process operation prompting and event recording, pressure difference alarm, historical data inquiring, drying state displaying, drying result recording, report table printing, and real-time displaying of bin number of a drying bin, seed variety, bin filling weight, drying starting time, drying time, temperature difference, fan direction and the like in the whole production process, the drying result is subjected to database link, and is automatically added, recorded in real time and stored, and historical production data can be traced.

Owner:LANZHOU YANXIN ELECTRONICS SCI & TECH

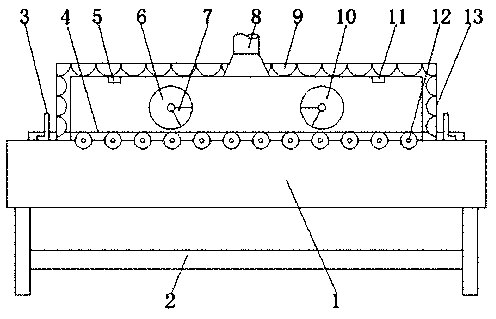

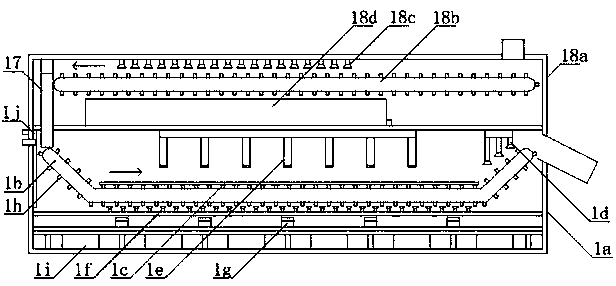

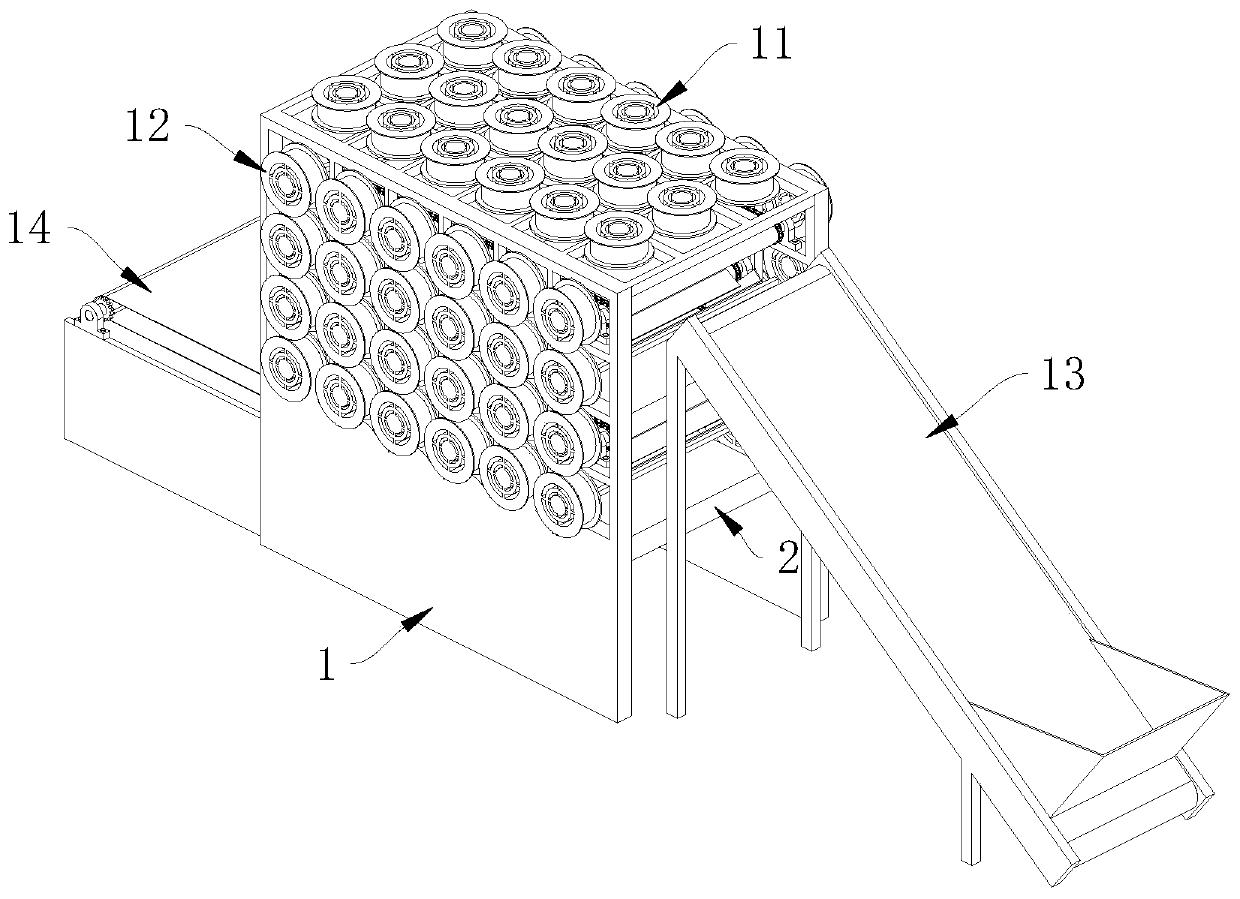

Novel vermicelli drying equipment

PendingCN107478036ASave drying spaceSpeed up the drying processDrying gas arrangementsDrying machines with progressive movementsTransmission systemEngineering

The invention discloses novel vermicelli drying equipment which is relatively high in degree of automation. The novel vermicelli drying equipment comprises a suspending transmission system, a detecting and drying system and an automatic rod collecting system, wherein the suspending transmission system drives an upper suspending circular disc to rotate through a transmission device, so that rotary conveying of vermicelli is realized. A temperature and humidity sensor and an infrared detecting system are mounted inside a box body of the detecting and drying system, so that monitoring on internal environment and quantity of the vermicelli is performed. The automatic rod collecting rod is mainly composed of a rod collecting slide rail on the rear part of equipment, and a conveyor belt. The novel vermicelli drying equipment has the characteristics of high production efficiency, high degree of automation, a good sanitary condition, no environmental limitation, high product quality and the like.

Owner:LINYI UNIVERSITY

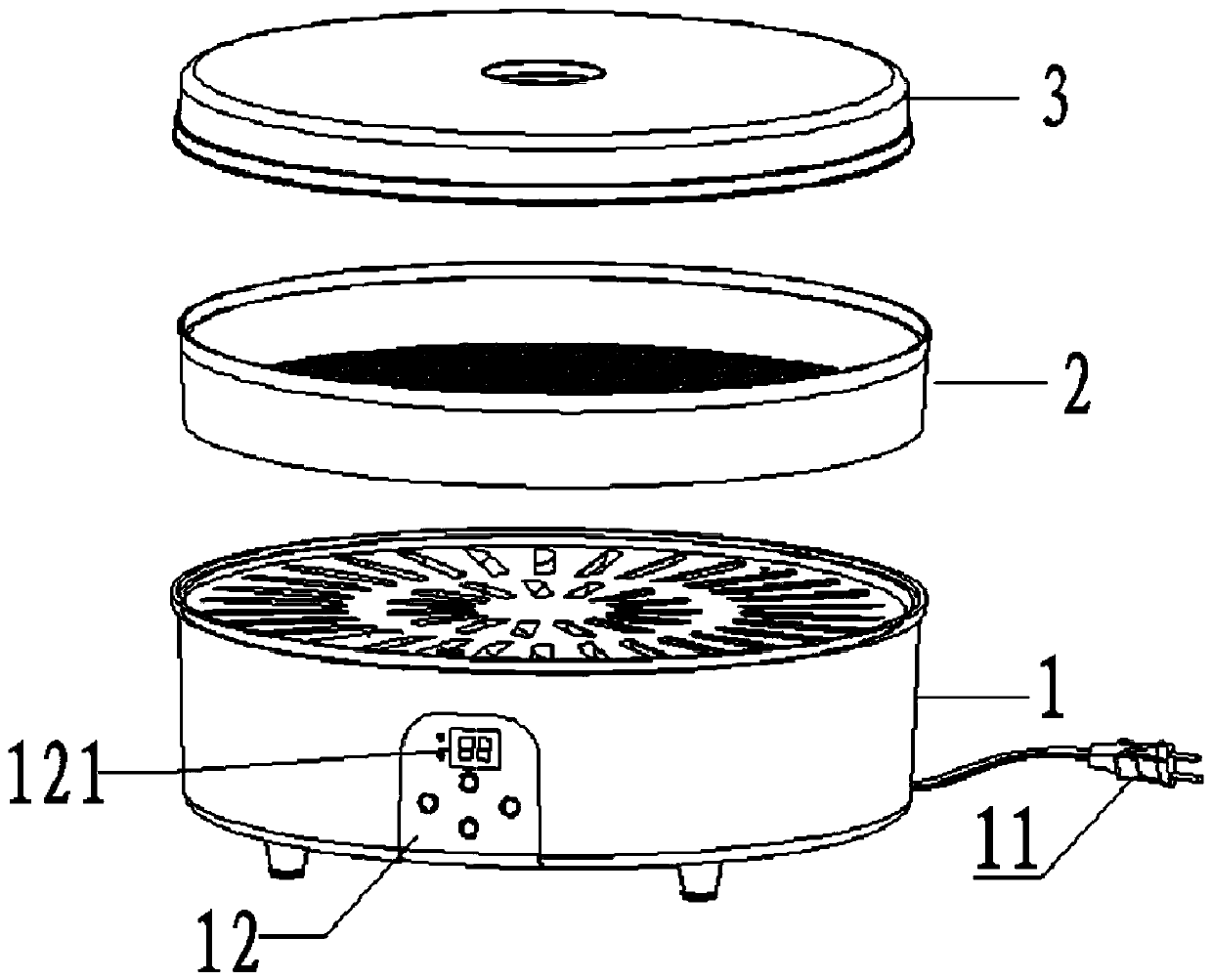

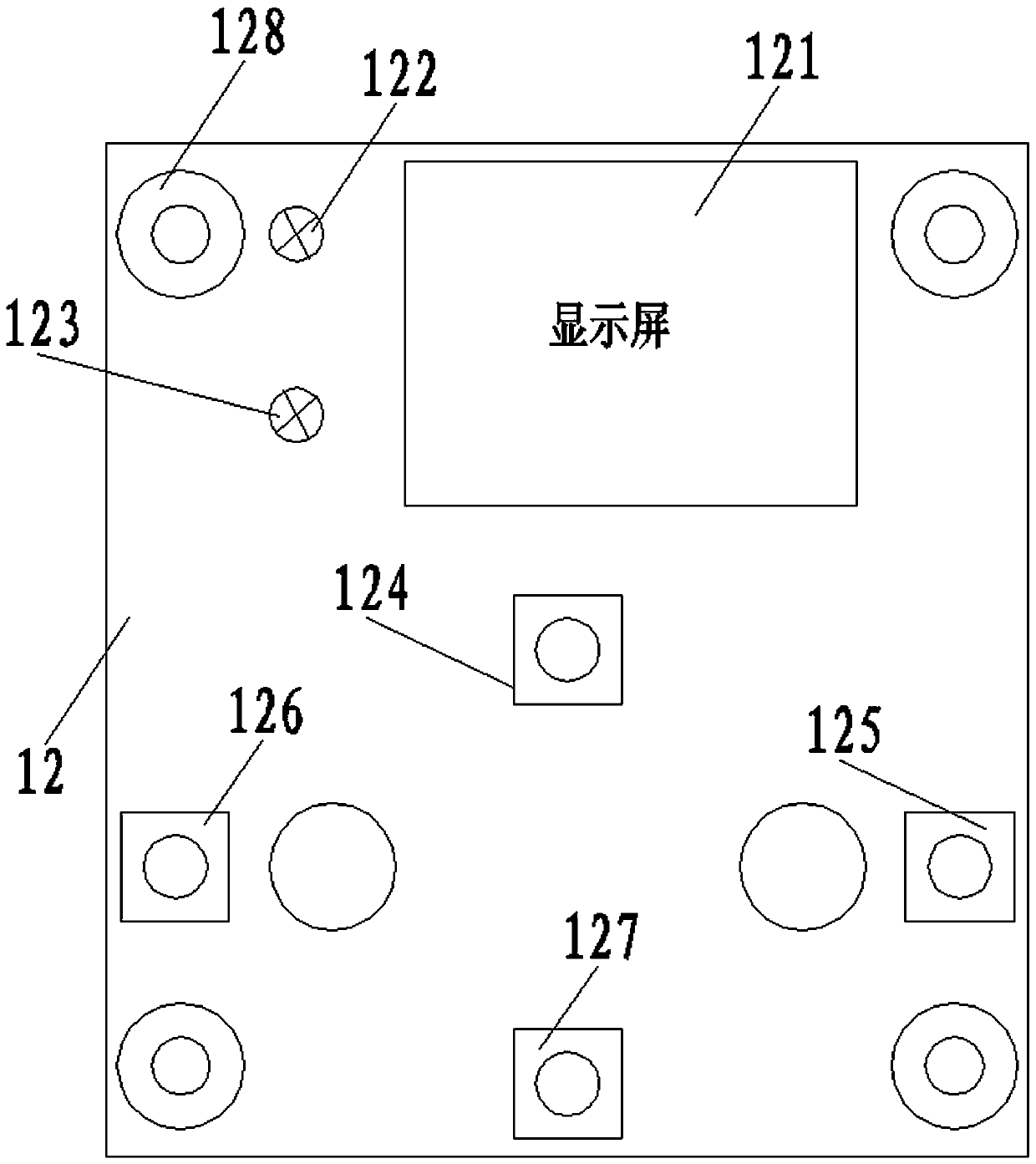

Household fruit-and-vegetable drying fragrance-improving method based on dryer

The invention discloses a household fruit-and-vegetable drying fragrance-improving method based on a dryer. The dryer comprises a base, a net disc and an upper cover, wherein the base, the net disc and the upper cover are sequentially stacked from bottom to top; an air outlet is formed in the upper cover; a drying bed is also arranged in the base, and is arranged below the net disc, and a controller is arranged in the base. The drying fragrance-improving method includes the following steps that (1) fruit-and-vegetable raw materials are laid on the net disc; (2) different working parameters areset for the different fruit-and-vegetable raw materials, are set through an operation panel arranged on the base, and comprise the temperature parameter and the time parameter; (3) heating is carriedout, an electric heating pipe is started, and the temperature in the dryer is heated and kept being at the set temperature; (4) an electric fan is started while the step (3) is carried out; (5) the dryer is stopped after reaching set working time.

Owner:ZHAOQING HI TECH ZONE GUOZHUAN TECH CO LTD

Tire

ActiveUS10994575B2Dry performanceDrying stabilityTyre tread bands/patternsStructural engineeringMechanical engineering

Owner:SUMITOMO RUBBER IND LTD

Ink Jet Printing Clear Ink Composition, Ink Jet Printing Ink Set, And Ink Jet Printing Method

ActiveUS20190284420A1Reliability advantageLow viscosityDuplicating/marking methodsInksPolymer sciencePrinting ink

Owner:SEIKO EPSON CORP

Ceramic drying equipment capable of working circularly

InactiveCN112013659ADrying stabilityAvoid breakingDrying gas arrangementsDrying chambers/containersCeramicElectric heating

The invention belongs to the technical field of ceramic production equipment, and particularly relates to ceramic drying equipment capable of working circularly. The equipment comprises a V-shaped ceramic drying base box, a ceramic feeding port is formed in one end of the V-shaped ceramic drying base box, a ceramic discharging port is formed in the other end of the V-shaped ceramic drying base box, and first electric heating pipes are evenly arranged at the bottom of the inner wall of the V-shaped ceramic drying base box. A driving transmission guide roller, a driven transmission guide rollerand a transmission chain are matched with one another, cyclic uniform-speed driving of a ceramic storage box can be realized, and ceramic is placed in the ceramic storage box, so that circular dryingtreatment can be carried out. A first pre-drying mechanism and a second pre-drying mechanism are arranged on the outer side of the ceramic feeding port and can be used for conducting preliminary heating and drying treatment on the ceramic, stress in a ceramic blank can be reduced, product quality is improved, and the quality of the ceramic can also be improved in the subsequent drying process.

Owner:GUANGDONG JIYU PORCELAIN CORP

Production system of dehydrated edible fungi and production method of production system

ActiveCN109805356ARealize non-stop transportationHigh degree of automationMetal working apparatusFood treatmentProcess engineeringSodium hypochlorite solution

The invention discloses a production system of dehydrated edible fungi. The production system comprises a washing device, a first lifting and conveying device, a slicing device, a disinfection and rinsing device, a second lifting and conveying device, a material distribution device, a centrifuging and dehydration device, a material guide and conveying device, a third lifting and conveying device and a drying device, which are arranged in sequence. The production system disclosed by the invention has the advantages of high automation degree and large treatment amount. The invention further discloses a production method of the production system of the dehydrated edible fungi; the production method comprises the following steps: firstly, washing edible fungi; then putting the edible fungi into a sodium hypochlorite solution and disinfecting and rinsing; blowing air to the disinfected edible fungi and carrying out pre-dehydration treatment; then centrifuging and dehydrating; then drying the edible fungi through hot air to obtain the dehydrated edible fungi. The production method disclosed by the invention ensures the food sanitation and safety of finished-product dehydrated edible fungi and the production time is easy to shorten.

Owner:YUNNAN LONGYUN DAYOU IND CO LTD

Plate processing invention equipment for furniture manufacturing

InactiveCN106813485AEffective compactionAvoid deformationDrying gas arrangementsDrying machines with progressive movementsEngineeringMoisture sensor

The invention discloses a board processing invention equipment for furniture manufacturing, which comprises a drive case, a frame, a conveyor belt, an active pressure roller, an infrared heating tube and a drying room body, the frame is provided with a drive case, and the drive case is installed There is a conveyor belt, and a drying room is installed above the conveyor belt. The drying room is installed on the drive chassis. The inner top wall of the drying room is installed with a temperature sensor and a humidity sensor, and an infrared heating tube is installed on the inner wall of the drying room. , the inside of the drying room is equipped with active pressure rollers and driven pressure rollers, and the top of the drying room is provided with a temperature and humidity adjustment port. The inventive equipment for processing boards for furniture manufacturing has a simple structure and is easy to use. The room body can achieve better applicability to different boards. The drying process is more stable, and the drying effect is better. It can effectively compact the boards, prevent the deformation of the boards caused by drying, and precisely control the drying temperature and humidity. , stable performance and good processing effect.

Owner:QINGDAO XINYIFA IND & TRADE

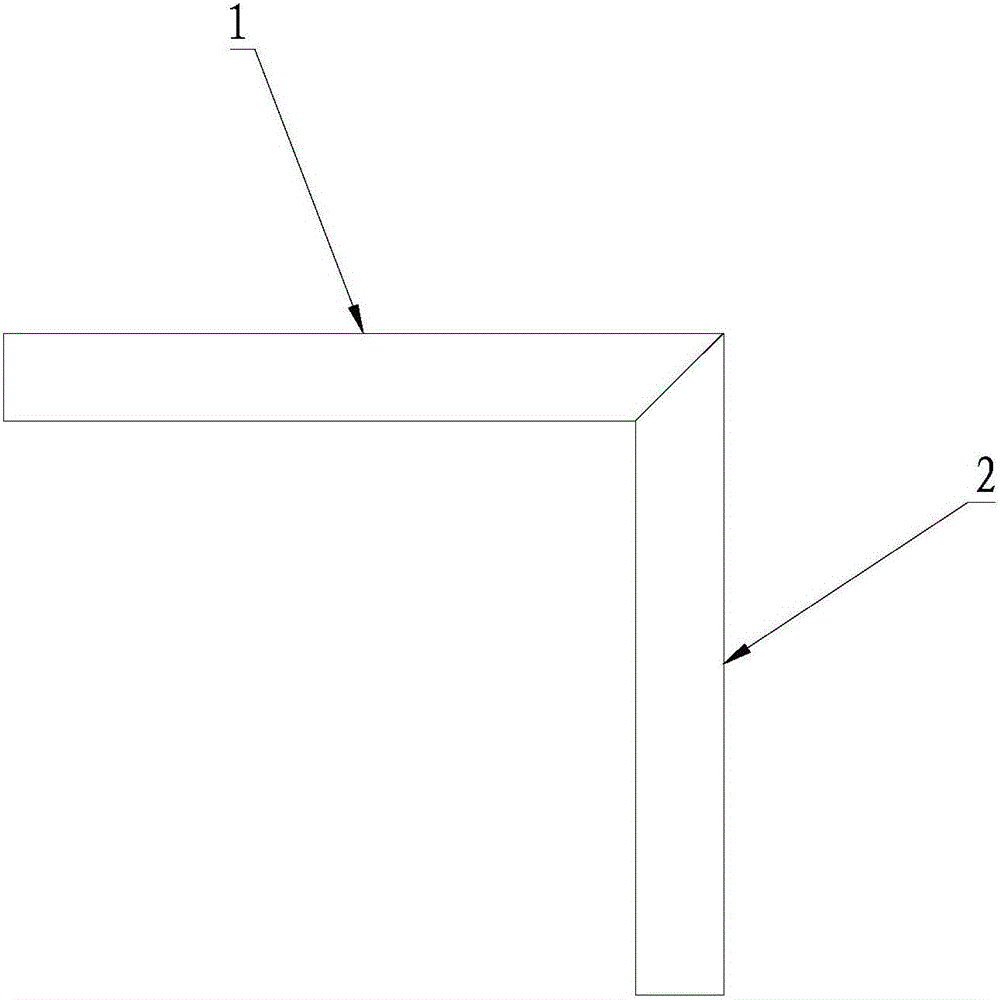

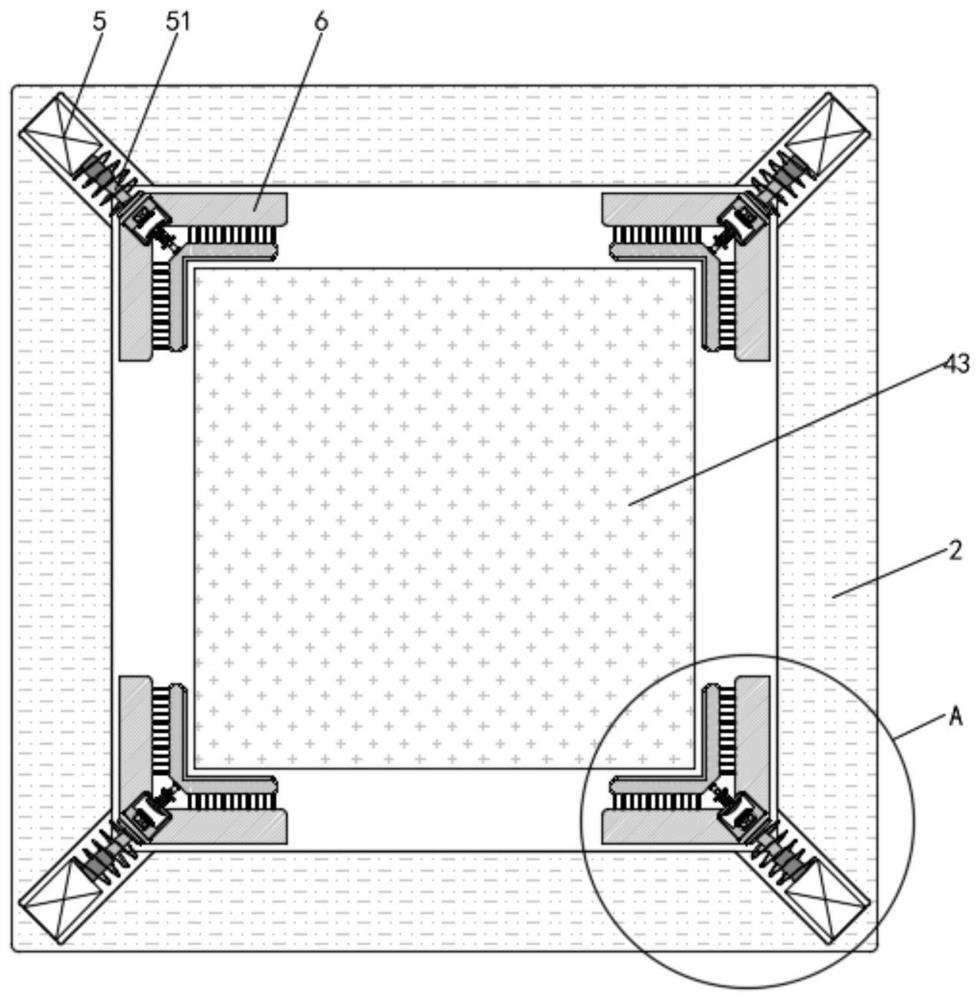

Rapid assembly clamp for right-angled plate

InactiveCN106076766ASimple production equipmentReduce drying energy consumptionPretreated surfacesCoatingsElectric heatingBonding strength

The invention relates to a rapid assembly clamp for a right-angled plate. The rapid assembly clamp for the right-angled plate comprises a clamp body and an electric heating bar. A right-angled groove is formed in the side face of the clamp body. The groove wall of the right-angled groove is composed of a first clamping surface and a second clamping surface which is perpendicular to the first clamping surface. A glue discharging groove is formed in the intersection of the first clamping surface and the second clamping surface. The upper end and the lower end of the glue discharging groove communicate with the top surface and the bottom surface of the clamp body correspondingly. An electric heating bar installation hole is formed in the clamp body. The electric heating bar is installed in the electric heating bar installation hole and used for heating the clamp body. The rapid assembly clamp for the right-angled plate is suitable for gluing production of the right-angled plate, can guarantee the squareness of the plate, improve the assembly efficiency, fix the plate stably, reduce drying energy consumption and improve the drying efficiency; and in addition, the situation that the bonding strength of products is reduced and the appearance of the products is affected due to overflowing of glue or bubbles generated in the products can be effectively avoided.

Owner:FUJIAN LONTAI BAMBOO HOUSEHOLD CO LTD

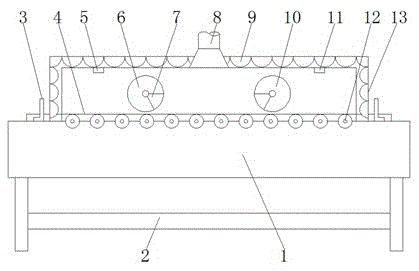

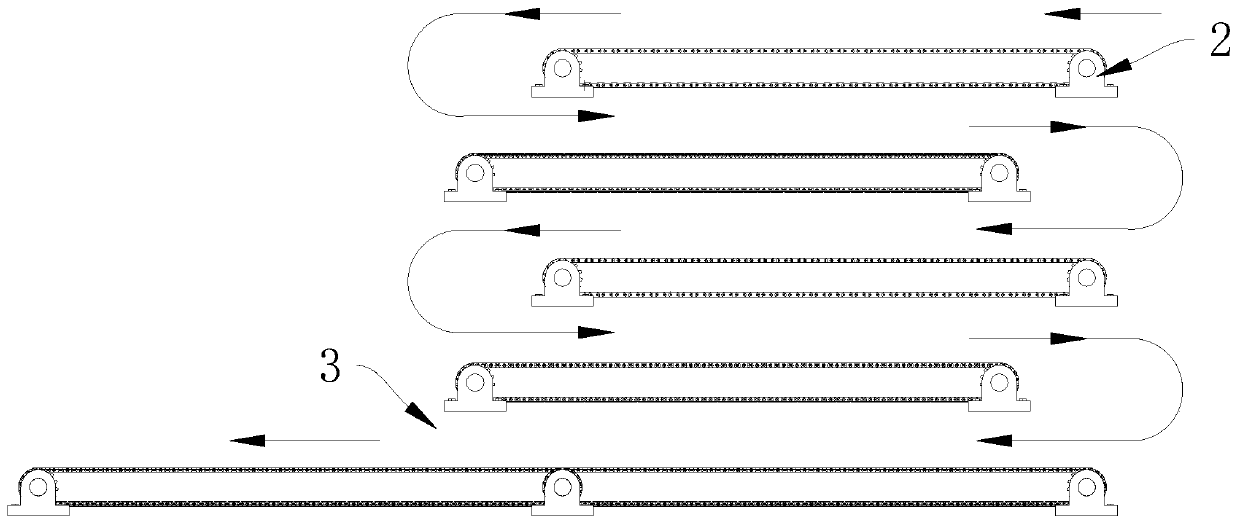

Rice crust drying machine

InactiveCN111397347AAchieve dryingDry thoroughlyCleaningDrying gas arrangementsAgricultural scienceAgricultural engineering

The invention relates to the field of rice crust production and discloses a rice crust drying machine which comprises a rack. A plurality of conveying mechanisms are horizontally arranged on the sidewalls of the two ends of the rack, the conveying mechanisms at the two ends of the rack are arranged in a staggered mode, the conveying directions of every two adjacent conveying mechanisms are opposite, and a snake-shaped conveying channel is formed by the multiple conveying mechanisms; and a plurality of first fans are evenly distributed on the upper end face of the rack, and a plurality of rowsof second fans aligned with the conveying channel are evenly distributed on the side wall. The rice crust drying machine has the following advantages and effects that by arranging the S-shaped conveying channel, long-time drying of rice crust or steamed bread slices is achieved, thorough drying of the rice crust or the steamed bread slices is achieved, the drying effect of the rice crust or the steamed bread slices is guaranteed, meanwhile, large-batch drying and continuous drying of the rice crust or the steamed bread slices are achieved, and the effect of improving the drying efficiency isachieved.

Owner:湖北卧龙神厨食品股份有限公司

Corrugated carton production equipment capable of avoiding baking cracking and deformation of corrugated boards

PendingCN114279184AEffective positioningDrying stabilityMechanical working/deformationDrying gas arrangementsCartonStructural engineering

The invention relates to the technical field of corrugated board production and processing, and discloses corrugated carton production equipment capable of preventing corrugated boards from cracking and deforming during baking, the corrugated carton production equipment comprises a fixing base, a positioning part and a fixing frame are fixedly mounted on the upper side of the fixing base, and a bearing assembly is arranged at the bottom of the inner wall of the positioning part; a driving power source is arranged on the upper side of the bearing assembly and located in the inner wall of the positioning part. According to the corrugated carton production equipment capable of preventing the corrugated boards from cracking and deforming during baking, the shaft ends of the electric telescopic rods are used for pushing the positioning plates, and the corrugated cartons are effectively positioned through the positioning plates and the positioning connecting plates, so that when the corrugated cartons are dried, the corrugated cartons can be kept stable in the drying process, and the drying efficiency of the corrugated cartons is improved. And meanwhile, the problem that the corrugated carton is prone to moving in the drying process so that deformation can occur in the drying process is solved, and therefore the drying effect of the corrugated carton is guaranteed.

Owner:昆山永立包装有限公司

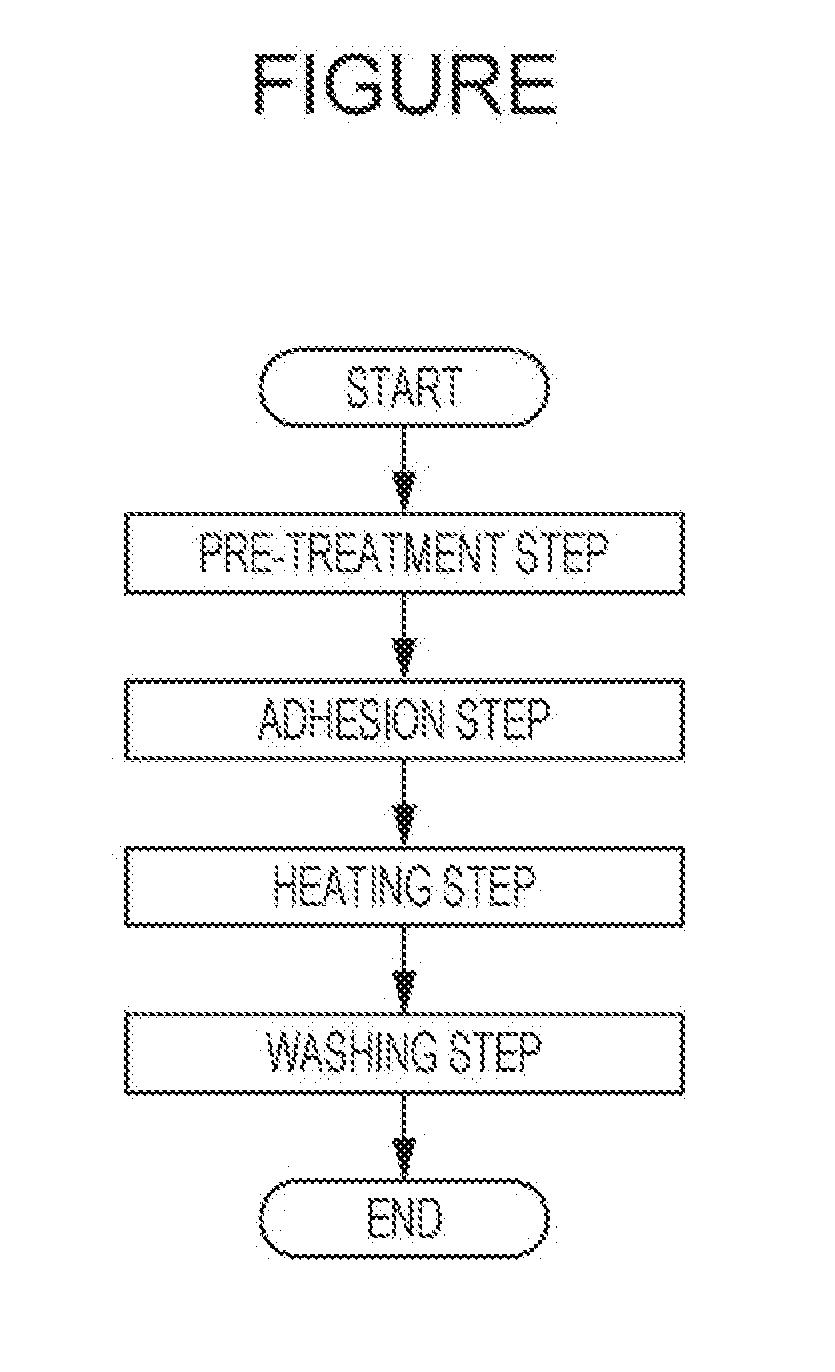

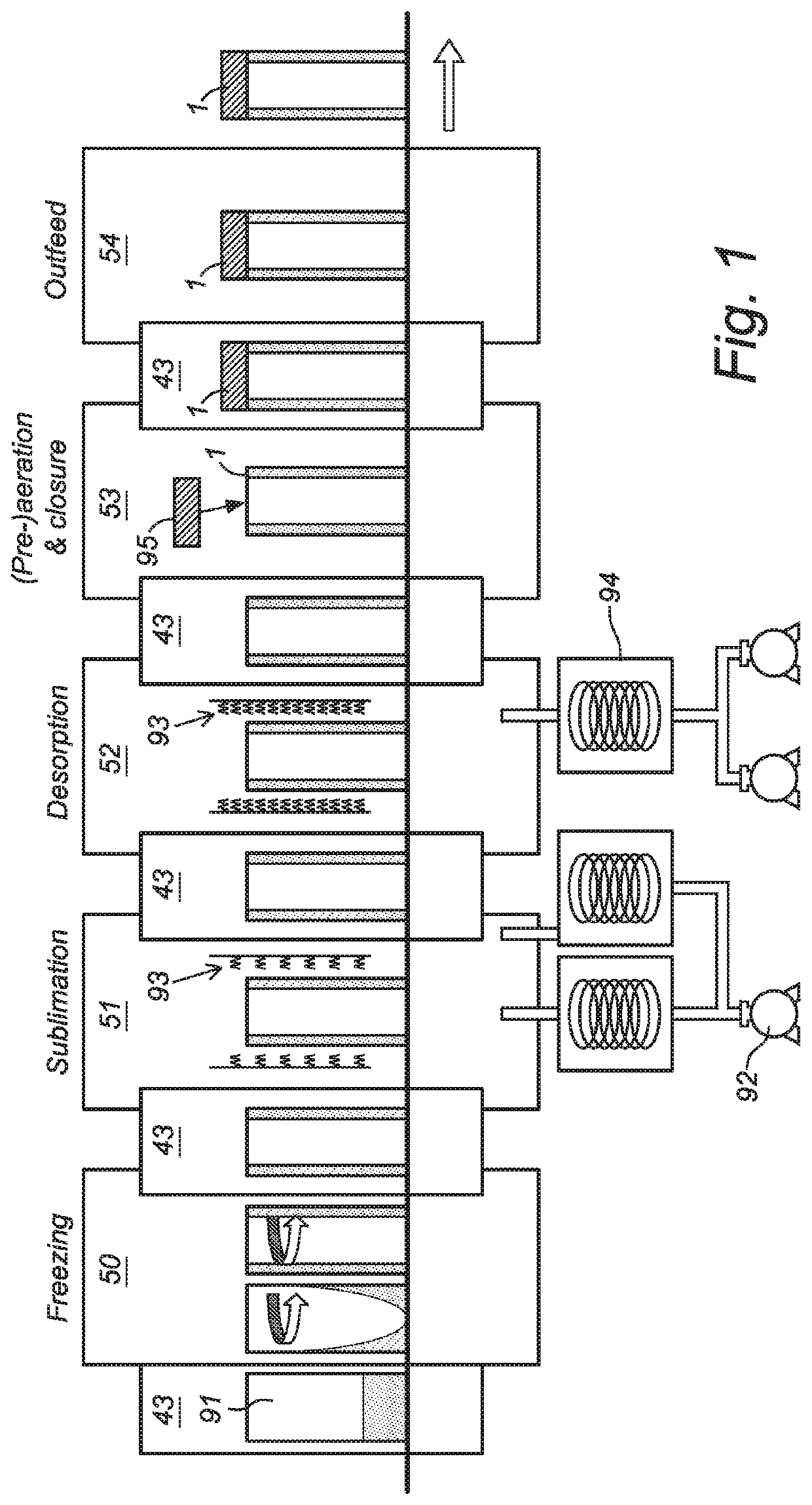

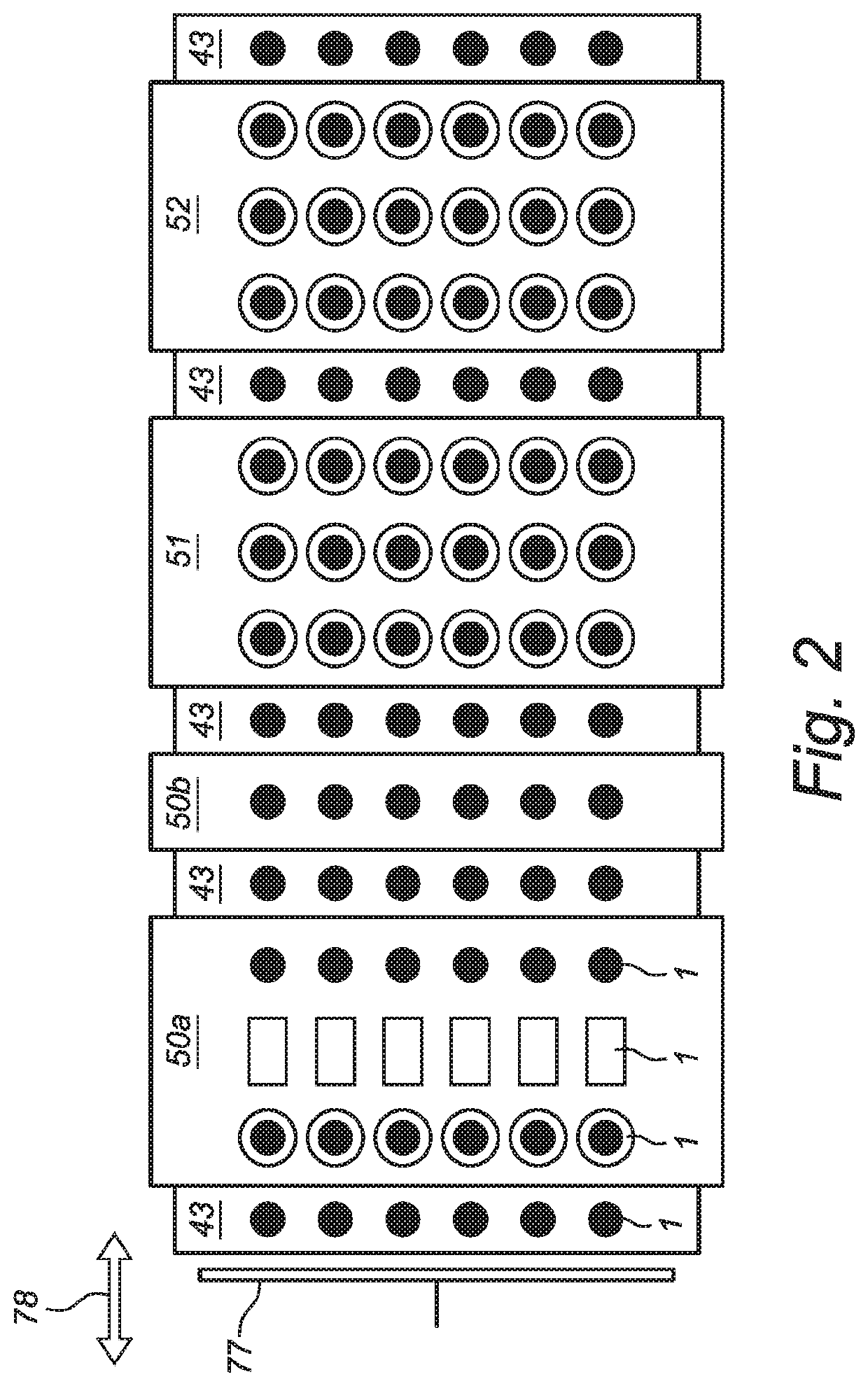

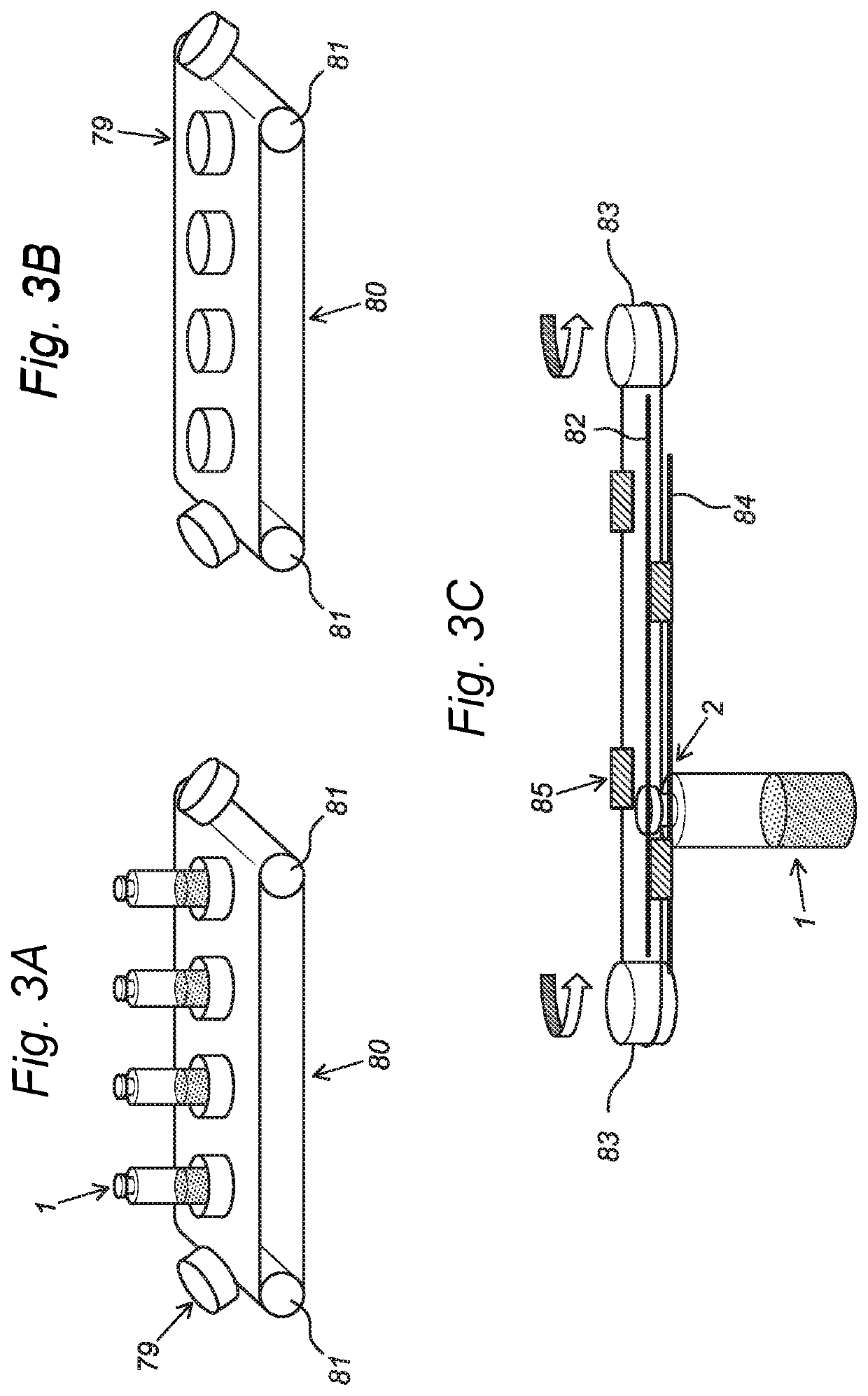

Method and system for freeze-drying injectable compositions, in particular pharmaceutical compositions

ActiveUS10670336B2Life of dryDrying stabilityDrying solid materials without heatFreeze-dryingPhysical chemistry

Methods and systems for freeze-drying injectable compositions, in particular pharmaceutical compositions, are provided whereby a freeze-dried composition may thus obtained by the method and systems. The systems for freeze-drying injectable compositions, in particular pharmaceutical compositions, make use of the method as described by storing a quantity of a dispersion of an injectable composition in an aqueous dispersion medium in at least one ready-to-use vial, cooling the vial to form ice crystals, applying a vacuum, and applying thermal heat to the dispersion while rotating the vial to homogeneously supply heat to the vial. The condition of the drying dispersion in the rotating vial is measured using an optical sensor using electromagnetic detection and adaptively controlling the amount of thermal heat.

Owner:RHEAVITA

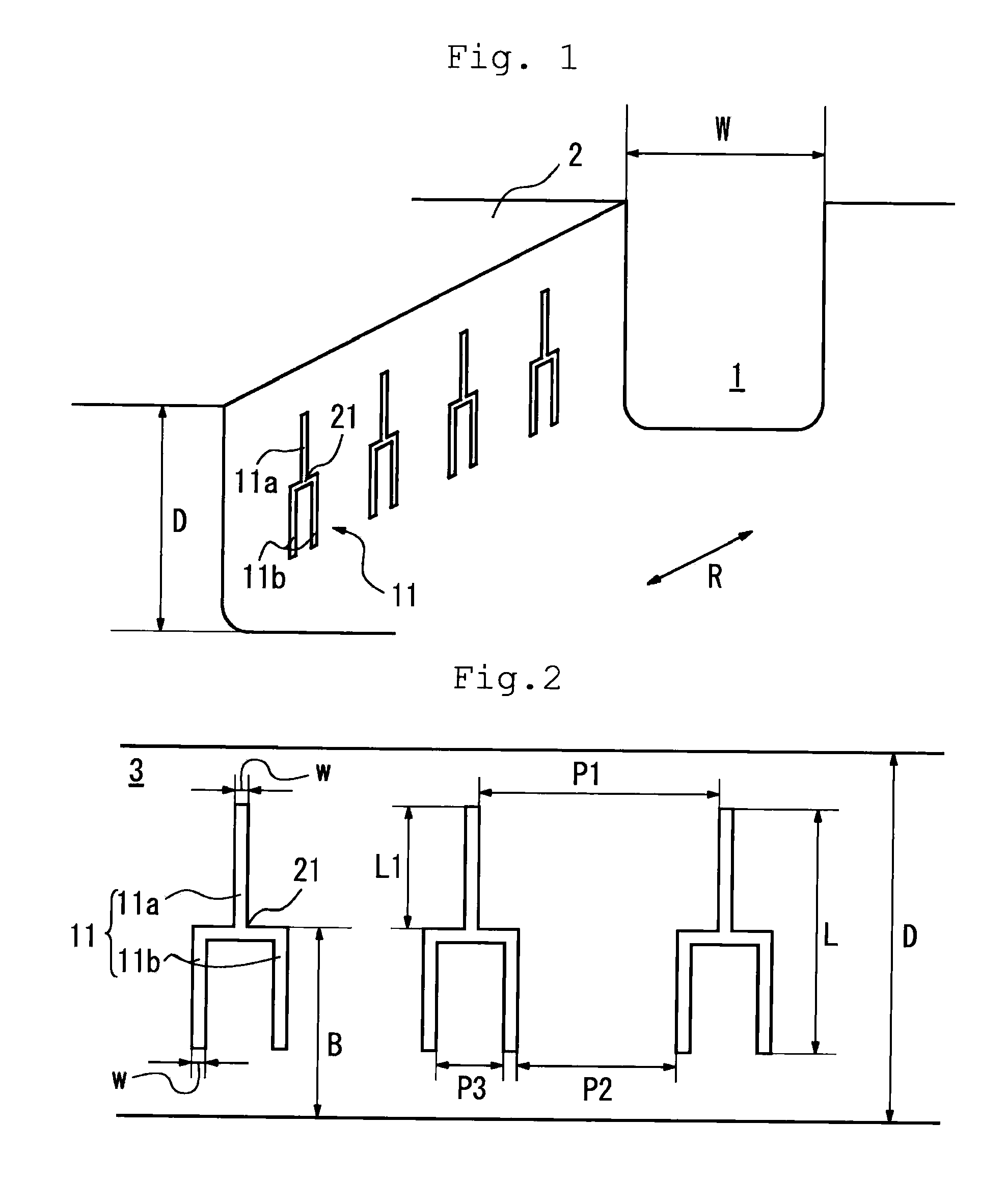

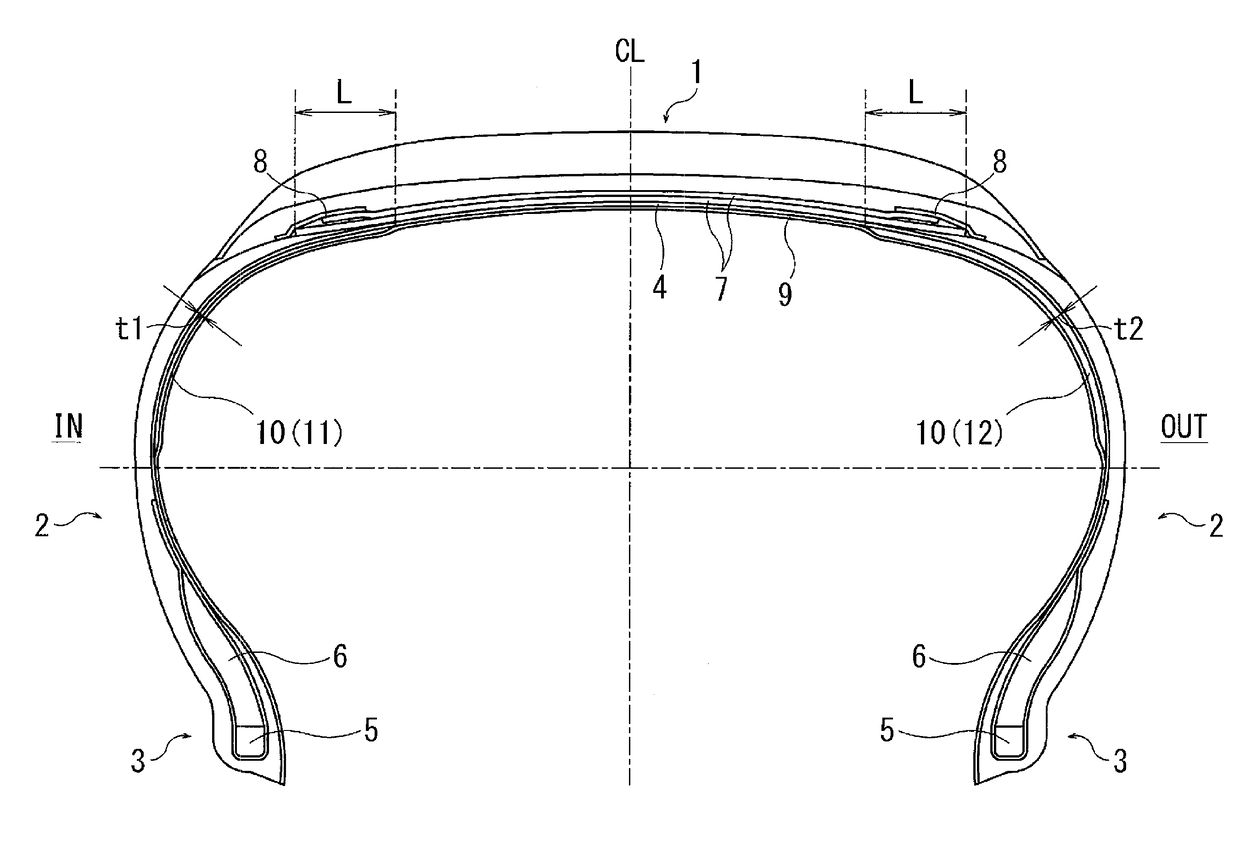

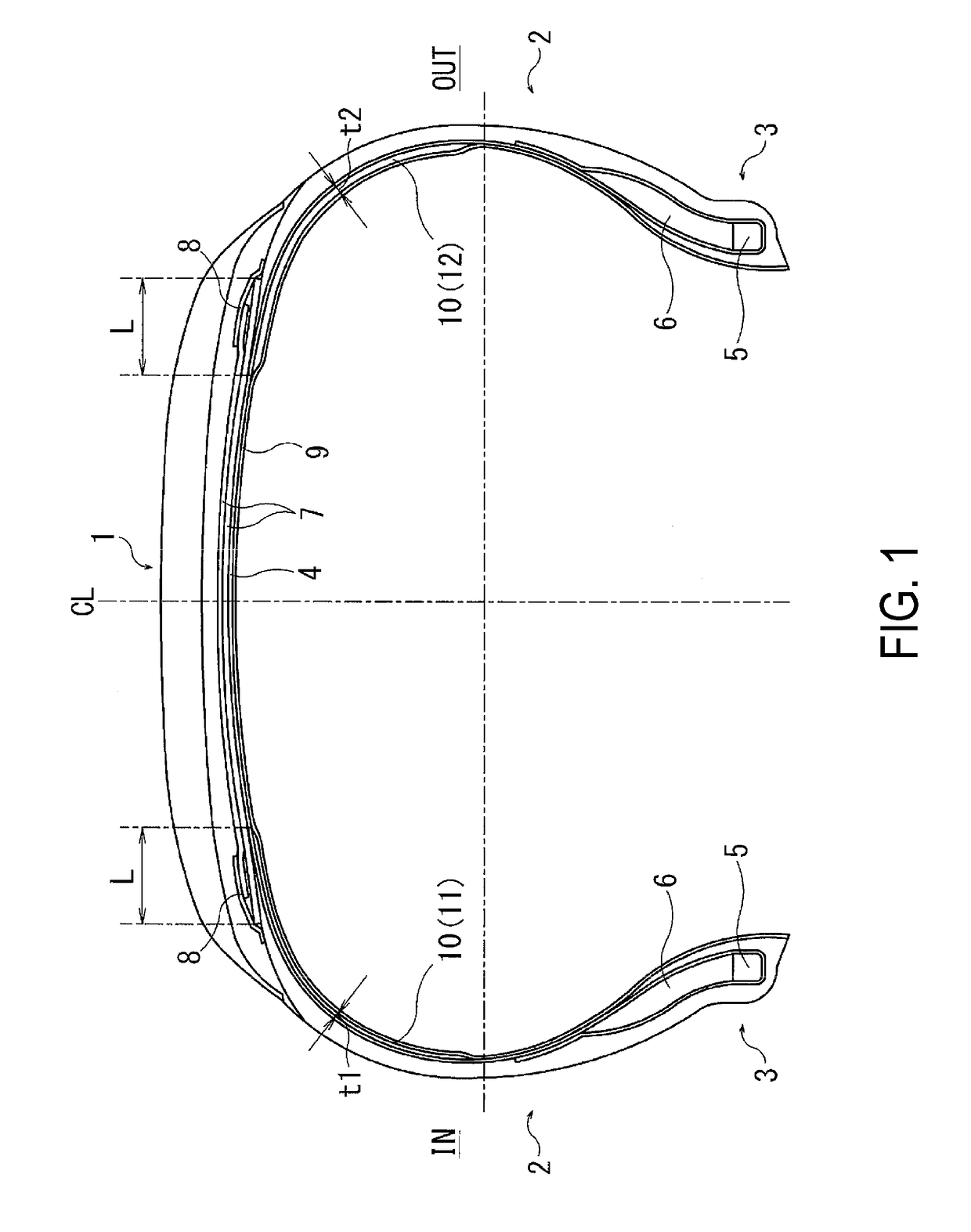

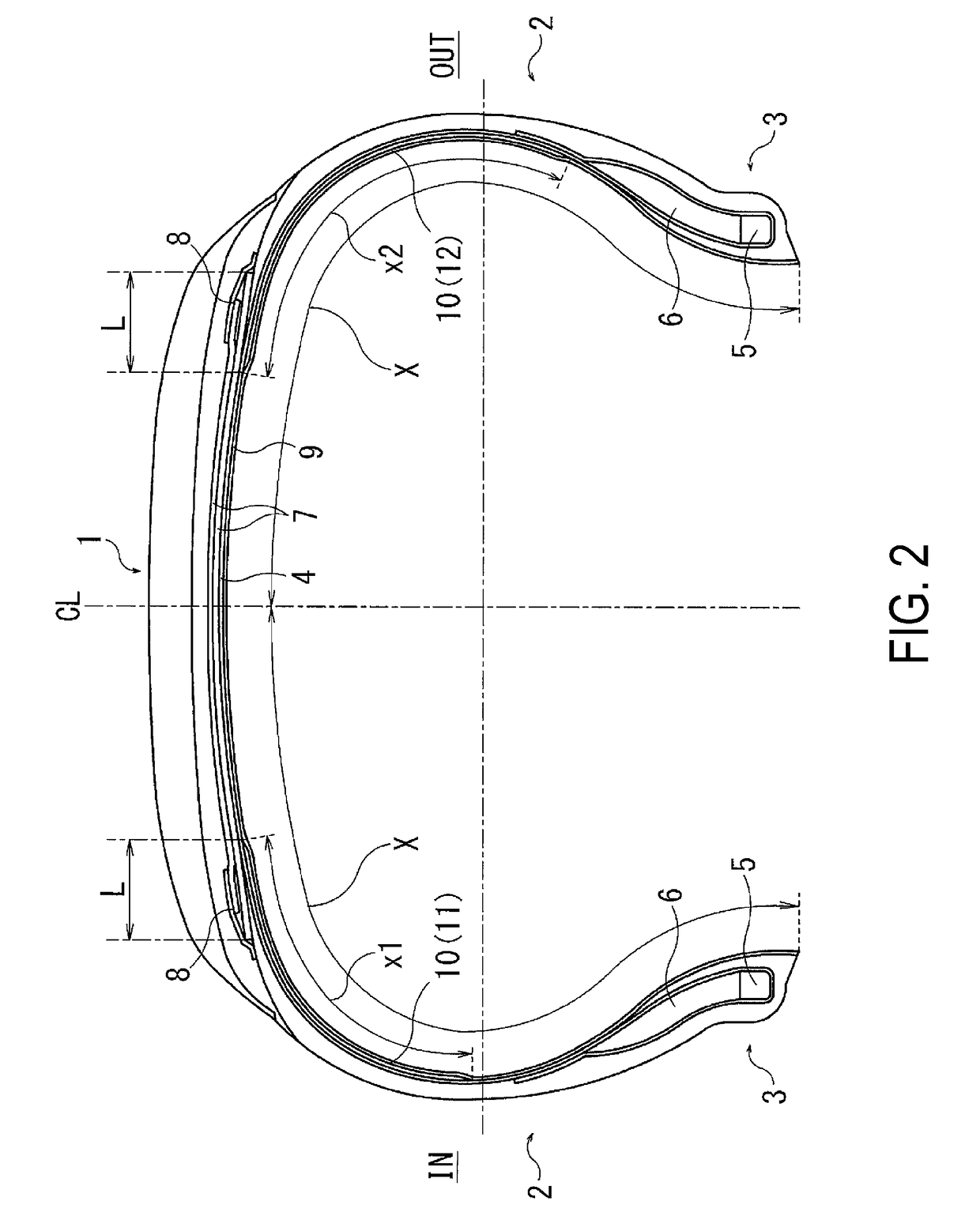

Pneumatic Tire

ActiveUS20180222253A1Reduce rolling resistanceReduce tire weightWithout separate inflatable insertsSpecial tyresEngineeringTread

A pneumatic tire is provided in which an inner tie rubber layer and an outer tie rubber layer are selectively disposed between a carcass layer and an innerliner layer in a region on both sides in a tire width direction excluding a center region of a tread portion. End portions of the inner tie rubber layer and outer tie rubber layer on a tire equator side are disposed within a range of from 10 mm to 25 mm on an inner side in the tire width direction from an end portion on an outermost side in the tire width direction of a belt layer. A rubber thickness t1 of the inner tie rubber layer differs from a rubber thickness t2 of the outer tie rubber layer. A rubber thickness of the outer tie rubber layer is from 120% to 200% a rubber thickness of the inner tie rubber layer.

Owner:YOKOHAMA RUBBER CO LTD

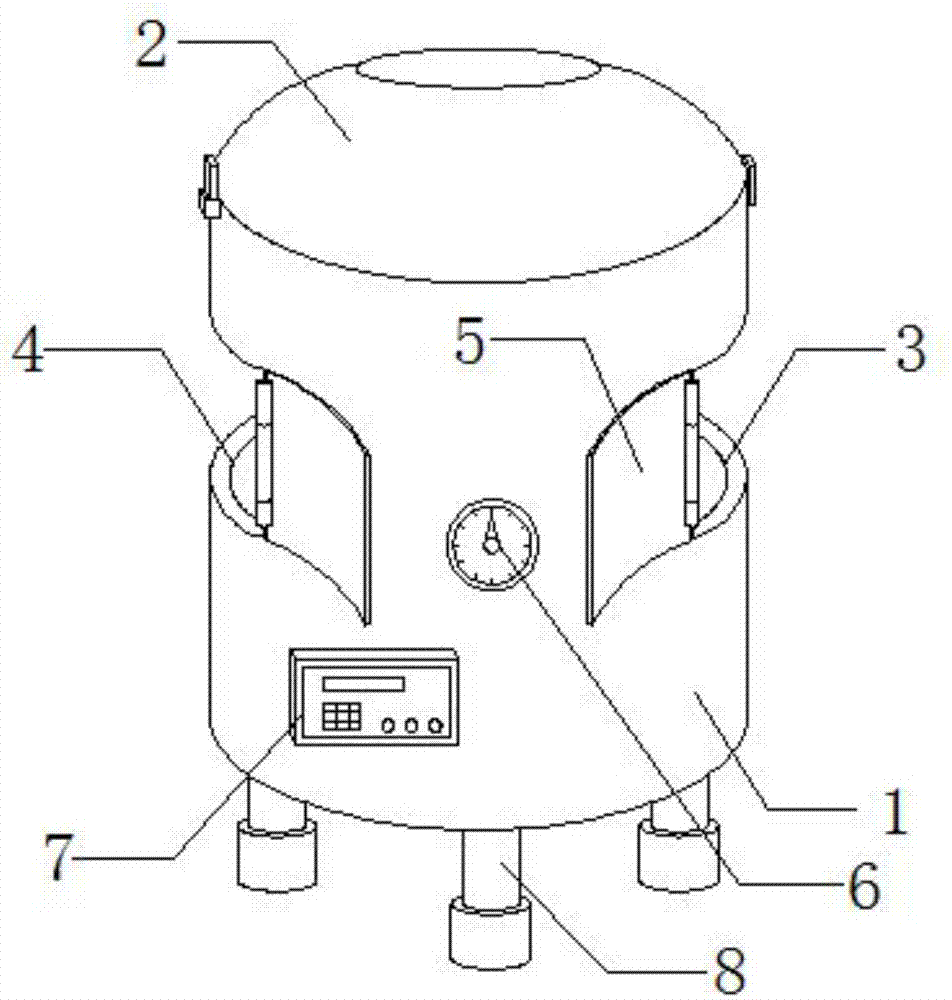

Drying device for shoe sole viscose

The invention discloses a drying device for shoe sole viscose. The drying device includes a drying cylinder, a top cover, a feeding port, a discharging port, cabinet doors, a thermometer, a control panel, a supporting leg, an electromagnet, a rotating rod, a horizontal rod, a motor, a turntable, a shoe hanging head, air heaters, a connecting column, a breather pipe and nozzles. The air heaters aredisposed on the two sides of the inner wall of the drying cylinder, the cabinet doors on the feeding port and the discharging port are closed, the air heater are started to make the temperature in the drying cylinder rise quickly, and a shoe lining is hung on the shoe hanging head for drying. Since the nozzle at the higher position is inclined downwards and the nozzle at the lower position is inclined upwards, the shoe sole viscose is quickly dried. Besides, in the rotating process of the rotating rod, the shoe is in full contact with hot air, and the shoe drying speed is improved. As the upper part of the shoe hanging head has a pointed end and the lower part is round pointed, the lining of the shoe is filled. The device has the advantages of being high in drying efficiency and preventing the shoe from deforming.

Owner:岳西县司空山鞋业有限公司

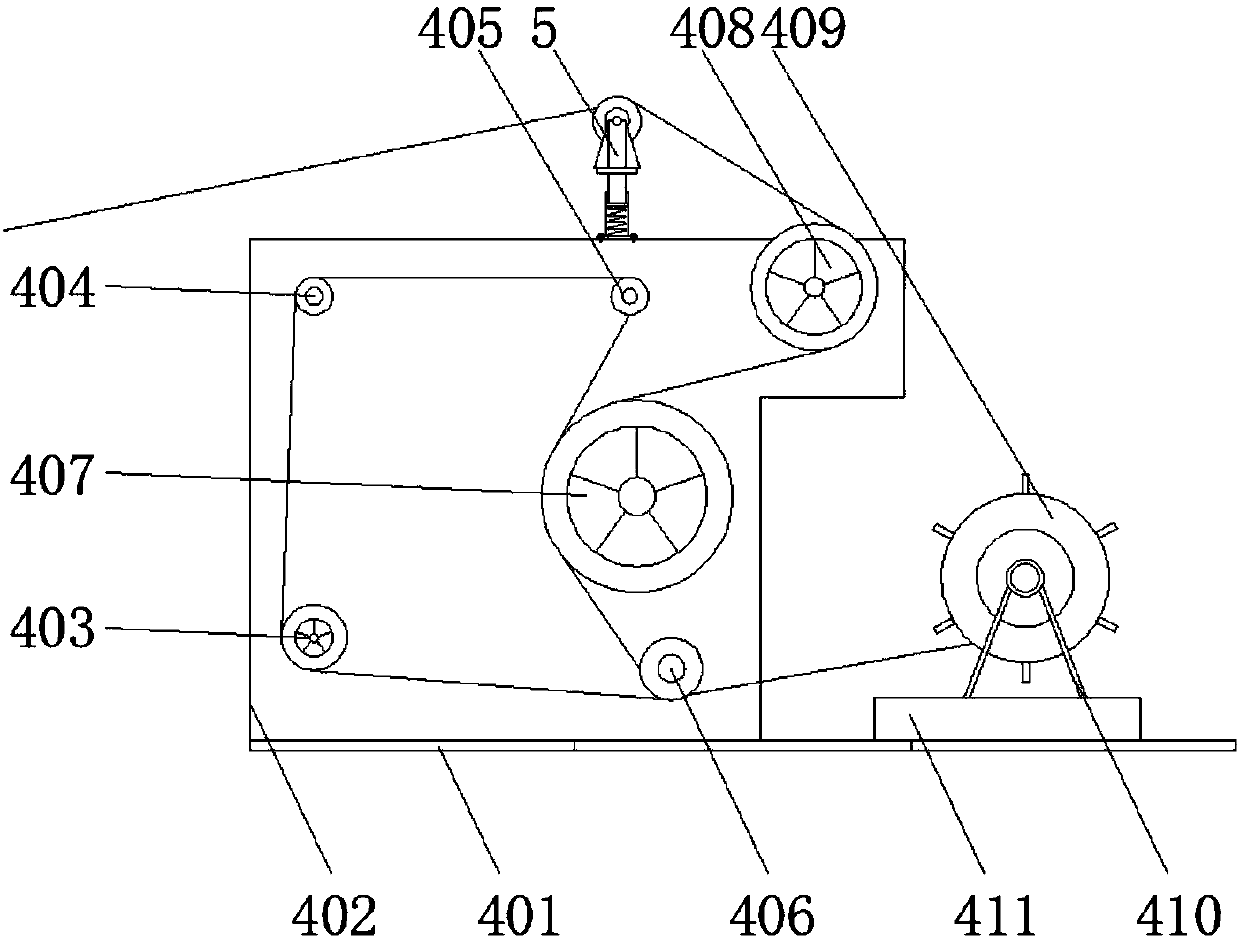

Chemical-fabric dyeing and drying automatic rolling machine

ActiveCN107723964AImprove efficiencyQuality assuranceTextile treatment machine arrangementsLiquid/gas/vapor removal by gas jetsDyeingFixed frame

The invention discloses a chemical-fabric dyeing and drying automatic rolling machine, and relates to the technical field of textile machinery. The chemical-fabric dyeing and drying automatic rollingmachine includes a bottom plate, one side of the top of the bottom plate is fixedly connected with a power motor through a motor fixing frame, the power motor is rotationally connected with a deceleration connector through an output shaft, the deceleration connector is rotationally connected with a first belt pulley through the output shaft, the first belt pulley is rotationally connected with a second belt pulley through a belt, the second belt pulley is rotationally connected with a rotation shaft through a flat key, and the bottom plate is fixedly connected with a heating box through a connection frame. The chemical-fabric dyeing and drying automatic rolling machine achieves the purposes of stably dyeing and drying chemical fabric, and the dried fabric is cooled through an air blower, therefore, the dyeing quality of the fabric is ensured, and the working efficiency can also be improved; by the adoption of the chemical-fabric dyeing and drying automatic rolling machine, the chemicalfabric is conveyed and rolled, a rolling device can reduce the tension of the chemical fabric, so that the situation cannot occur that the fabric is ripped apart, and the quality of the fabric is ensured.

Owner:浙江耐力拉链有限公司

A spraying device for eps line processing

ActiveCN114054276BRealize continuous feedingImprove processing efficiencySpray boothsStructural engineeringConveyor belt

The invention discloses a spraying device for EPS line processing, which includes a spraying box, a drying assembly, a spraying assembly, a conveying roller frame installed in the spraying box, and a conveyor belt installed on the conveying roller frame. One side is provided with a feed port, one end of the conveying roller frame extends out of the feed port, and installation frames are evenly arranged on the belt surface of the conveyor belt, and the installation frames are U-shaped structures, and the two sides of the installation frames are Clamping mechanisms are provided on the side walls, strip frames are fixed on the inner walls of both sides of the spraying box, and the inside of the strip frame is provided with a limiting groove for driving the action of the clamping mechanism. Components and drying components are arranged in sequence along the conveying direction. The invention realizes continuous feeding, spraying, drying, and discharging of EPS lines, greatly improves processing efficiency, and enables EPS lines to continuously rotate during the feeding process, thereby ensuring uniform spraying of EPS lines, uniform drying, and enhanced Processing effect.

Owner:南通杰西卡新型材料有限公司

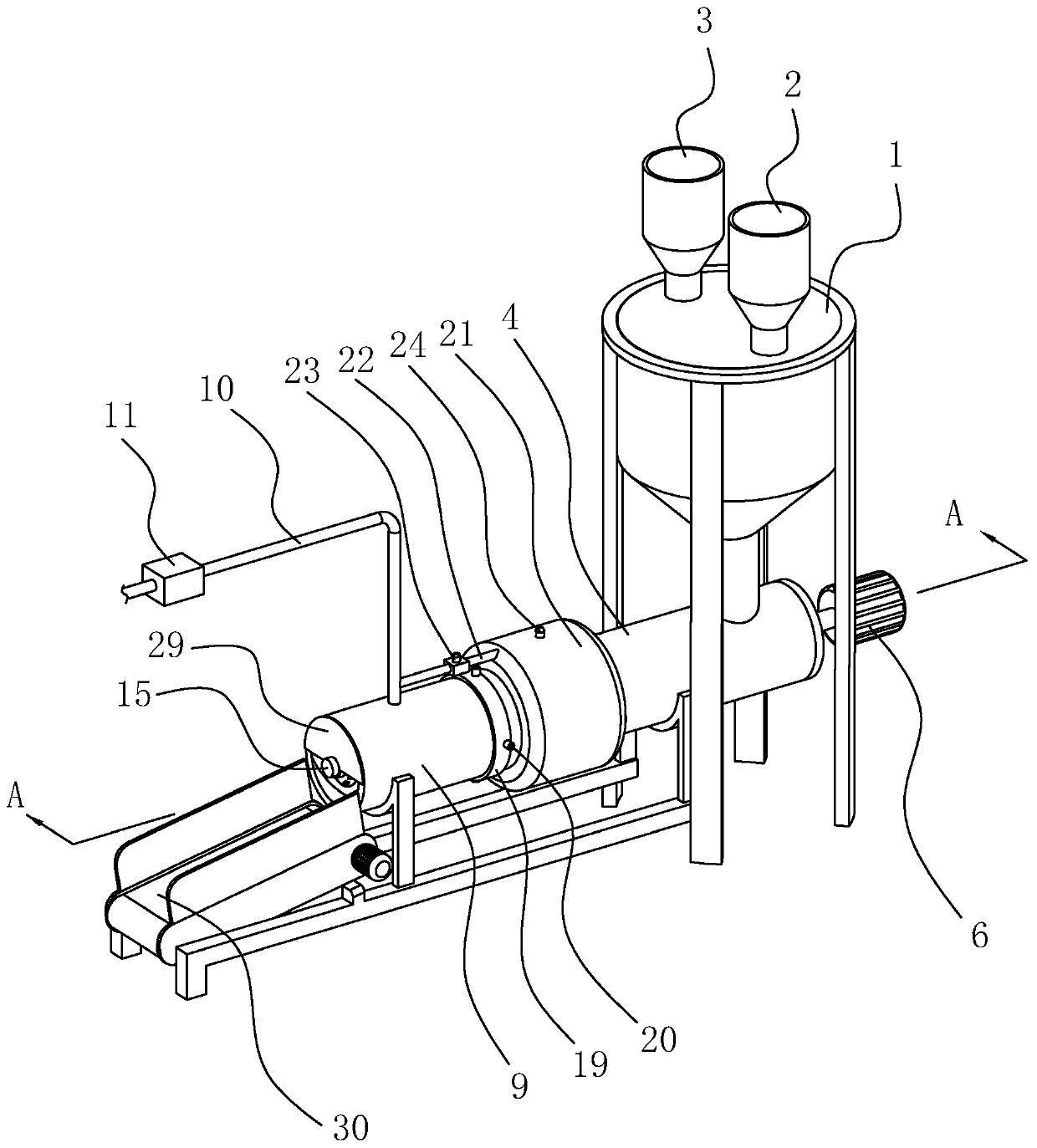

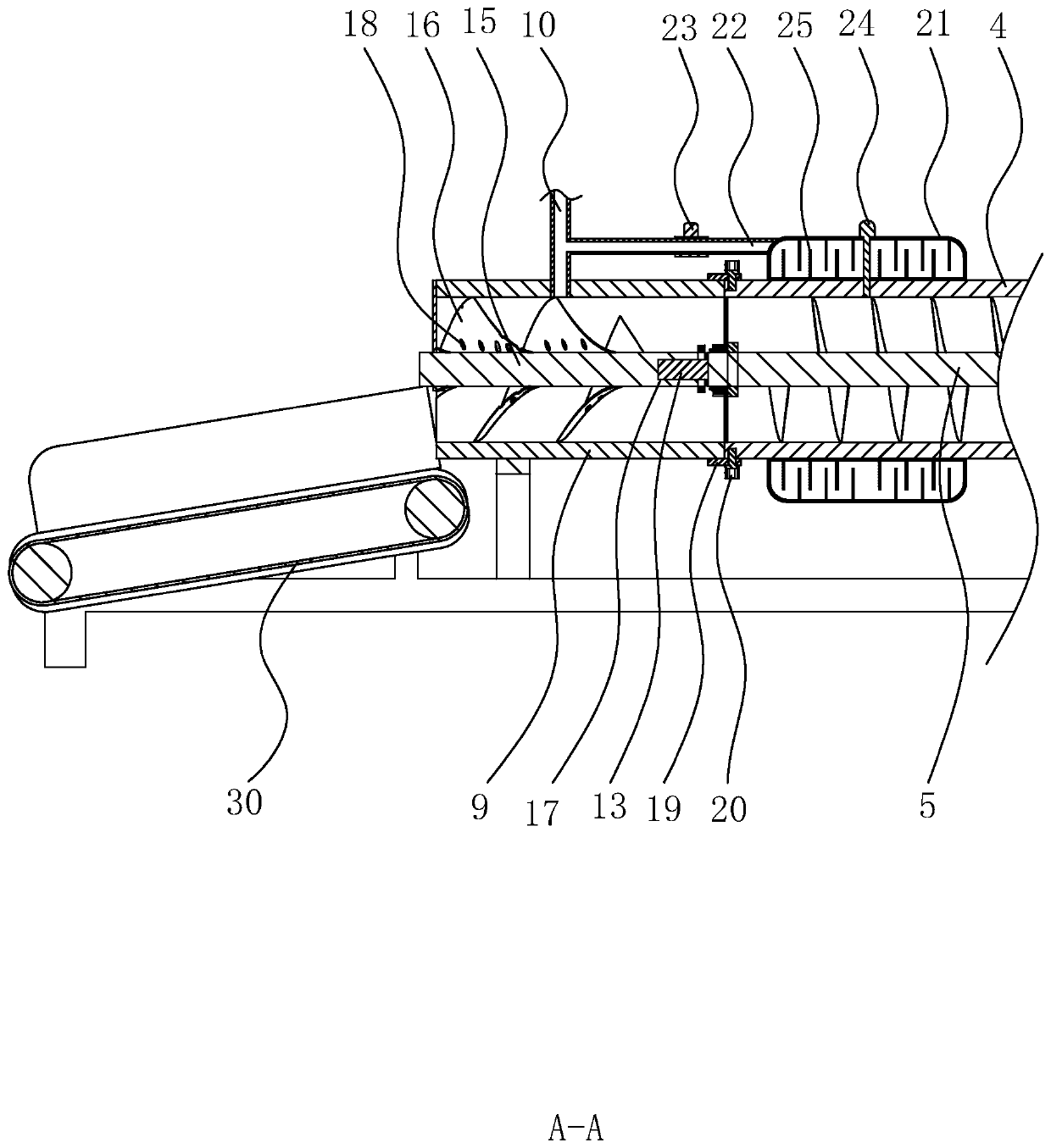

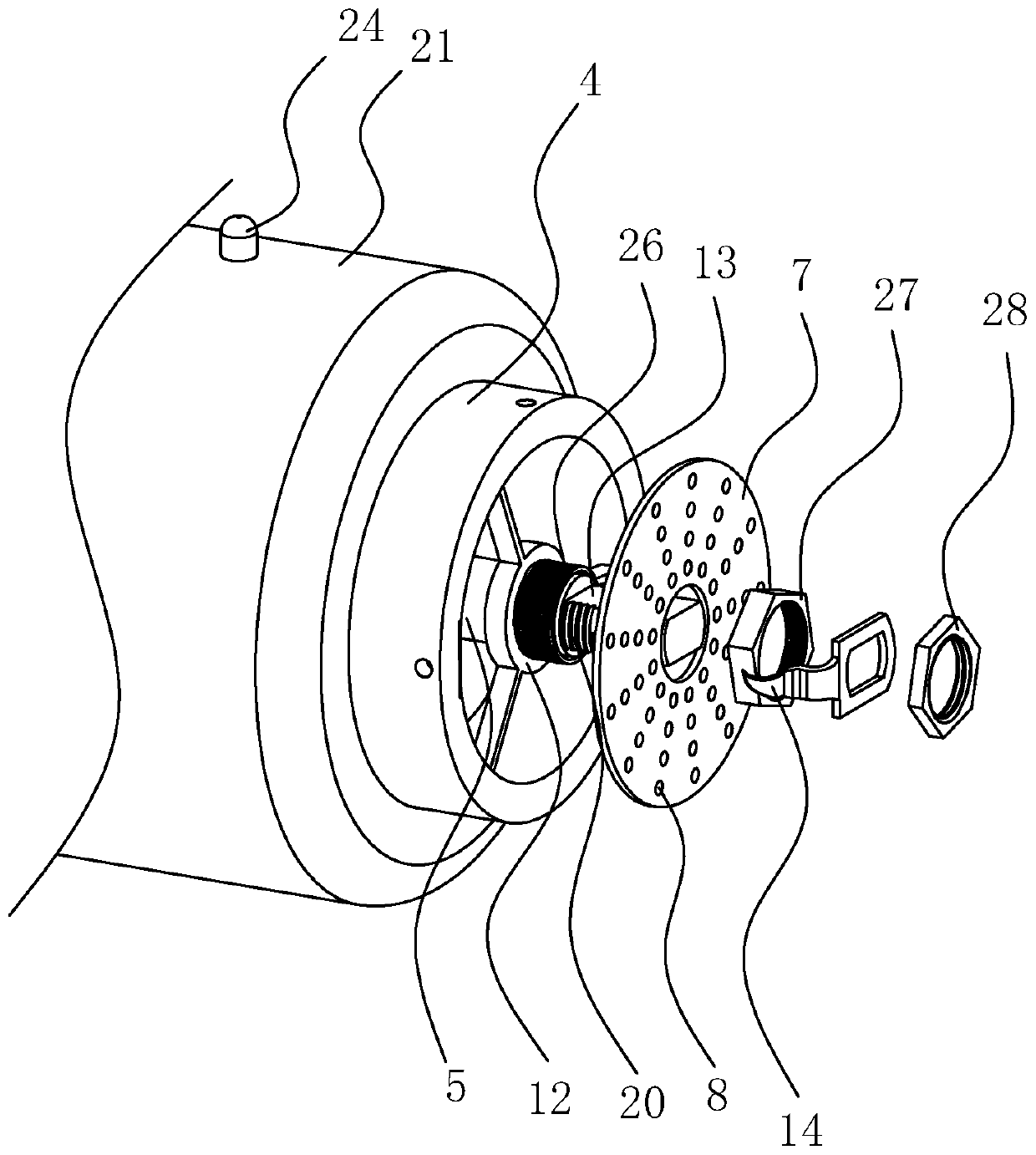

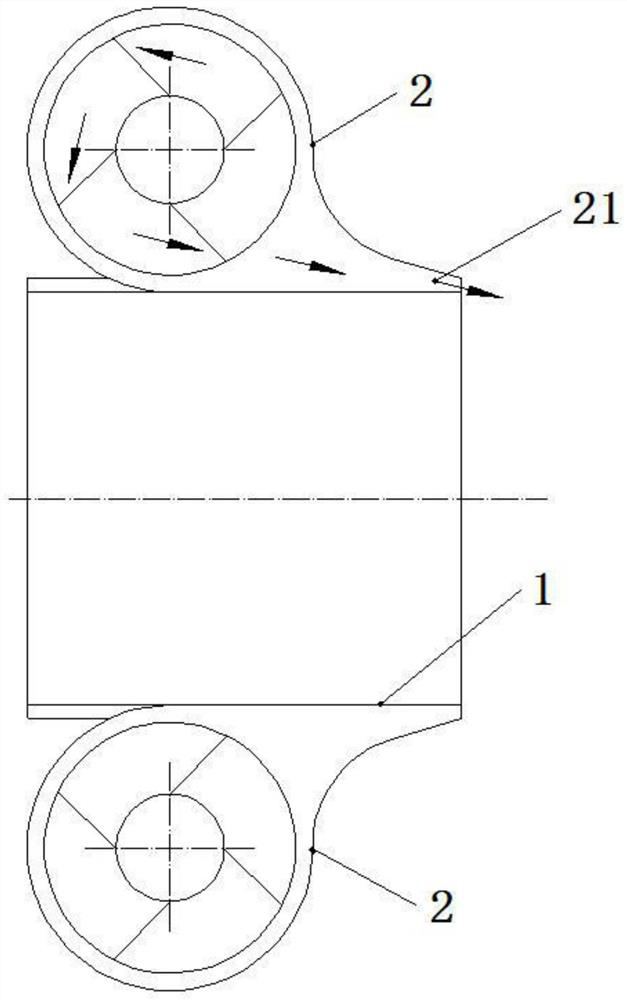

Fuel conveying system with drying device

InactiveCN111365729AGuaranteed calorific value of combustionDrying stabilityBiofuelsSolid fuelsHot blastProcess engineering

The invention relates to a fuel conveying system with a drying device. The fuel conveying system comprises a feeding device, a stirring barrel, a material extruding device, the drying device and a conveying device, wherein the feeding device comprises a coal powder hopper and a sludge hopper; a discharging port of the coal powder hopper and a discharging port of the sludge hopper both extend intoa feeding port of the stirring barrel; the material extruding device comprises a material barrel with the feeding port communicating with the discharging port of the stirring barrel; an auger is coaxially and rotationally connected in the material barrel; one end of the material barrel is closed, and a material extruding plate is arranged at the other end of the material barrel; a plurality of material extruding holes are formed in the material extruding plate; a preheating mechanism is arranged on the peripheral wall of the material barrel; the drying device comprises a drying barrel arrangedat the end, close to the material extruding plate, of the material barrel; a hot air pipe communicates in the drying barrel; and a material overturning mechanism is arranged in the drying barrel. According to the fuel conveying system, a coal powder and sludge mixture is preheated through the preheating mechanism and then extruded into strips from the material extruding plate, drying is conductedthrough the drying barrel, the coal powder and sludge mixture can be conveyed into a hearth to be combusted at a good proportion, and the good combustion heat value of the coal powder and sludge mixture is ensured.

Owner:杭州航民江东热电有限公司

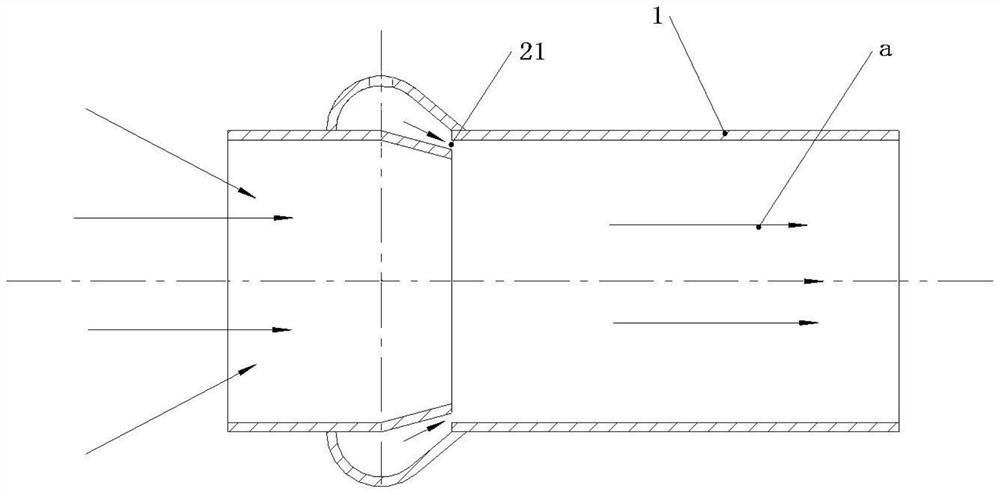

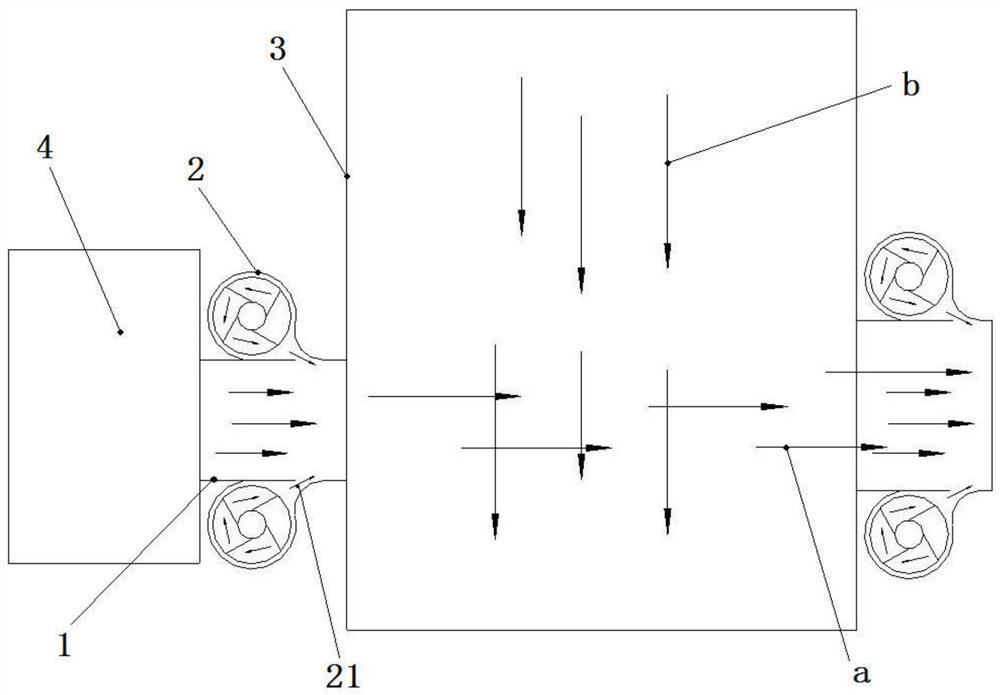

Dryer ventilation device and dryer

The invention discloses a dryer ventilating device and further provides a dryer using the ventilating device. The dryer ventilating device comprises a main air pipe (1) and fans (2). Air outlets (21)of the fans (2) are formed in the wall of the main air pipe (1) and communicate with the interior of the main air pipe (1). According to the dryer ventilating device, parts such as impellers which arearranged in an air channel are omitted, and the mode that the fans generate airflow and drive air is adopted, so that the stable air pressure and air speed are formed in the main air pipe, and the drying process is stably conducted advantageously; and meanwhile, the outlet air pipe does not need to be lengthened, and thus energy saving is better achieved.

Owner:HUNAN NONGYOU MACHINERY GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com