Rubber shoe lining impregnation device and method for automatically impregnating rubber shoe linings by rubber shoe lining impregnation device

A technology of rubber dipping and rubber shoes, which is applied in the direction of shoemaking machinery, footwear, applications, etc., can solve the problems of unguaranteed quality stability, endangering the health of personnel, and large limitations of manual operation, so as to reduce the probability of air bubbles and improve The effect of quality and process stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solution of the present invention will be further described below through the embodiments, in conjunction with the accompanying drawings.

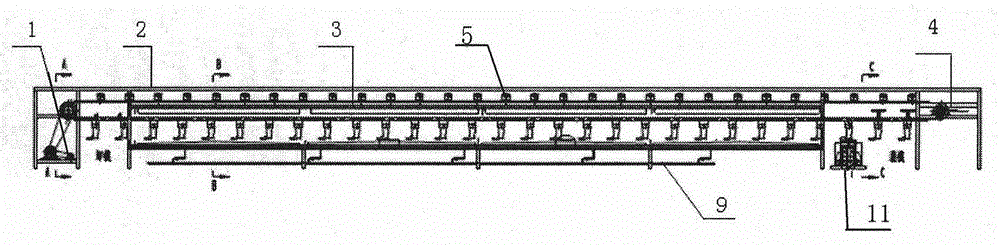

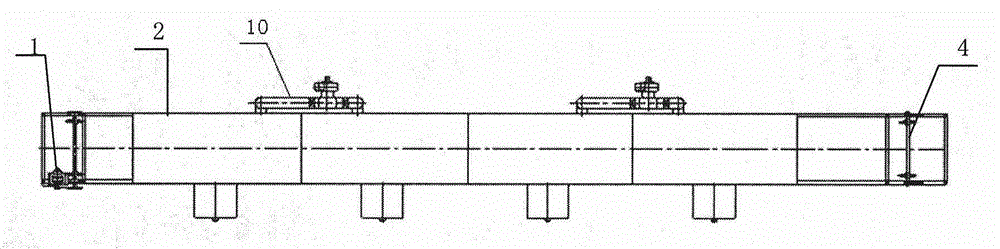

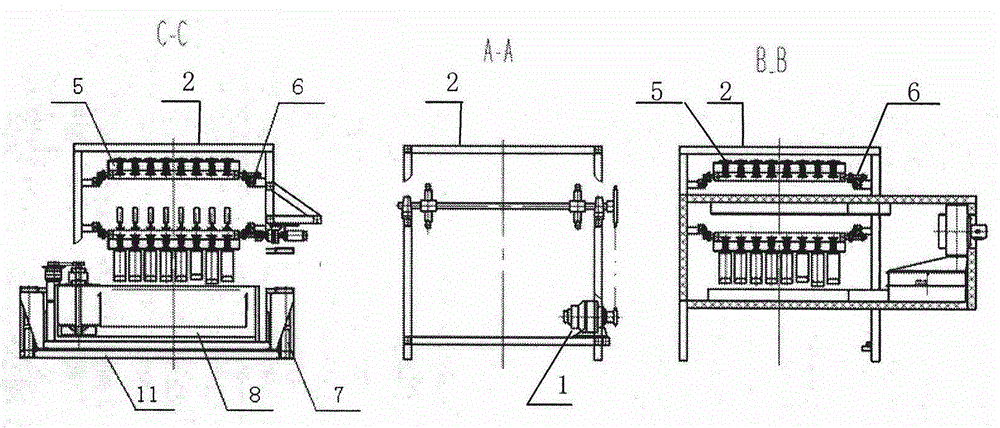

[0028] A dipping equipment for rubber shoes, comprising an active part 1, a frame 2, a drying box 3, a driven wheel part 4, a mold car 5, a chain part 6, a dipping tank 11, a steam pipe 9, and a dehumidification part 10, wherein the active Part 1, drying box 3, driven wheel part 4, mold car 5, chain part 6, dipping tank 11, steam pipe 9, and dehumidification part 10 are all fixed on the frame 2, which is characterized in that: the driving part 1 and the driven wheel The part 4 is arranged at both ends of the frame 2. In the frame 2, a drying box 3 and a dipping tank 11 are arranged in sequence from left to right. The chain part 6 is set on the driving part 1 and the driven wheel part 4. The driving part 1 The driven part 4 is driven to rotate by the chain part 6, and a series of mold cars 5 are arranged on the chain pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com