3D printing head, application method thereof and glue applied to 3D printing head

A print head and 3D technology, applied in the field of 3D printing, can solve the problems of unguaranteed firmness of layers, poor adhesion of printing materials with small cross-sections, difficult processing of parts, etc. Excellent, firmness-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

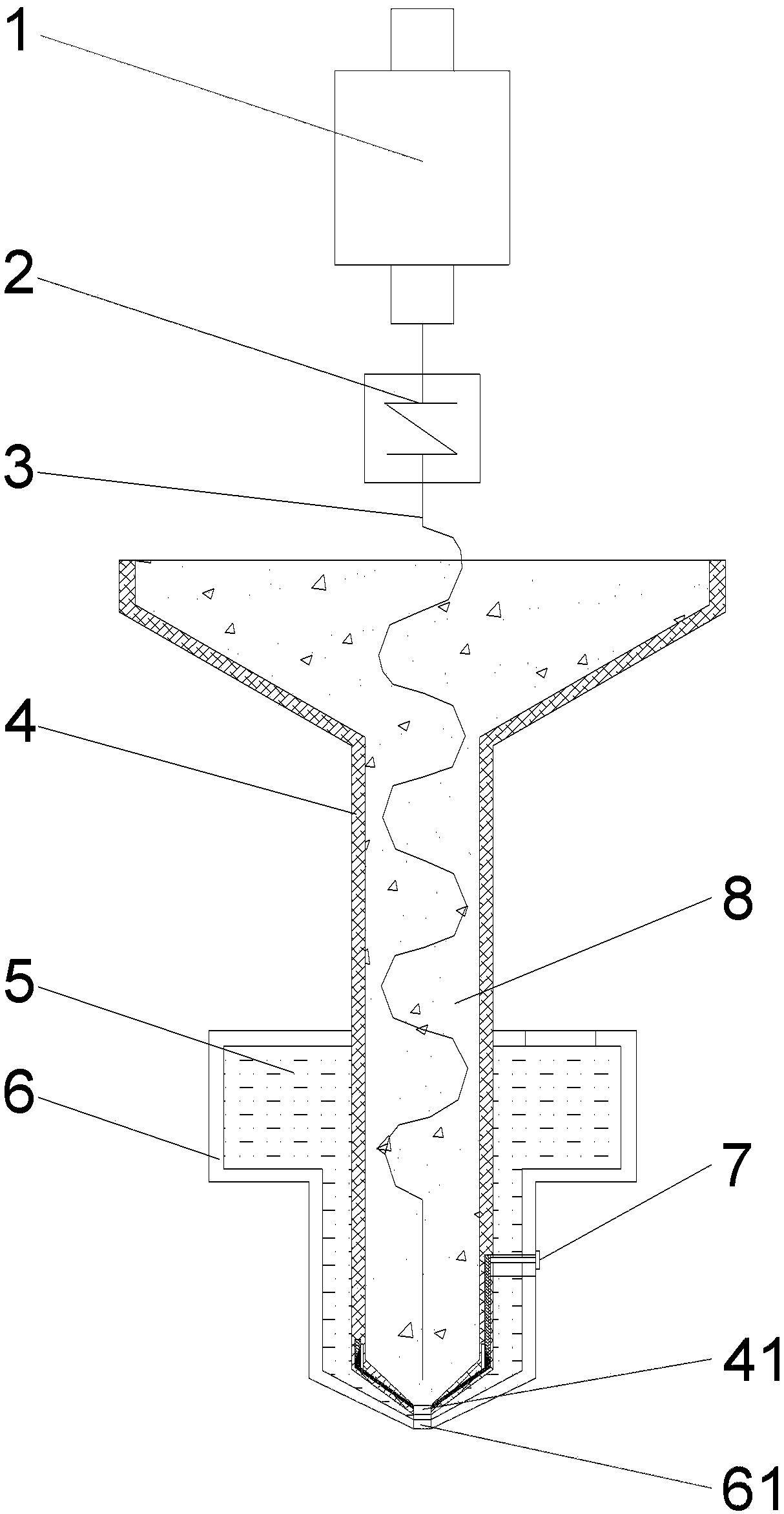

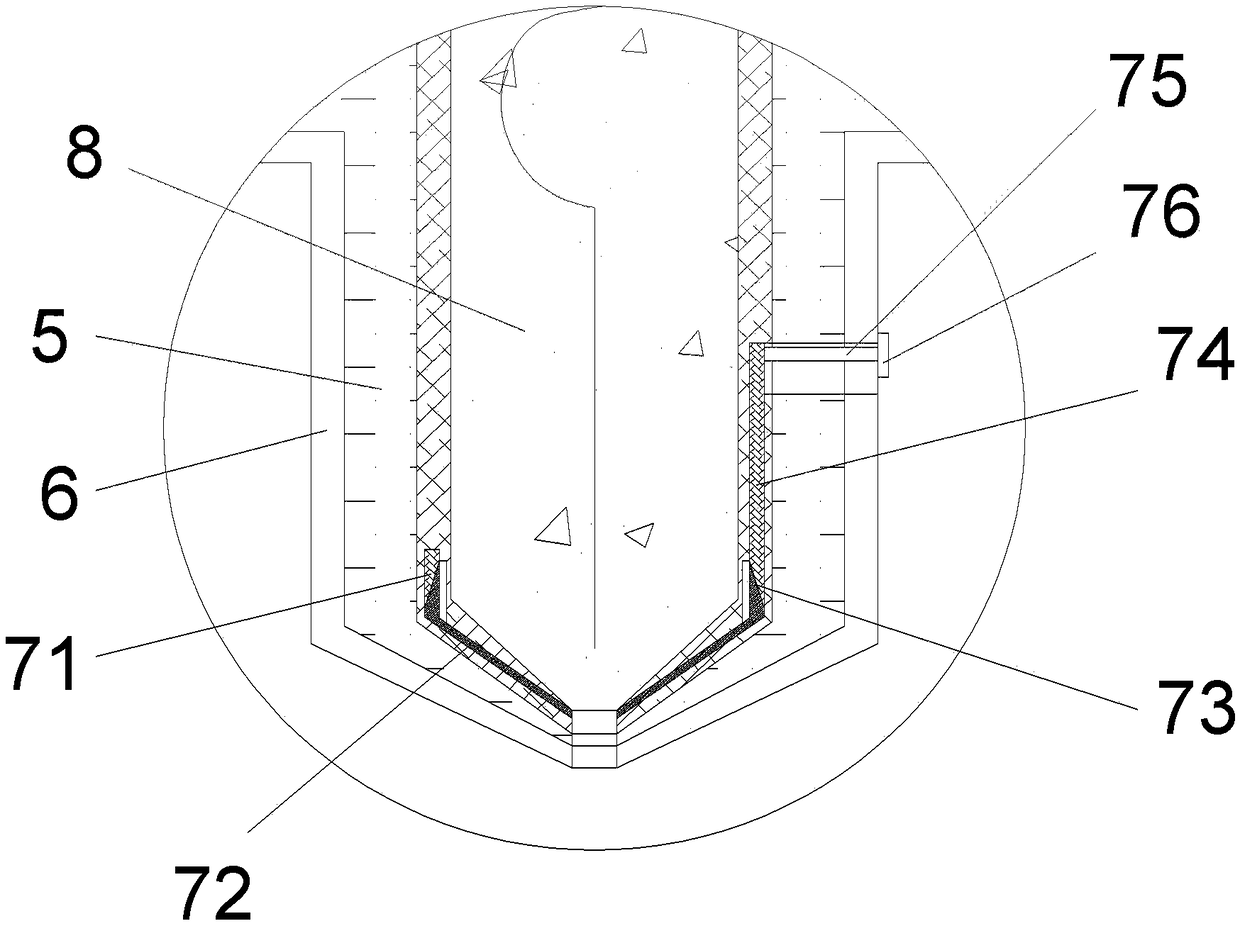

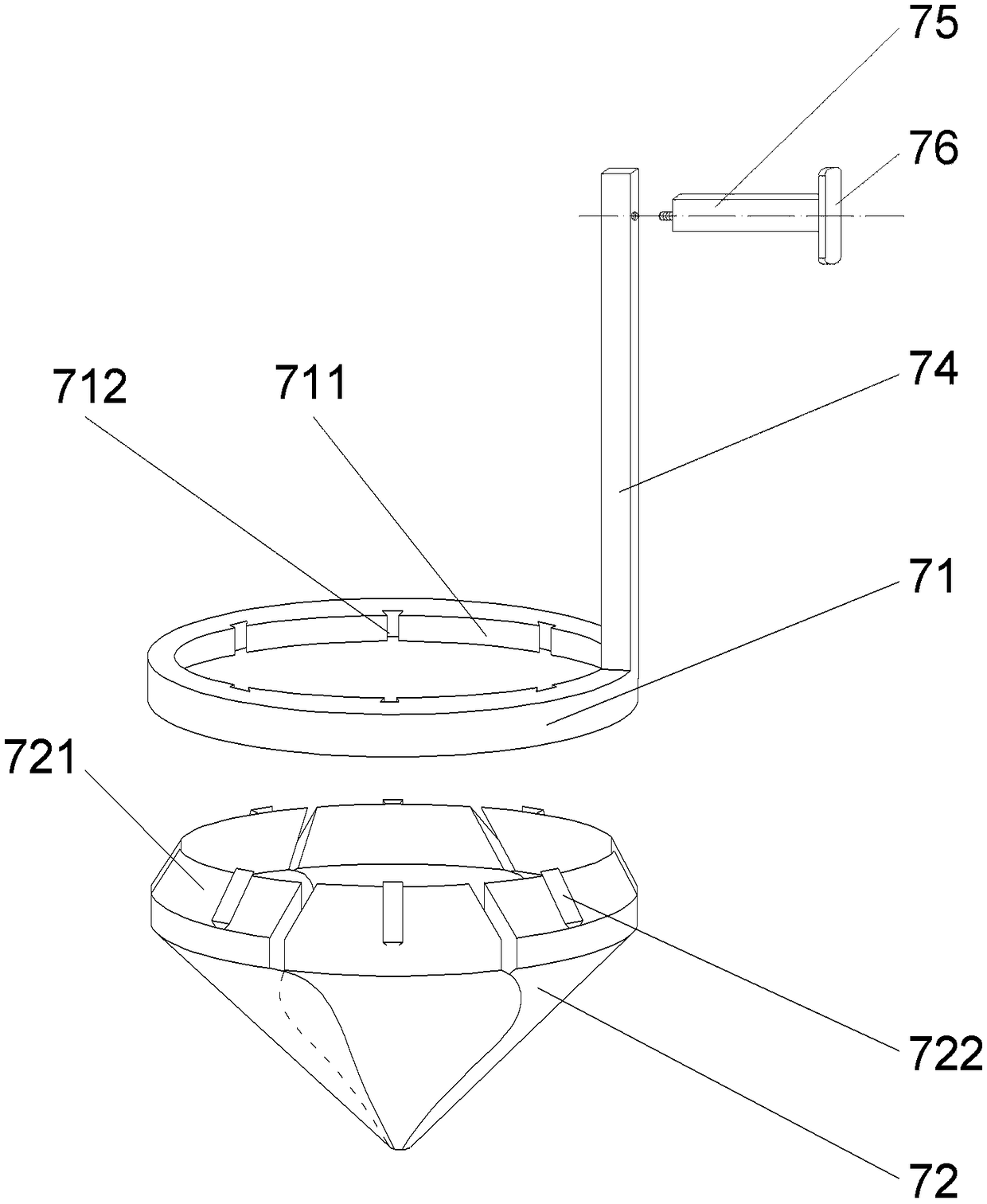

[0047] In an exemplary embodiment of the present application, a 3D printing head is provided. Such as figure 1 As shown, the present application includes a barrel 4, a bore telescoping device 7 and a glue discharge device.

[0048] Each component of this embodiment will be described in detail below.

[0049] The print head is a screw extrusion print head, the motor 1 drives the extrusion screw 3 through the coupling 2, the printing material is built in the barrel 4, the barrel 4 is vertically arranged, and the lower end of the barrel 4 is opened with a discharge hole 41, As the extrusion screw 3 rotates, the printing material is extruded from the discharge hole 41 .

[0050] Such as figure 2 As shown, the glue discharge device includes a rubber cylinder 6 which is arranged around the cylinder, and an annular glue storage chamber is formed between the rubber cylinder 6 and the cylinder 4. Glue 5 is stored in the glue storage chamber, and the lower end of the glue cylinder 6...

Embodiment 2

[0055] The printing material is concrete, and the glue includes the following components in parts by weight: 8 parts of softening oil, 6 parts of asphalt, 10 parts of rubber, 2 parts of reinforced fiber, 3 parts of diatomaceous earth, and 1 part of stabilizer. Among them, the rubber includes styrene-butadiene thermoplastic rubber, the reinforcing fiber is glass fiber, the softening oil is a mixed oil of aromatic oil and castor oil in a ratio of 1:1, and the ratio of aromatic oil and castor oil is 1:1.5. The stabilizer is trioctyl phosphate.

Embodiment 3

[0057] In the case that other technical means are the same as in Example 1, the glue includes the following components in parts by weight: 9 parts of softening oil, 7 parts of asphalt, 11 parts of rubber, 3 parts of reinforced fiber, 4 parts of diatomaceous earth, stabilizer 2 servings. The stabilizer is a mixture of trioctyl phosphate and polyvinylpyrrolidone in any ratio.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com