Coil component

a coil and component technology, applied in the direction of coils, transformer/inductance details, electrical devices, etc., can solve the problems of difficult automation of assembly using robots, difficult complex assembly process, etc., to improve assembly efficiency, simplify assembly process, and reliably catch chips and burrs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035]Preferred embodiments of a coil component will now be described with reference to the attached drawings.

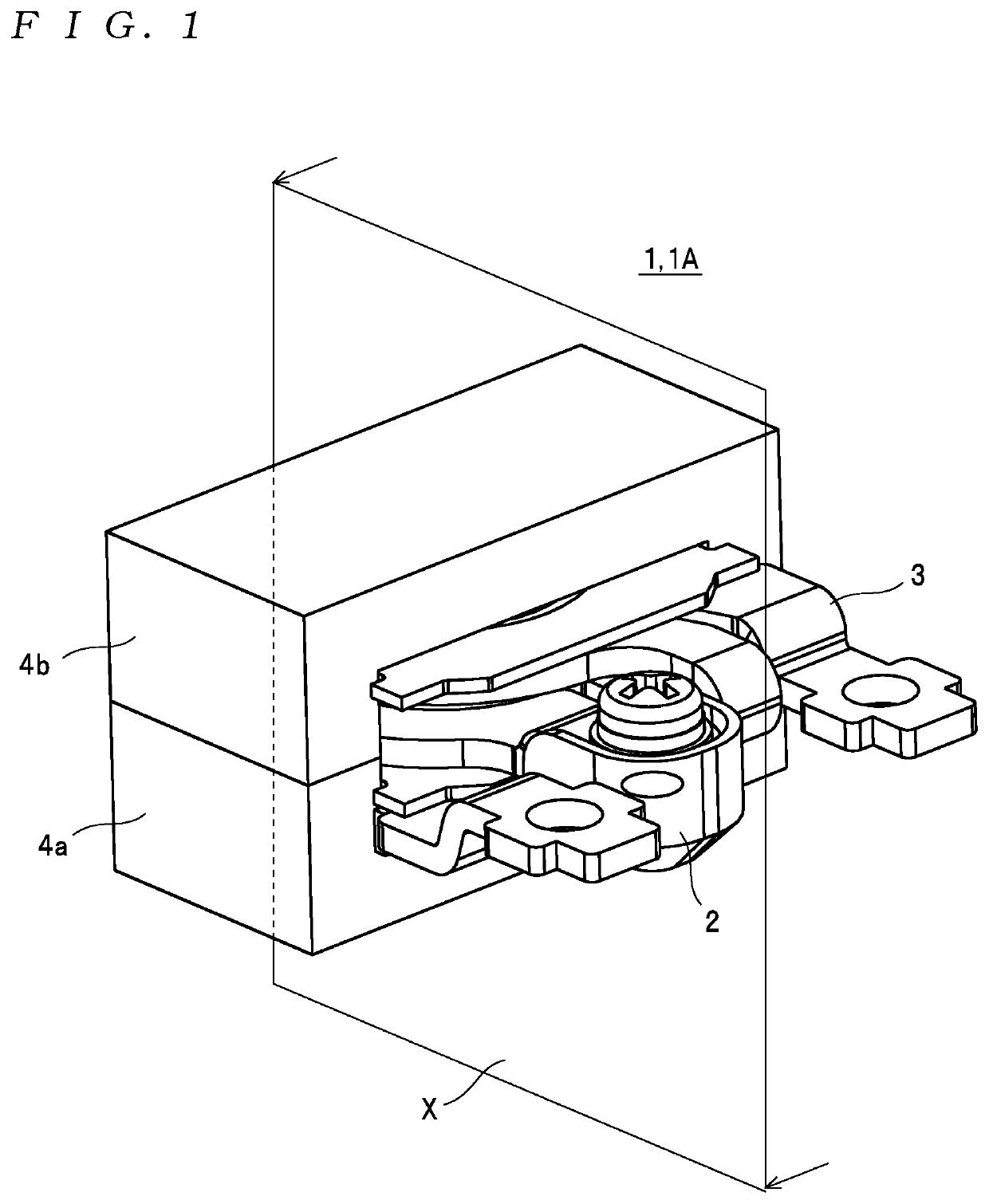

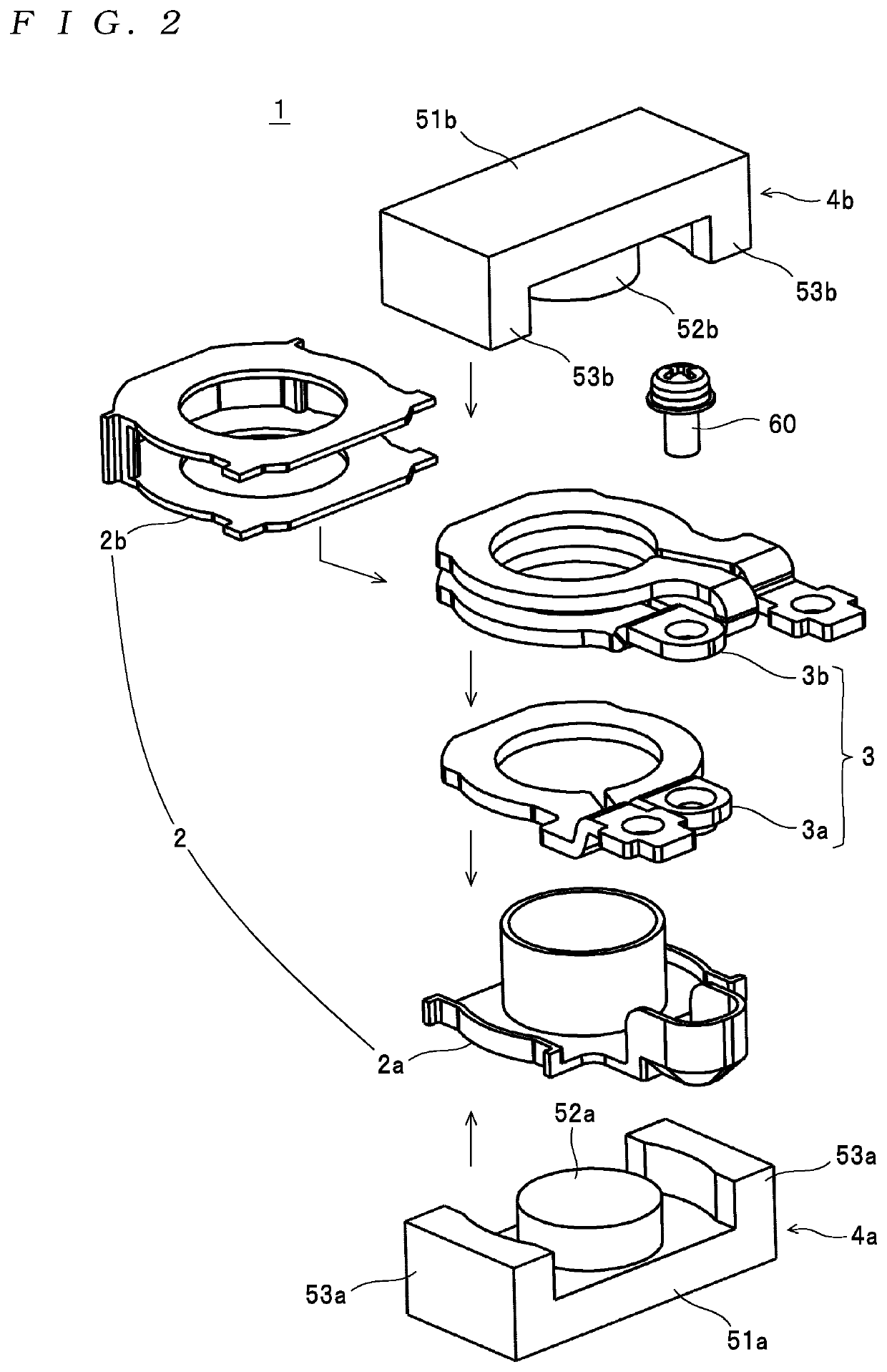

[0036]First, the configuration of a coil component 1 depicted in FIG. 1 will be described as an example of a coil component. The coil component 1 is an electrical component to be used in a switching power supply, for example, and as depicted in FIG. 1 and FIG. 2, includes a bobbin 2, a coil 3, and cores 4a and 4b. Note that a component composed of the bobbin 2 and the coil 3 without the cores 4a and 4b is also included in the intended meaning of the expression “coil component” used here.

[0037]As depicted in FIG. 2, the bobbin 2 includes a first bobbin member 2a (one example of a “first bobbin member” for the present invention) and a second bobbin member 2b (one example of a “second bobbin member” for the present invention).

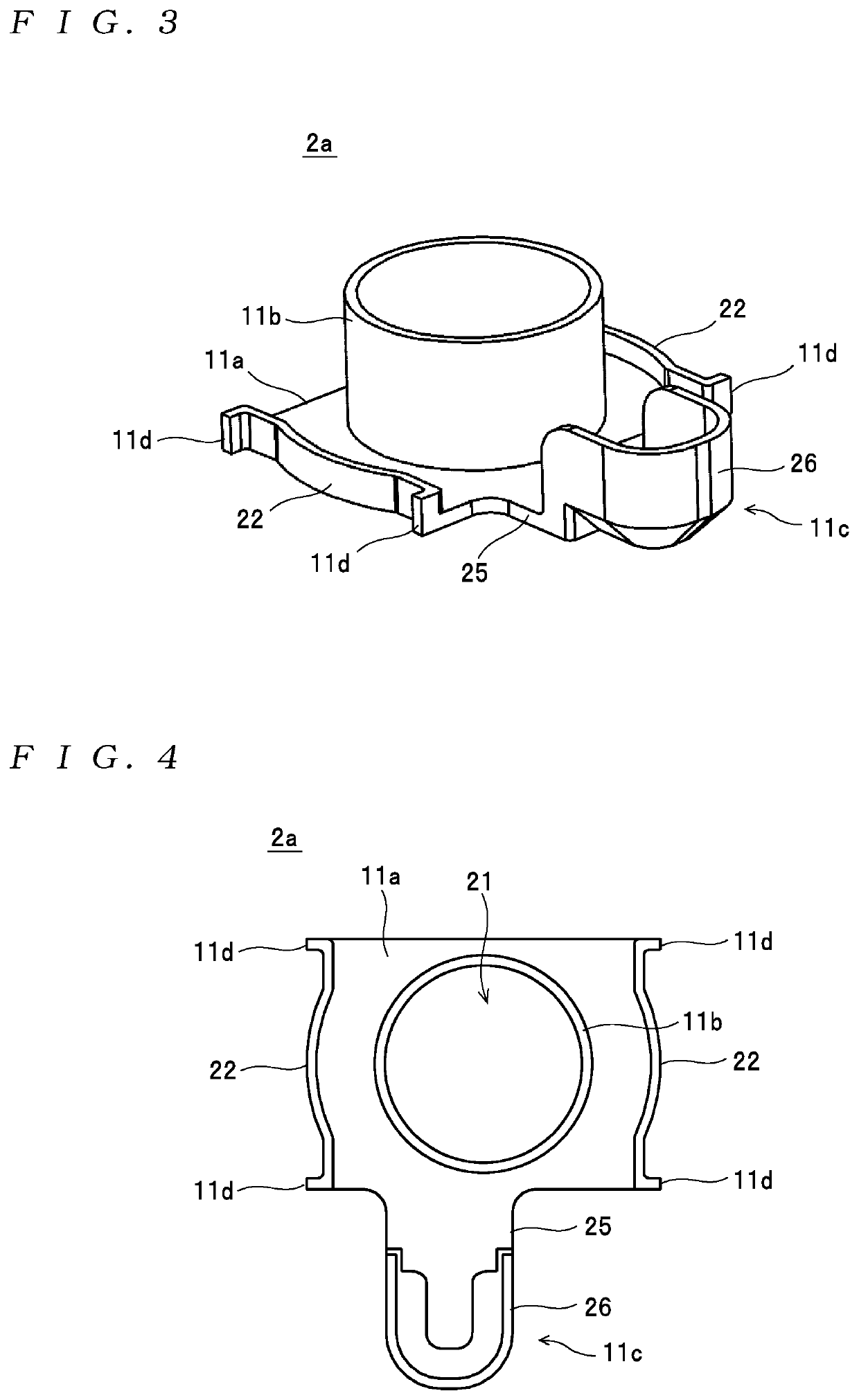

[0038]As depicted in FIGS. 3 and 4, the first bobbin member 2a includes a base plate 11a, a barrel 11b, a support 11c, and four projecting portions 11d, w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

| time | aaaaa | aaaaa |

| electrically | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com