Shock absorber for cycle and methodology incorporating the same

a shock absorber and cycle technology, applied in the direction of frictional roller transmission, steering device, cycle equipment, etc., can solve the problems of rider discomfort, rider fatigue in the knee joints, and inability to innovate very well, and achieve the effect of preventing the impact of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

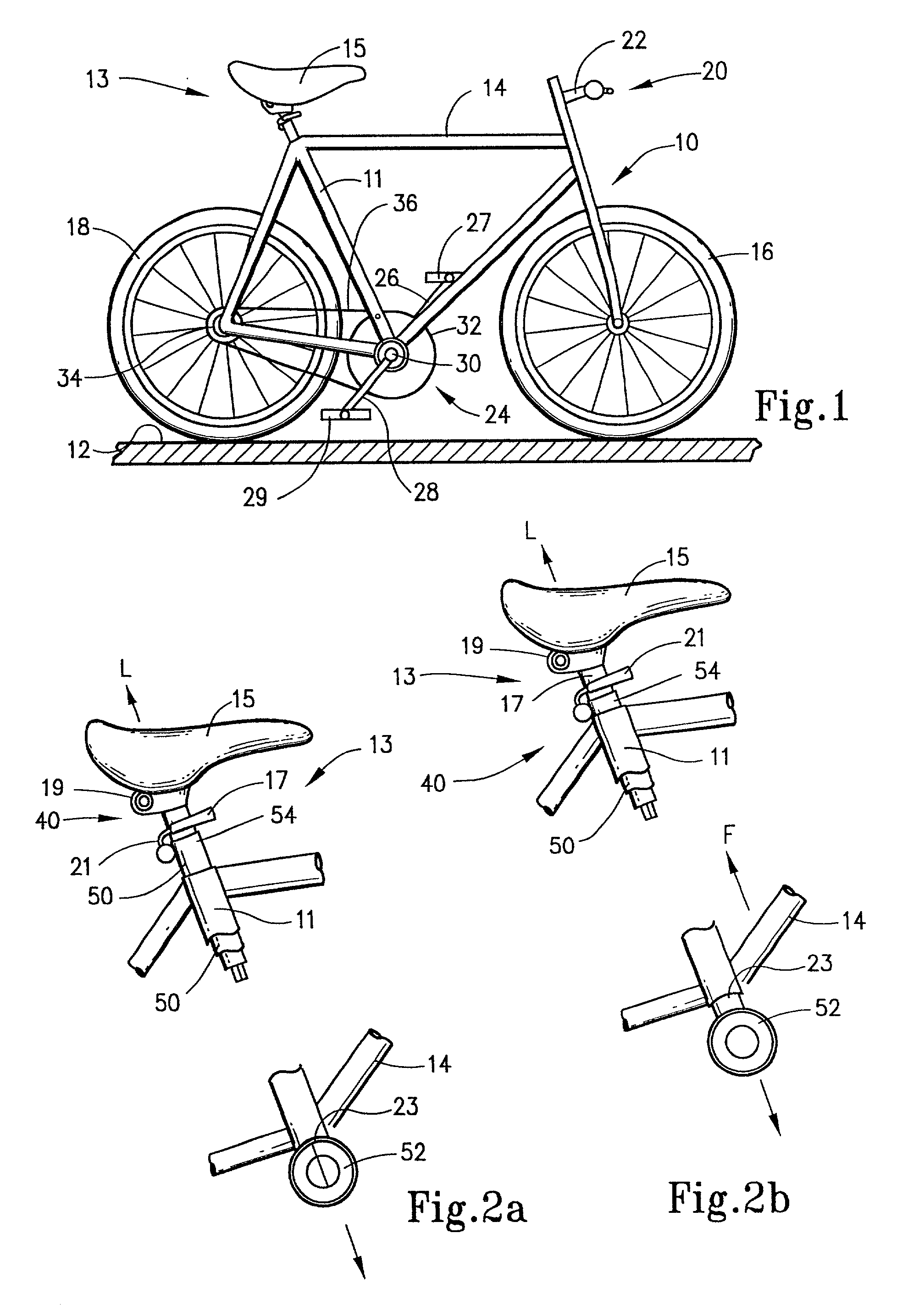

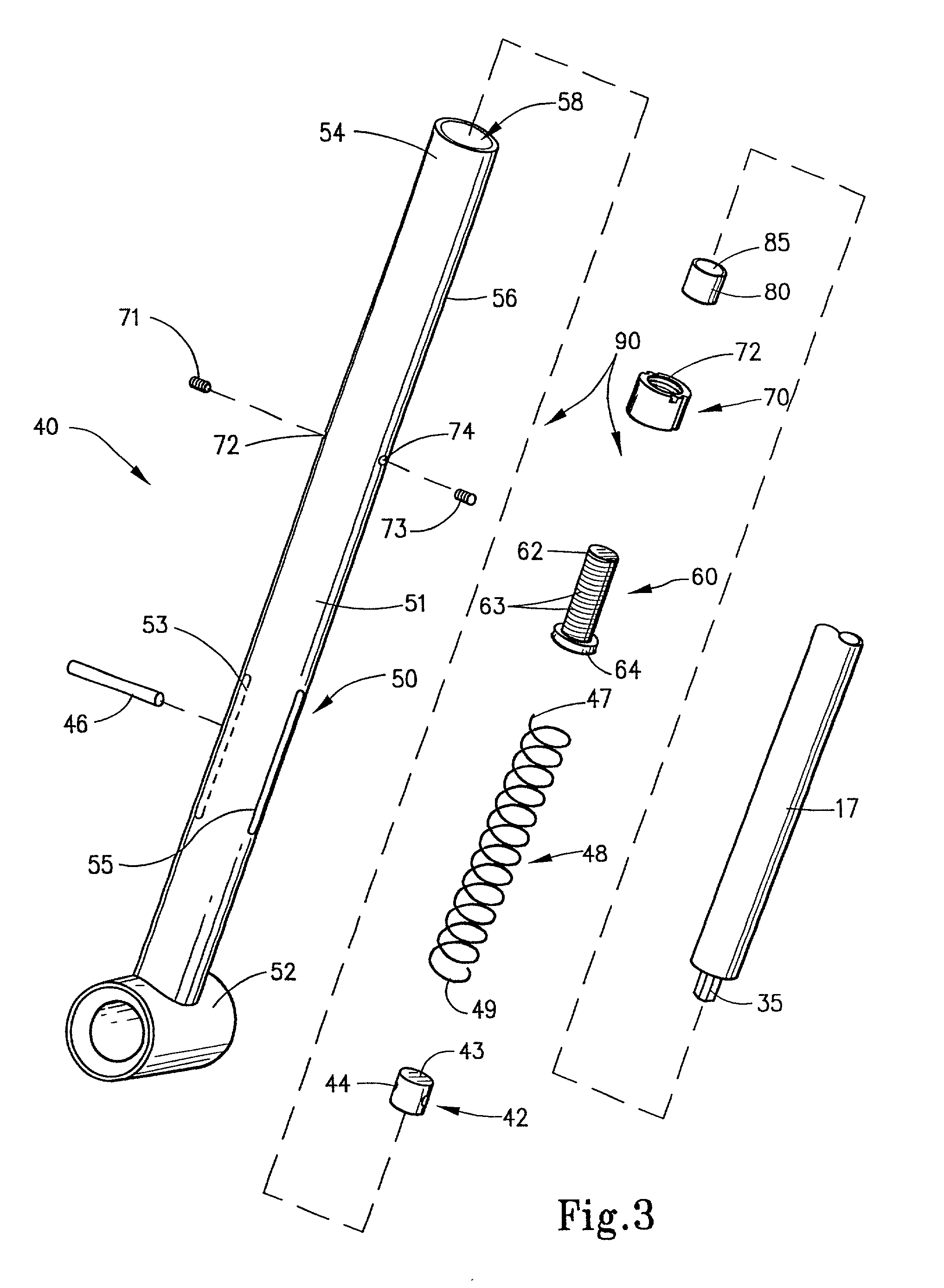

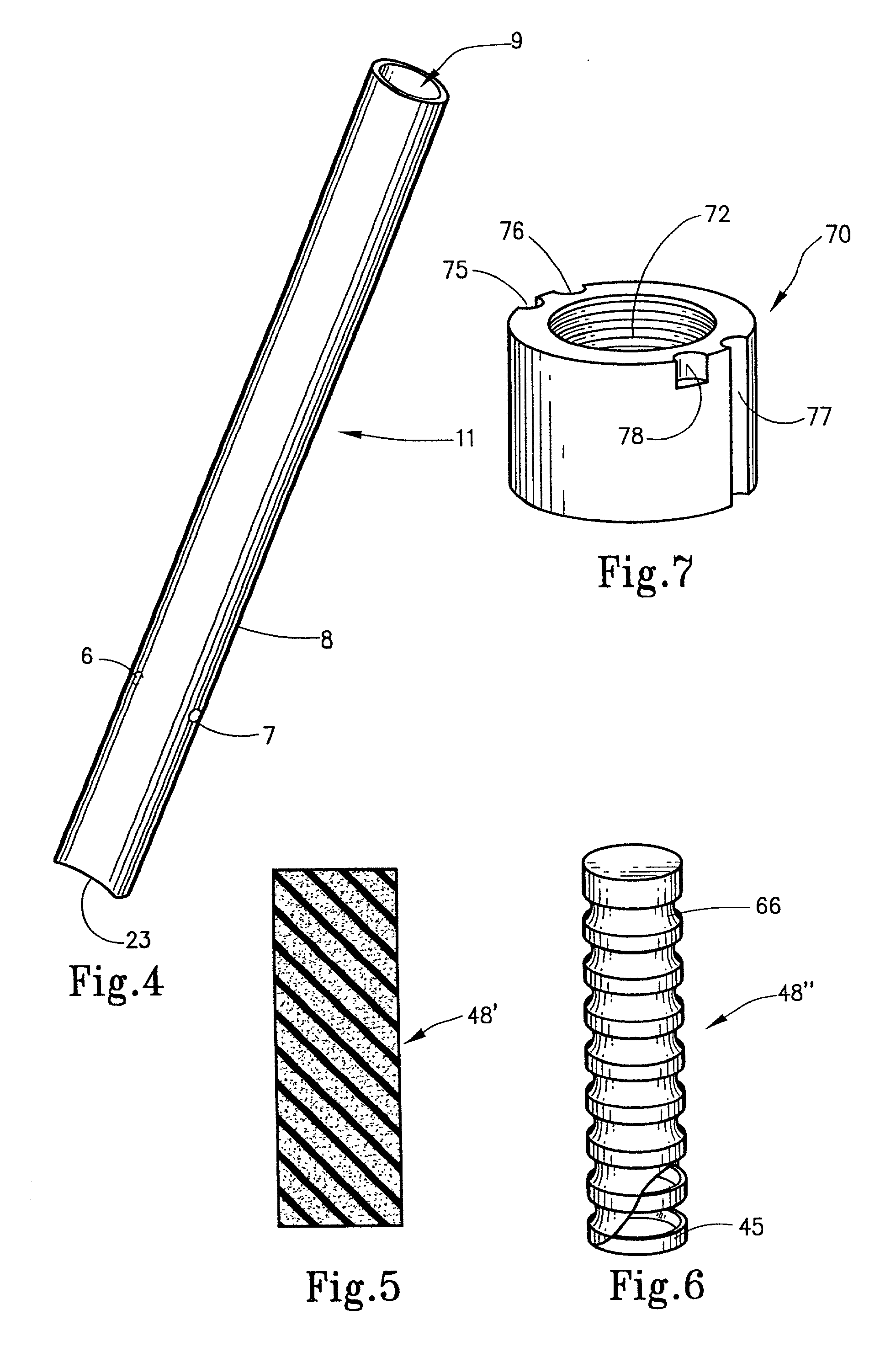

[0034] The present invention generally concerns shock absorbers, and is more specifically directed to shock absorbers for use with cycles to cushion against impacts occurring during operation. While the present invention is described herein with reference to a bicycle in the form of a mountain bike, it should be appreciated that the principal features of the shock absorber can also be implemented into other types of wheeled vehicles, such as tricycles, racing bikes or even some motorized vehicles. The shock absorber is especially adapted for use in the seated region of the cycle to cushion the seat assembly and the drive assembly relative to impacts resulting from bumps, pot holes, rocks or other discontinuities in the riding surface.

[0035] Accordingly, and as generally introduced in FIG. 1, the shock absorber is adapted for use with a cycle 10 adapted to travel in an upright position along a support surface 12. Cycle 10 may be a conventional mountain bike so that it includes a rigi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com