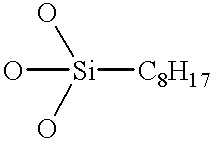

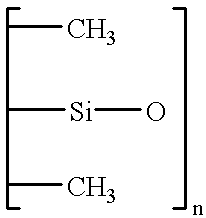

Hydrophobic silica

a technology hydrophobic silica, which is applied in the direction of colloidal chemistry, silicon oxides, silicon compounds, etc., can solve the problems of unwanted speckling, linear decline of thickening action, and limited application of pyrogenically produced silica

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 2

[0033] Investigation of the influence of higher compaction on applicational properties

2 AE R 812, AE R 812, AE R 812, compacted compacted uncom- RHE RHE pacted UB 3847-2 UB 3847-3 UB 3847-1 (4) (5) AE R 812 10 kg 15 kg 20 kg RHE sack sack sack specific. Tamped density (DIN ISO g / l 50 87 106 approx. 787 / 11) 50 Effectiveness, ethanol 184 214 209 216 1) (0955) Effectiveness (UT), 218 260 290 236 1) ethanol (0965) Settling vol. % 10 1 1 1) (effectiveness, high-speed mixer)

[0034] 1. Determined on standard sample (UB 3391) RHE in the above table indicates the Rheinfelden plant located in Germany.

[0035] Rheological testing:

[0036] Polymer: Araldit M (biphenol-1-expoxy resin by Ciba-Geogy, in the form of clear yellow liquid).

[0037] Thixotroping agent: R 202 and R 812 Additive:

[0038] Sample A R 812 10 kg 2-10123

3 Storage time 5 rpm 50 rpm in days [mPa*s] [mPa*s] T.I. Sample production date: 24.02.1994 Spindle: 5 0 16600 4460 3.72 80-85.mu. Sample AR 812 15 kg 1.0 / 8 min Sample production date:...

example 3

[0044] Investigation of the influence of higher compaction on applicational properties.

4 AE R 202, AE R 202, AE R 812, compacted compacted uncompacted RHE RHE UB 3848-1 UB 3848-2 UB 3848-3 2-02024 2-01024- 2-01024- AE R 202 10 kg (2) (3) RHE sack 15 kg sack 20 kg sack specific. Tamped density (DIN ISO 787 / 11) g / l 51 93 119 approx. 60 3) Effectiveness, ethanol (0955) 319 334 336 334 1) Effectiveness (UT), ethanol (0965) 346 365 373 339 1) Settling vol.% 10 5 1 (effectiveness, high-speed mixer)

[0045] 1) Determined on standard sample (UB 3391)

[0046] 3) Guide value

[0047] The compacted AEROSIL R 202 samples behave in a similar manner to the compacted AEROSIL R 812 samples.

[0048] Reference is thus made to Example 2 with regard to the discussion.

[0049] The parameter of "effectiveness" reported in the tables herein relates to the high degree of fineness of the particle. This is therefore an indicator of high transparency and good stability of the resulting dispersions.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| hydrophobic | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com