Swivel wheel assembly with adjustable shock absorption

a technology of shock absorption and adjustable shock absorption, which is applied in the field of swivel wheel assembly, can solve the problem that the energy absorption cannot be custom-set based, and achieve the effect of quick assembly and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

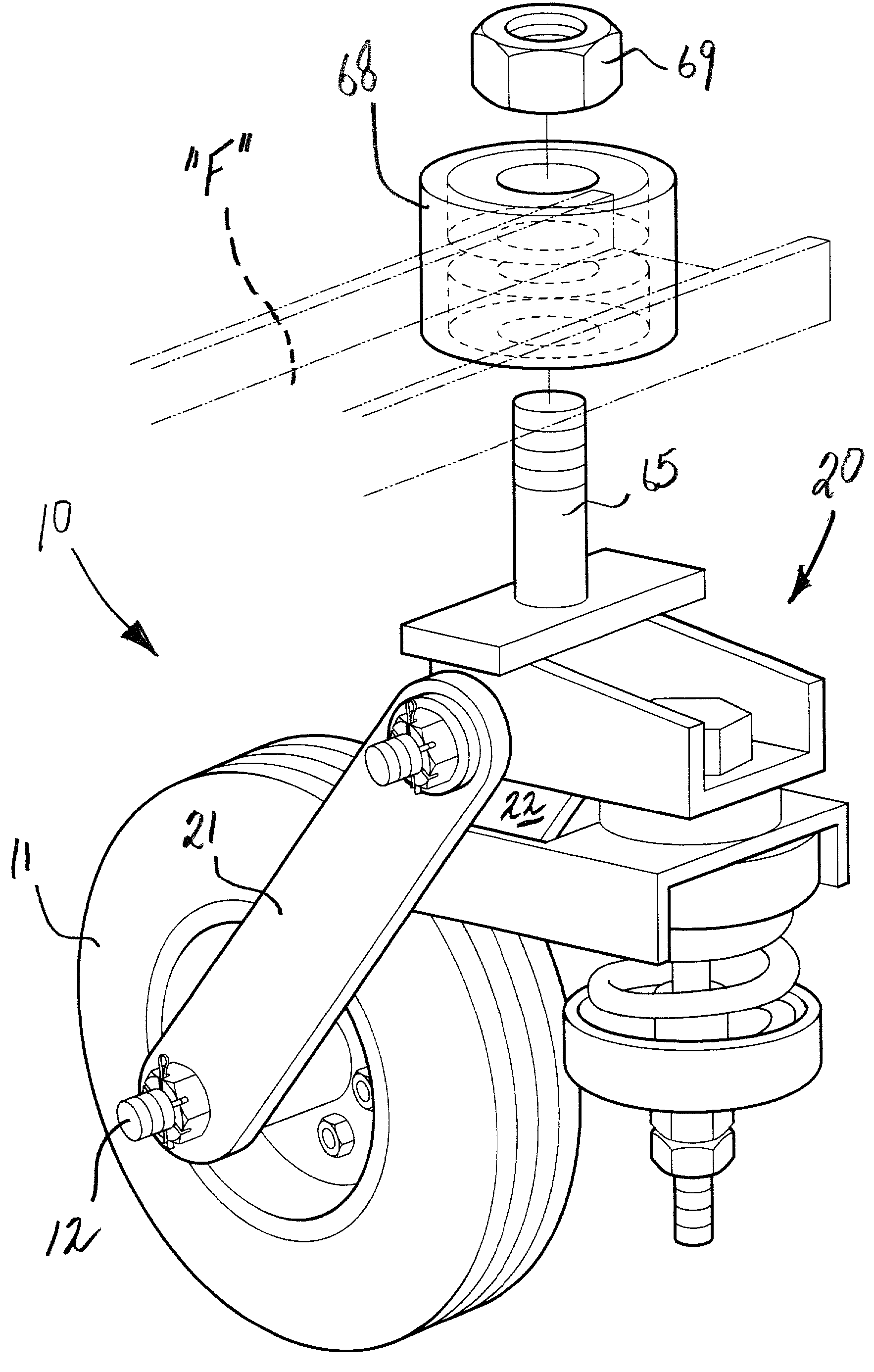

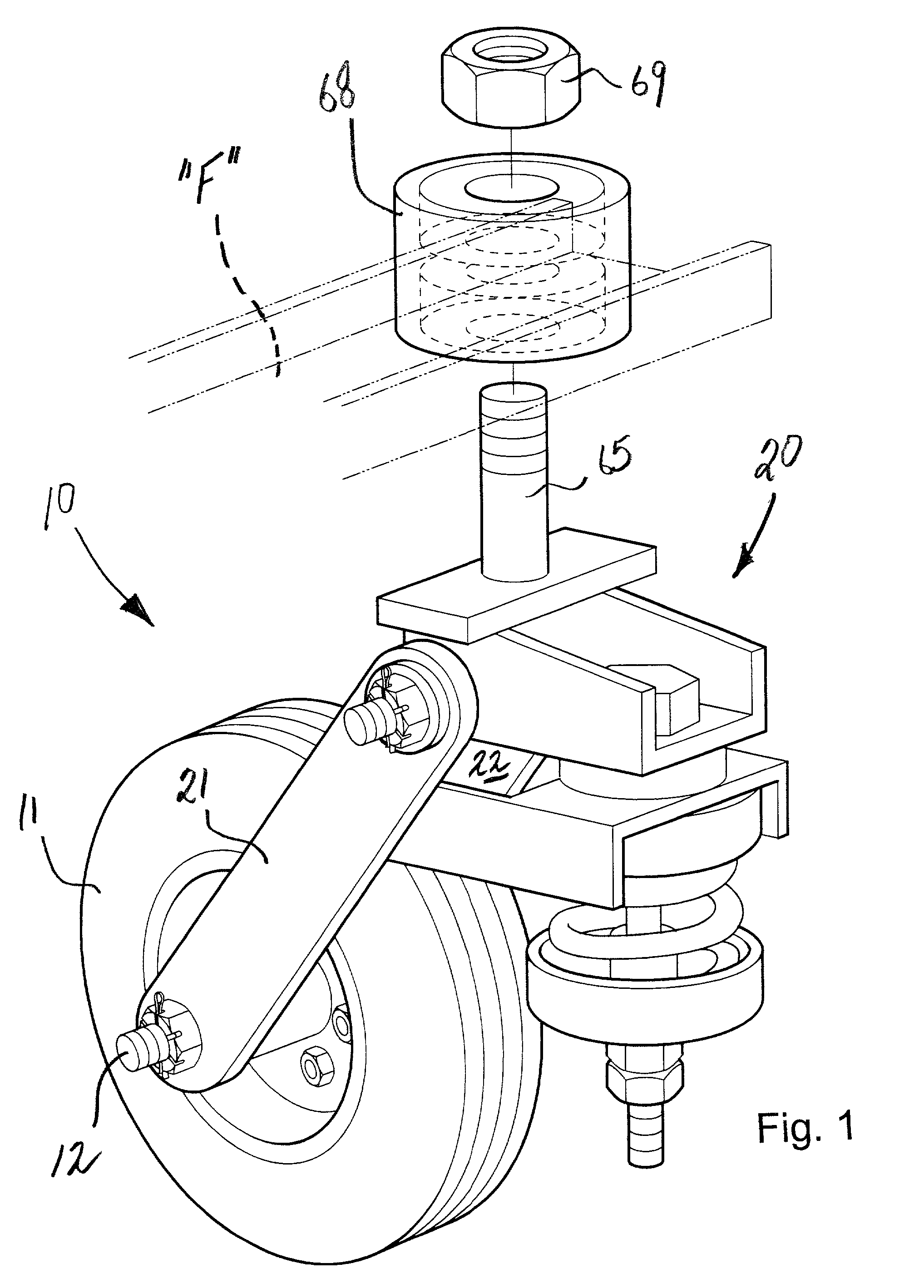

[0031] Referring now specifically to the drawings, a swivel wheel assembly according to the present invention is illustrated in FIG. 1, and shown generally at reference numeral 10. The wheel assembly 10 is especially applicable for use on utility vehicles, such as trailers, designed for being hauled. The trailer may be a three-wheeled vehicle with a single swivel wheel assembly 10 in the front and two conventional wheels in the rear, or a two-wheeled vehicle with two identical swivel wheel assemblies 10 on either side.

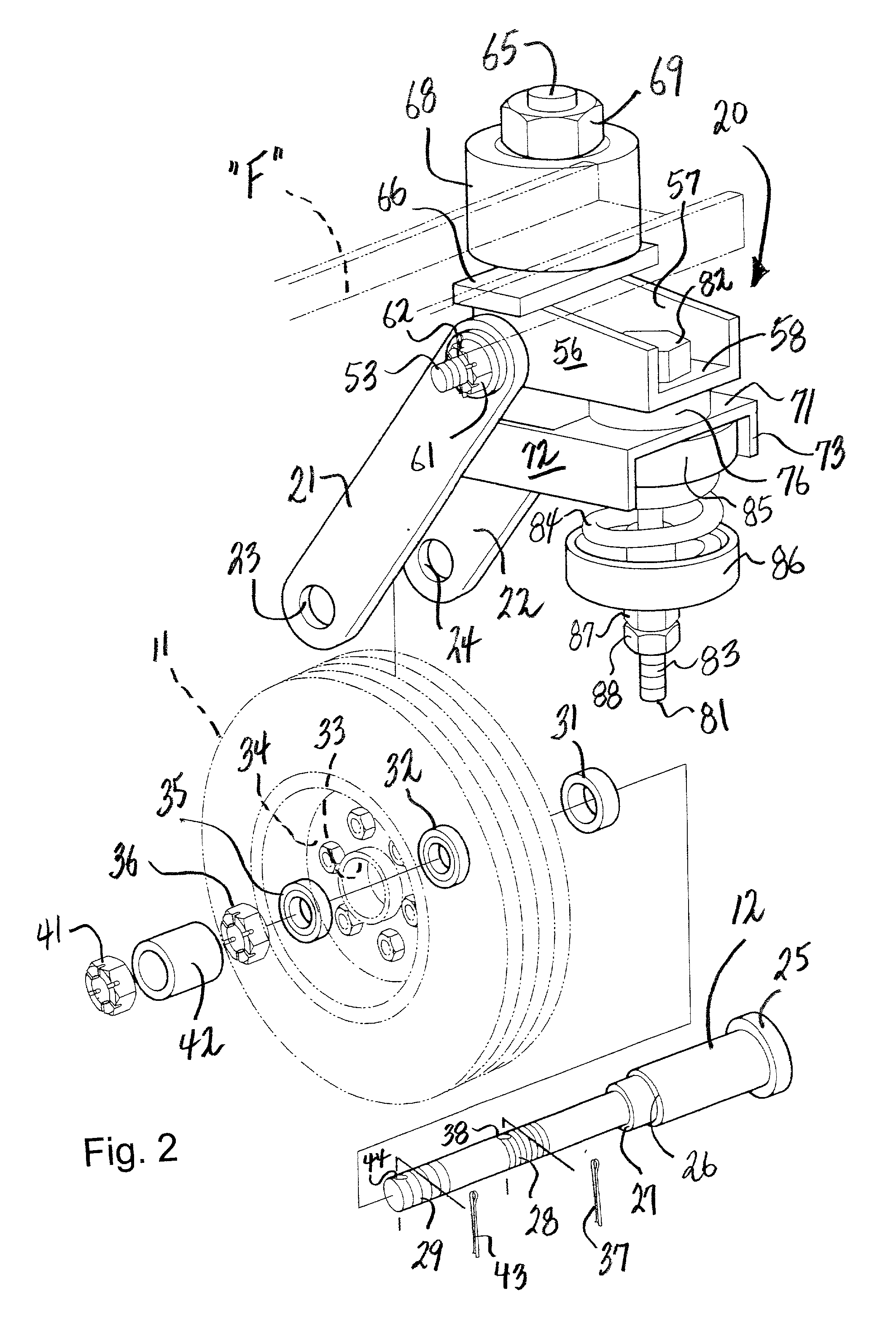

[0032] The swivel wheel assembly 10 includes a vehicle wheel 11 mounted for rotation on a wheel axle 12, and a shock-absorbing wheel fork 20 secured to the wheel axle 2 and an underframe "F" of the utility vehicle. As best shown in FIG. 2, the wheel fork 20 is constructed of first and second elongated, spaced-apart support arms 21 and 22 having respective distal and proximal ends. The distal ends define respective axle openings 23 and 24 which receive the wheel axle 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com