Trim component for use in a siding system

a technology of trim and component, which is applied in the field of trim component for use in siding systems, can solve the problems of requiring countless man hours and a great deal of natural resources to complete, and constructing an entire dwelling from logs or timbers remains an expensive, time-consuming and laborious proposition, and the use of natural resources is not easy and inexpensive, so as to achieve the effect of reducing the amount of time and effort to install and easy and inexpensive manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

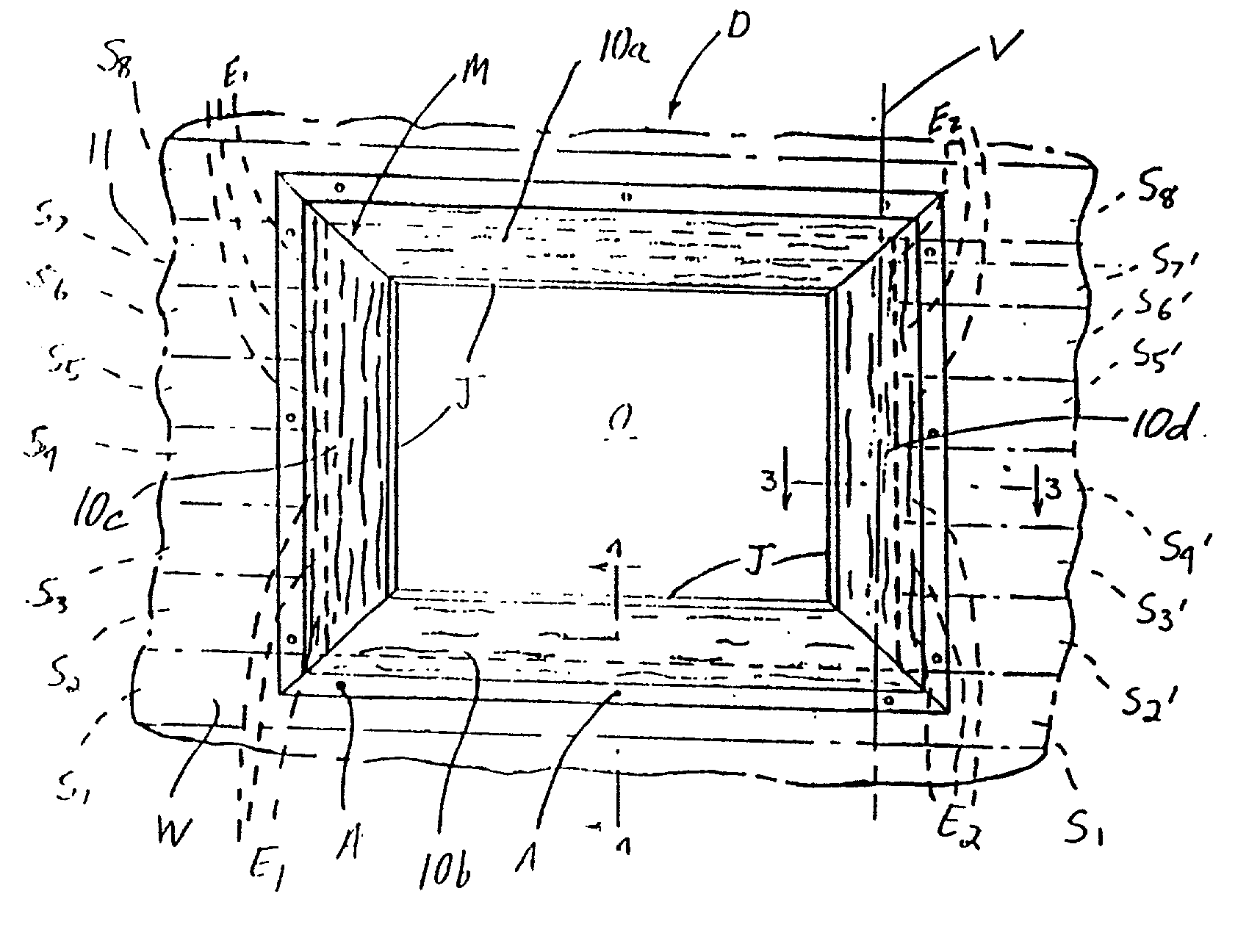

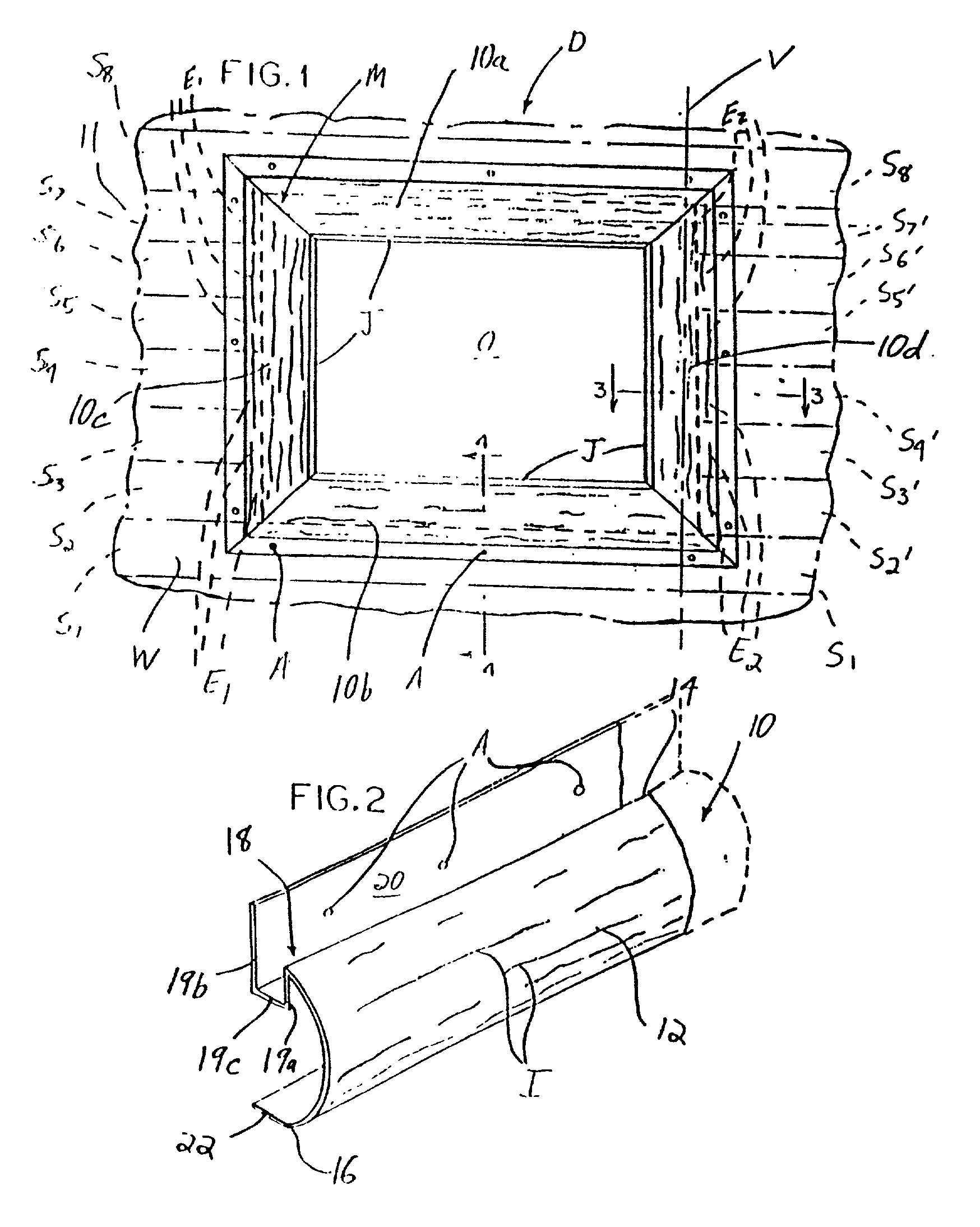

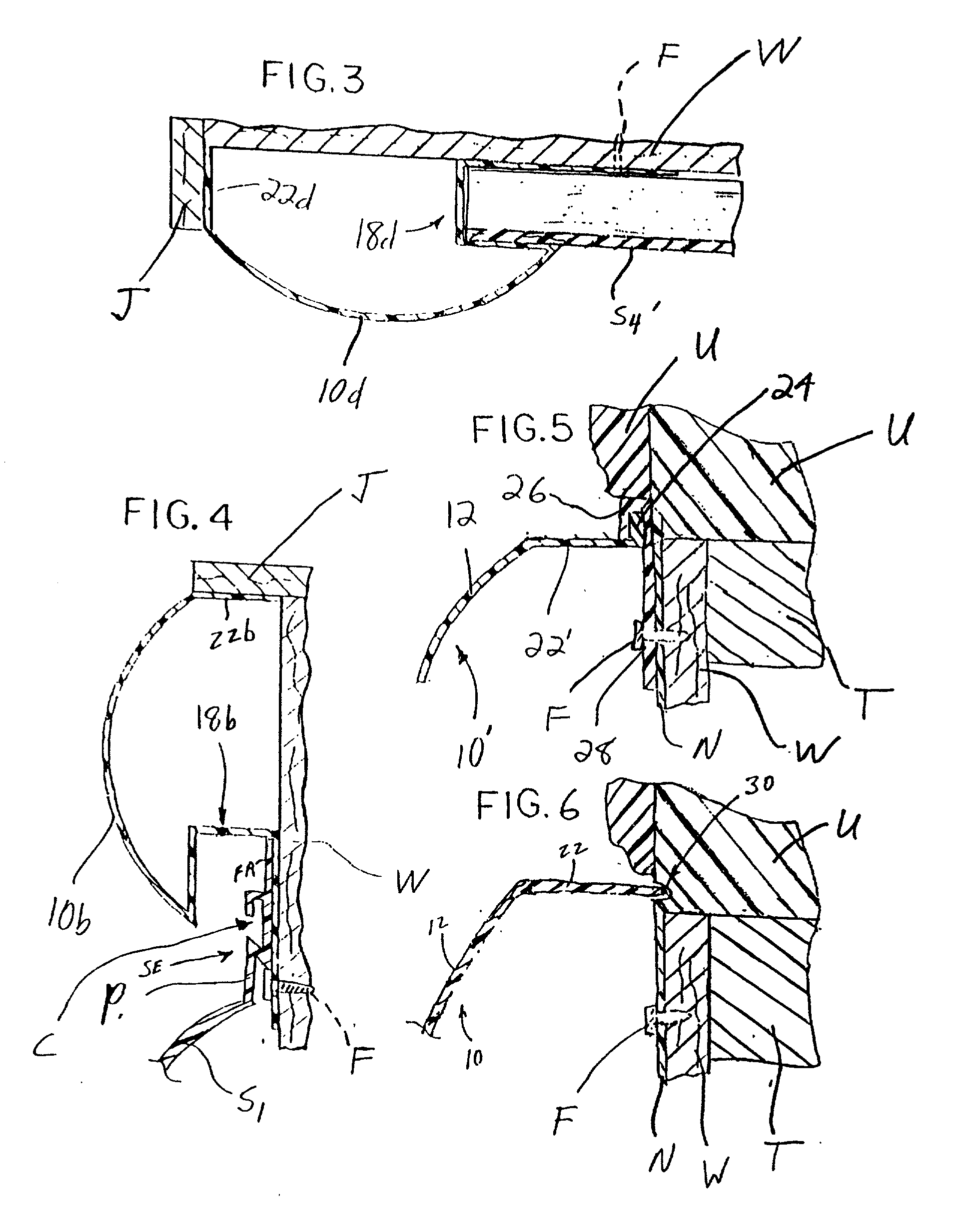

[0022] Reference is now made to FIG. 1, which illustrates a dwelling D comprising a stable mounting structure having at least one wall W in which an opening O is formed. In conventional construction, the wall W is usually formed of one or more sheets of plywood or oriented strand board nailed or otherwise fastened to the underlying framed construction (not shown). The opening O may be sized and shaped either for receiving a window (not shown) or door and the corresponding hardware, and may be surrounded by a plurality of jamb members J (a head jamb, side jambs, and in the case of a window, a sill jamb) that create seating surfaces for the corresponding sides of a door or window when installed. The jamb members are coupled directly to the framed construction. Alternatively, instead of jambs J or like members, the framing members alone may support a pre-assembled window or door unit U (see framing member T in FIGS. 5 and 6), which typically includes an integral nailing fin or flange N...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com