Adhesive roller construction

a technology of adhesive rollers and adhesive strips, applied in the field of adhesive rollers, can solve the problems of waste of adhesive rolls, difficulty in accurately identifying users, and the inability to use adhesive rolls, and achieve the effect of reducing or eliminating the stress on the strip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

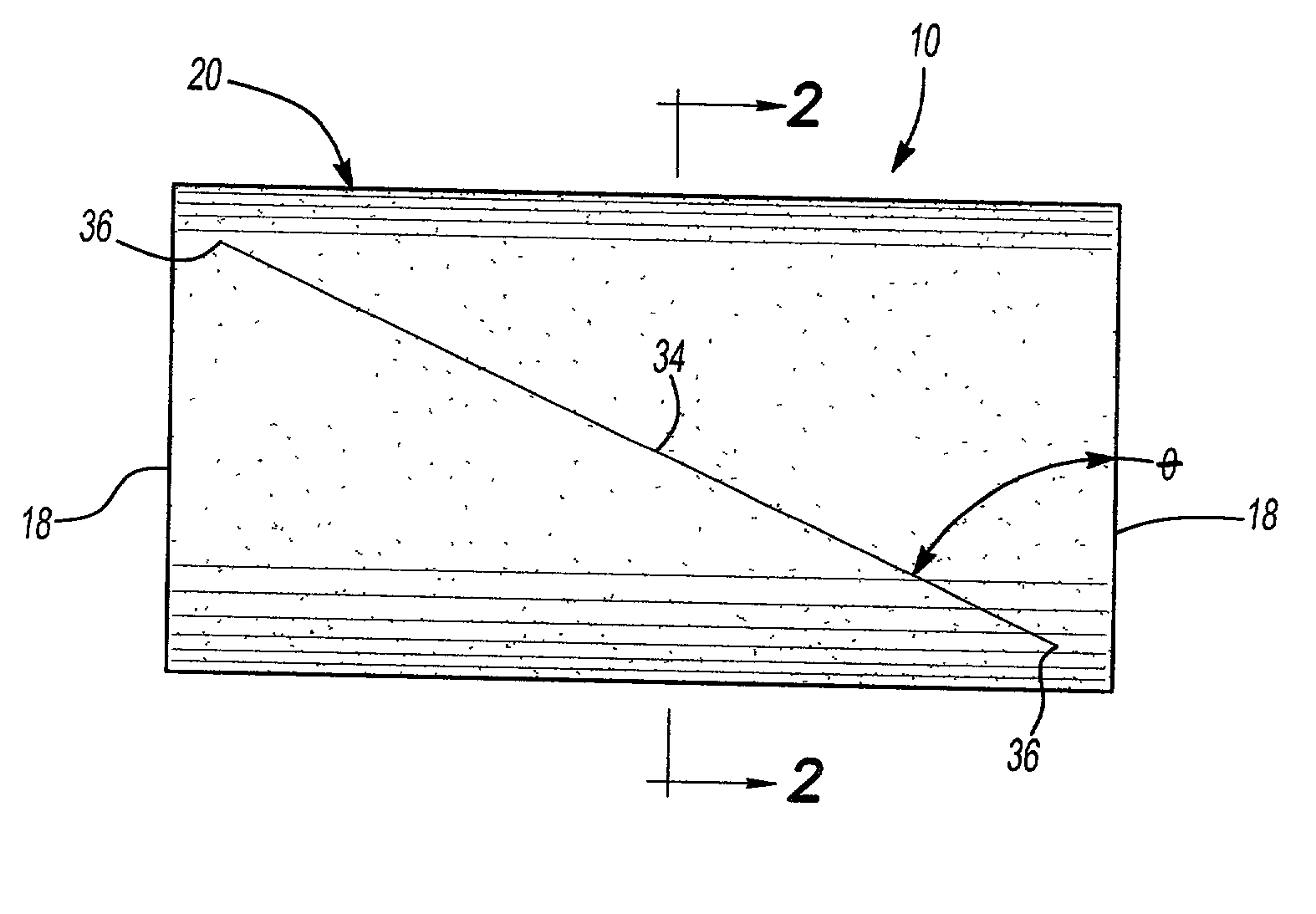

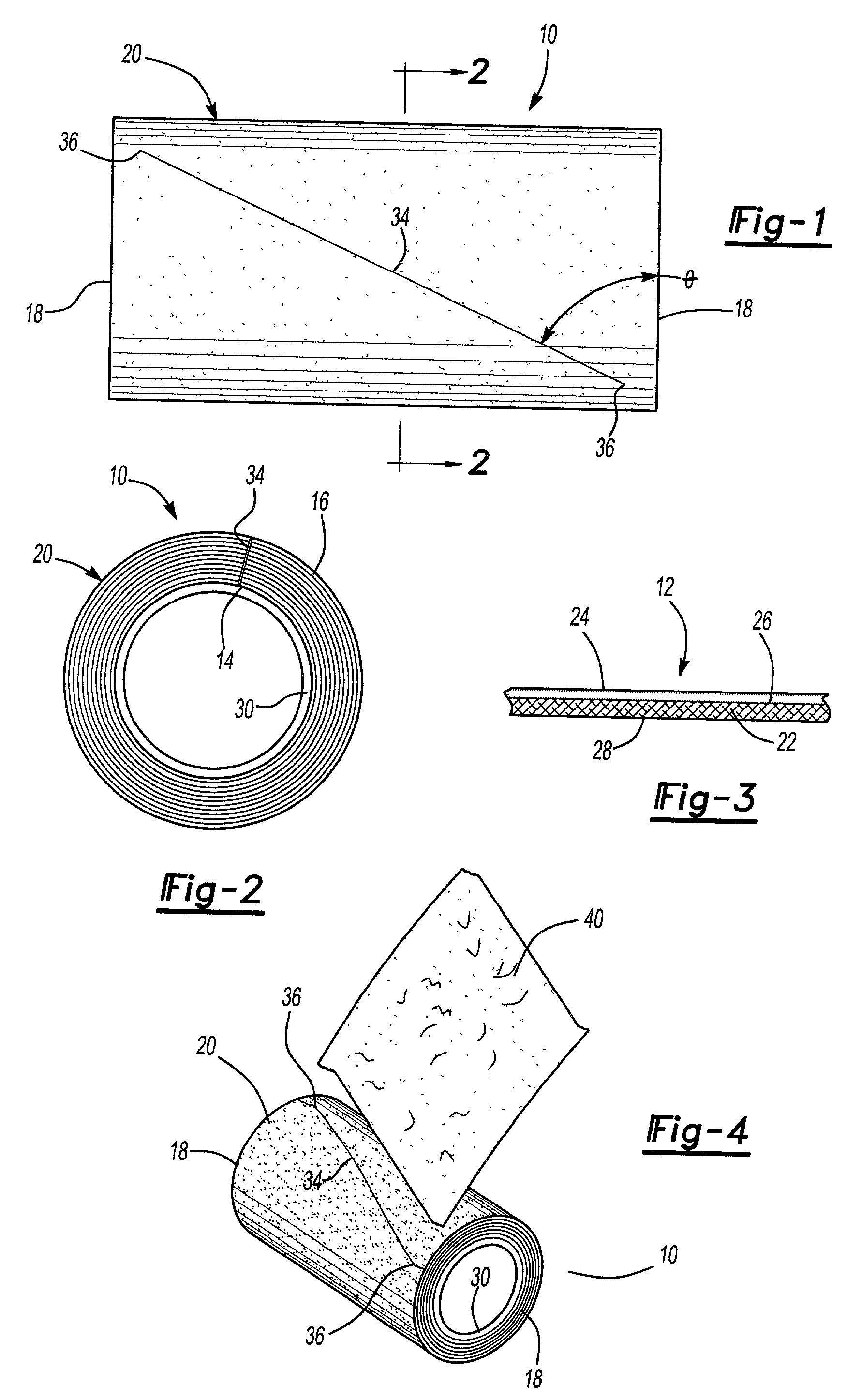

[0018] With reference first to FIGS. 1-3, a preferred embodiment of the adhesive roll construction 10 is there shown and comprises an elongated strip 12 having a first end 14 (FIG. 2), a second end 16 (FIG. 2) and a pair of spaced and substantially parallel sides 18. The strip is wound from the first end 14 and to the second end 16 into a tubular cylindrical roll 20 in which multiple layers of the strip 12 overlap each other.

[0019] As best shown in FIG. 3, the strip 12 comprises a backing layer 22 and an adhesive layer 24 on one side 26 of the backing layer 22. Preferably, the adhesive layer 24 overlies the entire side 26 of the backing layer 22 so that, when the strip 22 is wound into the cylindrical roll 20, the adhesive layers 24 adhesively, but detachably, engage the opposite side 28 of the backing layer 22 of the next outer layer of the strip 22 on the adhesive roll 20.

[0020] With reference now particularly to FIG. 2, the adhesive roller construction 10 preferably includes a tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com