Canister-type vacuum cleaner

a vacuum cleaner and canister-type technology, applied in carpet cleaners, carpet/fur/leather cleansers, detergent compounding agents, etc., can solve the problems of inability to clean stubborn stains on the floor or carpet, increased cost, inconvenience for users to use,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The preferred embodiment of the present invention will be described in greater detail with reference to the accompanying drawings.

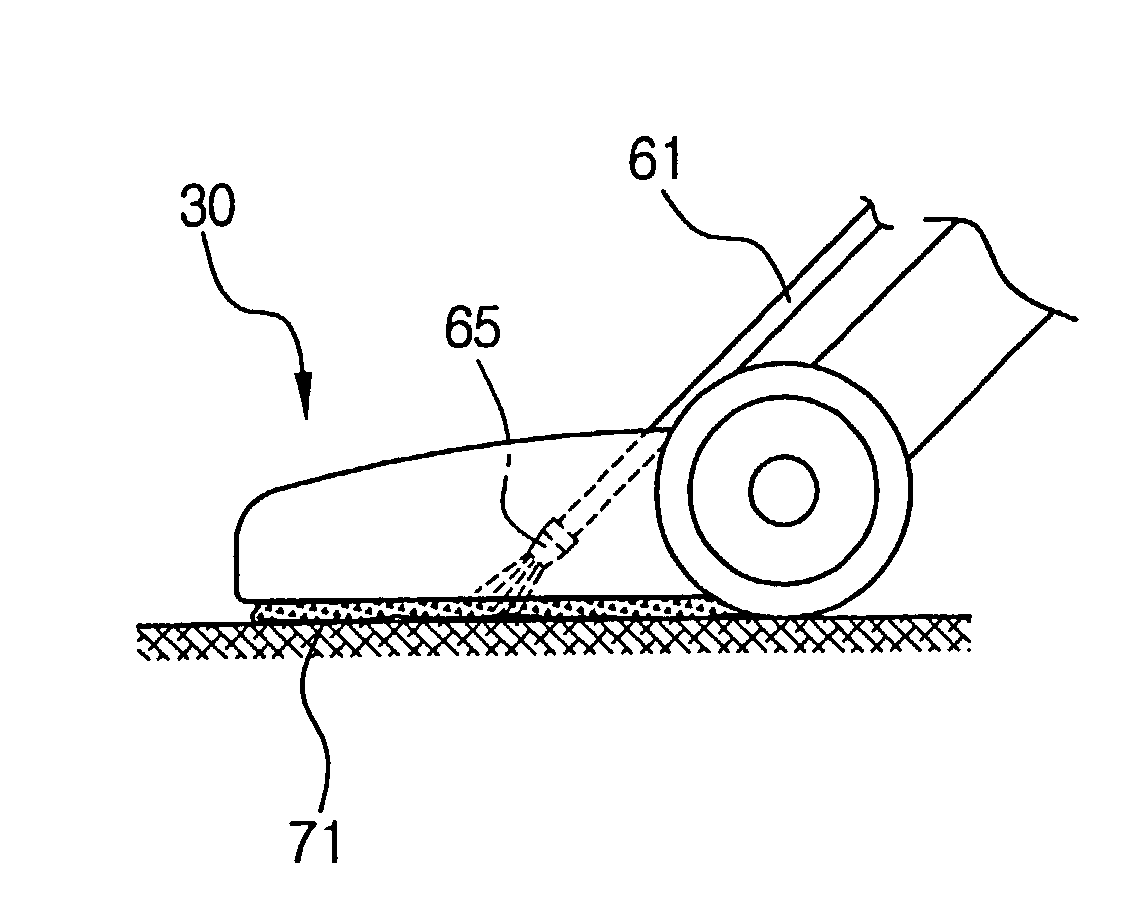

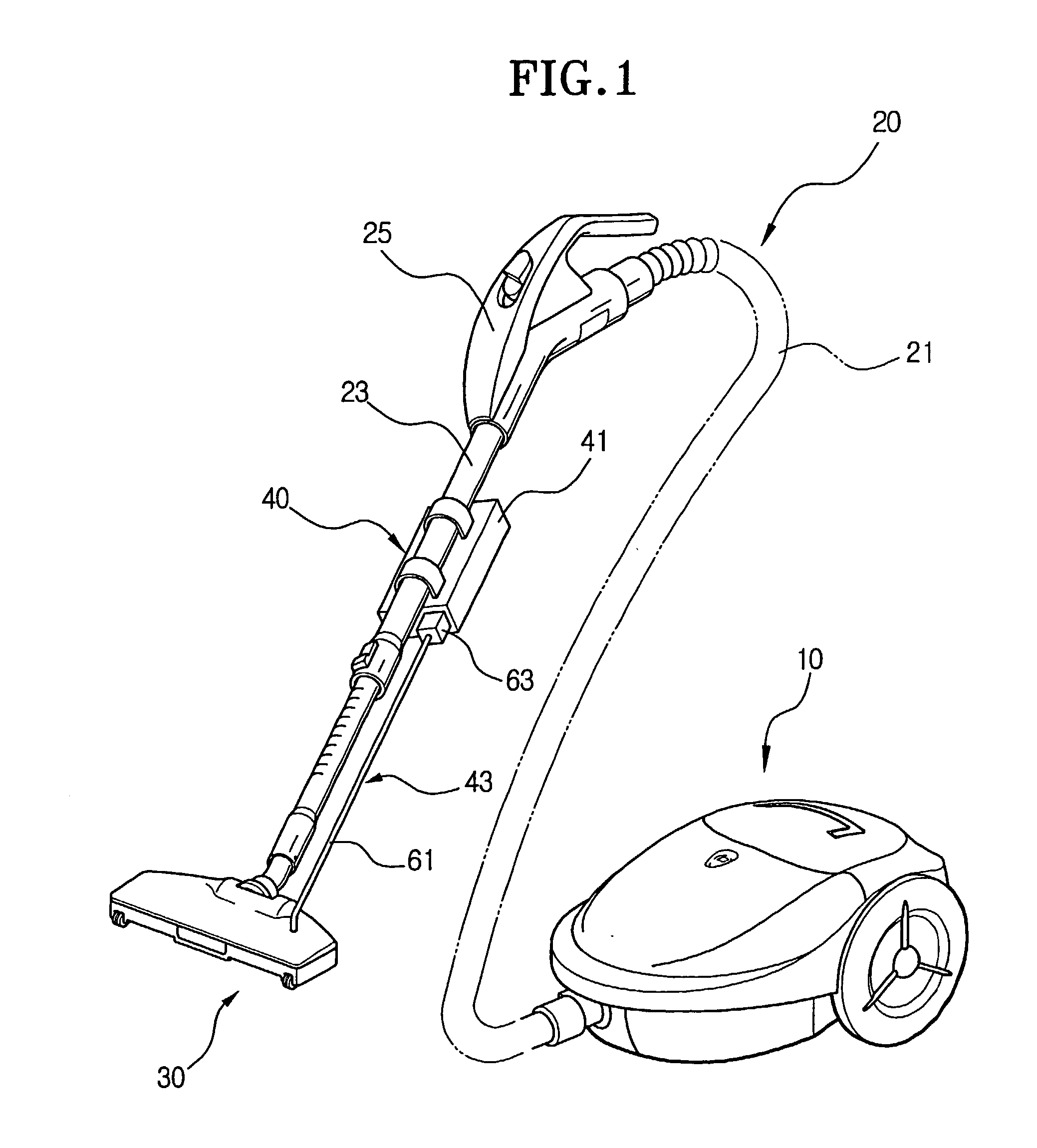

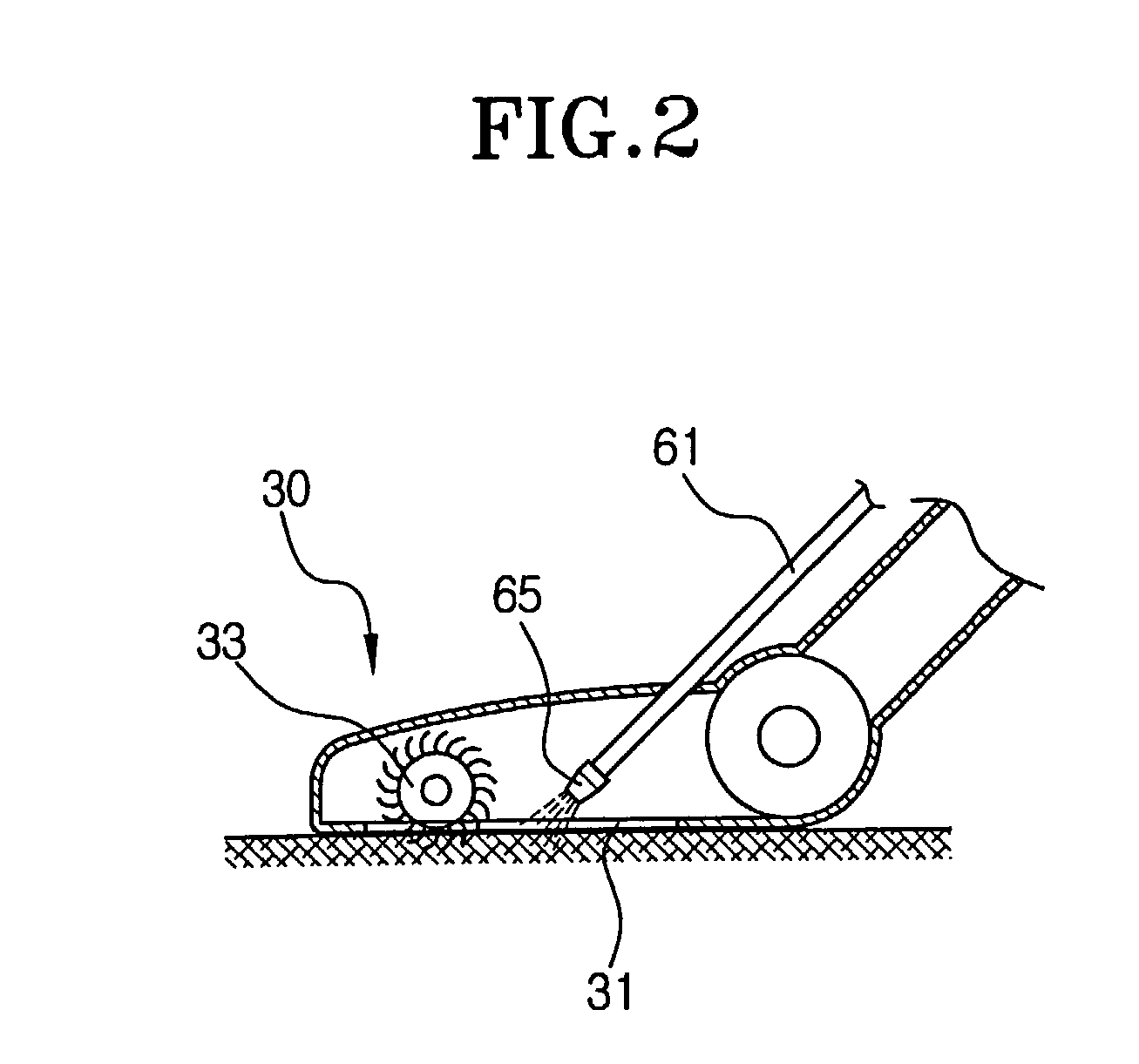

[0021] Referring to FIG. 1, the canister-type vacuum cleaner according to the preferred embodiment of the present invention includes a cleaner body 10, a suction extension pipe 20 connected to the cleaner body 10, a suction brush 30 disposed at an end of the suction extension pipe 20, and an electrolytic liquid supply device 40 disposed at the suction extension pipe 20.

[0022] Like a general vacuum cleaner, the cleaner body 10 has a driving unit and a dust chamber, which are respectively formed inside. The driving unit has a driving motor for generating a suction force. A dust collecting filter or cyclone dust collecting device is disposed in the dust chamber to filter the contaminants from the drawn air.

[0023] If the suction brush 30 also functions to draw liquids in addition to the contaminants, it can have a liquid separating unit for separately ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com