Self-attaching elastic cord

a self-attaching, elastic cord technology, applied in the direction of snap fasteners, buckles, press-button fasteners, etc., can solve the problems of insufficient pressure on the fastener to continue securing objects, limited binding possibilities, and user's inability to have unlimited flexibility to bind strips

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

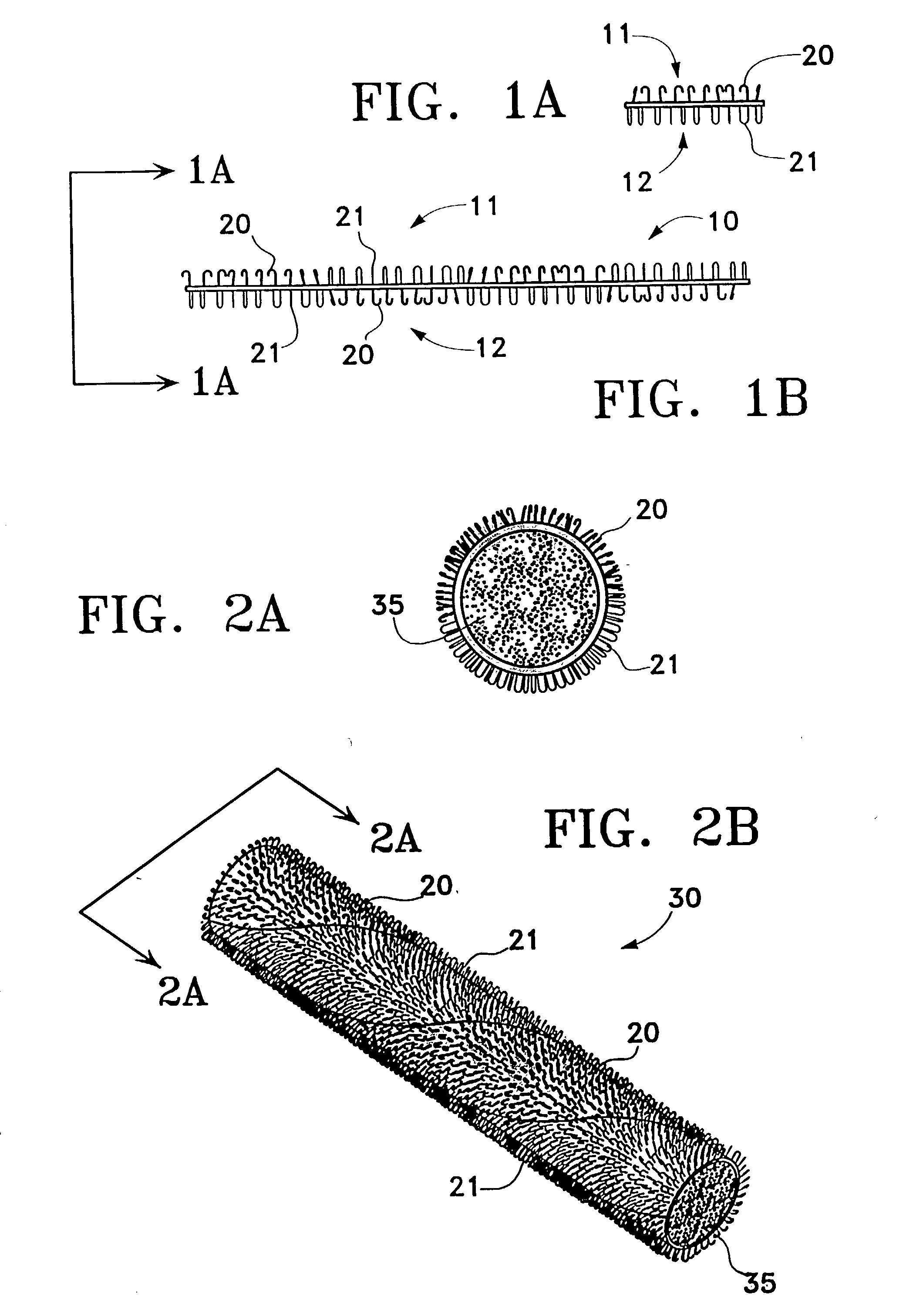

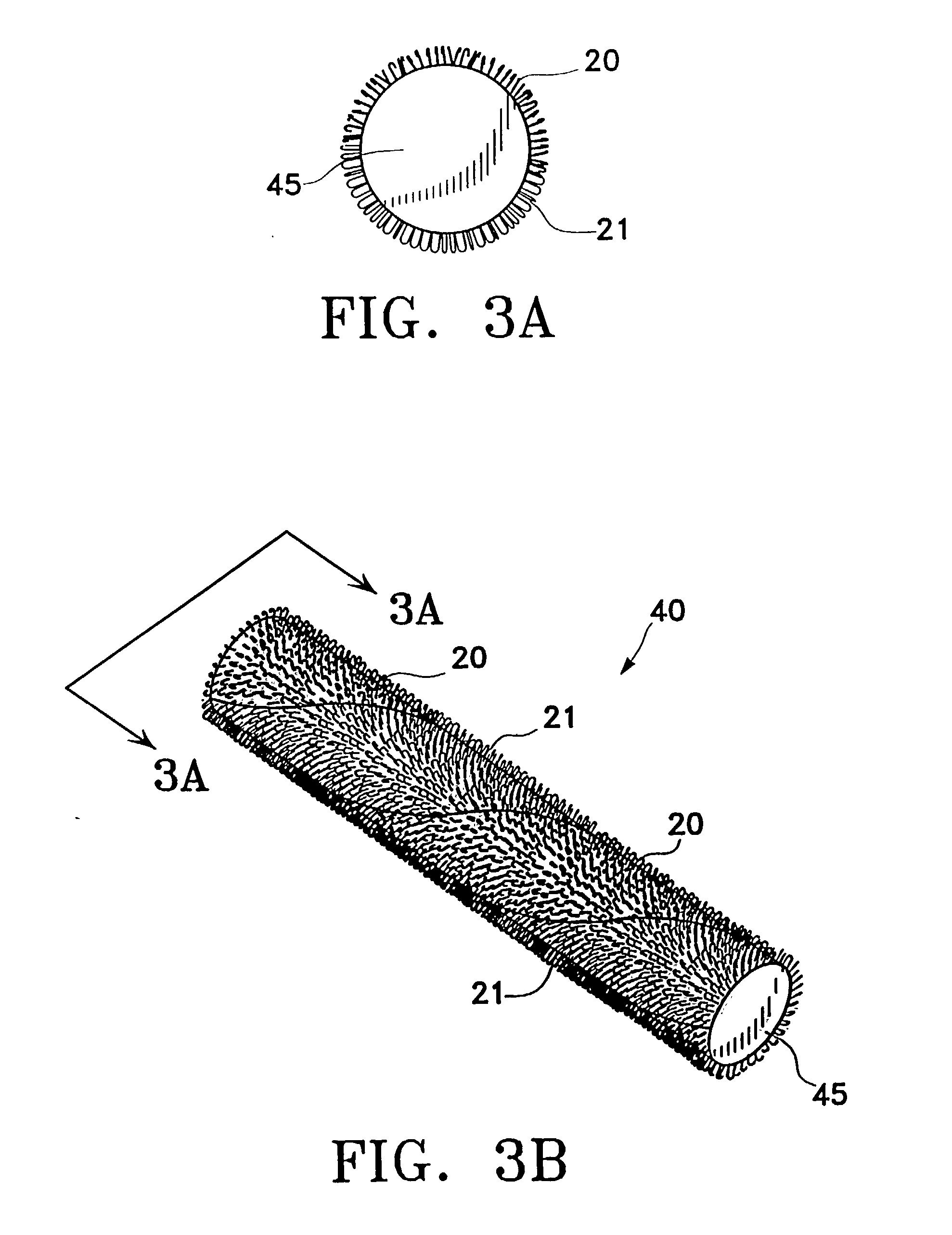

[0034] Throughout these figures, reference number 20 is used to generally designate hook material. Numeral 21 is used to generally designate loop material.

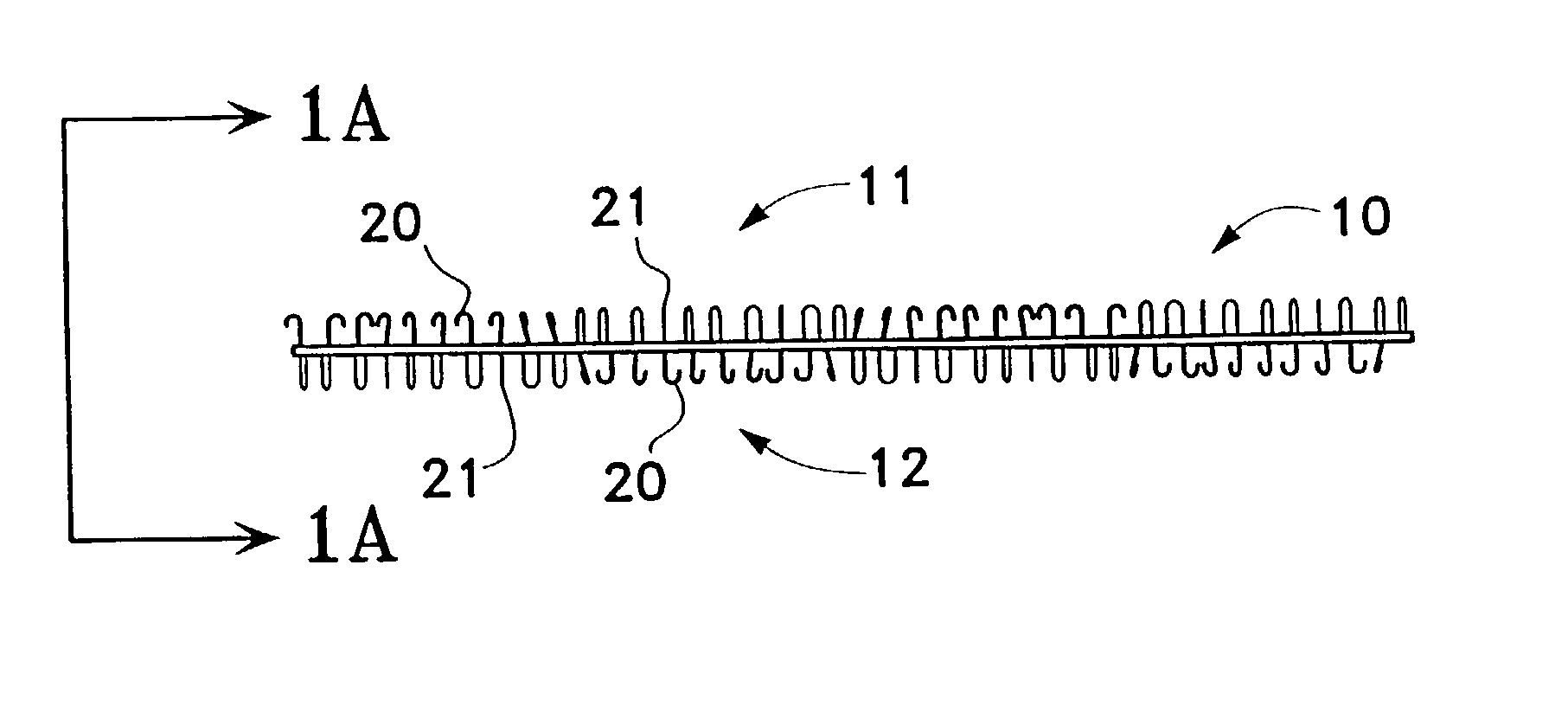

[0035] FIGS. 1A and 1B show a variation of the binding member of the present invention. FIG. 1A illustrates a cross sectional view of an elastic strip 10 that contains hook material 20 on face 11 and loop material 21 on face 12. As depicted in FIG. 1B on face 11, there is an area of hook material 20 and a generally adjacent area of loop material 21. The generally adjacent regions are also found on a second variation of the binding member as illustrated in FIGS. 2A and 2B. These figures show an elastic cord 30 with hook material 20 and loop material 21 generally adjacent on the surface 35 of the elastic cord 30. FIG. 2A illustrates a cross sectional view of the elastic cord 30 showing hook material 20 on one part and loop material 21 on the other part of the elastic cord surface 35. FIG. 2B depicts a side view of elastic cord 30 sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com