Modular platform system

a platform system and module technology, applied in the field of modules, can solve the problems of not facilitating efficient transportation, requiring labor-intensive field adjustments on the top of the deck pan, and not facilitating quick installation of the deck panels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

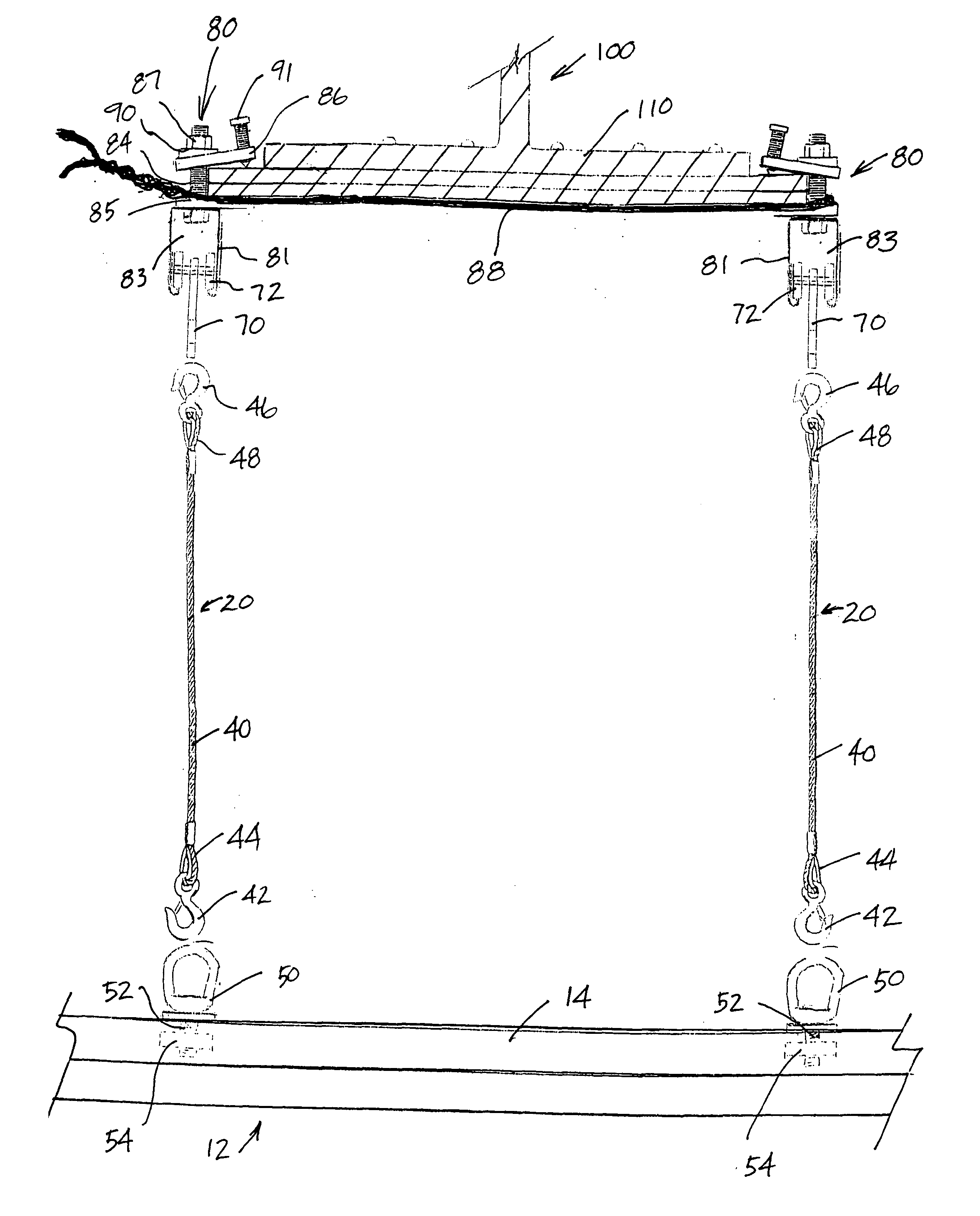

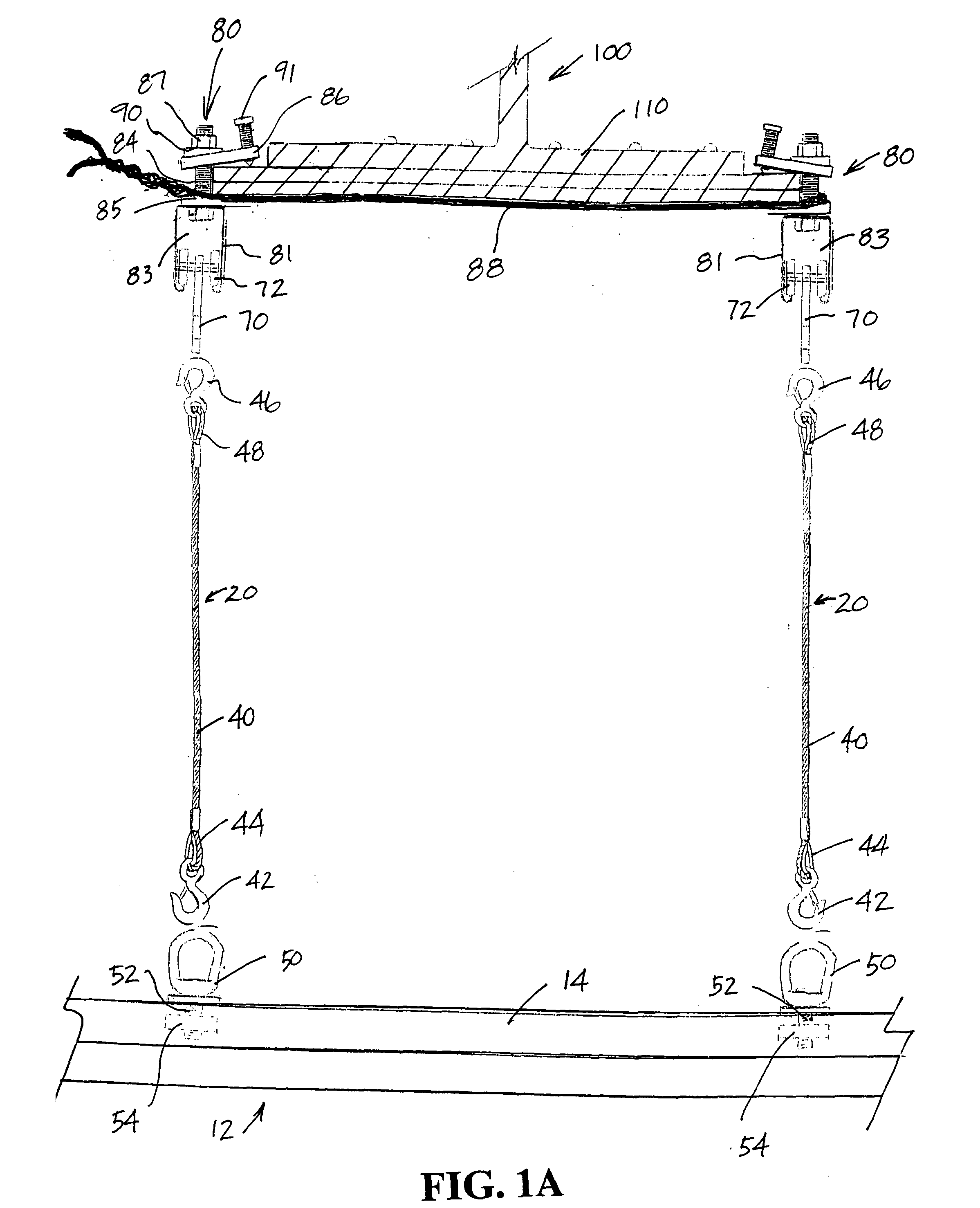

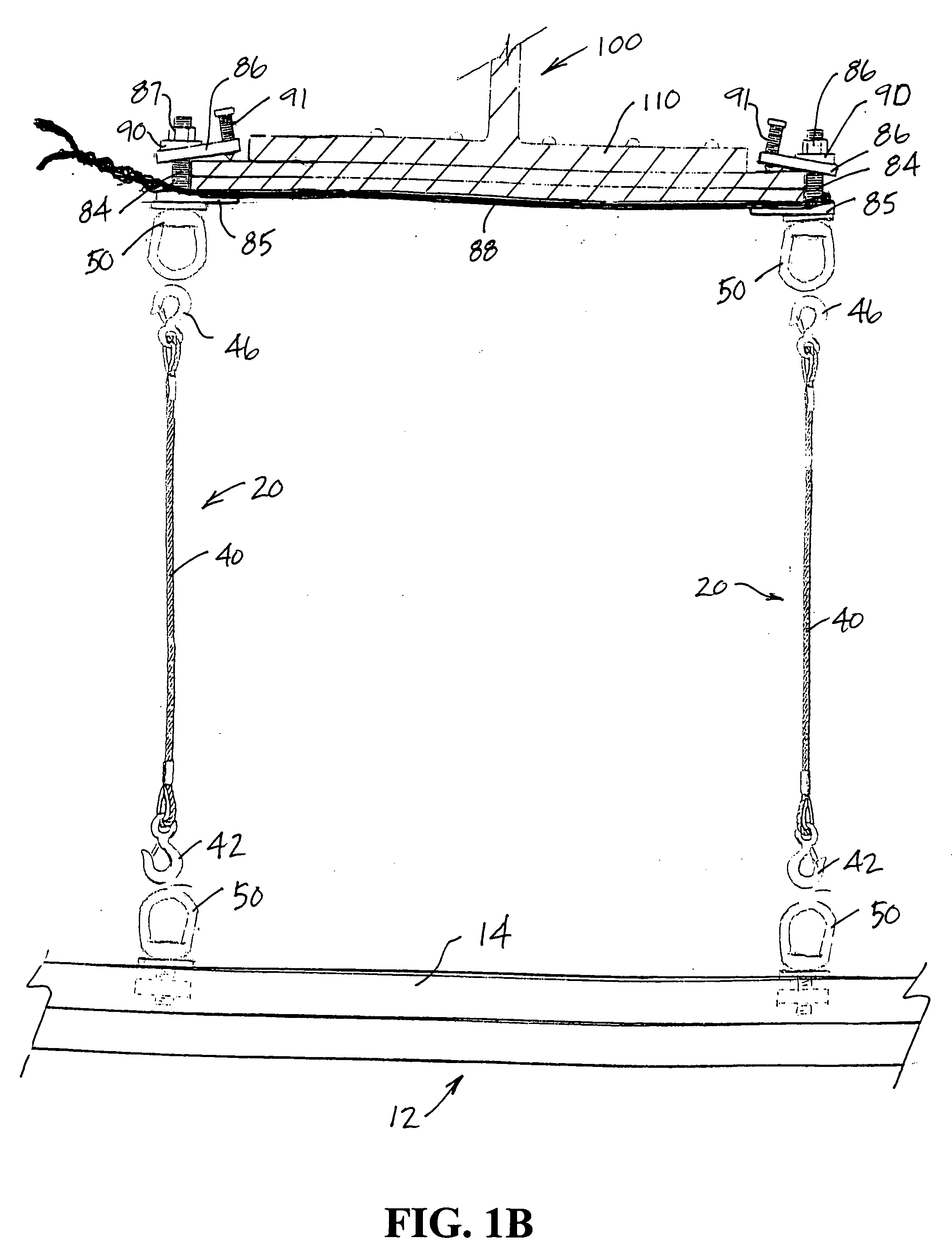

[0046] The modular platform system 10 of the present invention can be suspended with respect to a structure to support a dynamic and / or static load with respect to an underside surface of the structure. For example, the structure may comprise a bridge construction having a plurality of support beams or stringers extending along a length of the bridge to form support surfaces. In order to repair and / or paint the bridge, particularly an underside or bottom support surface of the bridge, modular platform system 10 can be installed to suspend from the underside of the bridge to allow access to desired areas of the structure. Such repair may include slab demolition, sand or shot blasting the supporting steel and painting the steel structure. Additionally, modular platform system 10 can be adapted to contain debris, such as concrete pieces, removed from the bridge to prevent the debris from falling to the ground or into the water. In one preferred embodiment of this invention, modular pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com