Compact disk (CD) storage case and method for storing a CD

a technology of compact disk and storage case, which is applied in the direction of transportation and packaging, instruments, packaged goods types, etc., can solve the problems of exposing the disk retained within to a greater potential for damage, the need for disposal, and the user's re-apply difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In the description herein, numerous specific details are provided, such as examples of components and / or methods, to provide a thorough understanding of embodiments of the present invention. One skilled in the relevant art will recognize, however, that an embodiment of the invention can be practiced without one or more of the specific details, or with other apparatus, systems, assemblies, methods, components, materials, parts, and / or the like. In other instances, well-known structures, materials, or operations are not specifically shown or described in detail to avoid obscuring aspects of embodiments of the present invention.

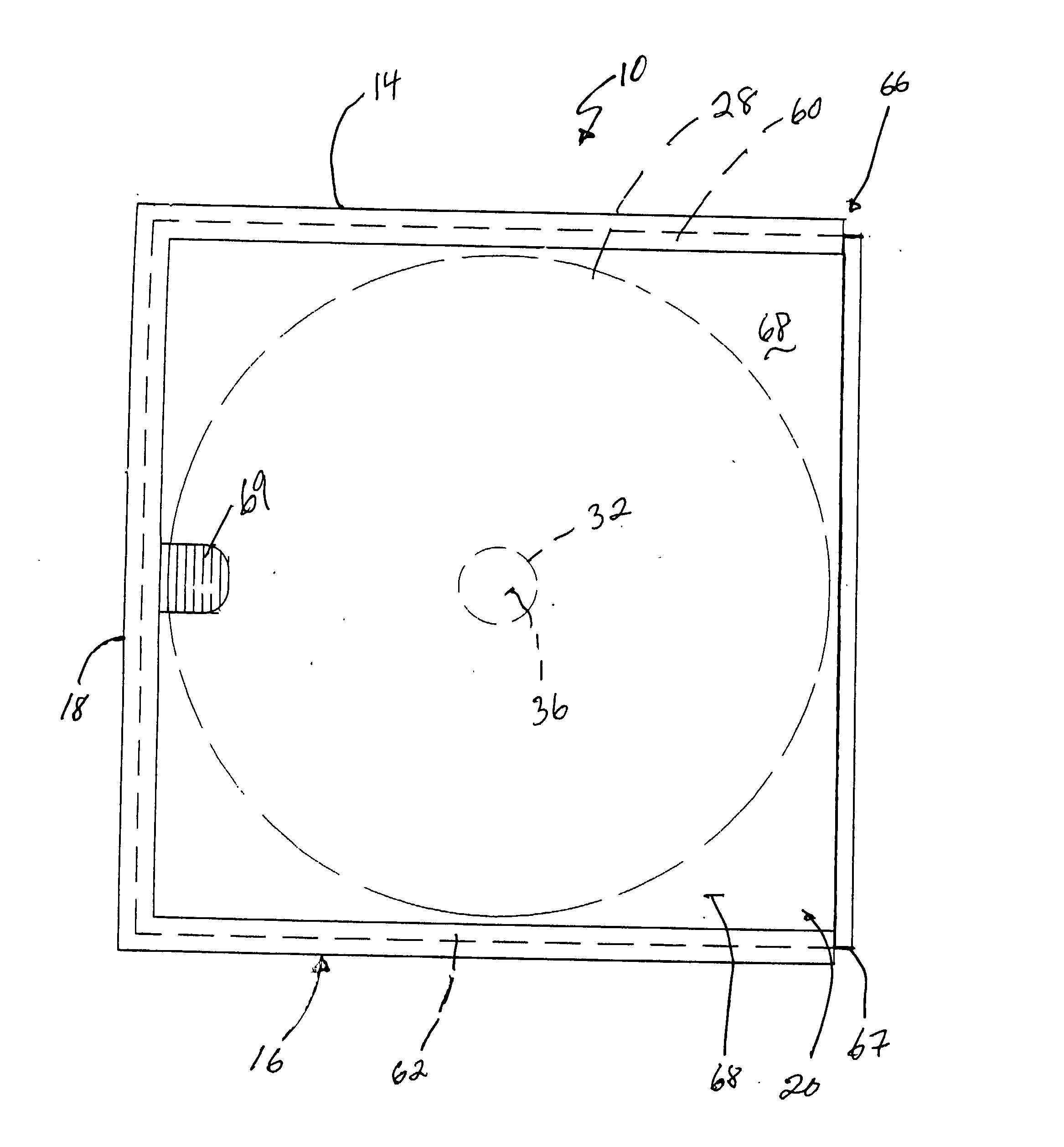

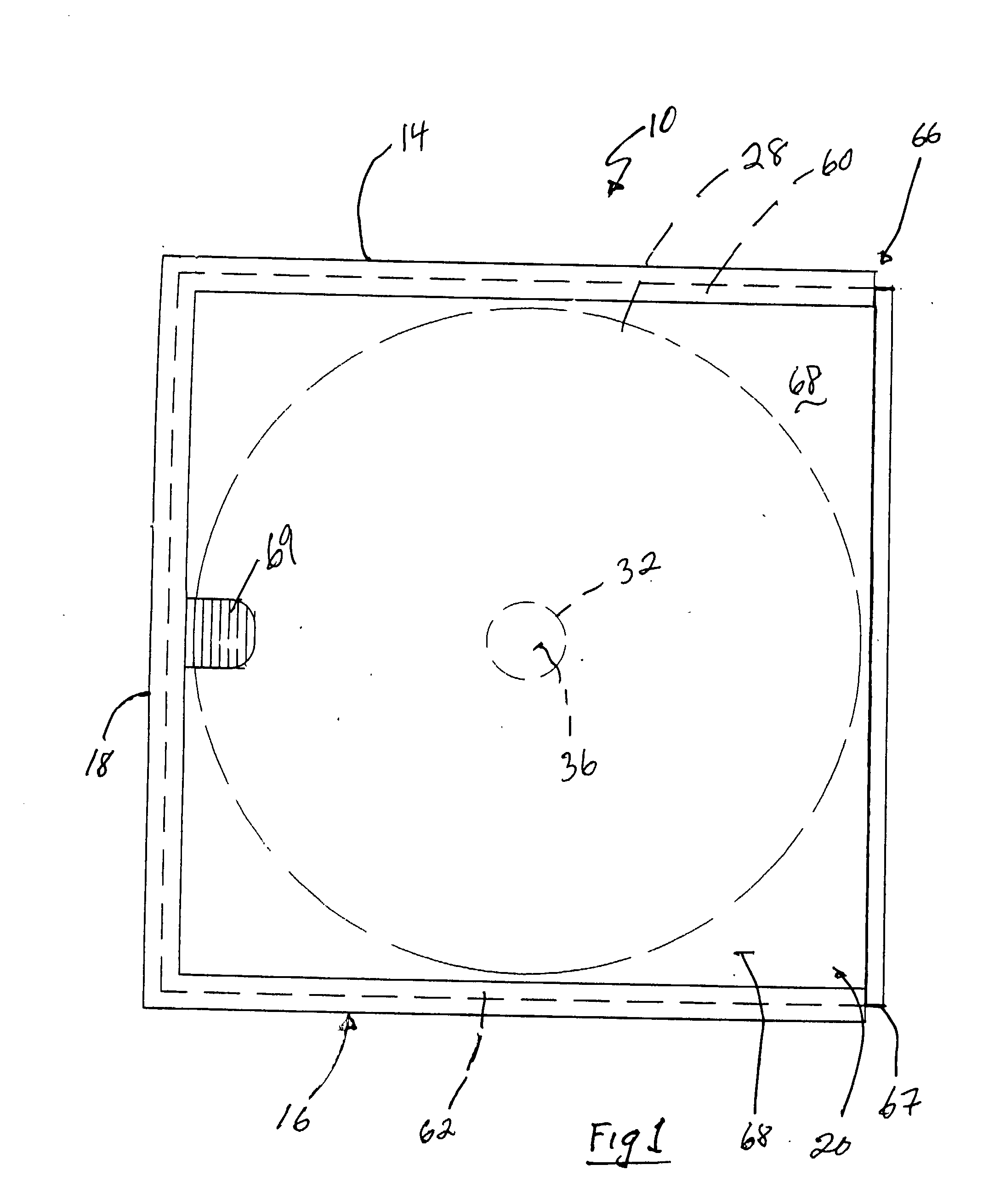

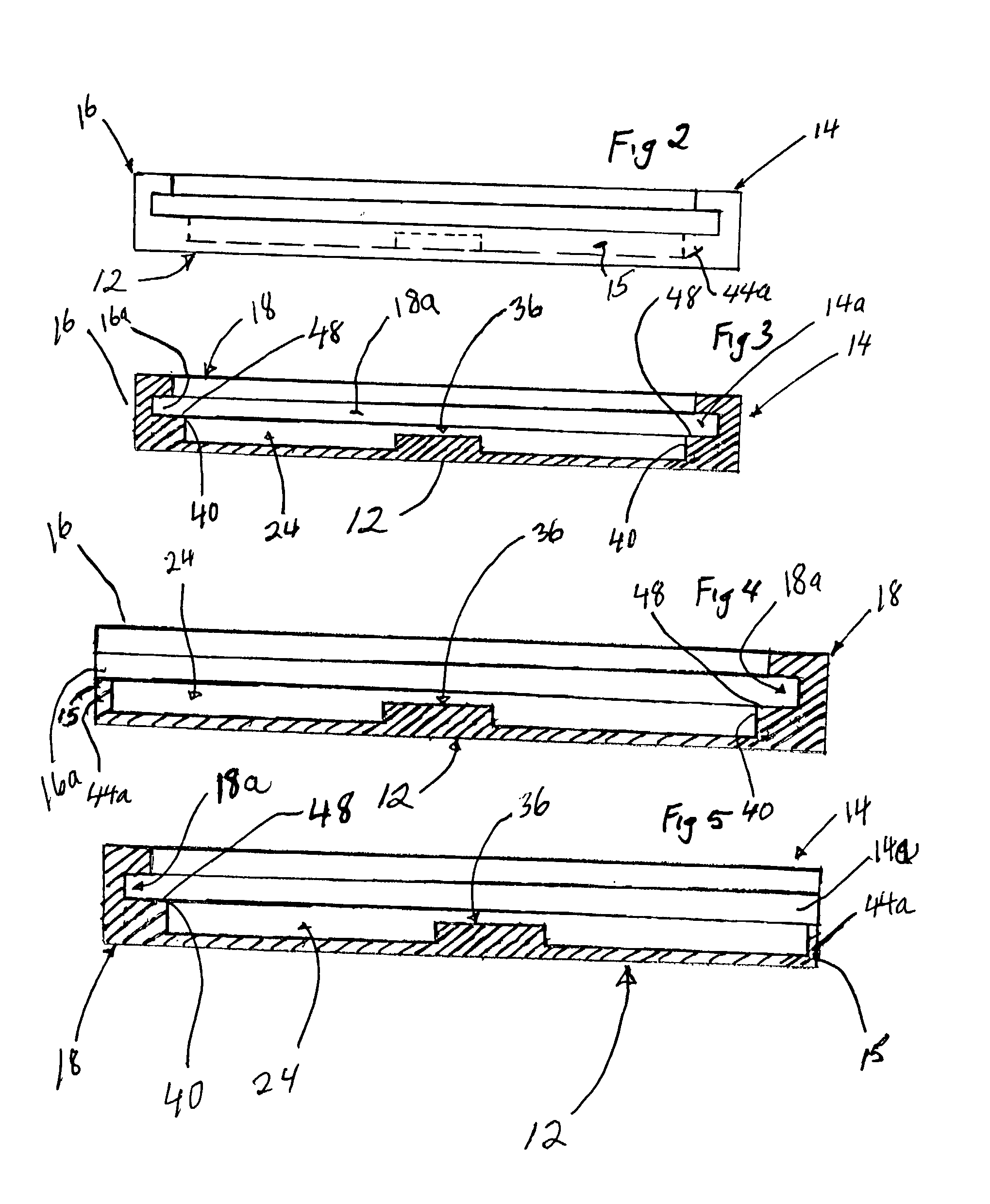

[0034] Referring now to the drawings wherein similar parts of the invention are identified by like reference numbers, there is seen a disk storage container, generally illustrated as 10. The storage container 10 comprises a base, generally illustrated as 12, a pair of side walls, generally illustrated respectively as 14 and 16 and secured to the base 12, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| structure | aaaaa | aaaaa |

| perimeter | aaaaa | aaaaa |

| transparent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com