Garment hanger

a technology for hanging clothes and clothes, applied in the field of garment hangers, can solve the problem that clothes hanging on a conventional garment hanger easily fall off,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Wherever possible in the following description, like reference numerals will refer to like elements and parts unless otherwise illustrated.

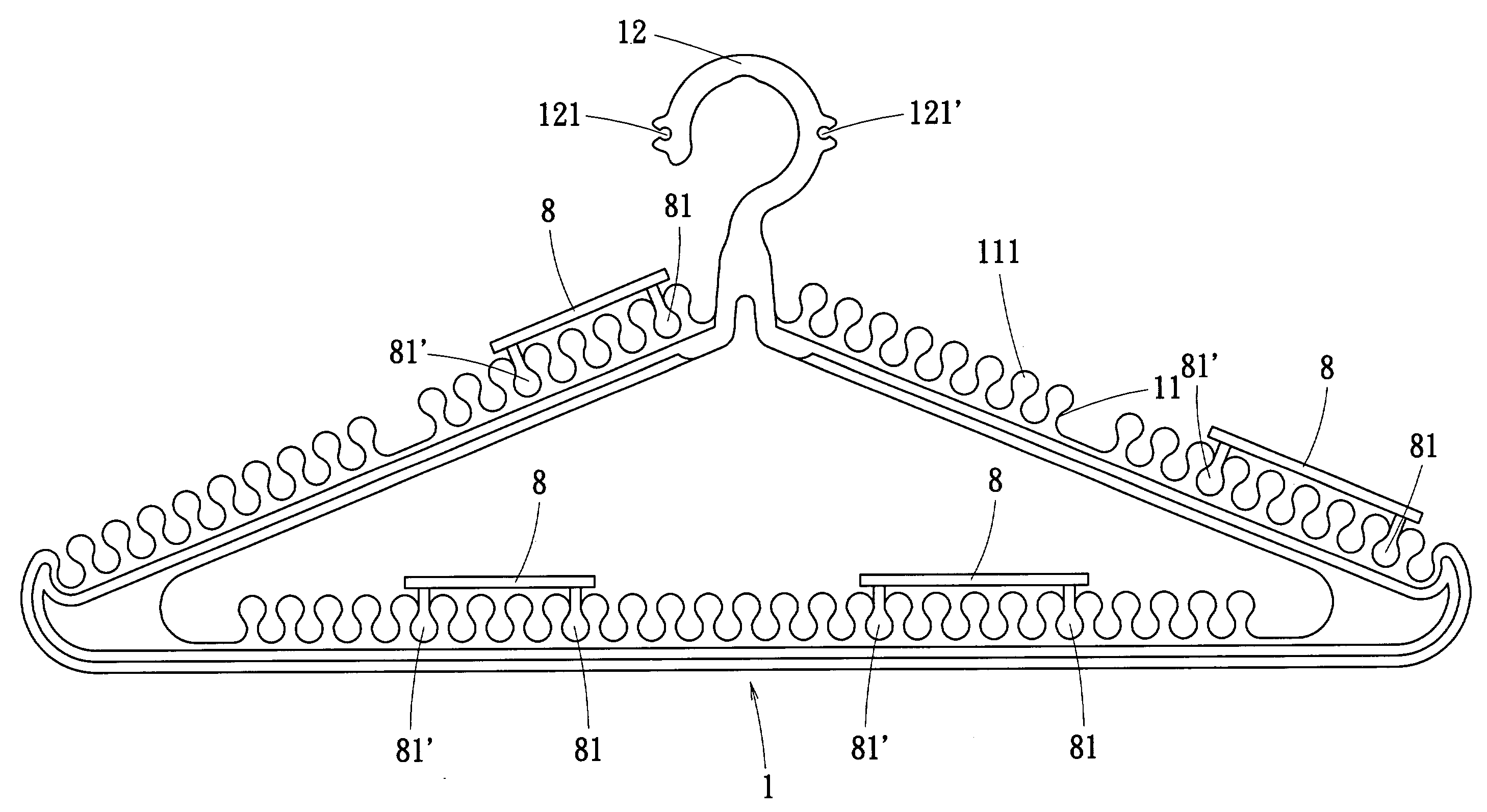

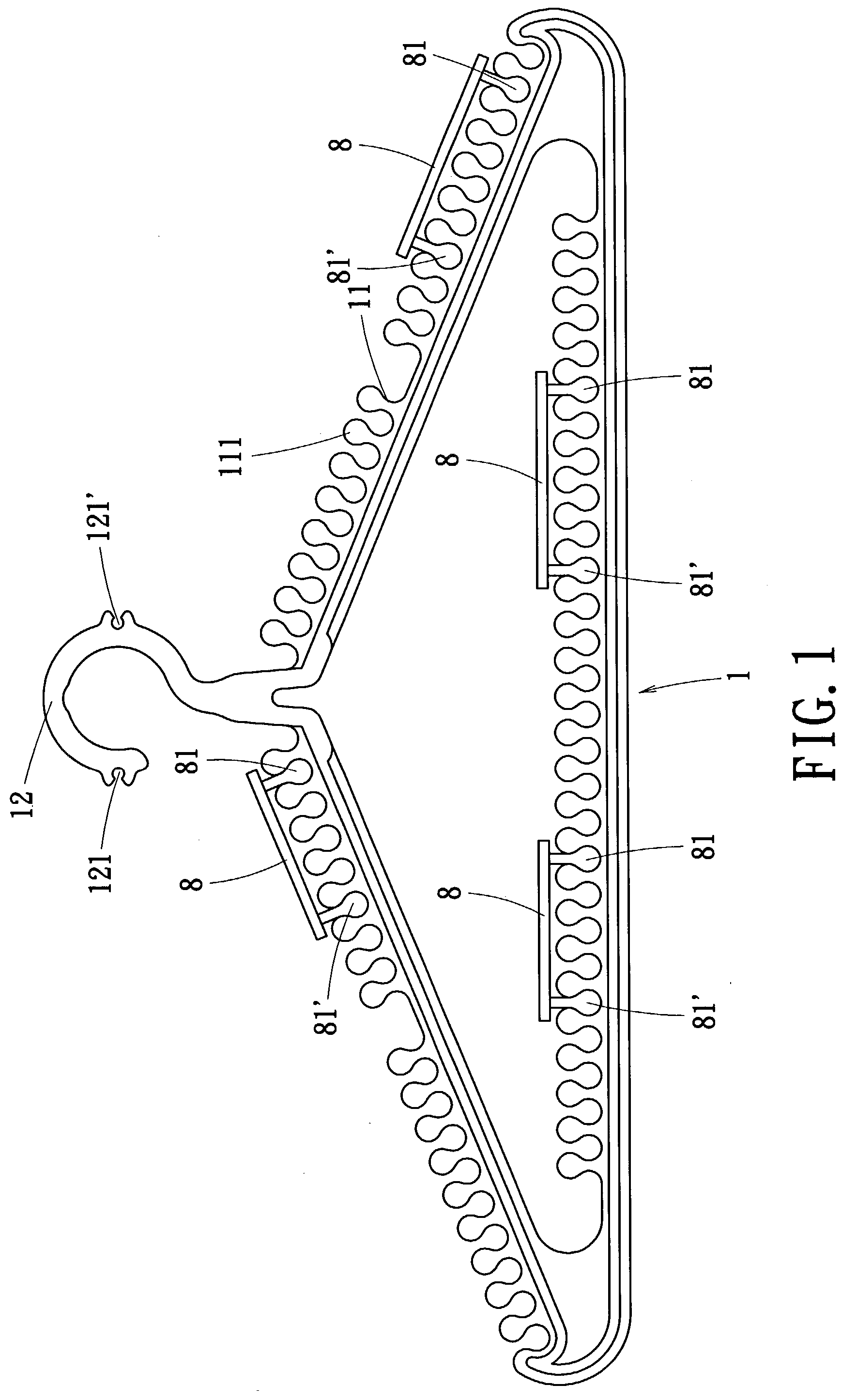

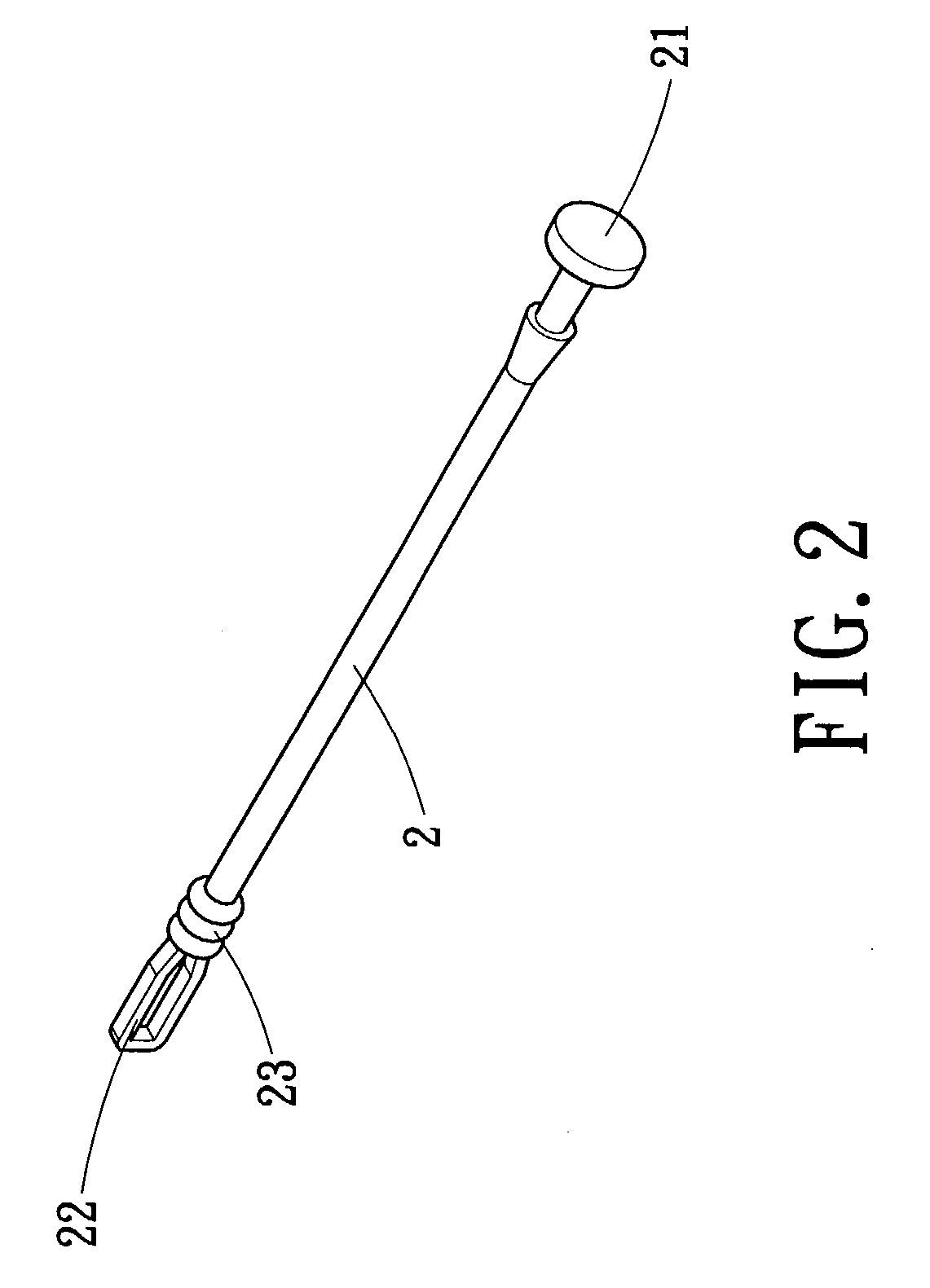

[0022] FIG. 1 is a schematic view of a garment hanger assembled with engaging elements according to one embodiment of the invention. FIG. 2 is a perspective view of a clasp that is used in a garment hanger according to one embodiment of the invention. The garment hanger of the invention includes a hanger body 1, a clasp 2, and at least one engaging element 8.

[0023] The hanger body 1 is made of, for example, plastic. The hanger body 1 is made by, for example, injection molding. The hanger body 1 is of triangular shape. First rounded teeth 11 are formed respectively along exterior surfaces of the sloped sides of the triangular hanger body 1, with a constant clearance between adjacent teeth 11. The first teeth 11 can be further formed on a bottom side of the hanger body 1. Each of the first rounded teeth has a top 111 larger than its bottom t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com