Sheet feed assembly defining curved and straight feed path

a feed path and assembly technology, applied in the field of feed sheets of materials, can solve the problems of paper jamming, printing artefacts, unsatisfactory print artefacts,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

Sheet Feed Chute Conforming to Shape of Bowed Sheet

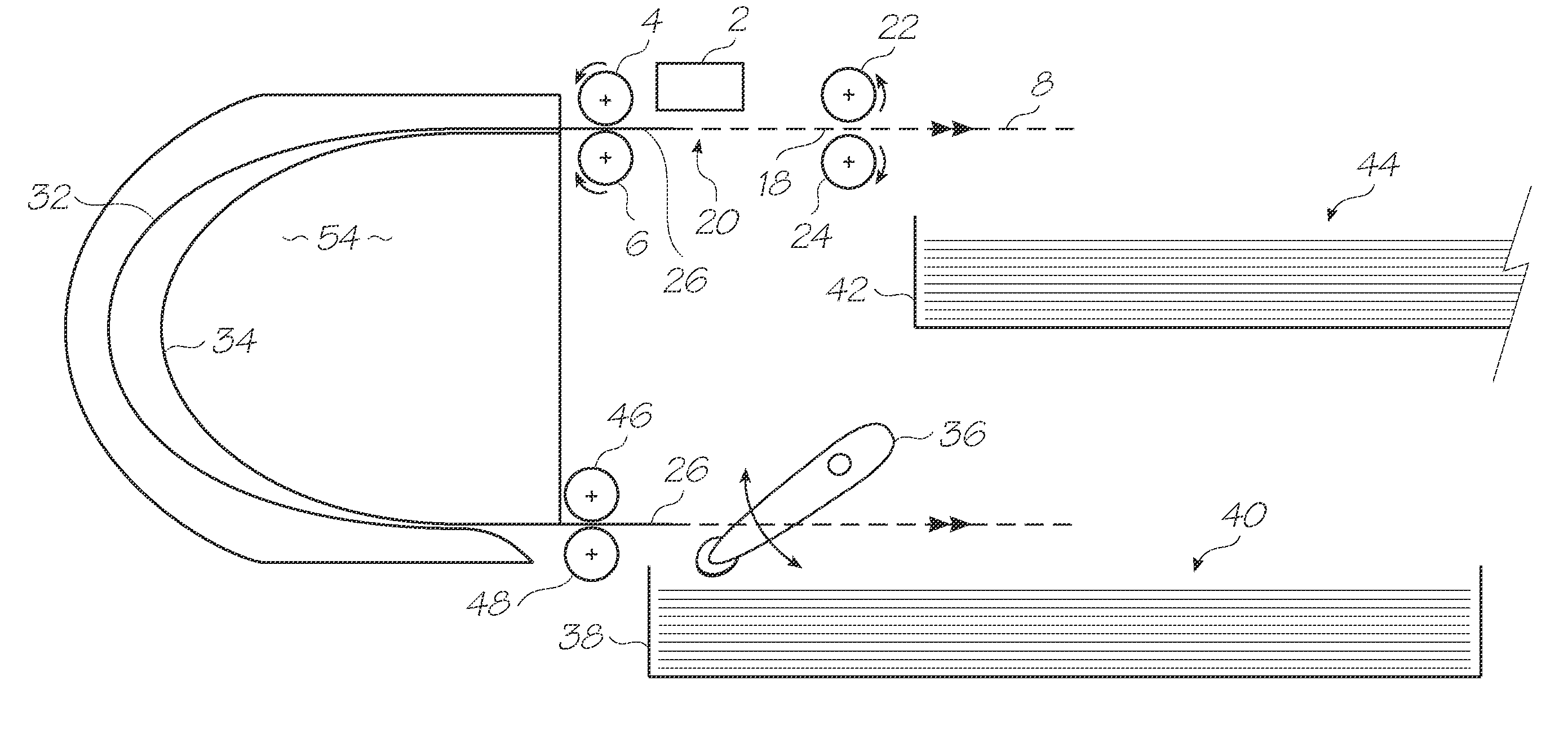

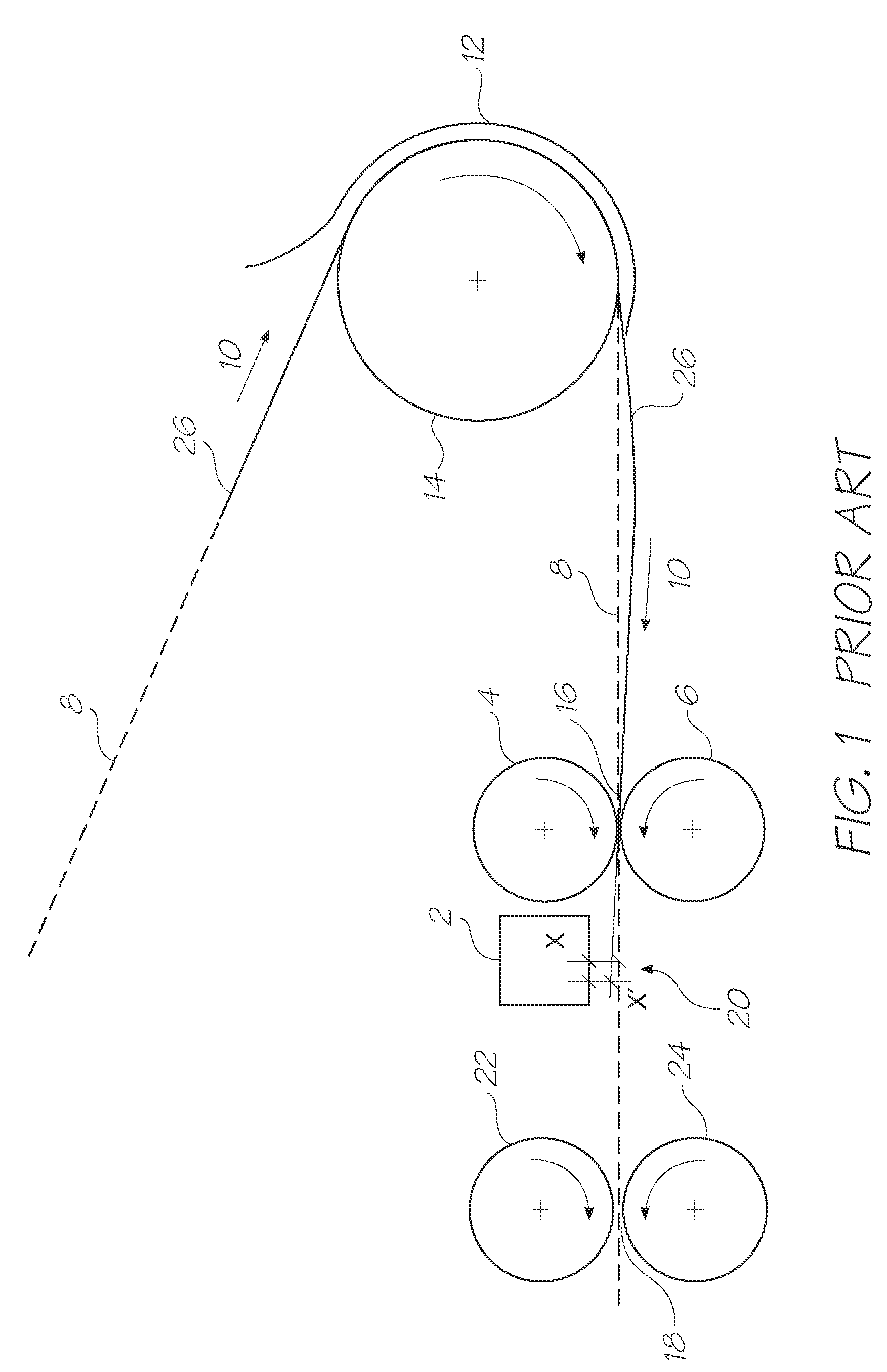

[0037]Referring to FIG. 1, a sheet feed assembly is shown feeding a sheet 26 of media substrate past a printhead 2. The feed path 8 is extends around an idler roller 14 and through the nip 16 of input drive rollers 4 and 6. The input drive rollers drive the sheet 26 past the printhead 2 and into the nip 18 of the exit rollers 22 and 24.

[0038]The inherent bending stiffness in the sheet 26 causes the leading edge to deviate away from the feed path 8 as it leaves the idler roller 14 and the guiding shroud 12. The input drive rollers 4 and 6 draw the sheet into the nip 16 and therefore back on to the feed path 8. However, the input drive rollers 4 and 6 are mounted so that the opposing pinch force from each roller are normal to the straight part of the feed path 8. This does nothing to redirect the sheet back to the feed path.

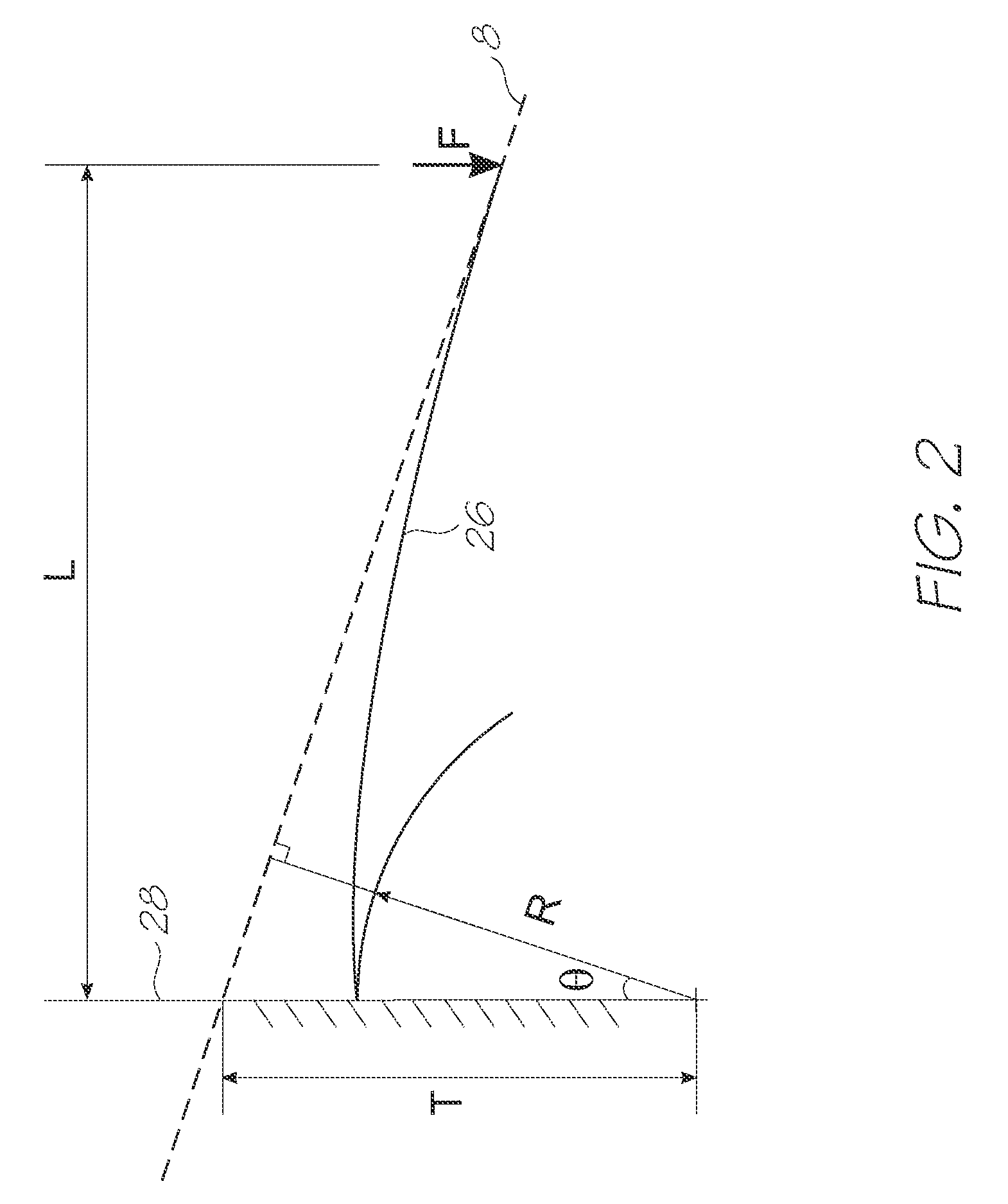

[0039]The leading edge of the sheet 26 continues to deviate as it crosses the printzone 20 of the feed path 8. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com