Electromagnetic coil for solenoid valve

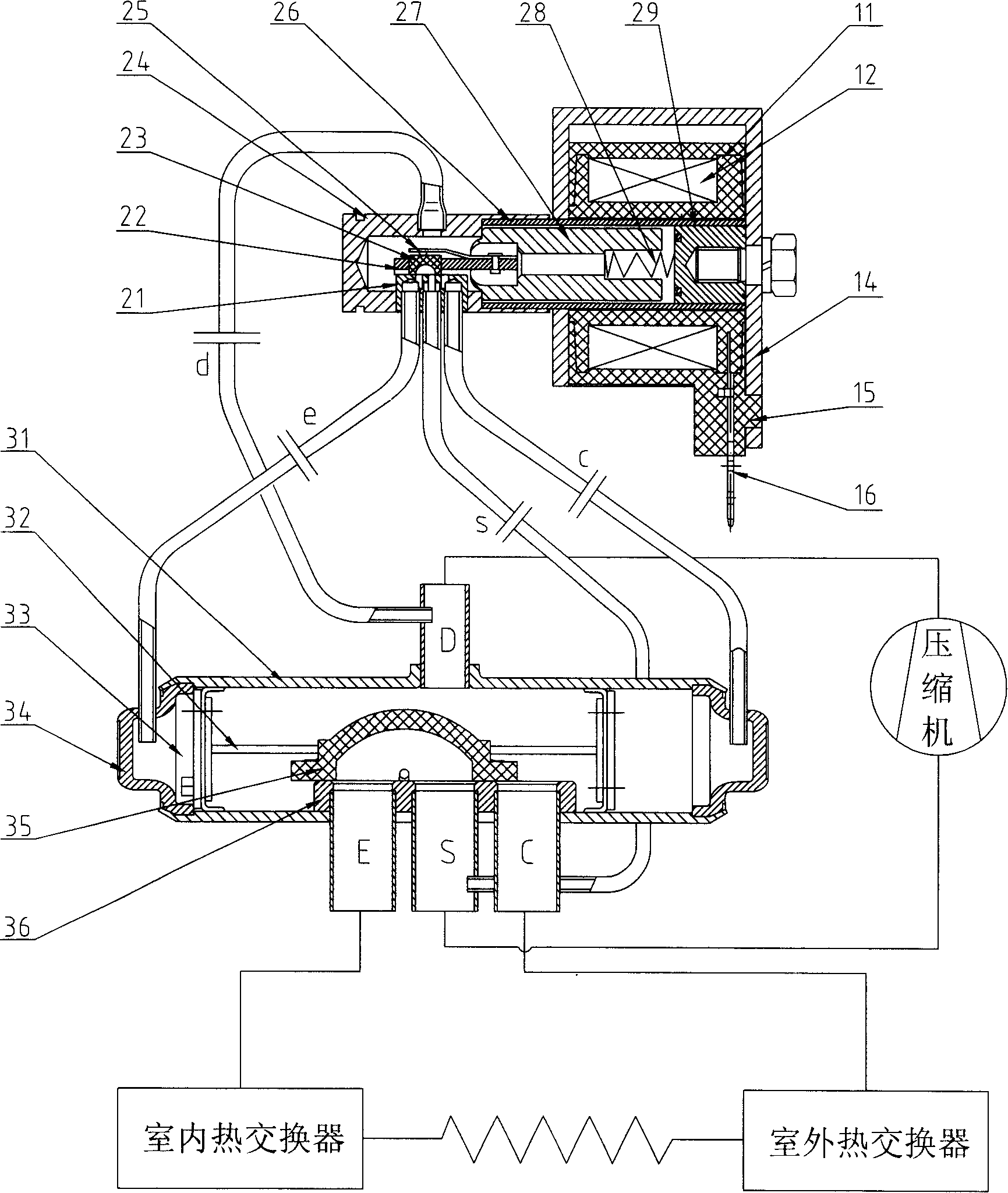

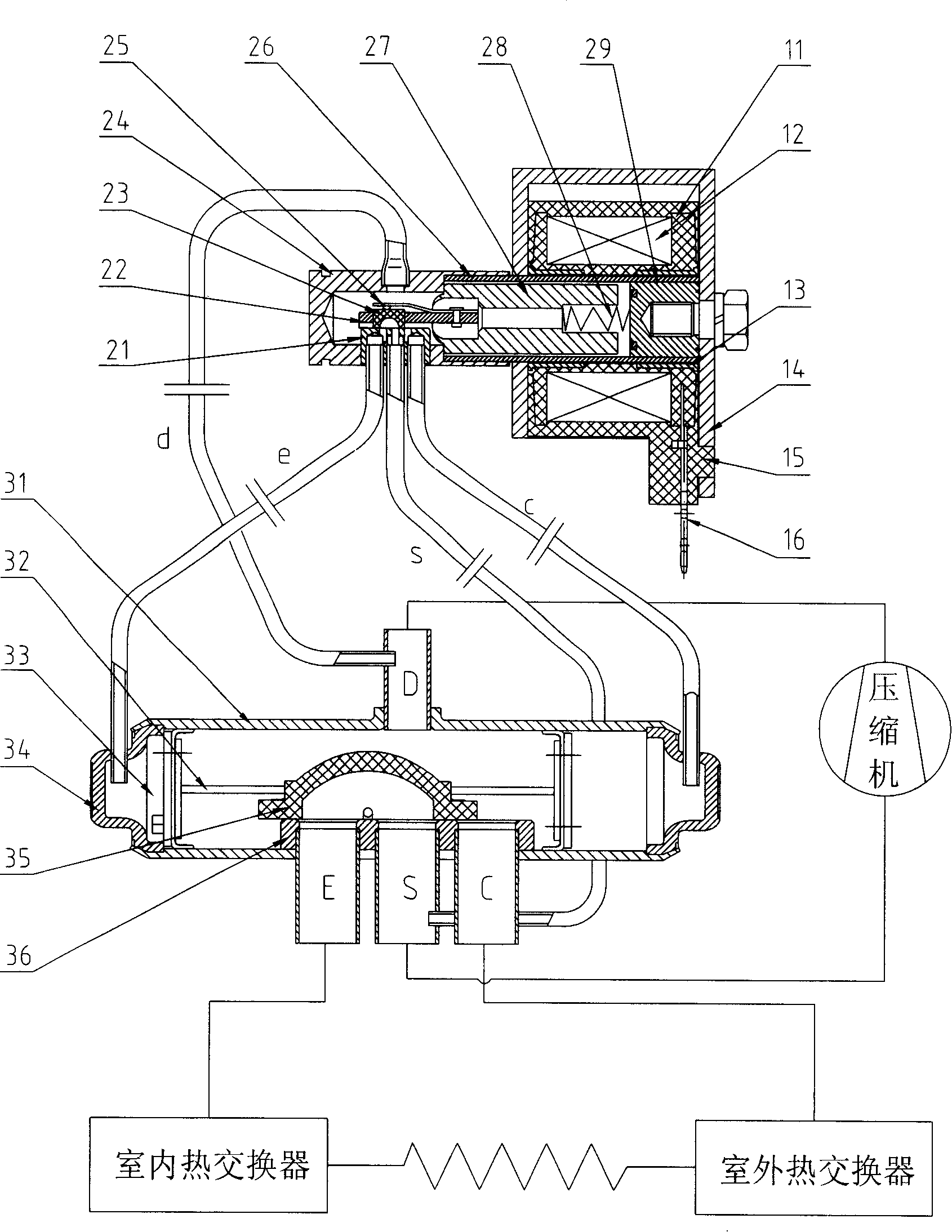

A technology of solenoid coil and solenoid valve, applied in valve details, valve device, valve operation/release device, etc., can solve the problems of difficult heat dissipation, large magnetic force loss, large electromagnetic force loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

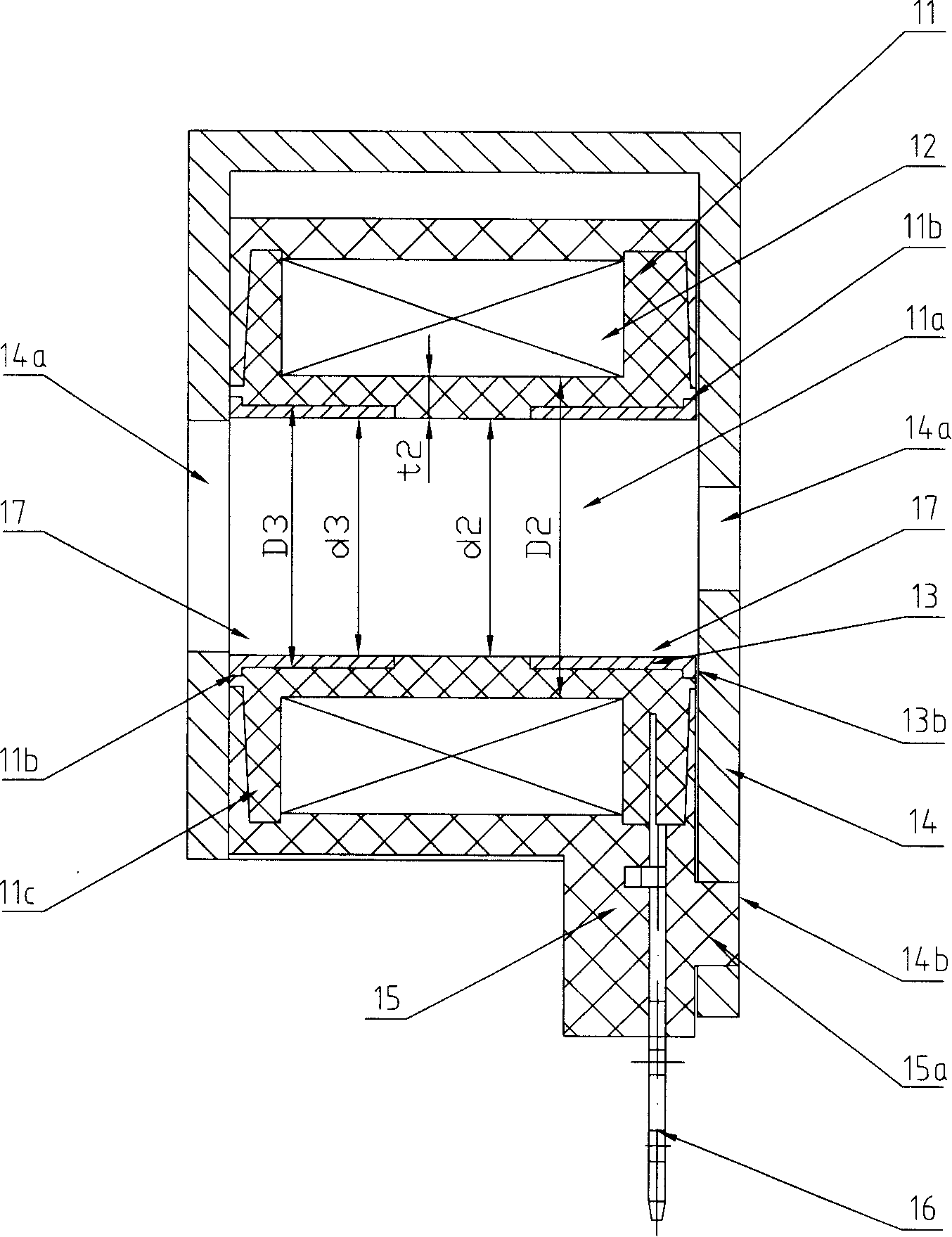

[0031] image 3 The electromagnetic coil shown is mainly composed of a skeleton 11, a winding 12, a magnetically conductive sleeve 13, a magnetically conductive body 14, an insulating coating 15, and a lead wire 16 (or insert), wherein:

[0032] Skeleton 11 is circular tube shape, and its center is inner hole 11a, and the diameter of this inner hole 11a is d2, and the outer diameter of the hole wall of this inner hole 11a is D2, and the thickness of the hole wall of this inner hole 11a is t2, and d2= d1, D2=D1, t2=t1, the two ends of the inner hole 11a have folded edges 11c, so as to form the accommodation part of the wound winding between the folded edges, so as to stabilize the wound winding; The hole 11b expands outward to form a positioning portion 11b;

[0033]The magnetic sleeve 13 is also in the shape of a round tube, made of carbon steel with excellent heat dissipation performance, its inner diameter is d3, the outer diameter is D3, and d3=d2, D1>D3>d2, and one end is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com