Diamond bearing with cooling/lubrication channels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

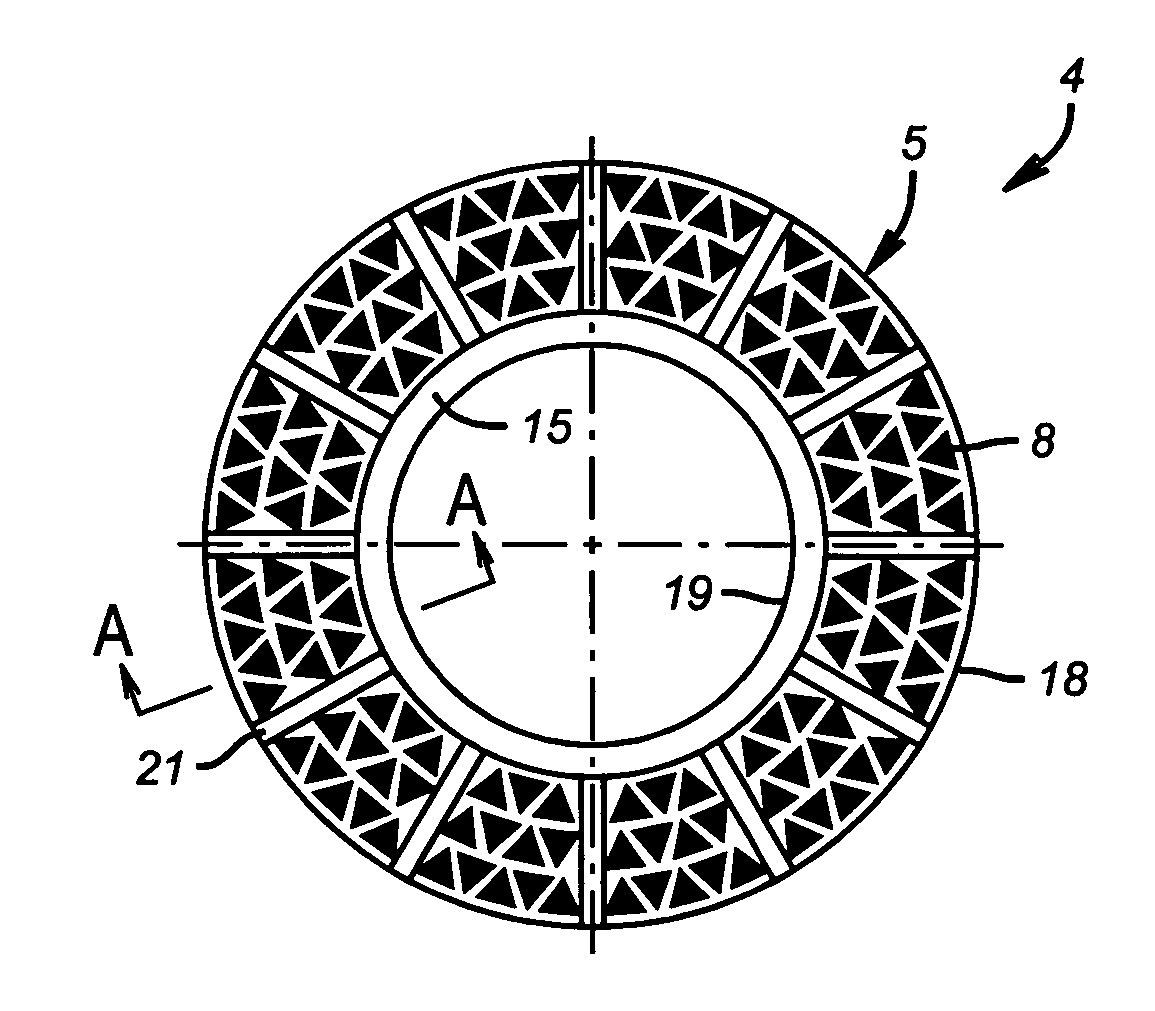

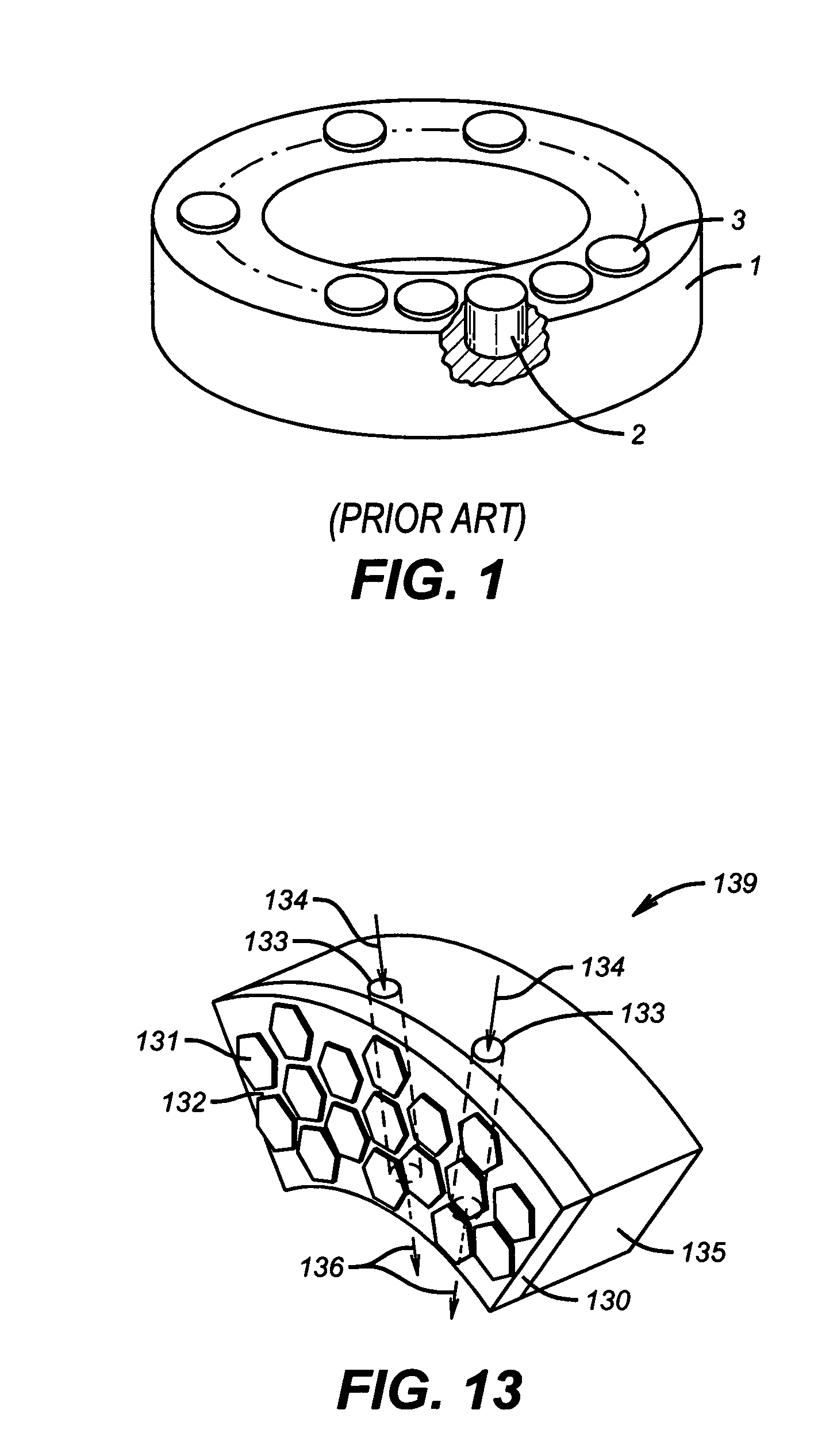

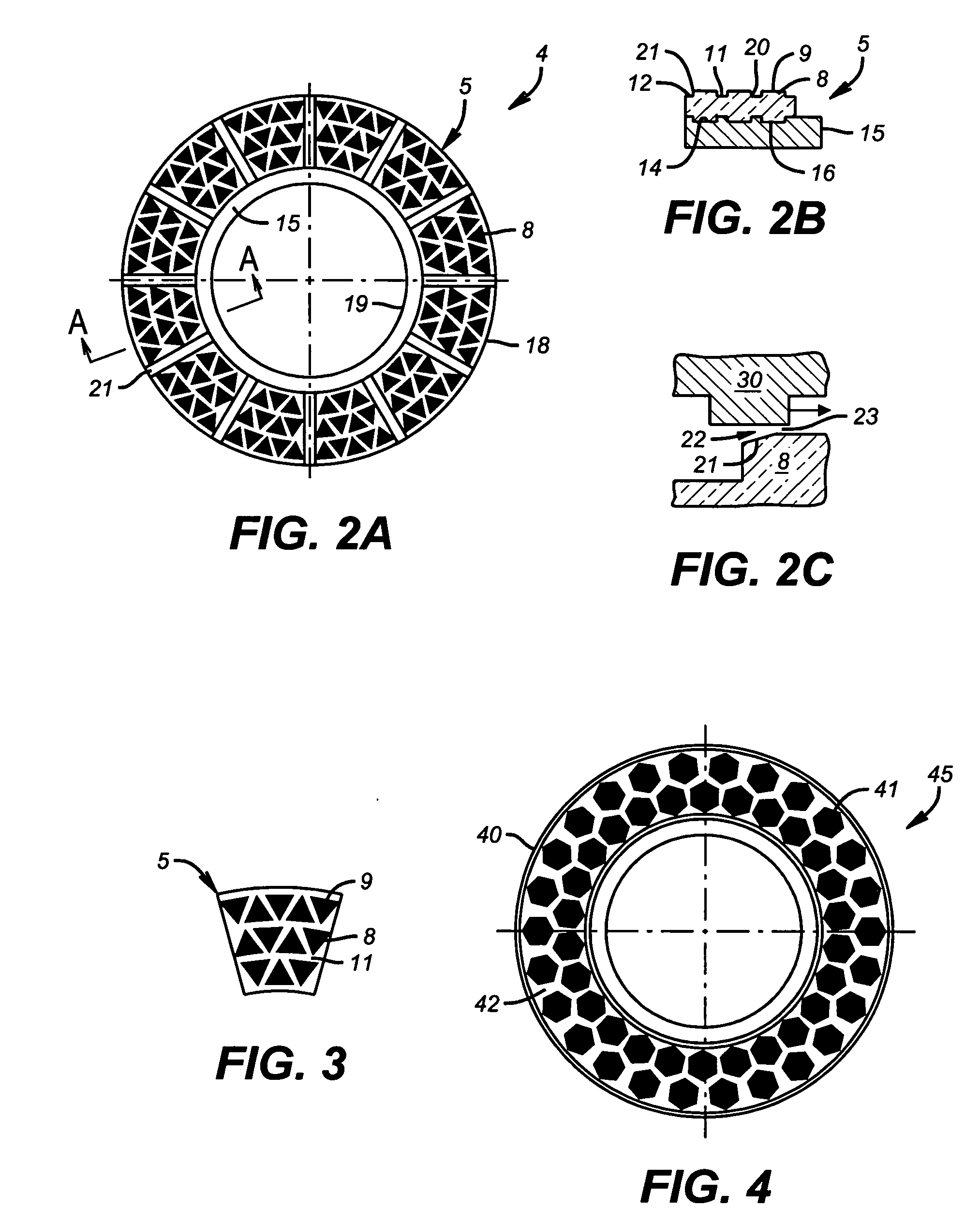

[0027] In one preferred embodiment, a diamond bearing assembly 4, FIG. 2A, has multiple bearing segments 5 attached to a bearing support ring 15, see FIG. 2B. A pattern of bearing pads 8 are disposed in the front surface 12 of the bearing segment 5 and each bearing pad 8 has an associated load surface 9. The bearing pads 8 are triangularly shaped such that the total area of all the load surfaces 9 of bearing assembly 4 is substantially greater than the corresponding load surface area of the prior art bearing of FIG. 1. The bearing pads 8 are spaced such that flow micro-channels 11 are created between the bearing pads 8. The micro-channels 11 provide a path for a fluid to flow for cooling and lubricating the bearing pads 8. As will be appreciated by one skilled in the art, the outer housings (not shown) surrounding and supporting such a bearing may force the cooling / lubricating fluid to flow from an outer diameter 18 of the bearing support ring 15 to an inner diameter 19 as shown in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com