Production method of detergent and producing apparatus

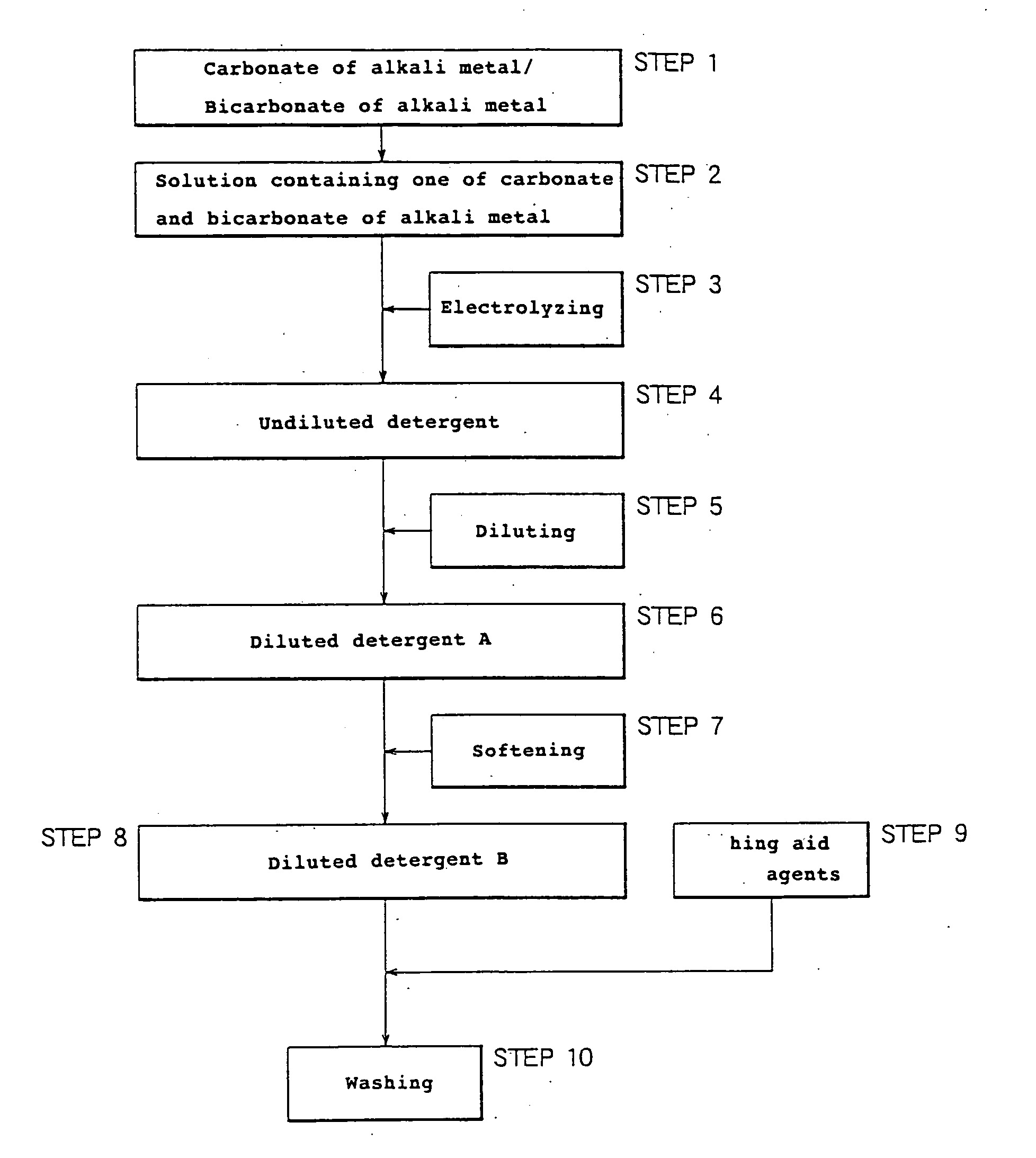

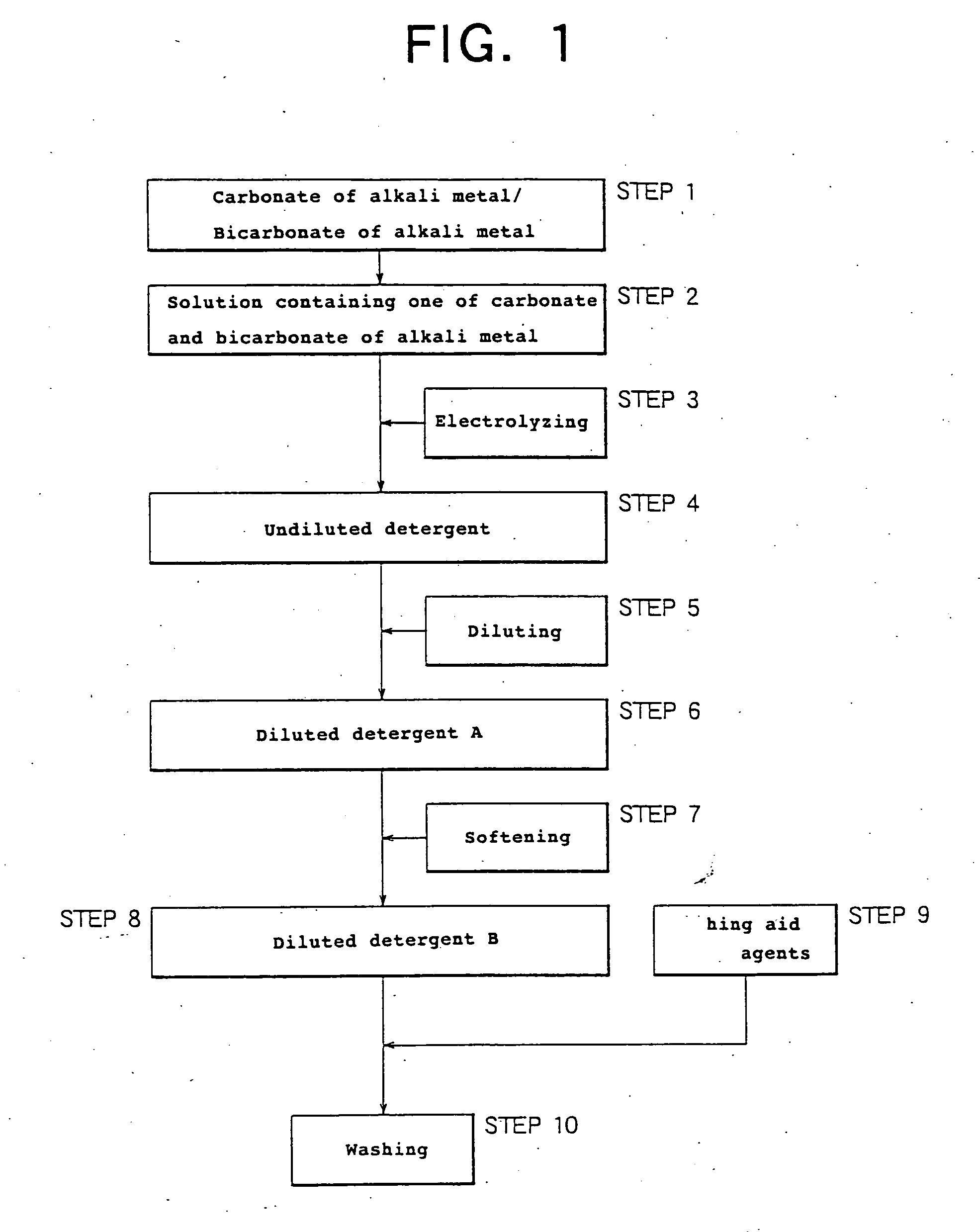

a production method and technology of detergent, applied in the preparation of detergent mixture compositions, inorganic non-surface active detergent compositions, cleaning using liquids, etc., can solve problems such as hand chafing, and achieve the effect of reducing the ph of cathode water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

fifth embodiment

[0086] From the result, it was confirmed that the weak alkaline detergent (mixed electrolytic water) obtained by the present invention had detergency comparable to or better than the commercially available synthetic detergent. Especially, it is remarkably improved as to blood stain. Note that the detergent of the fifth embodiment had no problems at all concerning safety and treatment of discharging water after washing.

embodiment 6 (

Neutral Detergent)

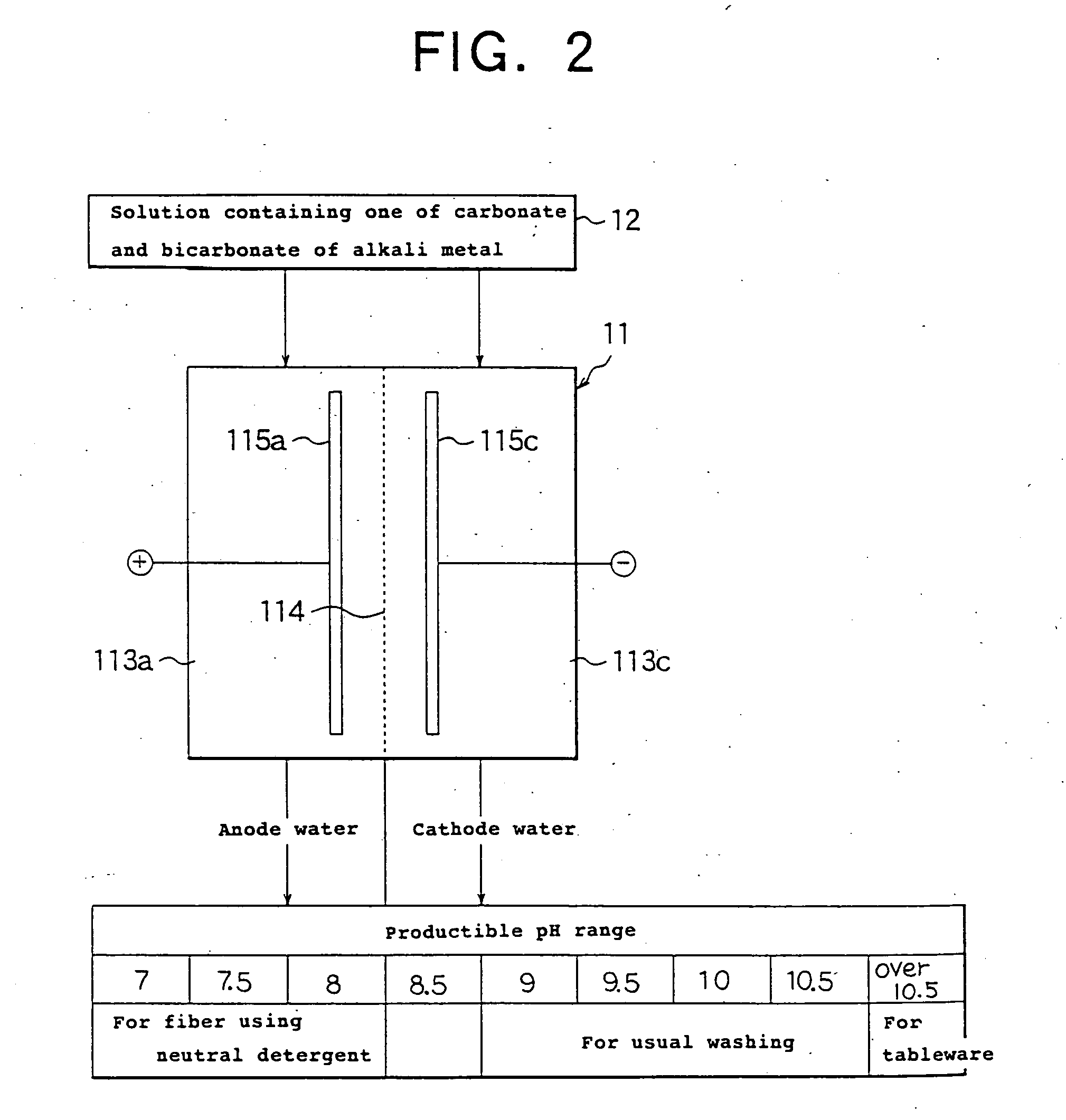

[0087] A solution prepared by dissolving and diluting 36 g of sodium hydrogen carbonate in 1 litter of tap water (municipal tap water in Fujisawa city, pH 7.2, EC 15.5 mS / m, water temperature 24.5.degree. C.) was supplied to the anode chamber 113a and the cathode chamber 113c of the batch type electrolysis cell 11 (a capacity of the anode chamber and the cathode chamber are both 1 litter) shown in FIG. 4C, and electrolysis was carried out by applying a direct current voltage so that a constant current of 15 A flows to both the electrode plates 115a and 115c for 36 minutes. When measuring a pH and EC value of thus obtained anode water, pH=7.06 and EC=971 mS / m.

[0088] The anode water was further added with 52 g of sodium hydrogen carbonate and additionally added with 3 g of cane sugar fatty acid ester and 2 g of carboxyl methyl cellulose.

[0089] A washing tub of a domestic automatic washing machine (trade name of AW-C60VP, 6 kg type, manufactured by Toshiba Corporation...

sixth embodiment

[0093] From the result, it was confirmed that the neutral detergent obtained by the present invention had detergency comparable to or better than the commercially available neutral detergent. Especially, it is remarkably improved as to blood stain. Note that the detergent of the sixth embodiment had no problems at all concerning safety and treatment of discharging water after washing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pH | aaaaa | aaaaa |

| electric conductivity | aaaaa | aaaaa |

| electric conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com