Exhaust fan

a technology of exhaust fans and exhaust fans, which is applied in the direction of positive displacement liquid engines, piston pumps, separation processes, etc., can solve the problems of accumulation of materials on such internal components, significant drawbacks, and general inconvenient removal of conventional exhaust fans, and achieve safe and efficient removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

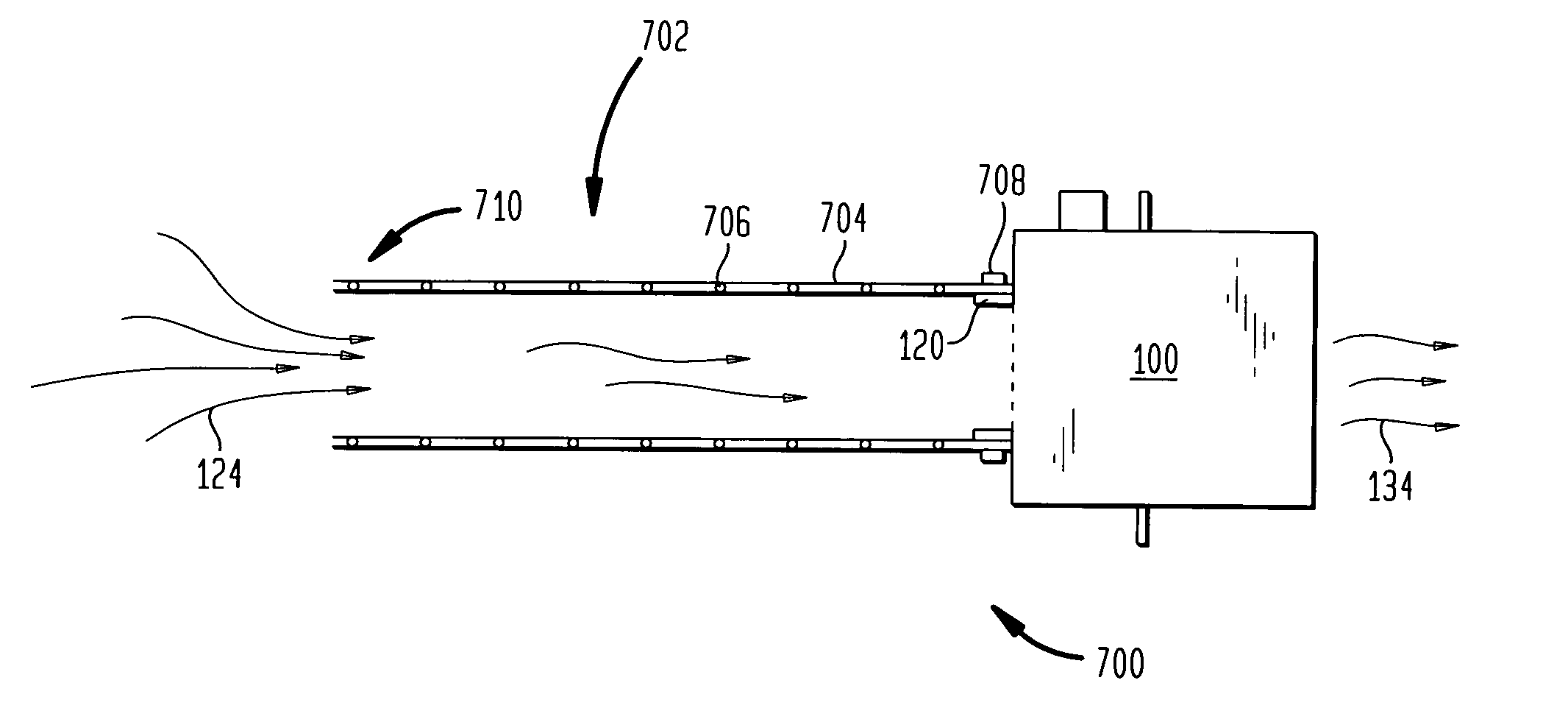

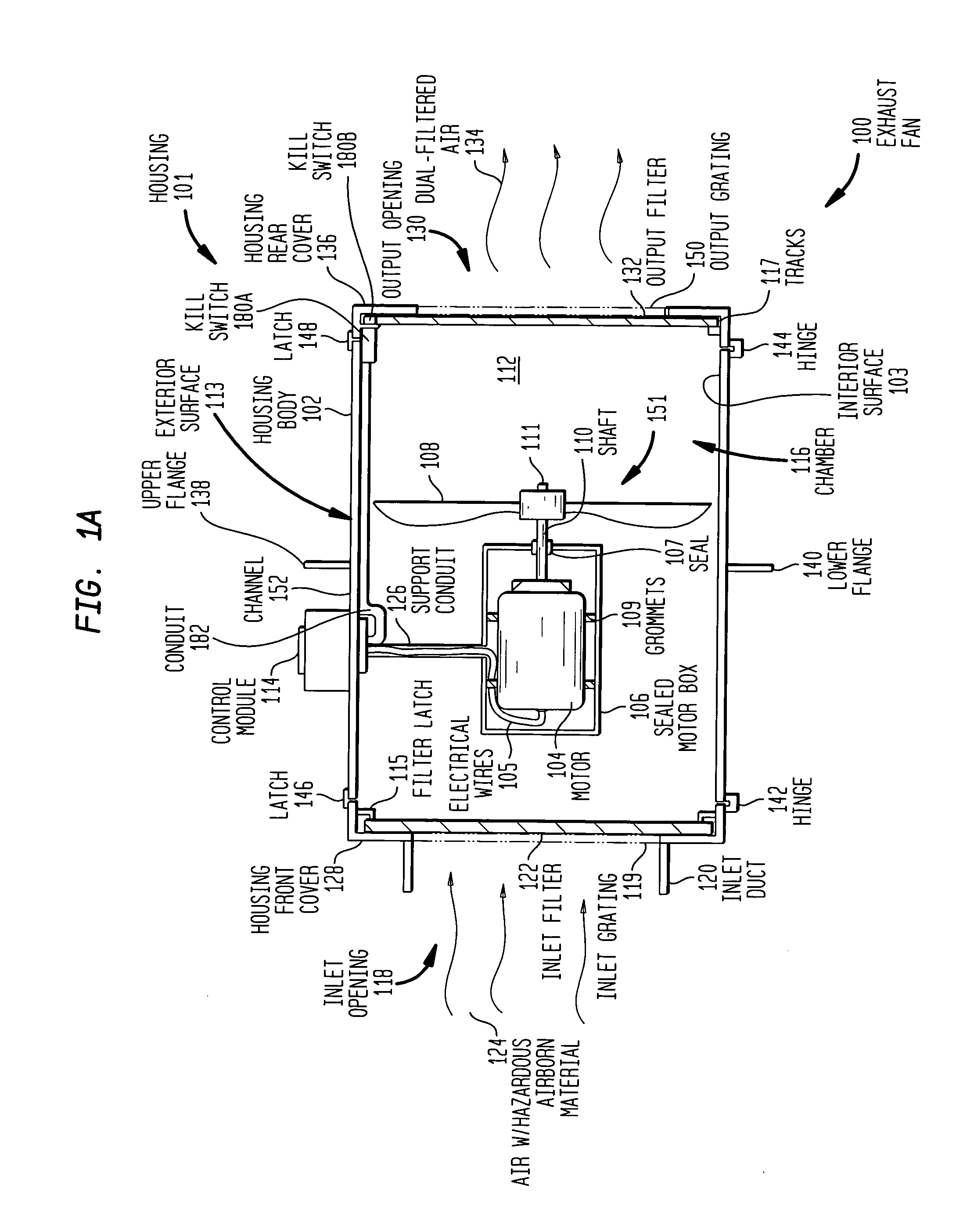

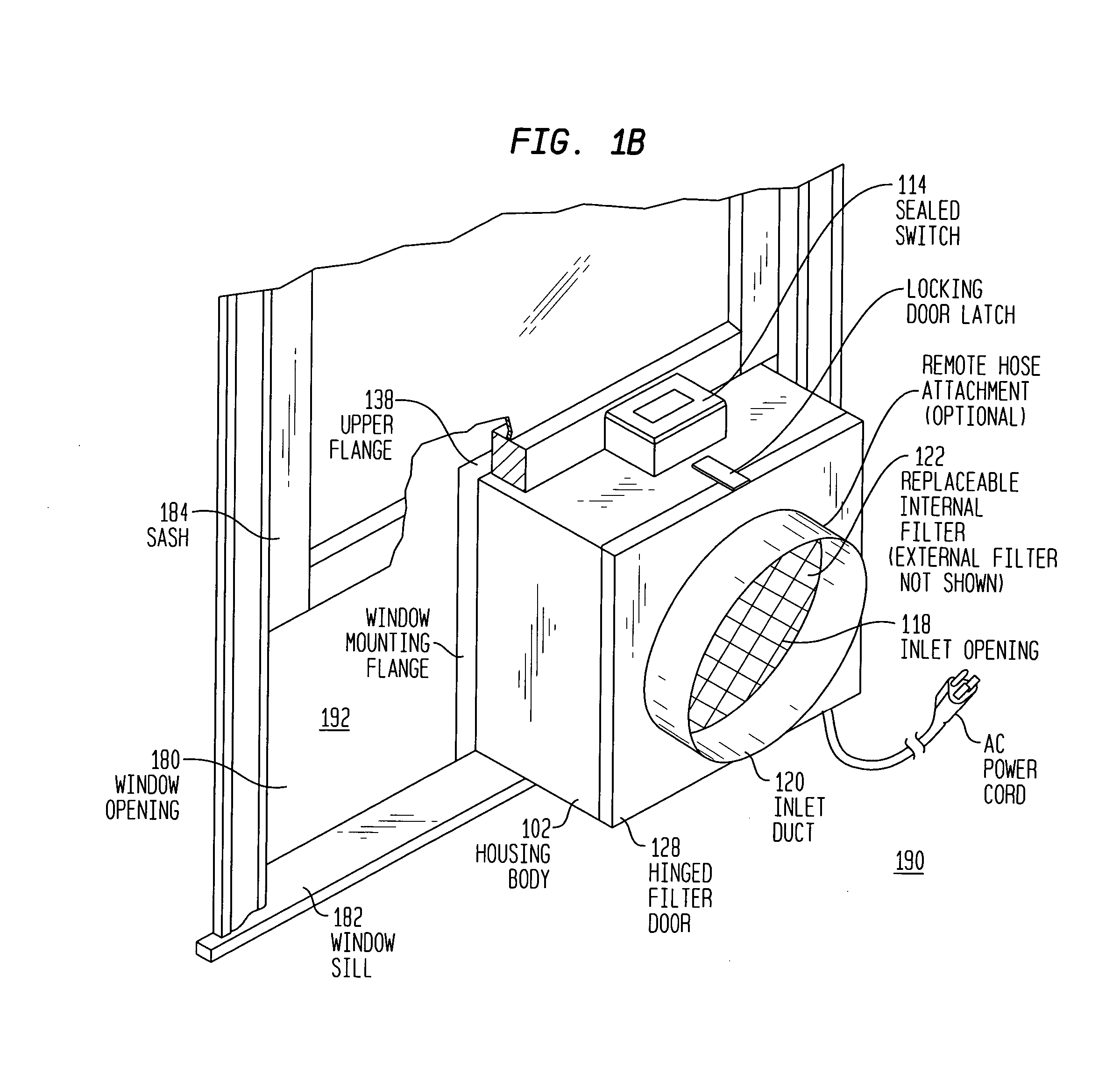

[0027] Embodiments of the present invention are directed to an exhaust fan that can easily and quickly be carried to and set up in a localized area to safely and efficiently remove airborne materials from the localized area. Exhaust fans in accordance with some embodiments of the present invention may be used to ventilate a localized area such as an enclosed room and may be placed in any aperture such as a window or doorway to remove such airborne materials and to exhaust filtered air directly or indirectly to the external environment. One embodiment of the present invention is directed generally to an exhaust fan constructed such that airborne materials contained in air traveling along an exhaust path through the fan are substantially prevented from contacting components of the fan that can be damaged by exposure to such materials. This enables the fan to efficiently remove airborne materials from a localized area while preventing the material from accumulating appreciably on exhau...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com