Ceramic plate cleaning liquid medicine for plasma chamber and application thereof

A technology of plasma and ceramic plates, which is applied to the field of cleaning chemicals for ceramic plates in plasma chambers, can solve problems such as difficult to achieve thorough cleaning, and achieve the effects of restoring color, odor, and reducing energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A plasma chamber cleaning liquid for a ceramic plate is composed of the following raw materials in mass percentage:

[0033] Citric Acid 12.5%,

[0034] Nitric acid 2.5%,

[0035] Deionized water 85%,

[0036] The preparation process is as follows: mix citric acid and nitric acid into deionized water, stir evenly until completely dissolved.

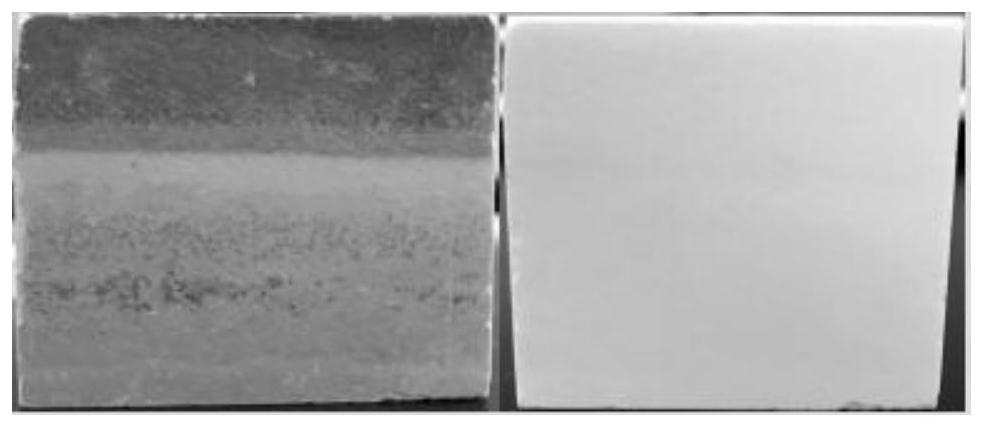

[0037] Put the contaminated ceramic plate into the ceramic cleaning solution with a mass concentration of 12.7%, heat it to 40°C, soak for 40 minutes, take out the ceramic and dry it with an air gun, and observe the cleaning effect of the ceramic. The results are shown in Table 1 and figure 1 As shown, there is no stain on the ceramic surface, and the cleaning effect is obvious.

Embodiment 2

[0039] A plasma chamber cleaning liquid for a ceramic plate is composed of the following raw materials in mass percentage:

[0040] Citric Acid 10%,

[0041] Nitric acid 3%,

[0042] Deionized Water 87%,

[0043] The preparation process is as follows: mix citric acid and nitric acid into deionized water, stir evenly until completely dissolved.

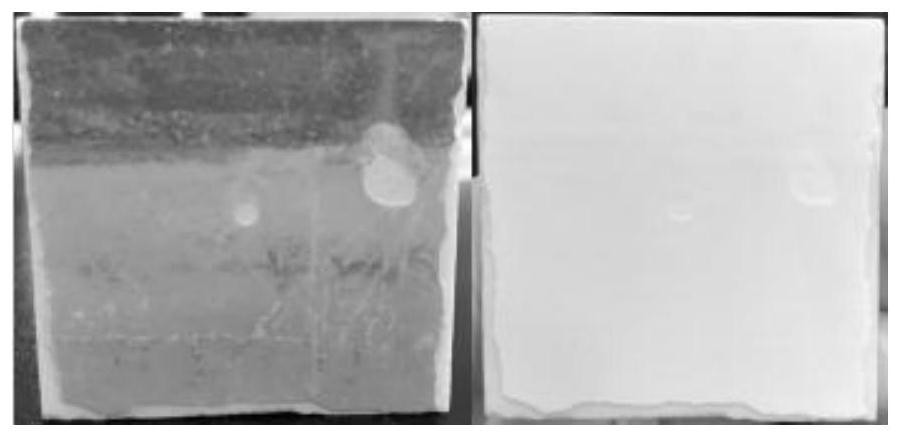

[0044] Put the contaminated ceramic plate into the ceramic cleaning solution with a mass concentration of 7.6%, heat it to 45°C, soak for 60 minutes, take out the ceramic and dry it with an air gun, and observe the cleaning effect of the ceramic. The results are shown in Table 1 and figure 2 As shown, there is no stain on the ceramic surface, and the cleaning effect is obvious.

Embodiment 3

[0046] A plasma chamber cleaning liquid for a ceramic plate is composed of the following raw materials in mass percentage:

[0047] Citric Acid 5%,

[0048] Nitric acid 0.03%,

[0049] Deionized Water 94.97%,

[0050] The preparation process is as follows: mix citric acid and nitric acid into deionized water, stir evenly until completely dissolved.

[0051] Put the contaminated ceramic plates into the ceramic cleaning solution with a mass concentration of 10%, heat to 48°C, soak for 70 minutes, take out the ceramics and dry them with an air gun, and observe the cleaning effect of the ceramics. The results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com