Modified shipping container

a technology of shipping containers and modified containers, applied in the field of platform-based freight containers, can solve the problems of sporadically transported freight in non-standard containers, and achieve the effects of low cost, simple construction, and convenient manufacturing, handling and transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

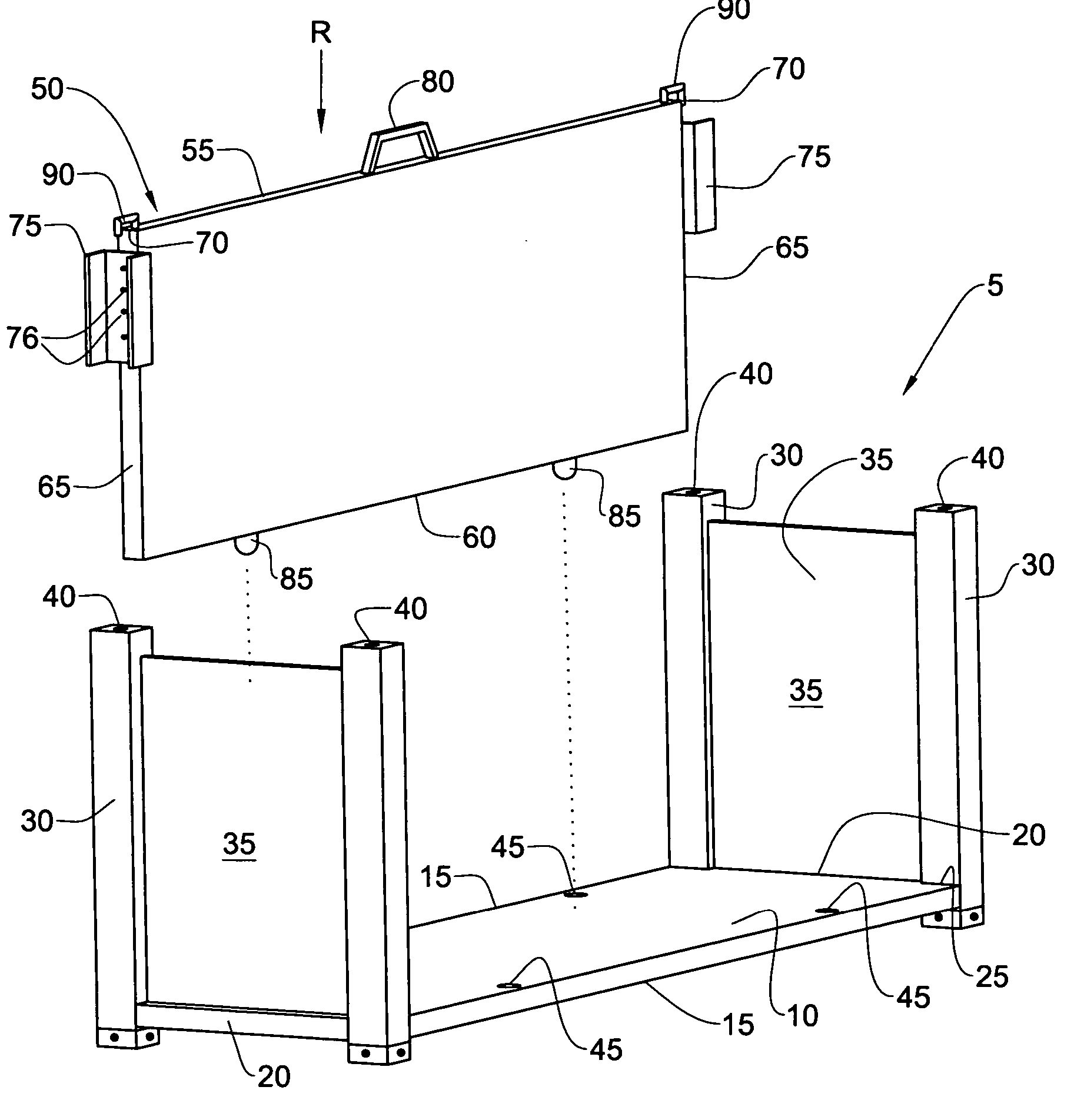

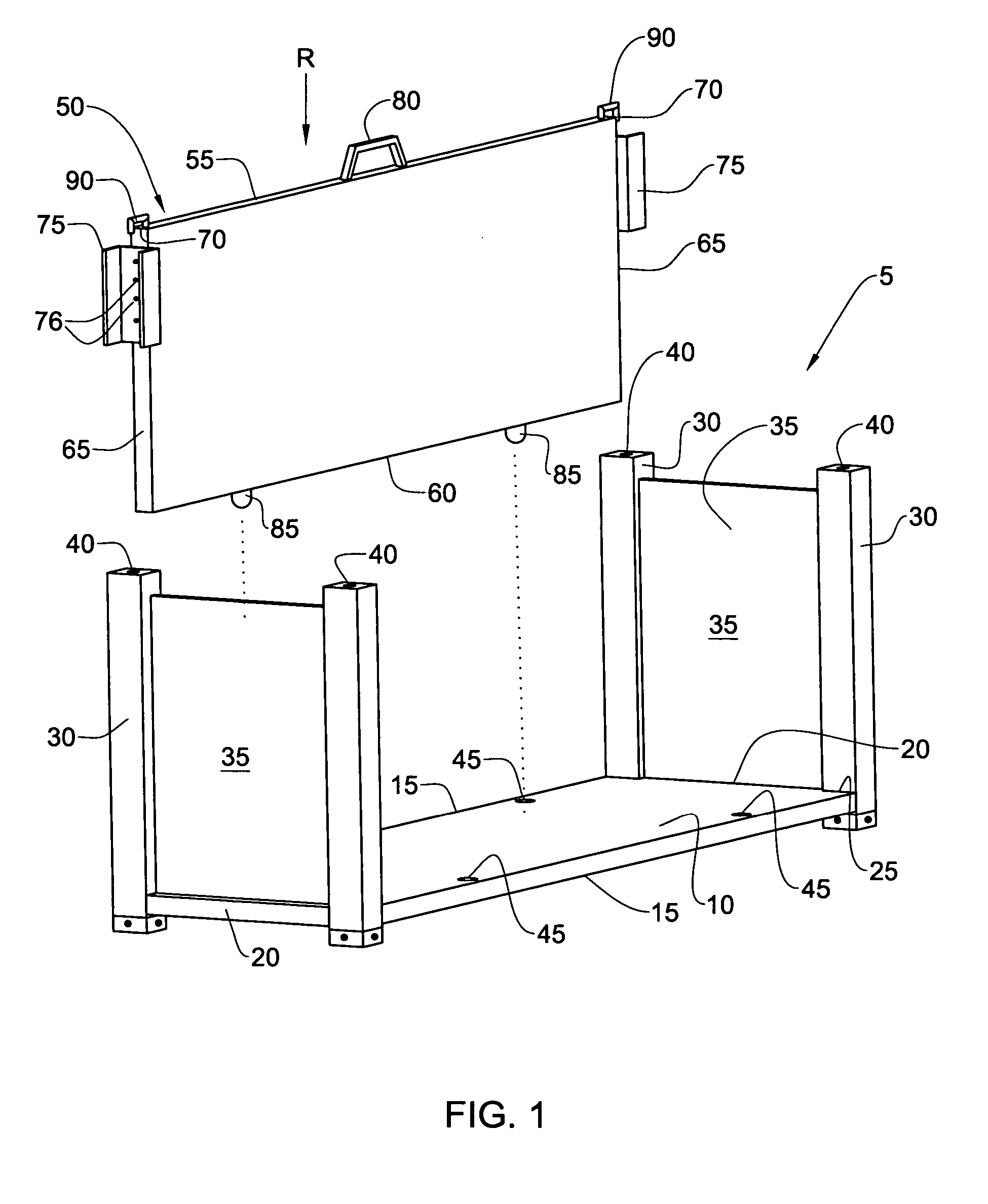

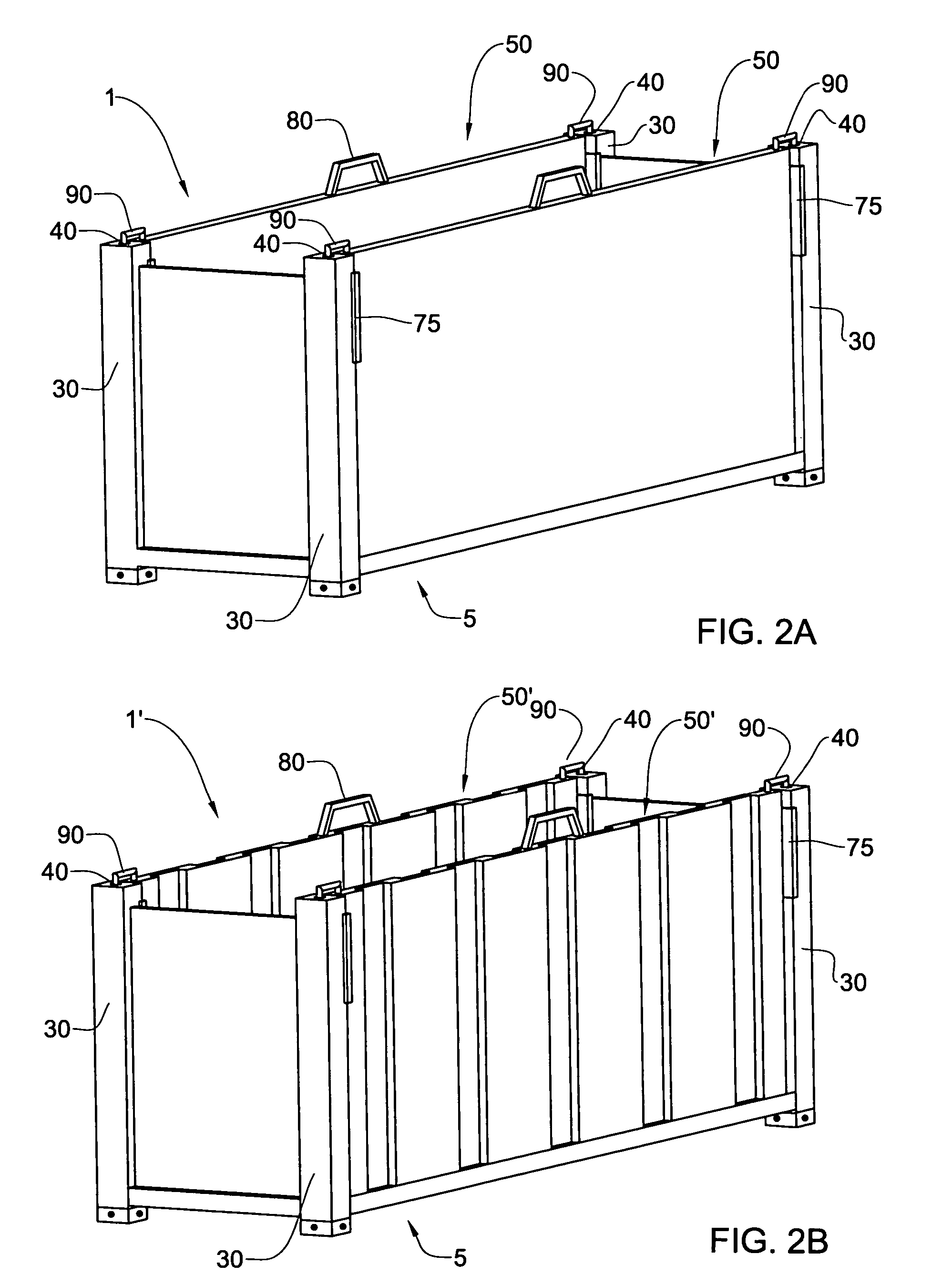

[0035] Referring to FIG. 1, retrofitting a standard flatrack 5 with a detachably attachable side wall 50 is illustrated, to obtain a shipping container 1 according to one embodiment of the present invention as shown in FIG. 2A. FIG. 2B shows a shipping container 1′ according to another embodiment of the present invention, which comprises the same standard flatrack 5 and in which side walls 50′ are corrugated so as to gain strength and rigidity without increasing weight. Since the containers 1 and 1′ are identical in their manner of mounting the side walls 50, 50′ on the flatrack 5, in further description hereinbelow only the container 1 will be referred to.

[0036] The flatrack 5 comprises a rectangular floor 10 having two side edges 15 and two end edges 20 intersecting with the side edges at four corners 25.

[0037] Four vertical stanchions 30 having rectangular cross-section are mounted on the floor 10 at the corners 25 and two vertical end walls 35 extend therebetween along the end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com